Ever found yourself with two hoses that just won't connect? It’s a classic problem—one end is too big, the other too small, and you're stuck. That’s where a hose reducer adapter comes in. Think of it as the universal translator for your equipment, creating a secure, leak-free bridge between parts that were never meant to fit together.

From the fuel lines on your boat to the air compressor in your workshop, these little connectors are the unsung heroes that keep things running smoothly.

What Exactly is a Hose Reducer Adapter?

Picture trying to fit a fire hose onto a garden spigot. It’s not going to work, and you’ll end up with a huge, wet mess. A hose reducer adapter is the simple, elegant solution. It’s a fitting designed with two different ends, allowing you to seamlessly join components that would otherwise be completely incompatible.

But this small part is more than just a convenience—it's essential for maintaining the integrity of your entire system. A solid, tight seal prevents fluids or air from escaping, which is a must for both safety and efficiency. A single, well-chosen adapter can stop a costly fuel spill, keep the pressure steady in a hydraulic line, or make sure your air tools get all the power they need.

To put it simply, here’s a quick breakdown of what these adapters do and why they matter.

Hose Reducer Adapter at a Glance

| Core Function | Primary Benefit | Common Application |

|---|---|---|

| Connect Mismatched Sizes | Creates a secure, leak-proof seal between different hose or pipe diameters. | Attaching a large fuel transfer hose to a smaller boat fuel fill. |

| Convert Thread Types | Allows components with different thread standards (e.g., NPT to BSPP) to join. | Connecting European equipment to American standard fittings. |

| Maintain System Integrity | Prevents pressure loss and ensures a consistent, reliable flow of fluid or air. | Keeping hydraulic systems operating at peak performance. |

These little fittings are the glue that holds many systems together, making them more versatile and reliable.

The Real-World Role of an Adapter

A hose reducer adapter does a few critical jobs that go far beyond just connecting two pieces of equipment. Each one plays a part in the overall health and performance of your system, whether it’s on a boat, in a factory, or in your garage.

Here’s what they really do:

- Size Reduction: This is its main job—stepping down from a larger hose to a smaller one. You can also find "increasers" that do the opposite.

- Thread Conversion: It’s a lifesaver when you’re dealing with different thread standards, like joining a tapered American NPT fitting to a straight British BSPP one.

- Pressure Management: By creating a tight, secure connection, the adapter helps maintain the pressure your system needs to run correctly, preventing performance drops.

- Leak Prevention: A properly installed adapter forms a tough seal, which is absolutely critical for safety when you're handling fuel or working with high-pressure lines.

The demand for these fittings shows just how important they are. The global market for parts like hydraulic hose adapters was valued at nearly $2 billion and is expected to climb to $3.5 billion by 2035. That’s a lot of connections! You can learn more about the growth of the hydraulic adapter market.

Why This Tiny Part is a Big Deal

It's easy to dismiss a small fitting, but a wrong or faulty adapter can cause a world of trouble. We're talking catastrophic system failure, expensive downtime, and serious safety risks. In a marine setting, a leaking fuel adapter isn't just a mess—it can cause environmental damage and create a major fire hazard.

A hose reducer adapter isn't just a piece of hardware; it’s an insurance policy against leaks, pressure loss, and incompatible equipment. Getting it right is the first step to a reliable system.

Once you grasp the real purpose of this component, you start to see why choosing the right type, material, and size is so incredibly important. It’s the key to building a system that’s efficient, safe, and built to last.

Navigating the Different Types of Hose Reducer Adapters

Picking out a hose reducer adapter is a bit like choosing the right key for a lock. It’s not just about the size—the pattern of the grooves has to be a perfect match. In the world of fittings, those "grooves" are the threads, and getting them right is everything. If you use the wrong thread type, you’re guaranteed to have a leak, no matter how hard you crank on it with a wrench.

Think of threads as a unique language. If your fuel hose speaks one language and the connection on your tank speaks another, they just can't communicate. A hose reducer adapter is the translator that steps in to create a perfect, leak-free conversation between the two.

Decoding the Language of Threads

While the world of pipe threads can seem overly complicated, most jobs, including marine fueling, boil down to a few common standards. Each one is designed a little differently to handle specific pressures and tasks. Getting a handle on these differences is the first real step to picking the right part for your boat.

-

NPT (National Pipe Taper): This is the undisputed champion in North American plumbing and industrial work. NPT threads are tapered, meaning they get slightly narrower toward the end. The idea is for the cone-shaped threads to wedge together to form a seal. In reality, that metal-on-metal contact is rarely enough on its own, so you almost always need a sealant like Teflon tape or pipe dope to make it truly leak-proof. It's a solid choice for general applications like water lines and standard fuel systems.

-

JIC (Joint Industry Council): You'll find JIC fittings everywhere in high-pressure hydraulic systems. Their trademark is a 37-degree flared seating surface. Here’s the key difference: the threads don't do the sealing. They just act as the muscle, pulling the flared male end tight against the conical female end to create a rock-solid metal-to-metal seal. This design is fantastic for systems that deal with a lot of vibration and pressure spikes because it won’t shake loose and needs no sealant.

-

BSPP (British Standard Pipe Parallel): As the name gives away, this is the standard you’ll often run into outside of North America. BSPP threads are straight, or parallel, not tapered. The seal isn't made by the threads at all. Instead, it relies on a bonded seal ring or an O-ring that gets squished against the flat face of the fitting. This makes them incredibly easy to install and gives you a fantastic seal, especially for connections that you might need to take apart and put back together.

The core difference lies in how the seal is made. NPT seals at the threads, JIC seals at the flare, and BSPP seals with a gasket or O-ring. Mismatching them is like trying to fit a square peg in a round hole—it just won't seal properly.

Choosing the Right Adapter Shape

Once you've sorted out the threads, you need to think about the physical shape of the hose reducer adapter. This is all about navigating tight spaces and making sure your fuel flows where it's supposed to. The right shape depends entirely on the layout of your system.

Common Adapter Shapes and Their Uses

| Shape | Description | Best For |

|---|---|---|

| Straight | The most common type, connecting two hoses in a direct line. | Extending a hose run or simply reducing the size between two points. |

| Elbow (90° or 45°) | Changes the direction of the hose run. | Routing hoses around corners or obstacles without kinking the hose. |

| Tee | A three-way connector that splits a single line into two. | Supplying fluid or air to two separate locations from one source. |

Choosing the right shape is just as important as getting the threads right. A well-placed elbow adapter can prevent a hose from kinking, which is a big deal—a kink restricts flow and can cause the hose to wear out and fail way too soon. Think about a boat's cramped engine compartment. Using a 90-degree elbow to route a fuel line safely away from a hot exhaust manifold isn't just convenient; it's a critical safety measure. Each shape is a tool designed to solve a real-world routing problem, ensuring your fuel system is both effective and safe.

How to Choose the Right Material for Your Adapter

Picking the right material for your hose reducer adapter is every bit as important as getting the size and threads perfect. It's like choosing tires for a vehicle; you wouldn't put slick racing tires on a 4x4 destined for muddy trails. The material simply isn't right for the job.

In the same way, your adapter's material has to stand up to the fluid running through it, the pressure it’s under, and the environment it lives in. A bad match can cause rapid corrosion, sudden failure, and dangerous leaks—a scenario no one wants, especially in a marine setting where saltwater is constantly on the attack.

Comparing Common Adapter Materials

When you're shopping for adapters, you'll generally run into four main materials: stainless steel, brass, aluminum, and carbon steel. Each one has its own set of pros and cons, which makes them suited for very different tasks. Knowing the difference is what separates a quick fix from a reliable, long-term solution.

Let's look at how they compare in the areas that really count.

-

Stainless Steel: Think of this as the top-tier choice for toughness and resilience. Thanks to its chromium content, it forms a protective layer that actively fights off rust and corrosion. This makes it the undisputed champion for marine applications and food-grade systems. It might cost a bit more upfront, but its ability to survive saltwater spray and harsh conditions makes it the safest and most economical option in the long run.

-

Brass: A classic, budget-friendly workhorse. Brass is a mix of copper and zinc that holds up well against corrosion in freshwater or dry environments. It’s a solid pick for things like workshop air lines, home water systems, and standard fuel lines on land. Its weakness? Saltwater, which can cause dezincification, a process that weakens the fitting and can lead to a complete failure.

-

Aluminum: Best known for being light, aluminum is a great choice when weight is a top priority. You'll find it in some fuel and oil lines, but it has a key vulnerability: galvanic corrosion. When it touches a different metal (like stainless steel) in a wet environment, it can corrode quickly. It’s also softer than brass or steel, so its threads are easier to strip if you overtighten it.

-

Carbon Steel: This is the heavyweight champion for high-pressure hydraulic systems that stay dry. It's incredibly strong but has a fatal flaw: it rusts almost instantly when it gets wet. To get around this, carbon steel fittings are typically plated with something like zinc. But if that coating gets scratched, rust is right behind it.

Matching Material to Your Specific Needs

The best way to pick a material is to think about what your system truly demands. An adapter for a boat's fuel tank needs a far more durable material than one used for an air compressor in a garage. For a deeper dive into these considerations, check out our guide on selecting the right fuel tank adapter.

To make things easier, here’s a quick-glance table to help guide your choice.

Adapter Material Comparison Guide

Here’s a comparative look at common adapter materials and their suitability for different applications and environments.

| Material | Corrosion Resistance | Pressure Rating | Best For |

|---|---|---|---|

| Stainless Steel | Excellent | Very High | Marine environments, saltwater, chemicals, food-grade applications. |

| Brass | Good | High | General air, water, and non-marine fuel and oil lines. |

| Aluminum | Good | Moderate | Lightweight applications, racing, some oil and fuel systems. |

| Carbon Steel | Poor (if uncoated) | Excellent | High-pressure hydraulics in dry, non-corrosive environments. |

As you can see, when it comes to marine fueling, the choice is pretty straightforward.

Stainless steel is the only material that provides the necessary long-term protection against the corrosive effects of saltwater. The initial investment pays for itself by preventing catastrophic failures and ensuring the safety and integrity of your fuel system.

At the end of the day, it all comes down to the fluid, pressure, and environment. Take a minute to weigh these factors, and you'll ensure the hose reducer adapter you buy isn't just a part, but a dependable cornerstone of your entire system.

A Practical Guide to Nailing the Perfect Fit

We’ve all been there. You order a new hose adapter, wait for it to arrive, and then discover it’s the wrong size. It’s one of the most common and frustrating setbacks you can face. Even a millimeter off can mean a nagging leak, project delays, or worse, damaged threads from trying to force a connection that just won't work.

The good news is that getting it right the first time isn't as hard as it seems. It just takes a little bit of care and a couple of basic tools. Let's walk through a simple, foolproof way to measure your hoses and fittings so you can choose the perfect adapter with total confidence.

The Two Measurements That Matter Most

When you're picking out a hose reducer adapter, you're really juggling two different things: the size of your hose and the threads on your fitting. This is where most people get tripped up. They see a 1-inch hose and assume it needs a 1-inch fitting, but that's almost never how it works.

Getting a handle on these two separate measurements is the key to a leak-proof system.

- Hose Inner Diameter (ID): This is exactly what it sounds like—the empty space inside the hose. It's the measurement that tells you how much fuel can flow through it and is the main way hoses are sized.

- Fitting Thread Size: This has nothing to do with the hose. It refers to the specific dimensions of the threads on the pump, tank, or port you’re trying to connect to.

Think of it like buying a frame for a favorite photo. The photo has its own size (that’s your hose ID), and the opening in the frame has its own size (that’s your fitting). They have to match up perfectly, but you measure them separately.

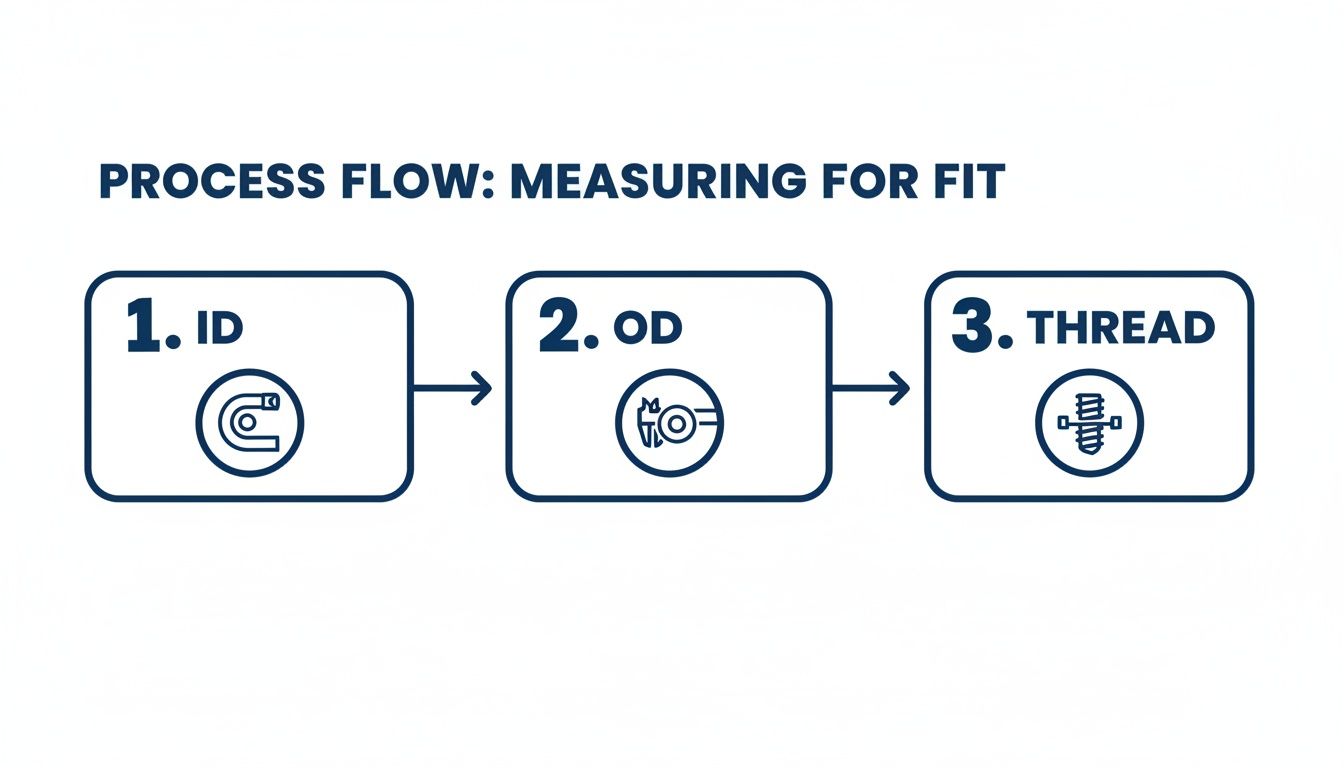

A Step-by-Step Guide to Measuring Like a Pro

To get this right, you’ll need a few tools. A digital caliper is your best friend here because it’s incredibly accurate, but a decent ruler or tape measure will do the job too.

- Measure the Hose Inner Diameter (ID): First, lay the end of your hose on a flat surface. Use your caliper or ruler to measure straight across the opening, from one inside wall to the other. Don't measure the outside of the hose (the Outer Diameter or OD)—that number includes the thickness of the hose wall and will throw you off completely.

- Figure Out the Fitting Type: Now, take a close look at the male fitting you're connecting to. Do the threads get narrower toward the end? That's a classic tapered thread, likely an NPT fitting. Or are the threads perfectly parallel and straight, maybe with a flared tip? That could be a JIC fitting. A quick visual check can narrow down your options fast.

- Measure the Fitting Thread Diameter: Grab your calipers again and measure the outside diameter of the male threads at their widest point. This measurement, paired with the thread type you just identified, will tell you its official size (like 1" NPT, for example).

Once you have these two separate pieces of information—the hose ID and the fitting thread size—you can find the right hose reducer adapter without any guesswork. For instance, you might realize you need an adapter for a 1.5" ID hose that has to connect to a 1" NPT male fitting.

Our deep-dive on choosing a fuel transfer pump hose can also give you more context on how all these parts work together in a complete setup.

Remember: The size of a hose (ID) and the size of a fitting (thread diameter) are two different things. You must measure both to find the right adapter.

Common Mistakes to Sidestep

Even with the right approach, it’s easy to make a small mistake that sends you back to square one. Keep an eye out for these common slip-ups.

- Confusing ID with OD: It’s worth saying again—always measure the inside of the hose, never the outside.

- Guessing the Thread Type: Don’t just assume your fitting is NPT because it’s common. Mismatched threads might seem like they're catching, but they will never create a proper seal.

- Measuring a Worn-Out Fitting: If the threads on your current fitting are stripped or damaged, your measurement won't be accurate. Always try to measure a new or undamaged fitting if you can.

- Forgetting About Regional Standards: Hose fittings vary around the world. In North America, certain types are far more common, especially in industrial settings. For example, one analysis showed quick-disconnect fittings captured about a 33% market share in the region, largely due to their heavy use in mobile equipment. Knowing a bit about these trends in the hydraulic fluid connectors market can help you understand why you see certain types more than others.

By following these steps and keeping these pointers in mind, you can take the guesswork out of the equation. A few minutes of careful measuring will save you hours of headache and give you a safe, reliable, and totally leak-free connection.

Mastering Installation and Safety Best Practices

Getting the right hose reducer adapter is just the first step. The real magic happens during installation—that’s what transforms a good part into a reliable, leak-free connection. This isn't about brute force with a wrench. It’s about careful prep work, solid technique, and a healthy respect for safety to keep your system running smoothly for years to come.

When you're dealing with critical applications, like connecting to various fuel storage solutions, getting this right is non-negotiable. A rock-solid connection protects your gear, prevents messy and expensive spills, and keeps everyone safe.

Preparing for a Secure Connection

Before you even think about threading parts together, a little prep work is essential. Start by giving both the male and female threads on your hose, adapter, and port a good look. You're hunting for any signs of damage—cross-threading, dirt, or tiny metal burrs that could stop you from getting a perfect seal.

Grab a clean, lint-free rag and wipe down every surface. If you run into stubborn grime on steel fittings, a wire brush can do the trick, but go easy on softer materials like brass or aluminum to avoid damaging the threads. Think of it this way: a clean surface is the foundation for a leak-proof connection.

The Great Sealant Debate: To Tape or Not to Tape?

One of the biggest questions I hear is about using thread sealant. The answer isn't a simple yes or no; it all comes down to the type of fitting you have. Getting this wrong is a classic mistake that can actually cause a leak.

-

For Tapered Threads (NPT): Yes, you absolutely need sealant. NPT threads are designed to create a seal by wedging together, but it's rarely a perfect metal-on-metal fit. A thin, even layer of quality thread sealant or 2-3 wraps of PTFE tape (you probably know it as Teflon tape) is crucial to fill those microscopic gaps.

-

For Flared Fittings (JIC): Never use sealant or tape on these. A JIC fitting seals when the 37-degree flared end of the male fitting seats perfectly against the female cone. The threads are just there to provide clamping force. Adding tape or sealant gets in the way of this precision metal-to-metal contact and is a surefire way to cause a leak.

A common rookie mistake is putting thread tape on a JIC fitting. The seal happens at the flare, not the threads. Always leave these connections clean and dry.

The Art of Proper Tightening

Here's another place where people often go wrong: over-tightening is just as bad as under-tightening. You’re aiming for the sweet spot—enough clamping force to seal, but not so much that you strip the threads or crack the fitting.

This is where starting with the right part makes all the difference. Following the core measurement steps ensures you’ve got the correct adapter from the get-go.

When you have the right fit, start by hand-tightening the adapter until it’s snug. Then, grab the right wrench. For NPT fittings, a good rule of thumb is 1 to 2 turns past hand-tight. For JIC fittings, you'll feel the resistance change as the flares meet; from there, another quarter-turn is usually all it takes.

Getting these connections right is a big deal across countless industries. In fact, the market for industrial hose assemblies, which includes these adapters, is expected to hit US$31.4 billion by 2032. It's all driven by the need for dependable parts in tough environments.

Non-Negotiable Safety Rules

Safety always comes first. Before you touch a single fitting, make sure the entire system is depressurized. Trying to loosen a fitting that's under pressure can turn it into a high-speed projectile, and nobody wants that.

Always wear your personal protective equipment (PPE), especially safety glasses and gloves, when you're working with fuel or hydraulic fluids. When you combine correctly installed adapters with a system like CLiX Fueling Solutions—which is designed to prevent spills—you create a powerful, layered safety net for all your fueling operations.

Troubleshooting Common Adapter Leaks and Failures

Even when you do everything right, a leak can happen. That persistent drip from your hose reducer adapter isn't just a nuisance; it's a warning sign. In a marine fuel system, ignoring it can lead to wasted fuel, environmental hazards, and a serious fire risk.

Don't panic. Most leaks come down to a handful of common issues that are surprisingly easy to fix. If you know what to look for, you can diagnose the problem quickly, get it fixed, and ensure your connections stay bone-dry and reliable for years to come.

Identifying the Source of the Drip

Before you can fix anything, you have to pinpoint exactly where the leak is coming from. A slow drip can be sneaky, running along the fitting and making it seem like the problem is somewhere it isn't. Your first step is to clean and dry the entire adapter and the area around it, then re-pressurize the system and watch it like a hawk.

The usual suspects for leaks include:

- Damaged or Worn O-Rings: These little rubber rings do the heavy lifting when it comes to sealing. Over time, they can get brittle, crack, or flatten out, creating a path for fuel to escape.

- Mismatched or Damaged Threads: This is a big one. Trying to force an NPT fitting into a BSPP port is a recipe for disaster. Cross-threading is just as bad, creating tiny gaps that tightening will never fix.

- Improper Sealant Application: Using too much thread tape—or not enough—on NPT fittings is a common mistake. Applying it to a flared fitting where it doesn't belong is another guaranteed leak-starter.

- Over-Tightening: It’s tempting to give it one more turn, but cranking down too hard can crack the adapter or strip the threads. This causes permanent damage and makes a proper seal impossible.

When it comes to bad seals, knowing how to pick the right replacement O-ring is a core skill for keeping any fluid system in top shape.

Actionable Fixes for Leaky Adapters

Once you’ve found the cause, the fix is usually pretty simple. The key is to be methodical instead of just wrenching down harder on the fitting, which often makes things much worse.

If you’ve got a bad O-ring, just replace it. Make sure the new one is the right size and material for handling fuel. If the threads are stripped or cross-threaded, the hose reducer adapter is toast—it has to be replaced. There's just no safe way to repair damaged threads. For sealant issues on an NPT fitting, take it apart, clean every trace of the old stuff off the threads, and re-apply fresh tape or sealant before reinstalling.

Remember the golden rule of troubleshooting: always start with the simplest fix first. Most of the time, a leak is just a worn-out seal or a simple installation mistake, not a major part failure.

This focus on proper maintenance is crucial for the entire fuel system. It’s a principle that applies to everything from a tiny adapter to the whole fuel line assembly, similar to the steps involved in maintaining and repairing outboard engine fuel lines. Regularly checking your fittings for corrosion or wear will help you spot problems before they become dangerous leaks.

Got Questions About Hose Reducer Adapters? We’ve Got Answers.

Even the most straightforward project can throw you a curveball. When you're dealing with something as important as your boat's fueling system, you want clear answers, fast. Here are some of the most common questions we hear about hose reducer adapters.

Can I Mix and Match Different Thread Standards?

You can, but you absolutely need the right adapter to do it. Think of it like trying to fit a square peg in a round hole—forcing two different thread types together, like NPT and BSP, is a guaranteed recipe for a leak.

A classic example we see all the time is connecting a European fuel pump (which usually has BSP threads) to an American-built boat's fuel tank (almost always NPT). You'll need a specific BSP-to-NPT hose reducer adapter to make that connection work. Without it, the threads just won't seal correctly, and they'll fail the moment they're under pressure.

What's the Real Difference Between a Bushing and an Adapter?

It's easy to get these two mixed up, but they do very different jobs. A reducer bushing is a compact little fitting, usually with male threads on the outside and smaller female threads on the inside. You screw it directly into a larger port on a tank or pump to make the opening smaller.

A reducer adapter, on the other hand, is built to connect two separate things, like two different hoses or a hose and a fitting. It acts as a bridge, often extending the connection. It might have female threads on one end and smaller male threads on the other, or any number of combinations to connect different sizes and even different thread types.

The Bottom Line: A bushing shrinks the size of a port. An adapter connects two different components. If you're modifying a port, you need a bushing. If you're joining two lines, you need an adapter.

The Adapter I Have Isn't Marked. How Do I Know Its Pressure Rating?

This is a tricky—and potentially dangerous—situation. Honestly, the best and only truly safe advice is to buy your adapters from a reputable source where the specs are clearly marked. Don't leave it to chance.

If you're in a pinch and absolutely must consider using an unmarked part, you're essentially making an educated guess based on a few clues:

- What's it made of? Stainless steel and carbon steel can typically handle much higher pressures than brass or plastic.

- How thick are the walls? Thicker walls are a good sign they were built for higher pressure.

- Where did it come from? If you know it was used in a low-pressure system before, don't even think about using it for high-pressure fueling.

When it comes down to it, never use an unmarked fitting in a critical system like your boat's fuel line. The risk of it failing is just too great. Your safety, and the environment's, depends on using parts you can trust.

For a fueling solution that takes the guesswork and spills out of the equation, check out CLiX Fueling Solutions. See how you can make every fill-up a safe and clean one at https://clixfueling.com.