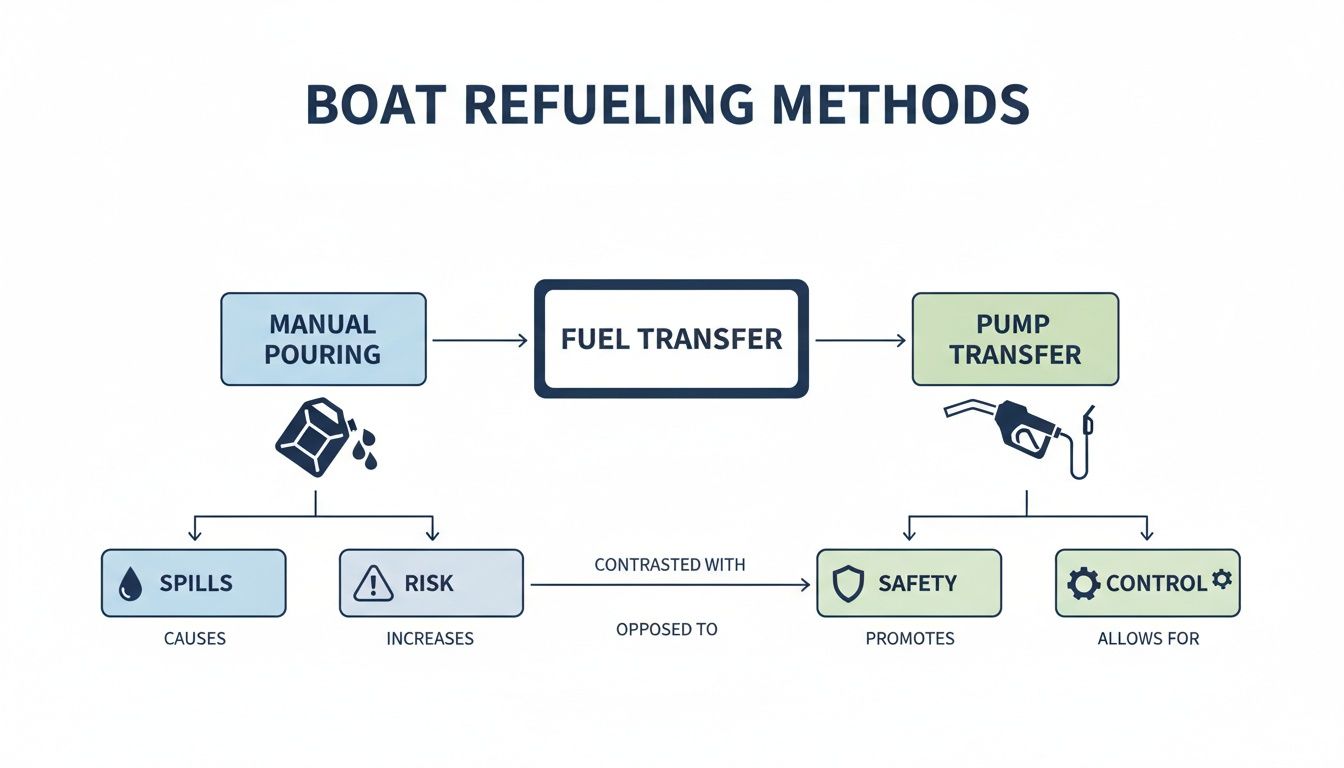

Let’s be honest, every boater has been there. You’re wrestling with a heavy, sloshing jerry can, trying to pour gas into your boat's tank without spilling it everywhere. The boat is rocking, the can is awkward, and you're just one clumsy move away from a dangerous and messy situation.

It's a frustrating, back-straining ritual that often ends with fuel in the water, on the deck, and on your hands. This isn't just an annoyance; it's a serious safety and environmental hazard.

Make Boat Refueling Safer and Simpler

Fortunately, there's a much better way. A portable gasoline transfer pump takes that risky, frustrating chore and makes it clean, controlled, and quick. Think of it as switching from a watering can to a garden hose—you get precision, control, and no more mess. Instead of fighting gravity and hoping for the best, a pump gives you a steady, manageable flow of fuel right where you want it.

This move toward smarter fueling isn't just a niche trend. The global market for fuel transfer pumps was valued at $1.87 billion, and it's the portable designs that are really catching on. In fact, the portable segment is projected to grow at a compound annual growth rate of 5.0% through 2030, which tells you just how many people are tired of the old "lift and pour" method. You can explore the full market report for more details about these industry shifts.

So, what does this mean for you on the water? By switching to a pump, you can:

- Prevent Dangerous Spills: A secure connection and a controlled flow mean the gasoline stays in the line, not in the lake.

- Boost Your Safety: No more heavy lifting and awkward pouring minimizes the risk of static sparks, fumes, and direct fuel contact.

- Save Time and Your Back: What used to be a ten-minute struggle becomes a simple, hands-free task.

This guide is here to walk you through everything you need to know. We’ll cover how these pumps work, what to look for when buying one, and how to use it like a seasoned pro. Let's make every trip to the water safer and more enjoyable, starting with how you refuel.

How a Portable Fuel Pump Really Works

Think of a portable gasoline transfer pump as a smart, powerful straw. Instead of tipping a heavy, awkward gas can and hoping for the best, a pump gives you a safe, controlled way to move fuel from point A to point B. It takes a frustrating chore and makes it clean and simple.

So, how does it do it? Every pump, no matter the type, works by creating a pressure difference. It creates a vacuum in the intake hose, and the higher atmospheric pressure on the fuel's surface simply pushes the gasoline up into the pump. Once inside, the pump’s mechanism takes over and shoves the fuel out the delivery hose and into your boat’s tank.

It's a straightforward process, all thanks to a few key parts working in harmony.

The Heart of the Machine: The Motor and Pumping Mechanism

The motor is what drives the whole show. On most portable electric pumps, you'll find a small but mighty DC motor built to run on a 12V source, like your boat's battery or a dedicated power pack. For handling gasoline, these motors absolutely must be explosion-proof. This means they're completely sealed to ensure any internal sparks can't meet flammable fuel vapors—a critical safety feature you can't compromise on.

That motor powers the pumping mechanism, which usually comes in one of two flavors:

- Impeller/Rotary Vane: Picture a tiny, high-speed paddle wheel inside a sealed housing. As the blades (vanes) spin, they sling the fuel outward, which creates a low-pressure void at the center that pulls in more fuel. It's this rapid, continuous cycle that produces a smooth, consistent flow.

- Diaphragm: This design works more like your own lungs. A flexible membrane (the diaphragm) gets pulled back and forth. When it pulls back, it creates a vacuum that sucks fuel into a chamber. When it pushes forward, it forces that fuel out the other side. This pulsing action is fantastic for self-priming.

What is Self-Priming?

A self-priming pump is a lifesaver. It can purge the air from its own intake line to create suction, meaning you don't have to manually fill it with liquid to get it started. It just works, even when the intake hose is full of air.

The Pathway Components: Hoses and Nozzles

The fuel's journey is guided by the hoses and the nozzle. The intake hose is the end that goes into your gas can. It should have a strainer or filter on the tip to keep gunk and debris from getting sucked into the pump, where it could cause damage or end up in your boat's engine.

At the other end, the delivery hose funnels the fuel into your tank, capped off with a nozzle. This isn't just a basic spout. Good nozzles are designed with ergonomics and safety in mind, often including a hook to hang on the fuel port so you don't have to hold it the whole time. The best ones even have an auto-stop feature that shuts off the flow when the tank is full, preventing those messy, expensive, and dangerous spills.

This image really drives home the difference between the old way and the new.

You can instantly see how a pump eliminates the guesswork and risk, replacing it with a precise, safe system. Once you understand how these simple parts work together, it's easy to see the value a good pump adds to your boating routine and helps you pick the right one for your needs.

How To Choose The Right Pump For Your Boat

With so many portable gas pumps out there, picking the right one for your boat can feel like navigating in the fog. But it’s not just about moving gas from point A to point B. It’s about doing it safely, cleanly, and without turning a simple top-off into a frustrating ordeal.

Think of it like choosing the right fishing rod. You wouldn't use a heavy deep-sea rig to catch stream trout. In the same way, the pump that’s perfect for a small skiff is all wrong for a big cabin cruiser. Let’s cut through the noise and focus on what really matters when you're on the water.

Flow Rate: The Balance Of Speed And Control

The first thing you’ll probably notice is the flow rate, measured in gallons per minute (GPM). It's easy to assume faster is always better, but that’s a rookie mistake when it comes to fueling a boat.

- Low Flow (2-4 GPM): This is your best bet for smaller boats, jet skis, or when you’re just topping off the tank. A slower, more controlled flow gives you time to react and prevents fuel from splashing back out—a common headache caused by high-speed pumps.

- High Flow (5-10 GPM): If you've got a larger vessel with a big tank, this is where you want to be. When you’re transferring 50 or 100 gallons, a faster pump saves a ton of time. The trick is to pair it with a quality nozzle that has an auto-stop feature to keep things under control.

For most boaters, the sweet spot is somewhere in the middle. A pump in the 4-8 GPM range usually offers a great mix of speed and precision, making refueling quick but not chaotic.

Power Source: Simplicity vs. Convenience

How your pump is powered is a huge factor. Your options range from old-school manual power to fully automated electric, each with its own pros and cons.

Manual pumps—the ones with a hand crank or a siphon bulb—are dead simple and incredibly reliable. No motors to burn out, no batteries to die. But they’re also slow and require a lot of effort, making them best for emergencies or moving just a gallon or two.

Then you have battery-powered electric pumps, which bring a whole new level of convenience. They do all the work for you, providing a steady, hands-free flow. This market is exploding for a reason. In North America alone, the DC fuel transfer pump market had a 43.9% market share, pulling in $34.3 million largely from these portable models. Experts predict the global market will swell to $128.8 million by 2034, all thanks to how incredibly useful these pumps are. You can read the full analysis about the DC fuel transfer pump market on Market.us.

Material And Build Quality: The Non-Negotiable

This isn't just about durability—it's about safety. Gasoline is incredibly corrosive and will eat through the wrong kinds of plastics and seals, leading to dangerous leaks.

Always, always, always make sure your pump is explicitly rated for gasoline. Look for parts made from stainless steel, brass, and fuel-grade polymers. For any electric pump, an explosion-proof motor isn't a luxury; it's a must-have to prevent a stray spark from igniting gas fumes.

A well-built pump with a tough housing and secure, leak-proof fittings will give you peace of mind every single time you use it. Never be tempted to use a pump meant for water or oil. It’s just not worth the risk. For a closer look at some top-tier models, check out our guide on the best electric fluid transfer pumps for 2025.

Key Features For A Hassle-Free Experience

Beyond the big three specs, a few other features separate a good pump from a great one. Let's compare the main types side-by-side.

Feature Comparison For Different Pump Types

This table breaks down the key differences between manual and electric pumps to help you see at a glance which one might be the best fit for your boat and your fueling habits.

| Feature | Manual Pump | Battery-Powered Rotary Pump | Battery-Powered Diaphragm Pump |

|---|---|---|---|

| Best Use Case | Emergencies, small fuel transfers | All-around use, medium to large tanks | Heavy-duty, frequent, or large-volume transfers |

| Flow Rate (GPM) | 1-3 GPM (Variable, depends on user) | 4-10 GPM (Consistent flow) | 5-15 GPM (High, consistent flow) |

| Priming | Manual (siphon bulb or cranking) | Often self-priming | Almost always self-priming |

| Portability | Excellent; very lightweight and compact | Good; slightly heavier with motor and battery | Good; can be bulkier and heavier |

| Safety Considerations | Lower risk of sparks, but higher spill risk | Requires explosion-proof motor and wiring | Requires explosion-proof motor and wiring |

| Maintenance | Very low; check seals and hoses | Low; check battery, brushes, and seals | Low; occasional check of diaphragm and valves |

Ultimately, the best pump is the one that aligns with how you boat. An occasional fisherman with a small skiff has very different needs than a cruiser who's constantly on the move.

What To Look For In The Details

- Self-Priming Capability: A self-priming pump is a lifesaver. It can pull fuel up the hose even when it's full of air, which means you don’t have to do the messy and dangerous job of pre-filling the hose yourself.

- Hose Length: Make sure the hoses are long enough to comfortably reach from your gas can on the dock to your boat's fuel port without being stretched tight. A total hose length of at least 6-10 feet gives you good working flexibility.

- Nozzle and Fitments: The nozzle really matters. Look for one that’s easy to hold and has a hook to hang on the fuel port. An auto-shutoff nozzle, just like the one at the gas station, is the gold standard for preventing spills.

By thinking through these factors, you can find a portable gasoline transfer pump that turns refueling from a chore you dread into a safe, clean, and simple part of your day on the water.

Essential Safety and Environmental Practices

Let's be honest: handling gasoline on or near the water is serious business. While a good portable transfer pump makes the job a world safer than trying to pour from a heavy can, it doesn't mean you can let your guard down. Fuel is volatile, its vapors are a ticking clock, and one small mistake can ruin a great day on the water.

Think of gasoline vapors as an invisible, flammable blanket. This blanket is heavier than air, so it sinks and pools in the lowest spots of your boat—the bilge, the cabin, you name it. It just sits there, waiting for a single spark to ignite it. That's why following a strict safety routine isn't just a good idea; it's the only way to protect your boat, your passengers, and yourself.

The Hidden Danger of Static Electricity

One of the sneakiest risks during fueling is static electricity. As gasoline rushes through a hose, it can build up a static charge—the same way shuffling your feet on a carpet does. But instead of a harmless zap when you touch a doorknob, that tiny spark on a boat can ignite fuel vapors with catastrophic results.

This is why grounding the pump is absolutely critical. Before you start the flow, make sure the fuel nozzle is pressed firmly against the metal of your boat's fuel fill pipe. That simple metal-to-metal contact gives any static charge a safe path to dissipate before it can become a dangerous spark.

Many of the best portable pumps come with built-in grounding wires or special anti-static hoses. These are fantastic features, but you should still always maintain that physical metal-to-metal contact. Consider it your non-negotiable backup.

Environmental Responsibility and Legal Consequences

A fuel spill isn't just a messy cleanup; it's an environmental problem with real legal teeth. It takes just one quart of gasoline to contaminate a massive amount of water, wreaking havoc on marine life and the entire ecosystem.

The U.S. Coast Guard and the EPA don't mess around. Under the Clean Water Act, any spill that leaves a visible sheen on the water must be reported. Ignoring it can lead to hefty fines and even criminal charges. Having a spill kit on board isn't just smart—it's often required and is a cornerstone of being a responsible boater.

If you ever find yourself in that situation, our guide on https://clixfueling.com/blogs/news/fuel-spill-cleanup-procedures-expert-response-guide walks you through the right steps. On a broader note, understanding how to reduce vehicle emissions is part of a larger commitment to keeping our environment clean, both on and off the water.

Your Safe Fueling Checklist

Make this checklist a habit. Run through it every single time you fuel up, no exceptions. Consistency is what keeps you safe.

- Moor Securely: Tie your boat up tight. The last thing you want is for it to drift and yank the hose out mid-transfer.

- Shut Everything Down: Kill the engine, turn off all electronics, and extinguish any open flames (like a stove in the galley).

- Ensure Proper Ventilation: Open up all hatches, ports, and windows. Let the air circulate. Run your bilge blower for at least four minutes before and during the entire fueling process to clear out any stray vapors.

- Inspect Your Equipment: Give your pump and hoses a quick once-over. Look for cracks, leaks, or any signs of wear and tear.

- Ground the Nozzle: Remember, maintain constant metal-to-metal contact between the nozzle and the fuel fill opening.

- Have a Spill Kit Ready: Keep an absorbent pad or your full spill kit within arm's reach. Just in case.

Key Pump Features That Enhance Safety

Today's portable gasoline transfer pumps are built with safety in mind. When you're shopping for one, prioritize these features. They're your first line of defense.

- Explosion-Proof Motors: This is the big one for any electric pump. The motor is completely sealed, guaranteeing that no internal sparks can ever escape and meet fuel vapors.

- Auto-Shutoff Nozzles: They work just like the pump at your local gas station, automatically stopping the flow when the tank is full. This feature is your best friend for preventing messy, dangerous overfills.

- Durable, Fuel-Safe Materials: The pump's body, hoses, and seals must be made from materials that won't degrade when exposed to gasoline. This prevents leaks and ensures the pump won't fail when you need it most.

When you combine the right gear with disciplined habits, fueling becomes just another safe, simple part of your boating routine.

Using and Maintaining Your Fuel Transfer Pump

A portable gasoline transfer pump is a fantastic tool, but like any piece of gear on your boat, its reliability comes down to how you treat it. Think of it like a good fishing reel—if you rinse it off and store it properly, it’ll work flawlessly for years. Neglect it, and it's guaranteed to seize up right when you need it most.

The secret isn't complicated. A simple, consistent maintenance routine is all it takes to make sure your pump is ready to go every time. By running through a quick checklist before, during, and after you fuel up, you can head off common problems and keep the whole process safe and clean.

Your Pre-Use Checklist

Before you even think about flipping a switch, take a minute to give your pump a quick once-over. This simple habit can catch a small issue before it turns into a dangerous mess.

-

Inspect Hoses and Connections: Run your eyes—and hands—over the entire length of the intake and delivery hoses. You're looking for any cracks, kinks, or brittle spots. Give the fittings a twist to make sure they're snug; a loose connection is a prime spot for leaks or air gaps.

-

Check the Power Source: If you're using a battery-powered pump, is it actually charged? It’s an obvious question, but one we all forget. For models with alligator clips, make sure the clips and wires are clean and free of corrosion.

-

Examine the Strainer: Your intake hose should have a filter or strainer on the end. Check that it’s clear of any gunk or debris that could get sucked in and clog up the works.

The Operational Steps for a Spill-Free Transfer

Once your inspection is done, you're ready to move some fuel. Just follow these steps for a smooth, controlled transfer.

- Get Positioned: Place your fuel can on a stable surface, preferably on the dock and not rocking around in the boat. Make sure your hoses can reach where they need to go without being stretched tight or bent at a sharp angle.

- Secure the Hoses: Drop the intake hose all the way to the bottom of the fuel can. Place the delivery nozzle securely into your boat's fuel fill port. If the nozzle has a hook or clip, use it to keep it from popping out.

- Start the Pump: Fire it up! You should hear the motor kick on and feel a slight vibration as it starts pulling fuel.

- Monitor the Flow: Never, ever walk away from a running fuel pump. Keep one eye on the fuel can to make sure the hose stays submerged and the other on your boat's fuel gauge to avoid overfilling.

- Shut Down and Secure: When you're done, turn the pump off before you pull the nozzle out of the tank. This simple trick minimizes drips. Then, carefully lift the hoses to drain any leftover fuel back into the can or tank.

Long-Term Maintenance and Troubleshooting

Good habits don't stop when the tank is full. A couple of post-use steps will keep your pump in top shape for the long haul. For a deeper dive, check out our complete boat fuel pump guide with expert selection and maintenance tips.

A great pro-tip is to run the pump dry for just a few seconds after each use. This clears any remaining gasoline from the internal parts, which helps prevent seals and diaphragms from degrading over time.

When it's time to put it away, coil the hoses loosely and store the pump somewhere dry and ventilated, away from direct sun or extreme temperatures. Every so often, it’s worth doing a deeper inspection of the seals and internal components if your model is designed to be opened up.

What about when things go wrong? Here’s how to fix the most common headaches:

- Pump Won't Prime: This is almost always an air leak. Go back and double-check that every single hose connection is absolutely airtight.

- Slow Flow Rate: The number one cause is a clogged intake strainer. Pull it out and give it a good cleaning. A low battery can also make an electric pump run sluggishly.

- Pump Stops Unexpectedly: On an electric model, check your power connection first. Many pumps also have a thermal overload protector that will shut it down to prevent overheating. Just let it cool off for a bit before trying again.

What's Next? A Look at Smarter Fueling Solutions

Portable pumps are a fantastic leap forward from the days of hoisting a heavy fuel can and hoping for the best. But the world of marine fueling keeps moving, and new systems are popping up that take convenience and safety to a whole new level. These aren't just pumps; they're complete solutions designed to tackle the last remaining frustrations of refueling, like those annoying little drips and the dreaded overfill.

This isn't just happening in the boating world, either. The demand for better fuel transfer methods is a global trend. The market for these pumps hit a staggering $2.1 billion and is projected to climb to $2.8 billion by 2030. Portable models are leading that charge, all thanks to their sheer versatility. This growth is a direct result of economic and manufacturing shifts worldwide. You can dive deeper into these global fuel transfer pump market trends if you're curious.

Moving Toward "Closed-Loop" Fueling

The big innovation we're seeing is the move toward closed-loop fueling systems. What does that mean? Well, think of a standard pump as an open garden hose—it gets the job done, but you have to aim carefully and know when to shut it off. A closed-loop system, on the other hand, is more like a quick-connect sprinkler line. It creates a sealed, self-contained connection that manages the entire process for you.

These systems are engineered to form a vapor-tight seal from the fuel can all the way to your boat's tank. That simple change is a game-changer. It doesn't just prevent messy fuel spills; it also traps the harmful gasoline vapors, which is great for your health and the environment.

The Upgrades That Really Matter

So, what makes these modern fueling systems different? It comes down to a few key features that solve the most common headaches boaters face at the dock or on the water.

- Vapor-Tight Connections: Forget just sticking a nozzle into the fill port. These systems use special connectors that lock firmly into place, often with a reassuring 'click'. That sound tells you you've got a secure, leak-proof seal before a single drop of fuel moves.

- Automatic Shutoff: This is the ultimate safety net. Instead of anxiously peering into the tank, advanced sensors know the second it's full and stop the flow instantly. It takes all the guesswork out of the equation and makes overfills a thing of the past.

- Works with Your Existing Gear: The smartest new systems don't force you to buy all-new equipment. They're built with universal compatibility in mind, using adapters that fit the standard portable fuel cans and boat fuel ports you already have.

When you put all these pieces together, you get something like CLiX Fueling Solutions. It's a perfect example of this next wave, turning a messy chore into a clean, click-and-forget task. By creating that secure connection and stopping the flow automatically, it directly solves the biggest refueling pains for boaters. It’s a genuine preview of a future where fueling is completely stress-free.

Frequently Asked Questions

Even with a solid plan, you're bound to have questions when you're out on the water. Let's tackle some of the most common things boaters ask about gasoline transfer pumps so you can fuel up with confidence.

Can I Use the Same Pump for Gasoline and Water?

That's a definite no-go. You should never, ever use the same pump for fuel and water. Pumps designed for gasoline are built with special materials and seals, like Viton, specifically to handle how harsh and corrosive gas can be.

If you try to pump water through it, you risk damaging the pump's guts. But the real danger is cross-contamination. Getting even a little water in your fuel tank is a surefire way to cause serious, and often very expensive, engine trouble. Always keep one pump dedicated to fuel and another for everything else.

What's the Right Speed for My Transfer Pump?

The ideal flow rate really comes down to your boat and how you use it. It's measured in gallons per minute (GPM), and it’s not always a case of "faster is better."

- For smaller boats, personal watercraft, or just topping off the tank, a slower pump in the 2-4 GPM range gives you much better control and helps prevent spills and messy splash-back.

- If you're filling a much larger tank, a faster pump pushing 5-8 GPM will obviously save you a ton of time at the dock.

Keep in mind that a really fast flow rate can sometimes overwhelm a tank's vent line, causing fuel to spit back out. A pump with a variable speed setting or a smart auto-stop nozzle gives you the best of both worlds—speed when you need it and safety when you don't.

What Does "Self-Priming" Mean and Do I Need It?

A self-priming pump is one of those features you'll be incredibly glad you have. Simply put, it means the pump can create its own suction to pull fuel up through the hose without you having to manually prime it first. It purges the air from the line all by itself.

Without this feature, you're stuck trying to get the pump started, which often involves pre-filling the hose with gasoline—a messy, frustrating, and unsafe job. A self-priming pump just makes the whole process faster, cleaner, and a whole lot less of a headache.

Ready to eliminate spills and make refueling a simple, clean, and safe task? Discover how the innovative system from CLiX Fueling Solutions can transform your boating experience. Visit the official CLiX Fueling website to see it in action.