When people ask about the "biggest gas can," there isn't one simple answer. The right size depends entirely on what you're fueling. For most of us at home, portable gas cans are kept to a manageable 5-10 gallons for safety reasons. But when you get into marine or industrial settings, the scale explodes into specialized tanks and massive storage systems.

What Is The Biggest Gas Can You Can Actually Use?

The idea of the "biggest gas can" really changes depending on your perspective. Are you filling up a lawnmower, gassing up your boat for a weekend on the water, or fueling an entire fleet of construction vehicles?

Think of it like carrying water. You'd grab a water bottle for a hike, pack a cooler for a picnic, but a town needs a water tower. Each one is the "biggest" and best tool for its specific job, and each comes with its own set of rules.

For everyday consumer use, you'll rarely find a portable gas can larger than 10 gallons. This isn't because manufacturers can't make them bigger; it’s a matter of practicality and safety. A full 10-gallon can of gasoline weighs over 60 pounds! That's a lot to lift and pour without risking a dangerous spill or a back injury. Regulations from agencies like the EPA and DOT are in place to make sure these containers are safe and manageable, which helps reduce fire hazards.

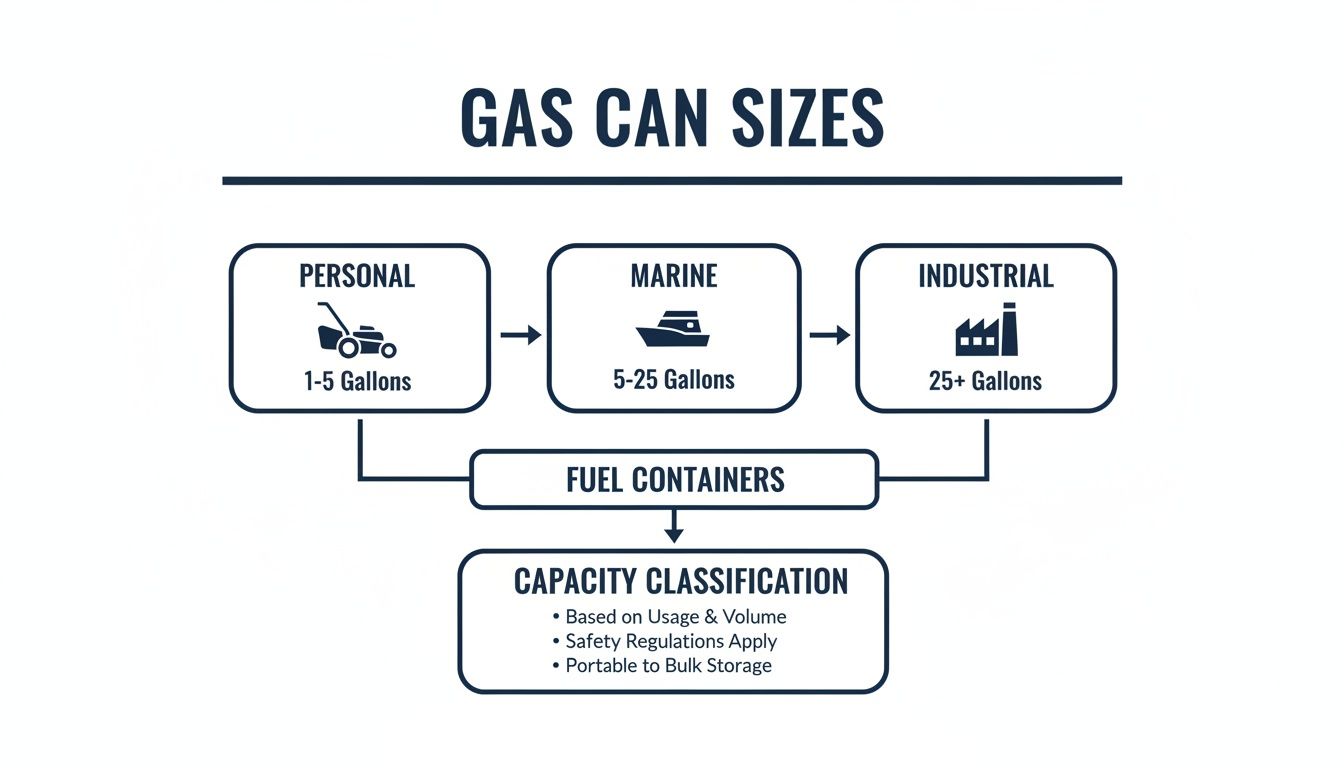

Classifying Fuel Container Sizes

To get a clearer picture, it helps to break down fuel containers into three common categories. Each one serves a different purpose and is built to different standards for safety, transport, and storage.

- Personal Use: These are the classic red plastic cans you see in garages everywhere, perfect for lawnmowers, generators, or ATVs. They usually hold between 1 and 10 gallons, with the 5-gallon can being the most popular because it's a good balance of capacity and portability.

- Marine Use: Boaters need a lot more fuel, so they rely on larger portable marine fuel tanks and, more often, permanent onboard tanks. While you can find portable marine tanks up to 12 gallons or so, the real capacity is in the installed systems, which can hold hundreds of gallons.

- Industrial Use: This is where you find the true heavyweights. Commercial operations use things like bulk fuel tanks and massive stationary storage systems that can hold thousands of gallons to keep their machinery and vehicle fleets running without interruption.

This diagram helps visualize how fuel container sizes scale up from a simple can in the garage to a massive industrial tank.

As you can see, the definition of the "biggest gas can" shifts dramatically with the job at hand. What starts as a portable can for personal use becomes a complex, stationary solution for industrial needs. So, while a 10-gallon gas can might seem huge for topping off your lawnmower, it's just the entry point for more demanding applications.

Understanding The Rules That Limit Gas Can Size

Ever wondered why you can’t just walk into a hardware store and buy a 50-gallon portable gas can? It’s not a simple manufacturing choice—it’s the result of a complex web of safety regulations designed to protect you, the public, and the environment.

Think of these rules like traffic laws for flammable liquids. They exist to prevent spills, fires, and dangerous accidents. Several key federal agencies manage this system, and each one governs a different part of a fuel container's life, from its design and labeling to how it’s transported.

The Key Agencies Setting The Standards

To really get why the biggest gas can you can easily buy is limited in size, you have to know who’s making the rules. It’s not just one group; several authorities have overlapping jurisdictions, creating a comprehensive safety net.

- Environmental Protection Agency (EPA): The EPA’s main concern is air quality. Their rules are all about minimizing harmful vapor emissions from portable fuel containers. That’s why we have the modern "spill-proof" spouts that automatically seal themselves.

- Department of Transportation (DOT): If you’re moving fuel on public roads, you’re in the DOT’s territory. They set the rules for transporting hazardous materials, dictating container strength, proper labeling, and how much fuel you can legally carry in your personal vehicle.

- Occupational Safety and Health Administration (OSHA): OSHA’s rules kick in at the workplace. They make sure fuel is stored and handled safely to protect employees, which is why you see specific types of approved safety cans on job sites.

- U.S. Coast Guard (USCG): For boaters, the USCG has its own set of very specific regulations. These rules cover everything from portable fuel tanks to permanent onboard systems, all aimed at preventing fires and spills out on the water.

These agencies all play a part, ensuring that any gas can sold in the U.S. meets a high safety standard, no matter how it's used.

Key Takeaway: The size and design of gas cans aren't random. They're the result of careful federal regulations from agencies like the EPA and DOT that prioritize preventing spills, fires, and harmful vapor emissions.

Translating Regulations Into Real-World Features

The rules from these agencies directly shape the gas cans you see on the shelf. It’s why a can today looks and works so differently from one made 30 years ago. It’s not just about how much it holds; it’s about a complete safety system built right into the container.

Take the classic red color for gasoline cans. That’s a universally recognized standard to help prevent someone from accidentally grabbing a diesel (yellow) or kerosene (blue) can. This simple color-coding is a direct result of safety regulations.

Another big one is the spill-proof spout. The EPA mandated these to cut down on evaporative emissions. While they can sometimes be a little tricky to use, they’re crucial for preventing both environmental contamination and the dangerous buildup of flammable vapors.

Here are a few other required features you’ll find on modern cans:

- Flame Arrestors: This is a small mesh screen, usually metal or plastic, sitting inside the spout. Its job is to stop an external flame from traveling back into the can and causing an explosion.

- Durable Construction: Cans have to be made from specific materials, like high-density polyethylene (HDPE), and must pass tough drop and pressure tests to make sure they won't easily break open.

- Proper Venting: Modern cans have built-in mechanisms to safely vent pressure that builds up from temperature changes, which keeps the container from swelling or bursting.

All these requirements mean that even a standard 5-gallon can is a highly engineered piece of safety equipment. This is why your search for the absolute biggest gas can for portable use usually hits a wall around the 10-gallon mark. Beyond that size, the safety, weight, and regulatory hurdles just become too great for a regular consumer product.

How Big Is Too Big For Your Garage Or Boat?

Knowing the rules is one thing, but making the right call in the real world is where safety really clicks. You can walk into a store and buy a big 10-gallon gas can, but that doesn't always mean it's the right tool for the job. When you're dealing with flammable liquids, you have to balance the convenience of carrying more fuel against the practical risks.

The biggest issue with large cans comes down to simple physics: weight. A single gallon of gasoline weighs a little over 6 pounds. That means a full 10-gallon container is going to tip the scales at more than 60 pounds.

Think about that for a second. That’s like trying to pour fuel from a jug holding nine bowling balls. The sheer difficulty of lifting and tilting that much weight makes a major spill far more likely. And let's not forget the risk of a serious back injury.

One Large Can vs. Multiple Small Cans

So, what's better: one giant 10-gallon can or two 5-gallon cans? While a single large can seems simpler because it's just one container to store, the advantages pretty much end there. In almost every other way, two smaller cans are the safer, smarter choice.

Let's break it down:

- Weight & Handling: A 30-pound, 5-gallon can is worlds easier for one person to lift and pour compared to a 60-pound monster. This means less physical strain and a much lower chance of losing your grip while fueling.

- Spill Risk: If you drop a can, which mess would you rather clean up? A 5-gallon spill is a serious problem, but a 10-gallon spill is a full-blown catastrophe that's incredibly difficult to contain.

- Stability: Tall, heavy containers are just plain tippy. Two lower-profile 5-gallon cans are much easier to secure in your truck bed or on your boat, so they’re less likely to fall over during transit.

For most people—whether you're filling up a lawnmower or topping off a small boat—sticking with multiple 5-gallon cans is the way to go. If you're a boater who consistently needs more fuel, you're better off looking into a proper, certified 10-gallon boat fuel tank. It's a much safer, permanent solution than wrestling with oversized portable cans.

Practical Tip: Always put your gas can on the ground before filling it to prevent static buildup. When you're fueling equipment, do it on the ground, never inside a vehicle or on the deck of a boat.

The Role of Modern Safety Tools

When you do have to use a larger container, having the right safety gear becomes non-negotiable. The higher volume and faster flow from the biggest gas can you can find also means the risk of overfilling your tank skyrockets. An overfill isn't just messy; it's a dangerous spill that can ruin your boat's gelcoat, pollute the water, and create a massive fire hazard.

This is exactly where modern fueling tools come in. Automatic shut-off devices were invented to prevent these exact situations.

Instead of trying to guess when your tank is full while also wrestling with a heavy, sloshing can, an overfill prevention device like CLiX handles the hard part for you. It snaps into your fuel tank’s inlet and automatically stops the gas pump nozzle the second the tank is full.

This simple tool completely changes the fueling game, especially when you're dealing with a lot of fuel. It takes the guesswork and the struggle out of the equation, making every fill-up safer and cleaner. By stopping spills before they even start, you protect your boat, your safety, and the waterways you love.

Exploring The True Giants Of Industrial Fuel Storage

To really find the "biggest gas can," we have to think way beyond the hardware store shelf. We're stepping into the world of industrial-scale fuel storage.

Think of it this way: if your 5-gallon can is a personal water bottle, these industrial tanks are the city's water tower. These aren't just big jugs; they're complex, engineered systems built to safely hold and move staggering volumes of fuel. This is the heavy-duty infrastructure that powers farms, construction sites, and entire transportation networks.

Bulk Fuel Tanks On The Job Site

Imagine trying to refuel a fleet of bulldozers and generators with a 5-gallon can. You’d be there all day. That’s why large construction sites and farms rely on stationary bulk fuel tanks.

These steel workhorses act like a private, on-site gas station. They can hold anywhere from a few hundred gallons to over 10,000 gallons, allowing workers to refuel heavy machinery quickly and keep the project on schedule. For the really big jobs, specialized industrial tank solutions are designed to meet massive commercial demands.

Of course, storing that much fuel comes with serious responsibility. These systems are bound by strict regulations and often include features like:

- Double-Wall Construction to prevent leaks from ever touching the ground.

- Spill Containment Basins that act as a failsafe to catch spills.

- Advanced Monitoring Systems that keep a constant electronic eye on fuel levels and detect potential leaks.

The World Of Cryogenic And ISO Tanks

When you move past gasoline and diesel into industrial gases like nitrogen or oxygen, the technology gets even more impressive. These gases are often stored as cryogenic liquids—chilled to incredibly low temperatures until they turn to liquid. This process lets you store an enormous amount of gas in a surprisingly small space.

This is where you find the true giants.

The largest commercial tanks are built for this very purpose, often holding between 3,000 and 40,000 liters. The massive ISO tanks and dewars you see on trucks and trains, which handle regional distribution, typically fall in the 10,000–40,000 L range. To give you some perspective, a single 20,000 L liquid nitrogen tank contains enough product to expand into 7–8 million liters of gas at room temperature.

These containers are basically giant, high-tech thermoses, built with vacuum-insulated walls to keep their contents at hundreds of degrees below zero.

Insight: In the industrial world, the "biggest gas can" isn't just about volume. It’s about using advanced science like cryogenics to pack a massive amount of energy into a transportable form.

Engineering And Safety On A Massive Scale

Let's be clear: handling thousands of gallons of a flammable or high-pressure substance is a whole different ballgame than carrying a portable can. The engineering and safety protocols are on another level.

Take ISO tanks. They are built inside standardized steel frames so they can be seamlessly loaded onto ships, trains, and trucks for global transport. These containers are designed to endure incredible physical stress and are fitted with multiple safety valves and rupture discs to prevent a catastrophic failure.

The engineering behind them is focused on a few critical areas:

- Material Strength: They use special steel alloys that can handle extreme temperatures and pressures without getting brittle.

- Pressure Relief Systems: Redundant safety valves are in place to vent excess pressure if things heat up.

- Structural Integrity: The entire frame is built like a fortress to prevent punctures or damage during transport.

So, the hunt for the "biggest gas can" takes us far away from the garage and deep into the world of industrial logistics. While a 10-gallon can might feel huge for your boat, it's just a drop in the bucket compared to the colossal tanks that keep our modern world running.

Essential Safety Practices For Handling Large Fuel Containers

Once you step up from a standard 5-gallon can, the game changes. Handling the biggest gas can you can find means dealing with new risks. The sheer weight and volume of fuel demand more than just a little caution; they require a serious, structured approach to safety. We're not just talking about avoiding a messy spill—we're talking about preventing fires, serious injuries, and environmental harm.

Think of it like this: carrying a bucket of water is one thing, but managing a fire hose is another entirely. Both involve liquid, but the forces at play and the consequences of a mistake are on completely different levels. One small slip-up with a large fuel container can spiral into a major hazard in seconds.

Proper Storage And Ventilation

Your first line of defense is simply where and how you store your fuel. Gasoline is always releasing flammable vapors. Without good airflow, those fumes can build up to dangerous concentrations, just waiting for a single spark from a nearby appliance or even static electricity to ignite.

Always keep your fuel in a well-ventilated area, like a detached shed or a garage that's separated from your living spaces. Make sure it's far away from any potential ignition sources—that includes things you might not think about, like water heaters, furnaces, and electrical outlets. For a full rundown, check out our guide on how to store gasoline safely.

Grounding And Static Prevention

Static electricity is the invisible enemy when you're handling fuel. Just the act of gasoline sloshing around inside a plastic container or flowing through a hose can build up a static charge. If that charge finds a way to discharge as a spark near the fumes, you're looking at a sudden, violent fire.

To keep that from happening, make these grounding rules second nature:

- Always place fuel cans on the ground before you start filling them. Never, ever fill a container while it’s sitting in a truck bed, on a trailer, or inside a boat.

- Keep the pump nozzle in constant contact with the container's opening the entire time you're filling it.

- Before pumping fuel into your boat, touch the nozzle to the boat’s metal fuel deck fill plate for a second to equalize any static charge.

Safe Lifting And Transport Techniques

A full 10-gallon can of gasoline weighs over 60 pounds. That’s more than enough to cause a serious back injury if you lift it the wrong way. Remember to bend at your knees, not your waist, and keep the container held close to your body. If you have to move it any real distance, do your back a favor and use a dolly or cart.

When you're on the move, make sure the containers are secured upright so they can't tip, slide, or slam into anything. Even a minor fender-bender can be enough to rupture a can that's not tied down properly.

In a commercial setting, maintaining a hazardous substance register for all stored fuels is standard practice. This log is crucial for keeping track of what you have on-site, which helps with regulatory compliance and gives emergency responders vital information if something goes wrong.

Got Questions About Big Gas Cans? We've Got Answers.

When you start dealing with larger amounts of fuel, a lot of questions pop up. Let's tackle some of the most common ones so you can handle your fuel safely and stay on the right side of the law.

How Much Fuel Can I Legally Haul In My Car?

This is a big one. While there isn't a single federal law that spells it out for your personal car or truck, the rule of thumb everyone in the industry follows is to keep it under 25 gallons total.

That doesn't mean one giant 25-gallon tank, though. The fuel needs to be in separate, DOT-approved containers, and none of them should be bigger than 5 gallons. If you go beyond that, you start falling under commercial regulations, which are a whole different ballgame. Always check your local fire codes, too—they can be even stricter. And make sure those cans are tied down upright in a well-ventilated spot. Nobody wants to be driving in a cloud of gas fumes.

Metal vs. Plastic: Which Can Is Better For Hauling More Fuel?

Both have their pros and cons. Metal cans are tough as nails and resist punctures well, but they're heavy and can eventually rust. On the other hand, modern plastic cans made from high-density polyethylene (HDPE) are surprisingly durable, much lighter, and obviously won't rust.

Think about it: a metal can holding over 5 gallons of fuel is going to weigh more than 60 pounds. That's a serious safety hazard just trying to lift and pour it. For that reason alone, a high-quality, certified plastic can is the go-to choice for most people. The real deciding factor isn't the material, but whether the can is certified by a group like UL or ASTM. That certification is your proof of safety.

A Quick Tip from Experience: No matter what your can is made of, give it a once-over before every use. Look for cracks, rust spots, or worn-out seals. A damaged can is a dangerous can, period.

How Can I Pour From A Heavy Gas Can Without Spilling?

Trying to pour from a full, heavy can without making a mess is tough. It's probably the number one cause of fuel spills. The secret is using the right technique and the right gear.

Here’s a simple process to make it spill-proof:

- Ground Everything: Before you start, make sure the lawnmower, boat tank, or whatever you're filling is sitting on the ground. This gets rid of any static electricity that could cause a dangerous spark.

- Grab a Funnel: A good, wide funnel gives you a much bigger target. It’s a simple trick that makes a huge difference when you're wrestling with a heavy container.

- Use an Overfill Preventer: The absolute best way to stop a spill is to prevent it from happening in the first place. An automatic shut-off device stops the flow as soon as the tank is full. It takes all the guesswork and struggle out of the equation.

Do I Need A Permit For A Large Fuel Tank At My House?

Almost certainly, yes. Once you get into storing fuel in a stationary tank, especially one bigger than 60 gallons (and sometimes even less), you'll need a permit from your local fire department. They have specific rules about where the tank can be, how it's installed, and what safety features it needs. Before you even think about buying a big tank for your property, your very first call should be to the local fire marshal.

Stop guessing and start fueling with confidence. With CLiX Fueling Solutions, you can prevent costly and dangerous overfills every single time. Learn how to make your fueling experience stress-free and spill-free at https://clixfueling.com.