That little fitting connecting your fuel line to the tank? It's way more than just a piece of hardware. It's a critical link for your boat's safety and performance. Getting the fuel tank adapter right prevents dangerous fuel leaks, stops hazardous vapor buildup, and avoids engine problems that could leave you high and dry. This isn't just about making parts fit; it's about keeping your boat safe and your engine humming.

Why the Right Fuel Tank Adapter Is So Important

It’s easy to ignore a small part like a fuel adapter, but its job is absolutely vital. I always tell people to think of it as the gatekeeper between your fuel supply and your engine. A perfect seal is the only option here. Even a tiny flaw can spiral into big, and often dangerous, problems out on the water.

Let’s walk through a situation I see all the time. A boater decides to upgrade to a bigger, modern polyethylene fuel tank to get more range. The old tank had a standard brass fitting, but the new tank has completely different threads. Trying to force that old adapter on is just asking for trouble. That kind of mismatch is a guaranteed slow-leak disaster waiting to happen.

The Risks of a Poorly Chosen Adapter

Using the wrong adapter, or just installing one badly, opens the door to a bunch of hazards. The most immediate threat is a fuel leak, which creates a domino effect of bad news.

- Fuel Leaks: What looks like a small drip can quickly pool in your bilge, turning it into a highly flammable mess.

- Vapor Buildup: As that leaked fuel evaporates, it fills confined spaces with explosive vapors. All it takes is one spark from a bilge pump or an engine start to have a catastrophic event.

- Engine Starvation: A bad seal doesn't just let fuel out; it can also let air in. Air gets sucked into the fuel line, creating bubbles that starve the engine of fuel. This leads to sputtering, stalling, or a total loss of power—usually when you need it most.

Picture this: you're trying to navigate a crowded channel or power through a storm to get back to the dock, and your engine suddenly cuts out. More often than not, the culprit is a simple, preventable fuel delivery issue that started right at the tank connection.

An estimated 70% of boat breakdowns are tied to the engine or fuel system. Making sure every single component, right down to the fuel tank adapter, is in top shape is one of the smartest preventative moves you can make as a boat owner.

When You Need a New Fuel Tank Adapter

So, when should you be shopping for a new adapter? The most obvious reason is when you're upgrading your fuel tank, since new tanks often come with different thread types or are made of different materials. Another common time is when adding an auxiliary tank—you'll need the right fittings to create a safe, leak-proof connection to your main fuel line.

But don't forget about regular wear and tear. During routine checks, you might find your current adapter is failing. Plastic fittings can get brittle and crack after years of sun exposure, while even brass can corrode, especially in saltwater. Always give your adapter a good look for cracks, corrosion, or stripped threads. Swapping out a questionable part before it fails is cheap insurance. A good fuel tank adapter isn't just another part; it's a smart investment in your safety and peace of mind.

How to Select the Perfect Fuel Tank Adapter

Picking the right fuel tank adapter isn't just about finding something that fits—it's about ensuring a safe, reliable fuel system. Get it wrong, and you're looking at frustrating leaks and potential danger. But get it right, and you've got a secure, worry-free connection. The good news is that with a little know-how, you can easily find the perfect match for your boat.

It all starts with looking at what you already have. Your adapter is simply the bridge between your fuel tank and your engine's fuel line. Take a moment to check your tank—is it a common polyethylene (plastic) tank or an aluminum one? Then, look at the fitting on the tank. Are the threads on the inside (female) or outside (male)? Knowing these two things will narrow down your options significantly.

Material Matters: Brass vs. Plastic

The material of your fuel tank adapter is a huge factor. You'll mostly find two options out on the market: traditional brass and modern engineered plastics or nylon. Each has its place.

- Brass Adapters: These have been the old standby for years. They're tough and hold up well, especially in freshwater. The big catch? Saltwater. Over time, saltwater can cause dezincification, where the zinc leaches out of the brass. This leaves you with a weak, porous copper fitting that’s just waiting to crack and fail.

- Engineered Plastic/Nylon Adapters: Modern composite adapters are a fantastic evolution. They're lightweight, incredibly durable, and completely immune to corrosion. This makes them a top choice for both saltwater and freshwater boaters. A great side benefit is they’re less likely to damage the threads on a plastic tank, since you aren't forcing a hard metal into softer plastic.

A quick word of caution: if you do pair a metal adapter with a plastic tank, be extremely careful. It’s incredibly easy to cross-thread or over-tighten a brass fitting and crack the tank's threads. That creates a permanent, dangerous leak. If you go this route, always start by hand-tightening, then use a wrench for no more than a quarter-turn past that.

For a deeper dive into tank types and care, check out our detailed boat fuel tank guide.

Your goal here is to create a solid connection that can handle everything boating throws at it—vibrations, temperature swings, and constant exposure to fuel. Choosing the wrong material for your environment just isn't a risk worth taking.

Understanding Threads and Connections

Once you've settled on a material, it’s time to get the connection details right. This is where most leaks happen, so paying close attention here is key.

You'll mainly run into two thread standards: NPT (National Pipe Taper) and BSP (British Standard Pipe). NPT is the standard in the US and uses tapered threads that seal themselves as you tighten them. BSP is more common in Europe and has straight threads that need a gasket or O-ring to seal. The two are not interchangeable, so trying to force one into the other is a surefire way to cause a leak.

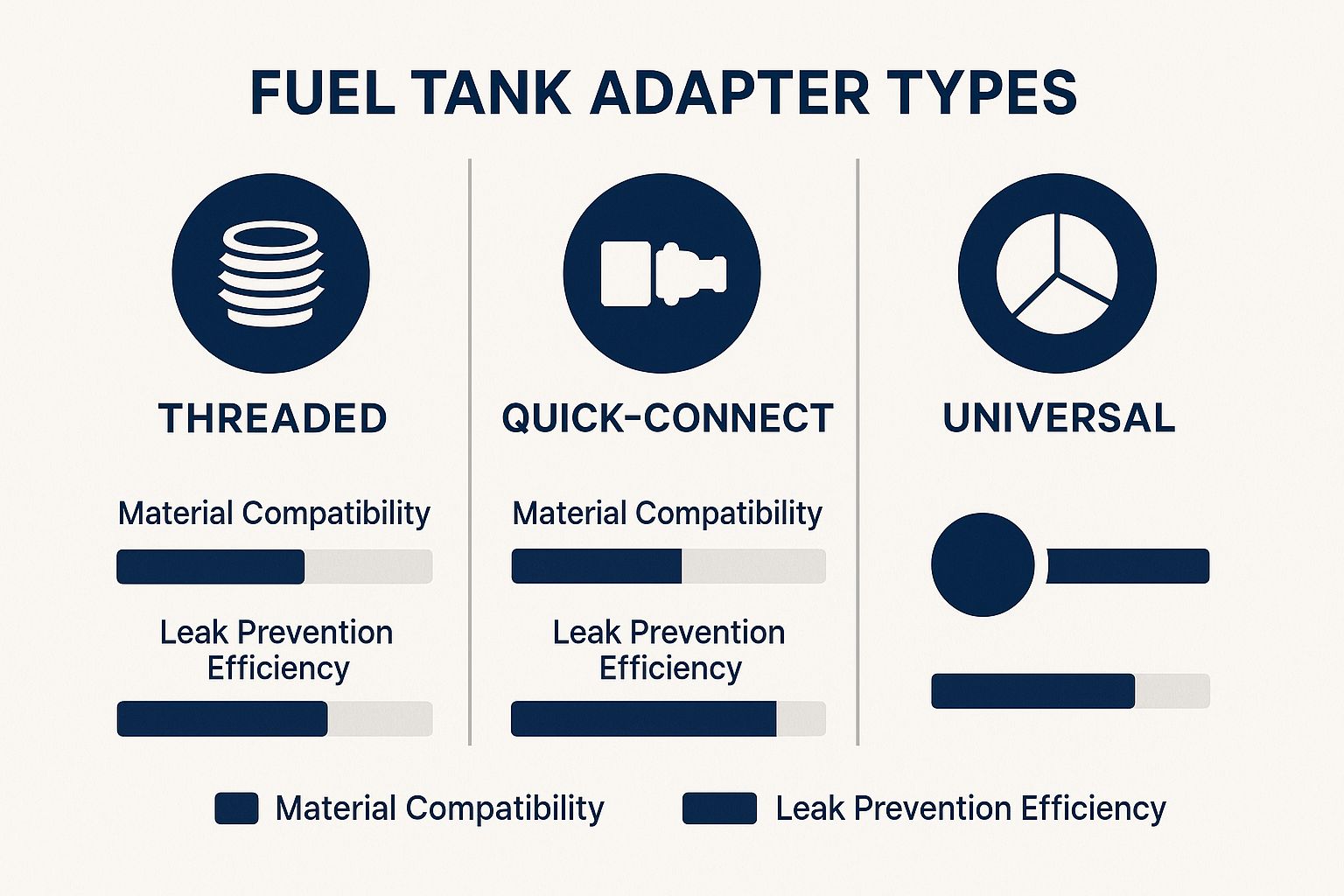

This image shows how different adapter types stack up.

As you can see, quick-connect systems, particularly those made from modern composites, offer excellent leak prevention and work with a wide range of setups.

Next, think about the other end—the connection to your fuel line. Major engine brands like Yamaha, Mercury, and Honda often use their own special quick-connect fittings. If you're using a universal fuel line, you'll probably need a barbed fitting. Just make sure the barb size matches the internal diameter of your hose, which is usually 1/4", 5/16", or 3/8".

Fuel Tank Adapter Material and Type Comparison

Choosing between different materials and connection types can feel complicated. This table breaks down the common options to help you see at a glance what might work best for your boat.

| Adapter Type | Material | Best For | Key Considerations |

|---|---|---|---|

| Threaded | Brass | Freshwater use; aluminum tanks. | Prone to corrosion in saltwater. Can damage plastic tank threads if over-tightened. |

| Threaded | Engineered Plastic/Nylon | Saltwater and freshwater; plastic tanks. | Excellent corrosion resistance. Less risk of cross-threading on plastic tanks. |

| Barbed | Brass or Plastic | Universal fuel lines without quick-connects. | Must match the fuel line's internal diameter. Requires a hose clamp for a secure seal. |

| Quick-Connect | Engineered Plastic/Nylon | OEM engine connections (e.g., Yamaha, Mercury). | Offers the fastest, most secure, and often leak-proof connection. Ensures compatibility. |

Ultimately, the best choice balances durability, compatibility with your existing gear, and the environment you boat in. For most modern setups, an engineered plastic adapter offers the most versatile and reliable performance.

It's interesting to see how advancements in other industries influence boating. The automotive fuel tanks market, for example, is projected to hit USD 32.7 billion by 2032. This growth pushes for safer and more advanced fuel systems, and we get to benefit from that innovation with better, more reliable parts like these adapters.

Installing Your New Fuel Tank Adapter

Alright, you've picked out the perfect fuel tank adapter. Now for the hands-on part. Getting the installation right is just as important as choosing the correct part in the first place. A sloppy job here can cause the exact leaks you’re trying to prevent.

But don't worry, this isn't some job reserved only for certified marine mechanics. With a little patience and the right approach, you can get a secure, reliable seal and enjoy total peace of mind out on the water.

First things first: safety. Before you even think about touching a wrench, remember you're working with gasoline. Good ventilation is non-negotiable. If you're working inside, open every door and window you can. I always get a fan going to keep the air moving. Critically, disconnect the boat's battery to kill any potential source of sparks, and keep a fire extinguisher rated for gasoline fires right beside you.

Preparing for a Clean Swap

The goal here is a clean swap with no surprises. Start by laying some absorbent shop rags around the tank’s fitting. No matter how careful you are, a few drips of fuel are bound to escape.

If you’re wrestling with an old, stubborn brass fitting, you might need two wrenches. Use one to hold the tank bung steady (the part the fitting screws into) and the other to turn the adapter itself. This simple trick prevents you from putting too much stress on the plastic tank, which could easily crack it.

Once the old fitting is out, the next step is absolutely vital for a good seal: cleaning the threads on the tank. Grab a clean, lint-free rag and wipe away every trace of old sealant, grime, or gunk. I personally like to use a small nylon brush—an old toothbrush works perfectly—to gently scrub the threads clean. Any leftover debris will get in the way of a proper seal.

Pro Tip: Whatever you do, don't use a metal wire brush on plastic tank threads. It’s way too aggressive and will gouge the plastic, creating tiny channels for fuel to leak through. Stick to a soft nylon brush and a little elbow grease.

Creating a Leak-Proof Seal

Now, let's talk about sealing those threads. This is where a lot of people go wrong. The common instinct is to reach for Teflon tape, but that's a huge mistake here. Most standard white Teflon tape isn't rated for gasoline and will eventually break down. When it does, it sends tiny white flakes into your fuel system, ready to clog up your fuel filter or, worse, your engine’s injectors.

You need to use a liquid or paste-style thread sealant that is specifically made for gasoline. You can find it at any auto parts or marine supply store. Apply a thin, even coat to the male threads of your new fuel tank adapter. Don't overdo it; you just need enough to fill the microscopic gaps in the threads.

A few pointers for a perfect installation:

- Start By Hand: Always, always, always thread the new adapter into the tank by hand first. This is the best way to feel if you’re cross-threading it. It should screw in smoothly for at least a few turns. If it fights you, back it out and try again.

- Just Snug Enough: Once it's hand-tight, grab your wrench and give it another quarter to half-turn. The goal is to make it snug, not to crank on it with all your might. Over-tightening is the #1 cause of cracked plastic tanks and fittings.

- Connect the Hose: If your adapter uses a barbed fitting, slide the fuel hose all the way on. Secure it with a high-quality stainless steel hose clamp, placing the clamp just behind the barb before tightening it down firmly.

The Final Check for Leaks

With everything buttoned up, it's time for the moment of truth. Reconnect your fuel line's primer bulb and give it a few good squeezes until it feels firm. This pressurizes the fuel line and will expose any potential leaks right away.

I always finish with a quick soapy water test. Mix a little dish soap and water in a spray bottle and give your new connection a good spray. Watch it closely. If you see any new bubbles forming or growing, you've got a leak.

Don't panic if this happens. Just carefully unscrew the fitting, clean off all the sealant from both the adapter and the tank, reapply a fresh coat, and reinstall it. This simple check takes less than a minute but can save you from a very dangerous situation later.

Keeping Your Fuel System Safe and Leak-Free

Let’s be honest, working on your boat's fuel system is serious business. It’s one of those jobs where you need to be completely focused. Even though a fuel tank adapter seems like a simple little part, getting the installation wrong can lead to some really dangerous situations. Making sure every connection is tight and every material is right for the job isn't just a recommendation—it's absolutely critical for keeping everyone on your boat safe.

One of the most common mistakes I see boaters make is grabbing that standard white Teflon tape to seal up the threads. That stuff is great for plumbing at home, but it's not made to stand up to gasoline. Over time, fuel will break it down. When that happens, little bits can flake off and head straight for your engine, clogging up the fuel filter or, worse, the tiny, sensitive passages in your fuel injectors.

Using the Right Sealant Matters

So what's the right way to do it? You need to use a liquid or paste-style thread sealant specifically made for gasoline and ethanol fuels. You can find it at any decent marine supply or auto parts store. When you apply it, just put a thin, even coat on the male threads of the adapter. You want enough to get a perfect, leak-proof seal, but not so much that you have big globs squeezing out and getting into your fuel tank.

Ethanol-blended fuels like E10 and E15 are another big reason we have to be so careful. Ethanol is tough on certain types of rubber and plastic, causing them to get brittle, swell up, or crack over time. This is exactly why you can't just install parts and forget about them.

Here's what to look for during your regular checks:

- Fuel Lines: Give them a gentle squeeze. They should feel firm but still have some flex. If they feel mushy, spongy, or rock-hard, it’s time to replace them.

- Primer Bulb: Check for any cracks, especially where it connects to the hose. A cracked primer bulb is a leak waiting to happen.

- Connections: Look closely at your fuel tank adapter and all the other fittings. You’re searching for any signs of fuel "weeping" or any visible cracks in the plastic or metal.

Staying on top of this is a key part of maintaining a safe boat fuel system. Finding these little problems early saves you a world of trouble down the road.

The Power of Routine Inspections

Before you turn the key every single time, get into the habit of doing a quick "sniff test." Stick your nose in the bilge and engine compartment. Your sense of smell is one of the best safety tools you have. If you smell gas, stop. Do not start that engine. Hunt down the source of that smell and fix it first.

A secure fuel tank adapter is the foundation of a safe fuel system. But it's the regular, diligent checks that keep small problems from turning into full-blown emergencies. It’s a simple routine that becomes a powerful safety habit.

Keeping an eye on your fuel system is getting easier, too, thanks to new technology. The market for fuel tank indicators, which work with adapters to help you monitor fuel levels safely, is projected to hit about USD 5.03 billion by 2033. This boom shows just how much the industry is focused on smart systems that prevent spills and leaks with real-time info. It really drives home how crucial even small components like your fuel tank adapter are in a modern, safe boat. If you're interested in the data, you can read more about the fuel tank indicators market here.

Troubleshooting Common Adapter Problems

Even with the most careful installation, sometimes things just don’t go as planned. You might spot a stubborn little drip from the threads or have a quick-disconnect fitting that puts up a fight. It’s frustrating, but don’t worry. We can walk through how to figure out what’s wrong and get it fixed, so you can get back on the water feeling secure.

One of the most frequent headaches I hear about is a small, persistent leak right where the adapter screws into the tank. The very first thing to do is check for cross-threading. If the adapter felt unusually tight or tough to screw in, you’ve probably found the culprit. You’ll need to back it out completely, carefully clean the threads on both the tank and the adapter, and then try again. Always start it by hand to make sure it's going in straight.

If the threads look good, the next suspect is your sealant. Did you use a liquid thread sealant specifically rated for gasoline and ethanol? If you grabbed Teflon tape out of habit, that’s your problem. Take it off, clean every last bit of residue from the threads, and apply the correct liquid sealant.

Diagnosing Fuel Flow Issues

Is your engine sputtering or acting like it’s out of gas? Before you start digging into the motor, remember that a fuel flow restriction often starts right back at the tank connection.

Here are a few common scenarios I’ve run into:

- Quick-Disconnects Won't cooperate: Some aftermarket adapters just have sloppy manufacturing tolerances. If your engine’s fuel line connector refuses to click securely into place, the O-rings or locking mechanism inside might be off-center, blocking the fuel path.

- Debris in the Line: It’s easy for a tiny piece of old sealant or gunk to fall into the tank when you remove the old fitting. That little piece can get sucked right up against the new adapter’s pickup tube, creating a nasty clog.

- Primer Bulb Stays Sucked In: If you pump the primer bulb and it collapses without re-inflating, that’s a dead giveaway for a blocked tank vent. This isn't an issue with the adapter itself, but it can definitely mimic a fuel flow problem.

If you’re running into issues like these, our guide on diagnosing and preventing common boat fuel problems has a lot more detail to help you sort it out.

Whatever you do, don't just crank down harder on the fitting to try and stop a leak. This is the #1 way people crack plastic tanks and adapters. The fix is almost always a better seal, not more muscle. A snug fit with the right sealant is all you need.

It’s worth noting that the market for fuel storage parts is growing incredibly fast—it's projected to hit USD 24.22 billion by 2035. That growth means more options, but it also makes it more critical to choose high-quality, reliable components like a good fuel tank adapter to keep things safe and efficient.

Frequently Asked Questions

Even after you've read a guide cover-to-cover, there are always those few nagging questions that pop into your head. This is where we tackle the most common things boaters ask about picking and using the right fuel tank adapter. Think of it as your quick-reference sheet for clearing up any last-minute doubts.

Material and Compatibility Questions

Can I Use a Brass Fuel Tank Adapter on a Plastic Tank?

Technically, yes, but you have to be extremely careful. Brass is much harder than the polyethylene plastic most fuel tanks are made of today. Because of this, it's incredibly easy to over-tighten and crack the plastic threads on your tank.

If you find yourself needing to use brass, make sure to apply a gasoline-safe thread sealant first. Start by tightening it only by hand. Then, use a wrench for no more than a quarter-turn past hand-tight. Honestly, though, a high-quality nylon or engineered plastic adapter is almost always the safer bet for a plastic tank.

What’s the Difference Between NPT and BSP Threads?

Getting this right is absolutely critical for preventing dangerous fuel leaks.

- NPT (National Pipe Taper): This is the American standard. The threads are tapered, meaning they get tighter and create a seal as you wrench them together.

- BSP (British Standard Pipe): This is common in Europe and other parts of the world. These threads are parallel (straight) and need a separate gasket or an O-ring to create the seal.

They are not compatible with each other. Forcing an NPT fitting into a BSP port (or vice versa) is a recipe for a persistent, hazardous fuel leak. Always double-check what you have on both your tank and fuel line before buying an adapter.

Inspection and Maintenance

How Often Should I Inspect My Fuel Tank Adapter?

You should give it a quick visual check every single time you head out on the water. It only takes a second to glance at your adapter, fuel lines, and primer bulb. Look for any tell-tale signs of trouble: cracks, soft spots, or the shiny, wet look of weeping fuel.

At least once a season, give everything a more thorough, hands-on inspection. Make sure all the connections are still snug. If you're a saltwater boater, you should probably do these hands-on checks more often, as the salty air and water will break down components much faster.

Ready to stop guessing and prevent messy, costly fuel spills for good? CLiX Fueling Solutions offers a simple, reliable way to protect your boat and the environment. Learn more and get your CLiX system today!