So, what exactly is a fuel drum pump? Think of it as a specialized tool designed to move fuel safely and cleanly from a large storage drum straight into your boat's tank. It gets rid of the need for the risky business of tipping heavy drums, which helps prevent messy spills and exposure to flammable fumes. For any boater or marina operator, it's a key piece of gear for a controlled and secure refueling process.

The Safer Way to Refuel Your Boat

We’ve all seen it, or maybe even done it: wrestling with a heavy, awkward fuel drum on the dock, trying to pour gas or diesel without making a mess. It’s a chore that often relies on a bit of muscle and a lot of hope, where one slip can lead to a costly spill that's bad for your boat and the environment.

There's a much better way. A fuel drum pump changes this whole scenario from a hazardous chore into a simple, controlled procedure. It’s like using a sealed, high-tech straw that moves fuel right where it needs to go without ever exposing it to the open air. This guide is here to walk you through everything you need to know about these essential tools.

Why Every Boater Needs a Better Fueling Method

Trying to refuel by just tipping a drum isn't just a hassle—it's a serious safety risk. It's so easy to overfill the tank, which can damage your boat's finish, pollute the water, and create a dangerous fire hazard. A proper pump gives you a closed-loop system, putting you in complete control of the fuel flow.

This shift toward safety and spill prevention is a big reason why the global drum pump market, valued at USD 556.5 million in 2025, is expected to hit USD 845.6 million by 2035. That's a steady growth of 4.3% CAGR, driven by people looking for smarter, safer solutions.

By using a dedicated pump, you are not just transferring fuel; you are investing in the safety of your vessel, the protection of the marine environment, and your own peace of mind.

This guide will cover the essentials to help you understand:

- The different kinds of pumps out there for marine use.

- The key features to look for when choosing one.

- Crucial safety rules for handling fuel around the water.

- The best ways to install, operate, and maintain your pump.

For a great overview of on-the-water safety, check out this ultimate boat safety checklist. It’s a solid resource for all your on-board procedures, including refueling.

How a Fuel Drum Pump Actually Works

A fuel drum pump might look a little complicated, but the way it works is actually pretty simple. The easiest way to think of it is as a high-tech, sealed straw made just for a fuel drum. It creates a completely closed system to move fuel safely and cleanly, getting rid of all the dangerous and messy guesswork you get with old-school methods.

At its core, the pump is built to solve one big problem: gravity. Trying to pour fuel from a 55-gallon drum is a nightmare. Not only is it incredibly heavy—weighing over 400 pounds when full—but it also lets volatile fuel and its vapors escape into the open air. That’s a huge risk for spills and ignition. A drum pump fixes this by creating a controlled, sealed path from inside the drum straight to your boat’s tank.

The Core Components Working Together

No matter what kind of fuel drum pump you have, they all rely on three key parts working together. Once you see how they interact, it’s easy to understand why these pumps are so good at preventing accidents and turning refueling into a simple, predictable job.

It all starts with the motor.

- The Motor: This is the engine of the whole operation. Whether it runs on electricity, air (pneumatic), or good old-fashioned muscle (manual), the motor provides the power to create suction.

- The Immersion Tube: This is the long, straight tube you stick down into the drum. It goes almost all the way to the bottom and acts as the main pipeline, pulling fuel up and out without exposing it to the air.

- The Discharge Nozzle: Connected to a hose, the nozzle is where you get all the control. It lets you aim the fuel right where it needs to go and, on most models, shut the flow off in an instant.

So, when you turn the pump on, the motor kicks in and creates a pressure difference. This suction pulls fuel up through the immersion tube, pushes it through the hose, and sends it out the nozzle. It’s a clean, contained transfer that keeps dangerous fumes locked in and prevents the fuel from touching anything until it's safely in your tank.

Why This Closed System Is a Safety Essential

That "closed system" design is hands-down the most important safety feature of a fuel drum pump. Think about the old ways of doing things, like using a simple siphon hose or—even worse—trying to tip and pour from the drum. Those methods are just asking for trouble because they break the chain of containment at every step.

The biggest dangers in marine fueling aren't always the spills you can see; they're the invisible ones. Flammable vapors and a spark of static electricity are a terrible mix, and a proper pump is your best defense against them.

When you use an unsealed method, you’re creating immediate hazards. Spilled fuel can find an ignition source in a heartbeat, and the vapors can build up in enclosed spaces like a boat bilge, setting the stage for an explosion. A dedicated fuel drum pump is specifically engineered to stop these things from happening. It keeps the entire process contained from start to finish, making it less of a convenience and more of an essential piece of safety gear for any boater who takes safety seriously.

Choosing Your Ideal Fuel Drum Pump

Picking the right fuel drum pump is a lot like choosing any other tool for your boat—the best one is always the one that fits the job you need to do. You wouldn't use a small hand tool for a heavy-duty repair, and the same logic applies here. The decision really boils down to balancing power, convenience, and safety for your specific setup, whether you're fueling a small tender or managing a fleet at a marina.

Getting this choice right makes every refueling smoother, safer, and faster. It’s no surprise that the global market for fuel transfer pumps, including these drum pumps, was valued at USD 1.76 billion in 2022 and is expected to hit USD 2.51 billion by 2030. That growth is all about the increasing demand for reliable and secure fueling methods, something every boater can get behind.

The Three Main Flavors of Fuel Drum Pumps

When you start shopping around, you’ll notice that fuel drum pumps generally come in three main types, each with a different power source. Let's break down the pros and cons to help you find your perfect match.

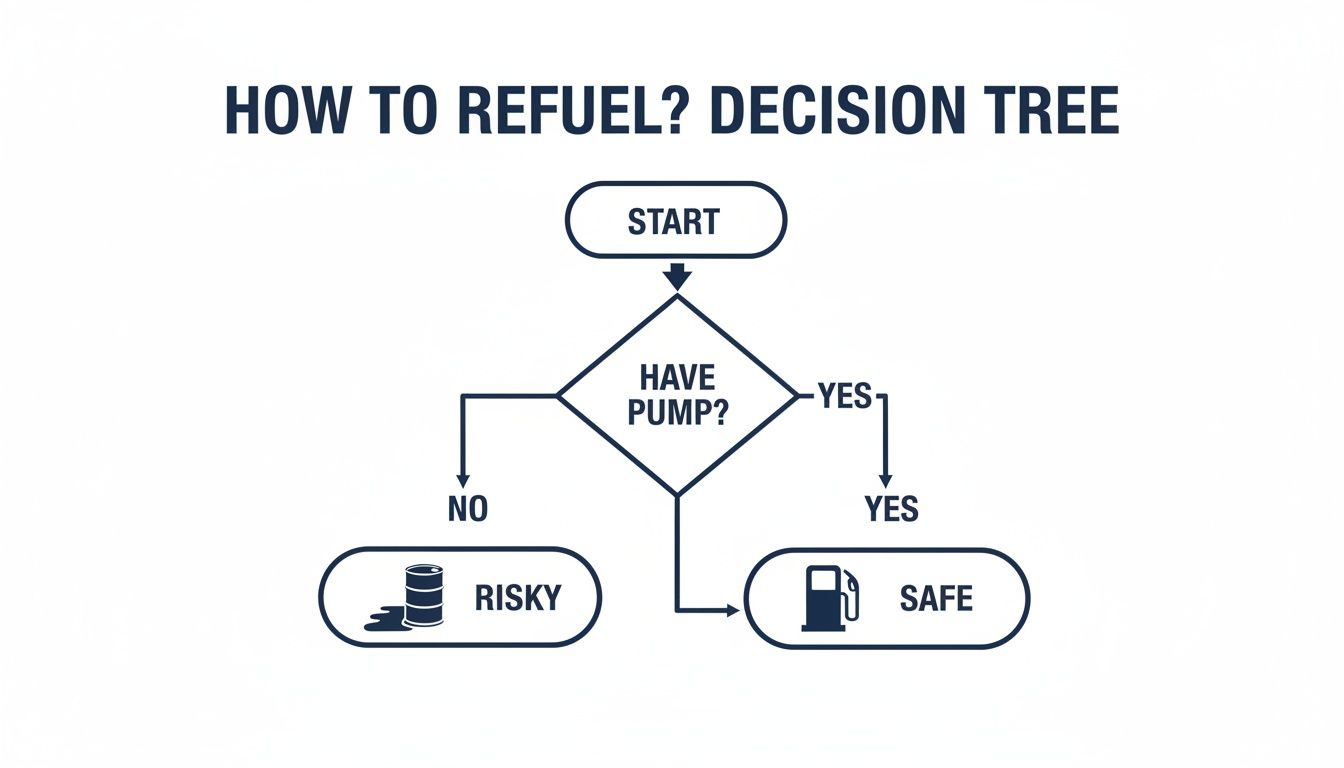

As the flowchart neatly shows, having the right pump is what separates a controlled, safe fueling process from a risky, messy one.

Comparing Fuel Drum Pump Types for Marine Use

To make the choice even clearer, let's put these pump types side-by-side. This table breaks down what you need to know to find the best fit for your boat or marina operation.

| Pump Type | Power Source | Best For | Pros | Cons |

|---|---|---|---|---|

| Manual | Hand Crank / Lever | Small boats, backup fuel transfer, or when no power is available. | Simple, reliable, no electricity needed, full control over flow. | Slow for large volumes, physically demanding. |

| Electric | AC (Dock) or DC (Boat Battery) | Most recreational boaters and marina settings. | Fast, convenient, and efficient for regular, high-volume use. | Requires a power source, more complex than manual pumps. |

| Pneumatic | Compressed Air | Commercial marinas, boatyards, and industrial applications. | Extremely powerful, durable, high flow rates for continuous use. | Needs an air compressor, overkill for most recreational use. |

Ultimately, the best pump is the one that aligns with how and where you refuel. A simple manual pump might be all you need for topping off a dinghy, while a powerful electric model is a must-have for a busy marina.

Key Specifications That Truly Matter

Once you've settled on a type, a few technical details will make all the difference in performance and, more importantly, safety. Pay close attention to these three specs to ensure you get a pump that’s up to the task.

-

Flow Rate (GPM): This is just a measure of how fast the pump moves fuel, measured in Gallons Per Minute. For most recreational boats, a flow rate between 5-10 GPM is the sweet spot. It's fast enough to get the job done without being so powerful that you risk spills.

-

Material Compatibility: This is a huge one for safety and isn't something to compromise on. Gasoline is incredibly corrosive and requires pumps built with materials like stainless steel and special seals (like Viton) that won't degrade or create static sparks. Diesel is a bit more forgiving, but you must never use a pump designed only for diesel to transfer gasoline.

-

Head Height and Suction Lift: Think of these specs as the pump's strength. Suction lift is how high it can pull fuel up from the drum, and head height is how high it can push that fuel into your boat’s tank. For a typical 55-gallon drum on a dock and a boat in the water, you need to be sure your pump has enough muscle to cover that vertical distance with ease.

Match the Power Source to Your Fueling Spot

Where you typically refuel is probably the biggest factor in choosing a pump. The power source isn't just a feature—it dictates where and when you can actually use it.

An AC-powered pump, which plugs into a standard wall outlet, is the perfect workhorse for marina operators or anyone who always refuels at a dock. They deliver consistent, high power for heavy use.

On the other hand, a DC-powered pump is the boater’s best friend. These hook right up to your boat’s 12V or 24V battery, giving you the freedom to refuel at a mooring, out at anchor, or anywhere else your adventures take you. For a deeper dive into these setups, check out our guide on the best marine fuel transfer pump options available.

Your choice of power source should really just mirror your boating lifestyle. If you value the freedom to refuel anywhere, a DC pump is what you need. If you're managing a dock, the reliability of AC power is the way to go.

Staying Safe and Compliant on the Water

Fueling a boat is nothing like filling up your car at a gas station. The stakes are much, much higher. Out on the water, you’re dealing with a whole different set of challenges—corrosive salt air, the constant motion of the waves, and the ever-present danger of static electricity. Following safety rules isn't just about avoiding a fine; it's about preventing a catastrophe.

The biggest invisible threat, especially with gasoline, is static electricity. As fuel rushes through a hose, it can build up a static charge. Without a safe way to dissipate that energy, a single spark is all it takes to ignite the fumes and cause a devastating explosion.

This is precisely why grounding and bonding are absolutely essential, non-negotiable practices for any marine fueling.

Mastering Grounding and Bonding

It helps to think of static electricity as a tiny lightning bolt just waiting for a place to strike. Grounding and bonding work together to create a safe path for that electrical energy, preventing it from ever creating a dangerous spark.

-

Bonding simply means connecting all the metal parts of your boat's fuel system together with a wire. This includes the fuel tank, the fill pipe, and the deck fitting. It keeps everything at the same electrical potential so a spark can't jump from one component to another.

-

Grounding takes it one step further by connecting that whole bonded system to the water. The water acts as a massive ground, safely carrying any static charge away from your boat.

Here's a simple, crucial habit: before you even turn on your fuel drum pump, make sure the nozzle is pressed firmly against the metal of the fill pipe. This small action helps equalize the electrical potential right away and is your first and best defense against a static-spark fire.

A fuel spill is a costly mistake, but a fuel vapor explosion is a life-altering event. Proper grounding and bonding are the most critical, yet often overlooked, steps in ensuring a safe refueling process every single time.

The Importance of Ventilation and Certified Gear

Gasoline vapors are heavier than air. This means they can sink and collect in low spots like your boat's bilge, quietly creating an explosive environment. Good ventilation is your best friend here. Always open up your hatches and run the bilge blower for at least four minutes after fueling and before you start the engine to clear out any lingering fumes.

The gear you use is just as important. Never use just any pump; make sure it's UL-listed or has a similar certification for flammable liquids. This certification is your guarantee that the pump has been tested and proven safe—its motor won't create sparks, and its internal parts can stand up to harsh fuels. Using uncertified equipment is a dangerous gamble.

Navigating Environmental Rules

Beyond the immediate risk of fire, every boater and marina operator has a serious responsibility to protect the environment. Even a small fuel spill can harm marine life and lead to hefty fines.

This is where modern fueling technology really shines. In fact, electric drum pumps now account for over 50% of the market share in recent industry reports, and for good reason—they help slash manual errors that lead to spills by as much as 70%. For marinas, systems with automatic shut-offs can prevent 90% of spills caused by overfilling, potentially saving $500 to $2,000 per incident in fines and cleanup.

Of course, you still need a plan for when things go wrong. Knowing exactly what to do in the event of a spill is critical. To make sure you're ready, check out our guide on creating an effective fuel spill response plan. Being prepared allows you to act fast, minimize the environmental impact, and stay on the right side of the law.

Proper Use and Maintenance of Your Pump

Getting the right fuel drum pump is a great first step toward cleaner, safer refueling. But like any piece of essential marine gear, it's only as reliable as the care you give it. Think of it like your pre-departure checklist—a few minutes spent on inspection and upkeep can be the difference between a smooth day on the water and a frustrating, costly problem.

This guide will walk you through the practical, real-world steps for installing, operating, and maintaining your pump. Following these simple routines won't just protect your investment; it will reinforce the safety standards that are non-negotiable in a marine setting.

Secure Installation and Pre-Use Checks

A solid installation is everything. It's the foundation of a safe fuel transfer. A wobbly connection isn't just an annoyance; it's a potential leak waiting to happen, releasing dangerous fuel and vapors. Before you even think about attaching the pump, make sure the drum itself is on stable, level ground.

First things first, get the pump attached correctly. Most drums have a threaded opening called a bung, and your pump will have a matching adapter. Thread the pump into the bung and hand-tighten it until it feels firm. Resist the urge to crank it down with a wrench—you can easily strip the threads and ruin the seal.

Once the pump is mounted, it’s time for a quick pre-use once-over. This simple checklist catches most of the common issues before they become a headache.

- Hose Inspection: Eyeball the entire length of the discharge hose. Are there any cracks, weird bulges, or spots that look brittle? Fuel, especially with ethanol blends, can eat away at hoses over time.

- Connection Integrity: Double-check that all the fittings are snug—where the hose meets the pump and at the nozzle. Look for any tell-tale drips or wet spots that signal a slow leak.

- Filter Check: If your pump has a filter (internal or external), make sure it’s clear of gunk. A clogged filter makes the motor work harder and kills your flow rate.

- Power Source: For electric pumps, give the power cable a quick look for any frayed wires or damage. Make sure it's plugged in securely to your battery or outlet.

Best Practices for Smooth Operation

With your pump securely installed and inspected, you're ready to start fueling. If your model needs priming, do that first. This usually just means running it for a few seconds to pull fuel up the tube and into the hose.

Always keep a firm hand on the nozzle and watch the fuel going into your boat's tank. If your pump doesn't have an automatic shut-off, listen for the sound to change as the tank gets full. That little audio cue can save you from a messy overfill. And it should go without saying: never, ever walk away from a running pump.

A well-maintained fuel drum pump is a reliable tool. A neglected one is an accident waiting to happen. Routine care isn’t just about longevity; it's about predictable, safe performance every single time you refuel.

Creating a Simple Maintenance Schedule

Being proactive is the secret to a long, trouble-free life for your pump. The good news is that most of these tasks are quick and easy to work into your normal boating routine.

After Every Use:

- Clear the Pump: Once the drum is empty, let the pump run for a few extra seconds. This clears any leftover fuel from the lines.

- Clean the Exterior: Give the pump, hoses, and nozzle a quick wipe-down to get rid of any spilled fuel or dirt. This makes your next inspection much easier.

- Proper Storage: If you take the pump off the drum, store it somewhere clean, dry, and well-ventilated. Keep it out of direct sunlight and away from extreme heat or cold.

Monthly or Bi-Monthly Checks:

- Deep Clean Filters: Pull the pump's filters or screens and give them a thorough cleaning, following the manufacturer's guide.

- Inspect Seals and Gaskets: Check the O-rings and gaskets around the bung adapter and hose fittings. If they look worn, cracked, or degraded, replace them.

- Test the Motor: For electric pumps, switch it on for a moment and just listen. Any unusual whining or grinding sounds could mean a bearing is on its way out.

To keep your electric pump running safely for years, understanding basic motor protection best practices is key to preventing overheating and electrical trouble. By taking these straightforward steps, you can ensure your pump stays a dependable part of your gear. For a deeper dive, you can find a great overview of the critical relationship between a fuel drum and pump and how to manage them together.

Taking Your Fueling Setup to the Next Level

A good fuel drum pump is a game-changer for refueling, but it only solves half the problem. Even the best pump still depends on you to know exactly when to stop. You're the one listening for that tell-tale gurgle or trying to eyeball the fuel level, ready to cut the flow at the perfect moment.

That manual shut-off is the oldest and most stubborn headache in marine fueling. All it takes is a moment of distraction—a conversation, a dropped tool—for fuel to spill all over your deck and into the water. This is where modern fueling technology provides a truly complete safety net.

Beyond the Pump: The Automatic Shut-Off

Imagine a system that knows precisely when your tank is full and stops the pump for you. That’s the peace of mind you get with an integrated automatic shut-off system. This technology completely removes the guesswork and risk of human error, giving you a critical fail-safe that a standard pump just can't offer.

It works a lot like the pump at your local gas station, but it’s designed specifically for marine use. These systems pair a special nozzle with a device installed in your boat’s fuel fill. As the fuel rises, it trips a mechanism in the nozzle, instantly and automatically stopping the flow.

An automatic shut-off system is the final piece of the puzzle. It takes a good fueling setup and makes it great, ensuring a simple mistake doesn't become an environmental mess or a costly repair job.

Creating a Truly Spill-Proof Experience

When you combine a reliable fuel drum pump with an automatic shut-off solution, you get a seamless, worry-free fueling process. The pump does the heavy lifting, moving fuel efficiently from the drum, while the smart nozzle handles the all-important final step of stopping the flow right on time.

This combination gives any boater several huge advantages:

- Total Spill Prevention: It practically eliminates the chance of overfills, which protects your boat's finish and, more importantly, the marine environment.

- Complete Peace of Mind: You can refuel without a hint of anxiety, knowing the system has your back.

- Enhanced Safety: Preventing spills means keeping flammable liquids and dangerous vapors off your boat.

This integrated approach is the next evolution in responsible boating. It’s not just about making refueling easier; it's about making it fundamentally safer for you, your vessel, and the waters you love.

Answering Your Top Questions About Fuel Drum Pumps

Even with a good grasp of the basics, some practical questions always pop up. Let's tackle a few of the most common ones we hear from boaters and marina staff who are getting started with a fuel drum pump.

Can I Use the Same Pump for Gasoline and Diesel?

You really shouldn't, unless the pump is specifically built and certified for both. Gasoline is a whole different animal than diesel—it's much more volatile and its vapors are highly flammable. This means a pump for gas needs specific materials, like stainless steel and special seals, plus grounding features to prevent a static spark from ruin your day.

Trying to pump gasoline with a diesel-only pump is asking for trouble. It's a major safety hazard. Before you do anything, double-check the manufacturer’s specs to see exactly what liquids your pump is rated for.

How Do I Know What Flow Rate I Need?

For most recreational boats under 40 feet, a flow rate in the 5-10 gallons per minute (GPM) range is the sweet spot. This gives you a fast-enough fill without feeling like you're wrestling a fire hose, which really helps prevent accidental spills and overfills.

Faster pumps pushing 15+ GPM are great for bigger yachts or commercial boats, but they can be a real handful. For most folks, sticking to a more manageable flow rate makes for a safer and cleaner experience at the dock.

What Is the Most Important Maintenance Task?

If you do only one thing, make it this: regularly check your hoses and seals. It’s hands-down the most critical piece of upkeep. Fuel, especially gasoline with ethanol in it, is notoriously tough on rubber and plastic parts. Over time, it will break them down, and that's how dangerous leaks start.

Before every single use, give your setup a quick visual once-over. Look for any cracks, brittle spots, or swelling on the hoses. Check every connection point for drips. A hose failing mid-pump is one of the biggest causes of major fuel spills.

Are Manual Hand Pumps a Safe Option?

Absolutely. Manual pumps are a fantastic, safe, and reliable choice, particularly if you're just moving smaller amounts of fuel. Because you're the one doing the work, the flow rate is naturally lower, giving you an incredible amount of control over the whole process.

Plus, from a fire-safety perspective, they're inherently safer. There are no electrical parts, which means there's no chance of an electrical spark. For smaller boats or to keep on hand as a foolproof backup, you really can't go wrong with a quality manual fuel drum pump.

Ready to eliminate overfills and make fueling your boat completely stress-free? The CLiX Fueling Solutions system pairs with your fuel drum pump to provide an automatic shut-off, guaranteeing a spill-free experience every time. Discover a safer, cleaner way to refuel by learning more about our patented fueling nozzle.