Picking the right fuel drum and pump for your boat is more than just a matter of convenience—it's one of the most important safety decisions you'll make. Get it right, and you’ve got a clean, efficient way to refuel. Get it wrong, and you're risking dangerous spills that can damage your boat and the environment. It all comes down to matching the equipment to your fuel and your boat.

Why Your Fuel Drum and Pump Choice Matters

Let's be clear: this isn't like choosing a new fishing rod. A bad choice here can have serious, fiery consequences. The biggest factor is material compatibility. Gasoline is incredibly corrosive and demands heavy-duty gear, while diesel is a little more forgiving. If you use a pump or drum made from the wrong material, it can start to break down, leading to leaks, pump failure, and a major fire hazard.

Safety aside, the right setup just makes life easier. A good electric pump can move 50 gallons in a few minutes, which is a lifesaver when you're trying to get a big sportfisher ready for a tournament. On the flip side, a simple hand pump is all you need to top off the dinghy without fussing with batteries or power cords.

Matching Materials To Your Fuel Type

Here’s the golden rule: never, ever use the same equipment for both gasoline and diesel. Cross-contamination is a real problem, and the materials just aren't interchangeable.

- For Gasoline: Stick with pumps made from stainless steel or another non-corrosive metal. Pay close attention to the seals and gaskets—they absolutely must be Viton or a similar material that can handle the ethanol and additives in today's gasoline. Anything less will degrade and fail.

- For Diesel: Stainless steel is always a great bet, but you can also use pumps made from certain high-grade plastics or polymers. They're often lighter and more affordable, but they don't have the same universal toughness as metal.

The need for robust containers isn't unique to boating. Industries rely on things like steel drums to transport fuels and chemicals safely. For a broader perspective, you can check out this guide to choosing durable containers to understand the principles of material selection.

To make this even simpler, here's a quick cheat sheet for matching your fuel with the right gear.

Fuel Drum and Pump Compatibility Matrix

This table is a quick-reference guide to help you match pump materials and types with different marine fuels, ensuring you make a safe and effective choice.

| Fuel Type | Recommended Drum Material | Compatible Pump Material | Best Pump Type for Volume |

|---|---|---|---|

| Gasoline | Coated Steel, Stainless Steel | Stainless Steel, Brass | Electric (for >20 gal), Manual Siphon (for <20 gal) |

| Diesel | Steel, High-Density Polyethylene | Stainless Steel, High-Grade Plastic | Electric (for >20 gal), Lever/Rotary (for all volumes) |

| Kerosene | Steel, High-Density Polyethylene | Cast Iron, High-Grade Plastic | Manual Lever or Rotary Pump |

Choosing the right combination from this matrix will prevent material degradation, ensure safety, and make your refueling process much smoother.

Sizing Up Your Pumping Needs

The best pump for you really depends on your boat and how you use it. If you've got a small skiff with a 6-gallon portable tank, a manual siphon pump is perfect. It's cheap, dead simple, and gets the job done without needing a power source.

But if you're running a cruiser with a 150-gallon tank, a 12V electric drum pump is practically a must-have. These pumps are designed to move a lot of fuel quickly with almost no effort on your part. Think about your tank size, how much fuel you burn, and how often you'll be transferring from drums. For a deeper dive, our guide on portable gas pumps for boats has a ton of great information to help you pick the perfect one.

How to Safely Transfer Fuel to Your Boat

Pumping fuel from a drum into your boat is one of those jobs that demands your full attention. It's not complicated, but cutting corners is a recipe for disaster. A methodical, unhurried approach is the key to getting it done quickly and, more importantly, keeping you, your boat, and the water safe.

Before a single drop of fuel moves, get your setup right. Place the fuel drum and pump on a solid, level spot. This could be on the dock or a secure place on deck where there's zero chance of it tipping over. Give all your gear a quick once-over—look for cracks in the hose and make sure every connection is tightened down.

And don't even think about starting without a spill kit right by your side. I'm talking absorbent pads, a boom for containment, and gloves, all within arm's reach. If a leak starts, you need to be able to react instantly, not go hunting for supplies.

Preparing for a Safe Connection

Here's a step that’s absolutely critical but often skipped: grounding. As fuel flows, it can build up a static charge, and one tiny spark is all it takes to ignite fuel vapors. It’s a scary thought, but easily prevented. Just run a grounding strap from the fuel drum to a metal fitting on your boat. This gives any static electricity a safe path to dissipate.

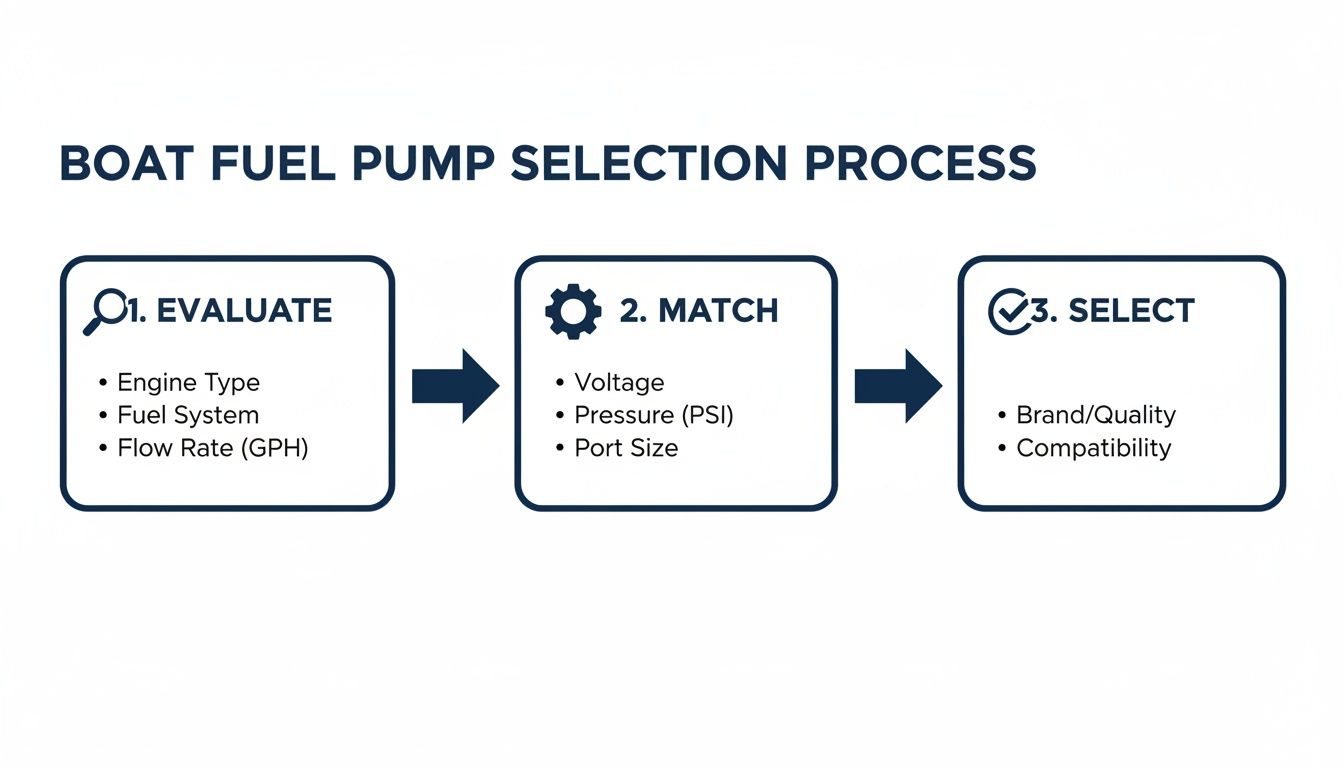

This first part—getting the right gear—is foundational to a safe transfer. Think of it like this:

Starting with the right equipment from the get-go makes the entire process smoother and safer.

Once you’re grounded, it's time to hook everything up. Attach the pump to the fuel drum first, making sure the bung is sealed tight to stop vapors from escaping. Next, connect the nozzle to your boat’s fuel intake. If you're using a modern system like CLiX Fueling Solutions, this is where you'll connect it to prevent overfills.

Executing the Fuel Transfer

Alright, you're ready to start pumping. Begin slowly and just listen. You should hear the steady hum of the pump and the smooth flow of fuel. Keep your eyes on everything—from the drum, along the hose, to the nozzle—watching for any sign of a leak.

Pro Tip: Never, ever lock the pump handle and walk away. Your constant attention is the best spill prevention there is. Tanks fill up faster than you think, and a momentary distraction is all it takes to cause a dangerous mess.

Listen for the air coming out of your boat's fuel tank vent. That sound changes as the tank gets full, which is your cue to slow down. Easing up on the flow rate for the last few gallons dramatically reduces the chance of fuel burping back out of the fill pipe.

If you're curious about the design of fuel intakes and how they impact this process, our guide on the marine fuel fill process dives deep into the technical details.

Using Technology for Spill Prevention

Modern tech can be a real lifesaver here. If you've got an automatic shut-off nozzle or a system like CLiX, let it do its job, but always be ready to intervene manually. These devices are designed to sense the pressure change when the tank is full, providing a reliable backstop.

The moment the tank is full or the auto-shutoff kicks in, stop the pump. Then, disconnect everything in the reverse order you connected it. Nozzle off the boat first, then work your way back to the drum.

Preventing Spills and Protecting the Waterway

Anyone who spends time on the water knows we're not just boaters; we're stewards. It’s on us to protect the very environment we love to be in. Even a tiny fuel spill can do a surprising amount of damage, spreading into a wide sheen that’s toxic to marine life. This isn't just about avoiding fines—it's about responsible ownership.

Using a fuel drum and pump gives you a ton of control over your fueling process, but with that control comes a greater need to be vigilant.

True prevention begins long before the fuel starts flowing. One of the best habits I ever developed was to always lay out absorbent pads around my boat’s fuel intake before I even grab the pump nozzle. It's like a chef prepping their station—it sets you up for a clean job and catches any unexpected drips from the get-go.

I also swear by a simple "fuel bib" or "fuel collar." It's basically a donut-shaped absorbent pad that fits right around the nozzle. This little thing is a game-changer for catching those last few drops that always seem to escape when you pull the nozzle out. That's honestly where most small, annoying spills happen.

Building a Spill Prevention Checklist

The secret to avoiding accidents is turning good habits into muscle memory. Whether you write it down or just run through it in your head, having a consistent routine is your best defense, especially when you're rushing to get out on the water.

Here’s a quick rundown of what should be on your mental checklist:

- Prep the Area First: Get those absorbent pads in place and make sure your spill kit is within arm's reach. Don't make you have to scramble for it later.

- Get a Good Seal: Make sure the nozzle is seated firmly inside the fuel fill pipe. A loose fit is just asking for a splash-back.

- Watch and Listen: This is not the time to get distracted. Pay attention and listen for that distinct gurgling sound from the tank vent—it’s the universal signal that you’re almost full.

- Ease Off at the End: Slow the pump way down for the last few gallons. This gives the air in the tank time to escape and helps prevent that dreaded "burp" of fuel right back at you.

A spill is always easier to prevent than it is to clean up. Adopting a strict pre-fueling routine turns best practices into automatic habits, protecting both your boat and the environment.

Responding to a Spill Immediately

Even with the best prep, mistakes can happen. If you do have a small spill, what you do in the first few seconds is critical. The absolute first move is to stop the fuel flow immediately. Then, grab the absorbent pads or booms from your spill kit to contain the spill and keep it from spreading.

Whatever you do, never reach for dish soap. Trying to break up the fuel with a detergent is often illegal because it just causes the fuel to sink, making the environmental harm much worse. Your goal is to contain and absorb.

Once you’ve soaked everything up, make sure you dispose of the used pads correctly. They can't go in the regular trash. They are hazardous waste and need to be taken to a proper facility. For a complete breakdown of what to do, check out our expert fuel spill cleanup procedures guide.

This focus on spill prevention is really pushing the industry forward. The market for drum pumps was valued at around USD 556.5 million in 2025 and is expected to hit nearly USD 845.6 million by 2035. That growth is a direct reflection of boaters and regulators demanding safer, more reliable equipment to keep our waterways clean. You can read more about the trends in the drum pump market to see where the technology is headed.

Making Your Pump Talk to Your Boat

A modern fueling setup is more than just a drum and a hose. When you intelligently connect your transfer pump to your boat's own systems, fueling becomes safer, more efficient, and a lot less stressful. It's where a bit of smart tech and good old-fashioned electrical know-how really pay off.

The biggest game-changer here is an automatic shut-off system. Think of it as a safety net that catches you before you even stumble. Devices like CLiX Fueling Solutions are designed to connect your pump directly to your boat's fuel fill. They create a sealed connection, sense the pressure change the instant your tank is full, and automatically kill the flow.

This completely takes the guesswork out of listening for that gurgle from the fuel vent. It’s an almost foolproof way to prevent a messy, expensive, and dangerous overfill.

Powering an Electric Pump the Right Way

If you're using an electric pump, getting the power right is absolutely critical. You’ve got a few good options, and each one has its pros and cons.

- A Dedicated Marine Battery: This is my top recommendation. It gives your pump a clean, steady power source without ever risking your main engine starting battery.

- A Portable Power Pack: A good quality lithium power pack offers great flexibility. You can bring the power right to the pump instead of running long wires.

- Your Starter Battery: This works in a pinch, but treat it as a last resort. Make sure the engine is off and keep a close eye on it—you don’t want to be stranded with a dead battery.

No matter which power source you choose, don't skimp on the components. Marine-grade wiring is a must. It’s built to handle the constant vibration, moisture, and corrosive salt air that will eat standard automotive wire for breakfast. The same goes for connectors; use marine-grade terminals and seal every connection with heat-shrink tubing to make it waterproof and durable.

A cheap, poorly wired connection isn't just a breakdown waiting to happen—it's a serious fire hazard on a boat. Do it right the first time.

Tying It All Together

The whole point is to create a single, cohesive system where your fuel drum and pump are working in sync with your boat. For instance, if you have a fuel flow meter or a boat with a modern NMEA 2000 network, you can watch the fuel transfer in real-time right on your main display.

This lets you see exactly how many gallons have gone in, so you can double-check it against your tank’s known capacity. It's another layer of security that adds a ton of confidence to the process.

When you integrate these systems, fueling stops being a high-anxiety chore and becomes a controlled, monitored procedure. You're no longer just sloshing fuel around; you're managing it with precision. That gives you peace of mind and protects both your boat and the water you enjoy.

Maintaining Your Fuel Drum and Pump for Reliability

Your fuel drum and pump are lifelines, but only if you can trust them. Proper maintenance is what turns this simple gear into a reliable tool you can count on, season after season. Skipping it can lead to frustrating clogs, dangerous leaks, or a pump that just gives up the ghost at the worst possible moment.

Think of it like this: you wouldn't dream of skipping an engine oil change. Treat your fuel pump with the same respect.

After every use, especially if you're playing around with different fuel blends or additives, give the system a good flush. Running a little clean, compatible solvent through the pump and hoses clears out any gunk and stops sticky deposits from forming. It's a five-minute job that prevents a world of headaches.

When it's time for off-season storage, this step is absolutely critical. Old fuel left sitting in the lines will degrade, leaving behind a nasty varnish that can seize up the pump's moving parts. A clean, dry pump is a happy pump.

Your Visual Inspection Checklist

Before stowing your gear, take a few minutes to give everything a once-over. This simple habit can help you spot a small problem before it escalates into a major failure or a dangerous spill. Finding a worn-out gasket is a cheap and easy fix; replacing a pump that's been ruined by a slow leak is a different story.

Here’s a quick rundown of what to look for:

- Hoses: Check the entire length for cracks, brittle spots, or areas that feel mushy. Give the hose a gentle bend—if you see any stress marks or tiny cracks appear, it's time for a replacement.

- Seals and Gaskets: Eyeball every connection point. The gaskets should look and feel pliable, not dry or compressed. A dried-out seal is just a leak waiting to happen.

- Pump Mechanism: If you have a manual pump, work the handle a few times. It should feel smooth, with no grinding or unusual resistance.

Seasonal Fuel Pump Maintenance Checklist

A little proactive care goes a long way. Here’s a simple checklist to keep your fuel transfer system in top shape, ensuring it's always ready when you are.

| Check Point | Action Required | Frequency | Notes |

|---|---|---|---|

| Hoses & Nozzle | Inspect for cracks, brittleness, or damage. | Before Each Season & Monthly | Replace immediately if any damage is found. Don't risk it. |

| Seals & Gaskets | Check for signs of drying, cracking, or compression. | Before Each Season | Lubricate with a fuel-safe compound or replace if they look worn. |

| Pump Function | Operate the pump to check for smooth action. | Monthly | For electric pumps, listen for unusual noises. |

| Filter/Strainer | Inspect and clean any inline filters or strainers. | At Season Start & End | Debris here can starve your pump and engine of fuel. |

| Flush System | Run a compatible cleaning solvent through the system. | At Season End (Before Storage) | This is crucial to prevent varnish buildup from old fuel. |

Following this routine helps guarantee your gear will work flawlessly from the first trip of spring to the last run of fall.

The final piece of the puzzle is proper storage. Always keep your fuel drum and pump in a cool, well-ventilated space, far away from potential ignition sources like a furnace or water heater. And never, ever store fuel drums in direct sunlight.

Long-Term Care in a Changing World

Good maintenance isn't just about reliability; it's also about adapting. The fuel you buy today might be different from what's available next year. As fuel blends evolve, having a well-maintained system made of quality materials becomes even more critical to prevent hoses and seals from degrading prematurely. Keeping up with these changes is part of responsible ownership. For those interested in the bigger picture, you can find a detailed analysis of global fuel market trends on spglobal.com.

Ultimately, a simple maintenance routine transforms your fuel gear from a potential liability into a trusted asset. It’s a small investment of your time that pays huge dividends in both safety and confidence on the water.

Got Questions About Fuel Drums and Pumps?

When you start using a fuel drum and pump system, a few questions always pop up. It's only natural. Getting the right answers is crucial for keeping things safe and simple on the water. Let’s tackle some of the most common ones I hear from other boaters.

Can I Use the Same Pump for Gasoline and Diesel?

This one comes up all the time, and the answer is a hard no. It's not just a bad idea; it's genuinely dangerous.

Gasoline is much more corrosive than diesel and needs a pump built to handle it—think stainless steel components and special Viton seals. If you try to run gasoline through a pump meant for diesel, you're asking for trouble. The internal parts will break down quickly, leading to leaks, pump failure, and a serious fire risk.

Bottom line: Keep things separate. Dedicate one pump for gasoline and another for diesel. No exceptions.

How Do I Legally Transport a Fuel Drum?

Moving fuel around isn't as simple as just throwing a drum in the back of your truck. You’ve got to follow the rules, which are there for a reason.

First off, you absolutely must use a DOT-approved drum. Make sure it's in good shape and strapped down securely so it can't slide or tip over. The drum also needs to be in a well-ventilated spot, completely isolated from where any passengers are sitting.

Always double-check your local and state regulations. There are strict limits on how much fuel you can transport without needing special permits and placards on your vehicle.

A quick tip for storing a drum that's not quite full: Find a cool, dry place with good airflow, and keep it out of direct sunlight and away from anything that could spark a fire. Make sure those bung caps are cranked down tight to keep moisture out and vapors in.

What’s the Best Way to Store a Fuel Drum?

Storing your fuel properly is just as important as transporting it safely. Good storage protects your fuel's quality and, more importantly, prevents accidents.

You're looking for a spot that's cool, dry, and has plenty of ventilation. Keep it far away from potential ignition sources like a furnace, water heater, or any power tools.

Always store the drum upright on a flat, stable surface and ensure the caps are sealed tight. If you know the fuel will be sitting for a while, it's a great idea to add a good quality fuel stabilizer. This will keep the fuel from breaking down and ensure it’s ready to go when you are.

Tired of watching the fuel gauge like a hawk and worrying about spills? CLiX Fueling Solutions takes the guesswork out of refueling with an automatic shut-off system that delivers total peace of mind. See how it works at https://clixfueling.com and make your next fill-up a breeze.