A fuel spill isn't just an accident. It's a full-blown crisis that can shut down your operations, wreck local ecosystems, and bring on staggering financial penalties. A comprehensive fuel spill response plan isn't some bureaucratic checkbox; it's one of the most important operational safeguards any marine business can have. It gives you a clear, step-by-step playbook to control a spill, protect your assets, and limit the environmental fallout.

Why Your Marine Operation Needs a Response Plan

When a fuel spill happens, the consequences ripple out far beyond the initial cleanup. For a small marina or a commercial fishing dock, even what seems like a minor incident can spiral out of control fast if you don't have a solid plan.

Picture this: a routine refueling goes wrong. Maybe it's a faulty nozzle, or someone just gets distracted for a second. Suddenly, 50 gallons of diesel are pouring into the harbor. Chaos. Without clear protocols, your team scrambles. Who do they call first? Where's the spill kit? How do you even deploy a containment boom correctly?

The fallout from that moment of confusion is swift and severe. Your entire operation grinds to a halt while authorities investigate. Your reputation, built over years, takes a massive hit with customers and the community. All the while, the financial clock is ticking—cleanup costs, regulatory fines, and the looming threat of lawsuits. A single, preventable event can put your whole business on the line.

To get a handle on what goes into a solid plan, let's break down the essential pillars. This is the foundation you'll build on.

Key Components of an Effective Spill Response Plan

| Component | Core Objective |

|---|---|

| Risk Assessment | Identify potential spill scenarios and their likely impact. |

| Emergency Contacts | Create a clear list of who to call and when (internal and external). |

| Spill Response Procedures | Detail step-by-step actions for containment, cleanup, and reporting. |

| Equipment & Supplies | List the location and use of all spill kits, booms, and safety gear. |

| Training & Drills | Ensure your team knows their roles and can execute the plan effectively. |

| Prevention Measures | Integrate tools and practices to stop spills before they happen. |

Each of these components is a link in a chain. A weakness in one can cause the entire response to fail when you need it most.

The True Cost of Inaction

So many operators I've talked to underestimate just how bad a spill can be. The costs aren't just what you pay for the cleanup. Think about the prolonged downtime, the equipment that gets damaged, and the harm to local wildlife. It’s a simple truth: proactive management is always cheaper than reactive crisis control.

The smartest move you can make is to shift your focus from just cleaning up messes to preventing them from ever happening. We've put together a guide on exactly this: how to prevent marine pollution for essential steps you can take now.

This isn't just a local issue; it's a global one. The emergency spill response market is set to explode, growing from $33.8 billion in 2025 to nearly $58.8 billion by 2035. That massive number tells you everything you need to know about the increasing regulatory heat and financial risks involved.

A fuel spill response plan transforms your crew from bystanders into a coordinated first-response team. It replaces panic with procedure, ensuring that every action taken in the first critical minutes is effective and decisive.

Integrating Safety into Daily Operations

Your spill response strategy shouldn't be a dusty binder sitting on a shelf. It needs to be a living, breathing part of your daily operations and your overall safety framework.

Think of it as one crucial chapter in your complete safety manual. For a broader look at preparedness, it's worth reviewing an ultimate boat safety checklist to make sure you've covered all your bases. When you create and, more importantly, practice your plan, you build a culture of preparedness. That culture is what ultimately protects your business, your people, and the marine environment you rely on.

Conducting Your Site-Specific Risk Assessment

A truly effective fuel spill response plan isn’t something you can just download and print. It has to be built from the ground up, based on the unique reality of your marina or fueling dock. Before you write a single procedure, you have to get out there and walk the site to understand your specific vulnerabilities. This is your site-specific risk assessment, and it's the foundation for everything that follows.

The goal here is to move past general worries and create a detailed, documented risk profile. It means looking at your entire facility with a critical eye, pinpointing every single spot where fuel could potentially escape. And trust me, it's not just about the nozzle at the pump.

Identifying Potential Spill Sources

First things first, you need to map out every single piece of your fuel system. Where are the weak spots? Think about the entire journey fuel takes at your facility, from the delivery truck all the way to a customer's boat.

I've seen spills originate from all sorts of places. Here are the usual suspects:

- Fuel Storage Tanks: How old are they? What are they made of? Are they above-ground where you can see them, or buried? Look closely for any signs of corrosion or slow leaks around the fittings.

- Fuel Lines and Hoses: Every hose needs a thorough inspection. You're looking for cracks, brittleness, or abrasions. Pay special attention to the connections and couplings—they’re under pressure and are common failure points.

- Dispensing Equipment: The pumps, meters, and nozzles can all fail. One of the most classic (and messy) causes of a big spill is a malfunctioning automatic shut-off valve on the nozzle, leading to a major overfill.

- Vessel Refueling Points: The moment fuel transfers from your dock to a vessel is a high-risk activity. Simple human error, a faulty deck fill, or even a boat shifting unexpectedly can cause a spill in seconds.

For each potential source you find, try to estimate a worst-case spill volume. What happens if a hose ruptures completely? How much fuel could pour out of a tank overfill before someone hits the shut-off? These numbers are absolutely vital for figuring out how much response equipment you'll need on hand.

Analyzing Environmental and Site-Specific Factors

Once you know where a spill might happen, the next question is where it will go. A spill in a calm, contained basin is one thing; a spill in a fast-moving tidal channel is a completely different beast. This is where you have to get granular about your specific location.

A critical mistake I see people make is underestimating how local conditions can turn a small problem into a big one. A minor leak can spread over a huge area in minutes if strong currents or winds are a factor, transforming a manageable incident into an environmental crisis.

Your assessment has to document these local characteristics:

- Water Currents: Map out the typical direction and speed of currents around your docks at different tides.

- Prevailing Winds: What's the dominant wind direction? Wind will push a surface slick faster than you think.

- Environmentally Sensitive Areas (ESAs): You need to identify and map any nearby resources that are especially vulnerable. Think wetlands, shellfish beds, public beaches, or wildlife habitats. Being close to an ESA raises the stakes and the complexity of a response.

- Site Accessibility: How quickly can your crew—and outside help—get to a spill with heavy equipment? Are there narrow piers, locked gates, or other physical barriers in the way?

This level of detailed analysis isn't just a good idea; it's become a cornerstone of modern preparedness. Government regulations have gotten much stricter over the years. Following massive incidents like the 2010 Deepwater Horizon disaster, which spilled an estimated 4.9 million barrels of oil, agencies like the US Coast Guard now mandate these assessments. The event was a major wake-up call that shaped how the emergency response market and its growth drivers evolved globally.

By building this detailed profile of your site's vulnerabilities and its environmental context, you create the bedrock for a robust fuel spill response plan. It allows you to tailor your equipment, procedures, and training to the real-world scenarios you’re most likely to face.

Assembling Your Essential Spill Response Toolkit

A well-written fuel spill response plan is a great start, but it's just paper without the right gear to back it up. When a spill happens, every second counts. You simply won't have time to go shopping for supplies. That's why having a fully stocked, easy-to-grab spill kit isn't just a good idea—it's absolutely critical for putting your plan into action.

Think of your toolkit as a carefully chosen arsenal, not just a random collection of items. The gear inside should directly counter the risks you found during your site assessment. A good rule of thumb I've always followed is to have enough sorbent material to handle at least 1.5 times the volume of your single largest potential spill. It’s an investment that pays for itself the first time you need it.

Primary Containment and Cleanup Gear

These are the tools that do the heavy lifting—stopping the spread and pulling fuel out of the water. They are your first line of defense, so your crew needs to know them inside and out.

- Containment Booms: These are the floating fences that circle a spill. For most marinas, a standard calm-water boom does the job. But if you’re dealing with strong currents or tides, you’ll need a more robust boom with a deeper skirt to keep fuel from slipping underneath.

- Sorbent Pads and Rolls: Picture these as industrial-sized sponges for oil. They’re designed to soak up hydrocarbons while repelling water. Pads are perfect for wiping down contaminated gear and tackling smaller slicks, while rolls are great for skimming a larger surface area.

- Sorbent Pillows and Socks: These are what you grab for more concentrated pools of fuel. You can toss pillows right into a thick patch, and socks are ideal for wrapping around a leaky fuel line or forming a small barrier around a scupper.

- Skimmers: For bigger operations or higher-risk areas, a skimmer is a must. Deployed from a boat or dock, these machines actively pull oil off the water's surface and pump it into a collection tank for proper disposal.

Proper deployment is everything. I once saw a crew at a small harbor deploy a boom incorrectly during a drill, leaving a massive gap that would have rendered it useless in a real spill. This is a perfect example of why hands-on training is so vital. Knowing how to connect boom sections quickly and anchor them effectively makes all the difference.

Essential Spill Kit Equipment Breakdown

Choosing the right equipment can feel overwhelming, but breaking it down by function helps clarify what you truly need. Here’s a quick guide to the core components of any effective marine spill kit.

| Equipment Type | Primary Function | Best For | Pro Tip |

|---|---|---|---|

| Containment Booms | Encircle a spill to prevent it from spreading. | Containing spills on the water's surface, from small sheens to larger releases. | Choose a boom with a skirt depth appropriate for your water conditions (currents, waves). |

| Sorbent Pads & Rolls | Absorb hydrocarbons while repelling water. | Wiping down surfaces, cleaning up small spills, and skimming sheen from the water. | Oil-only (white) sorbents are best for marine use as they won't become waterlogged. |

| Sorbent Socks & Pillows | Absorb concentrated pools of fuel. | Placing in contained areas with deeper fuel, or wrapping around active leaks. | Socks are flexible for conforming to uneven surfaces or machinery. |

| Nitrile Gloves | Protect hands from fuel and chemicals. | All spill response activities. | Avoid latex gloves, as they degrade quickly when exposed to petroleum products. |

| Splash Goggles | Protect eyes from splashes. | Any situation where fuel could splash into the face. | Look for anti-fog models for better visibility during a stressful cleanup. |

This table covers the basics, but remember to tailor your kit to your specific vessel or facility. Having the right tools on hand removes a huge variable when you’re under pressure.

Personal Protective Equipment (PPE)

Protecting the environment is the goal, but protecting your people comes first. Fuel and its vapors are hazardous, and your crew needs to be shielded from skin contact and inhalation.

Your basic PPE stash should include:

- Nitrile Gloves: These offer the best protection against petroleum products.

- Splash Goggles: An absolute must for protecting eyes from fuel and contaminated water.

- Respirators: If you're dealing with a spill in an engine room or another poorly ventilated space, respirators with organic vapor cartridges are non-negotiable.

- Coveralls: Liquid-resistant, disposable coveralls keep fuel off skin and clothing.

A common oversight is not having enough PPE for everyone who might be involved, including managers or even helpful bystanders. Always stock more than you think you'll need for your primary response team.

Storage and Accessibility

The best spill kit in the world is useless if you can't find it or get to it. Store your response gear in a clearly marked, weatherproof container in a central, easy-to-access location. For a larger facility, like a long fuel dock, it makes sense to have a few smaller kits staged at high-risk points.

Make sure the storage location protects the gear from sunlight and moisture, which can break down sorbents and other materials. A quick inventory check once a month and a full inspection every six months is a simple habit to get into. This routine ensures that when you reach for that kit in an emergency, it's 100% ready to go.

Defining Clear Procedures for Spill Response

When fuel hits the water, every second counts. Panic and confusion are your worst enemies, turning a small leak into a major environmental incident. The only way to combat that chaos is with a clear, practiced response plan. A solid fuel spill response plan takes the guesswork out of the equation, empowering your crew to act decisively and effectively, even when the pressure is on. This part of your plan is all about the immediate, boots-on-the-ground actions for those first critical moments.

The first few minutes are everything. The moment someone sees a rainbow sheen or smells diesel, the clock starts. The very first action should always be to confirm the spill and lock down its source. Is a boater overfilling their tank? Is a fuel hose on the dock leaking? Finding and stopping the source is priority number one. Always.

With the source handled, the next immediate step is communication. Who gets called, and in what order? A free-for-all of phone calls just burns precious time. This is where a crystal-clear communication protocol, or escalation plan, proves its worth.

Crafting a Communication and Notification Plan

Your response plan needs a dead-simple contact list that leaves zero room for error. This should cover both your internal team and external agencies. A swift, organized response hinges on getting the right information to the right people. Knowing how to set up an effective escalation process template for crisis management is a huge help here, as it gives you a framework for who to notify and when.

Your internal call sheet should include:

- On-Site Spill Response Leader: The go-to person on the ground who coordinates the initial hands-on response.

- Facility Manager or Marina Operator: Senior leadership needs to be in the loop immediately to greenlight resources and make bigger-picture decisions.

- Response Team Members: The crew who will actually be deploying booms and grabbing sorbents.

At the same time, you have to get on the phone with external authorities. Reporting spills to federal and state agencies isn't optional—it's the law. Dragging your feet can lead to hefty fines. Key contacts always include:

- The National Response Center (NRC) at 1-800-424-8802. This is the federal government's main line for reporting all oil and chemical spills.

- Your state's environmental or emergency management agency.

- Local first responders, like the fire department or harbormaster.

Pro Tip: I've seen this make all the difference: print your call list on pocket-sized, laminated cards for every key employee. When stress is high, nobody should be fumbling through a binder or scrolling through their phone. The card should also list what key info to provide: location, type of fuel, and a rough estimate of the spill size.

Initial Containment and Action Steps

Once the calls are being made, the on-site focus shifts to containment. The mission is simple: trap the spill and stop it from spreading. This is where your team’s training and familiarity with your equipment truly shine.

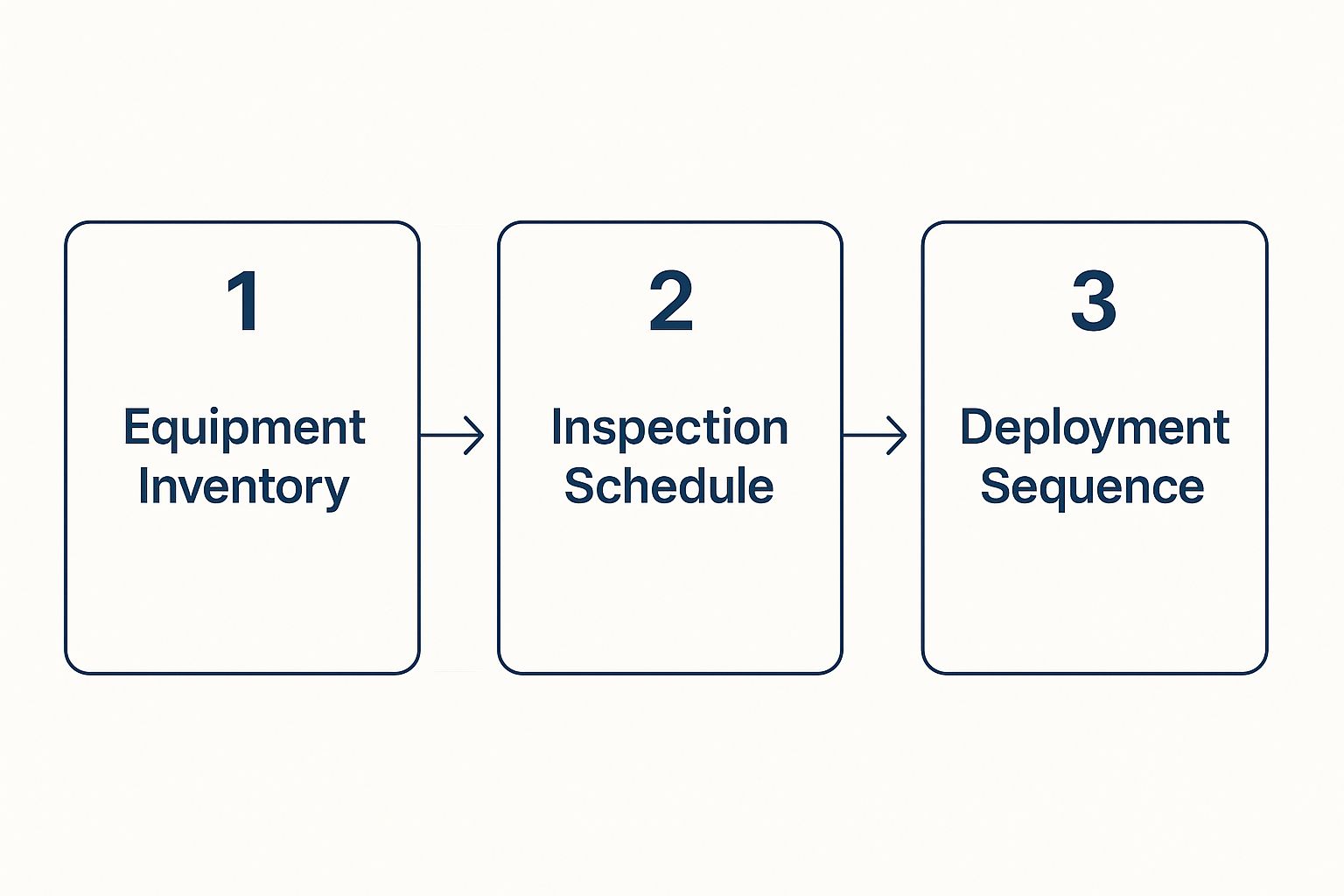

The infographic below walks through the flow from preparation to action—from checking your inventory to deploying gear when an incident occurs.

As you can see, a successful deployment doesn't just happen. It’s built on a foundation of diligent inventory checks and regular equipment inspections. You can't use what you don't have or what's broken.

Take deploying a containment boom, for example. In a calm, protected basin, the tactic is pretty straightforward: encircle the entire spill. But what if the spill is in a channel with a current? Your strategy has to adapt. The crew needs to know how to deploy the boom in a "U" or "V" formation to funnel the moving fuel toward a collection point.

These specific, location-based procedures need to be documented clearly in your plan. To help you think through these details, our team has put together a guide on specific fuel spill cleanup procedures you can use to refine your own process. These are the clear, actionable steps that form the heart of a plan that actually works.

Bringing Your Plan to Life with Training and Drills

Let's be honest: a beautifully written fuel spill response plan gathering dust in a binder is worthless. The paper itself has no power. Its real value only comes alive when your team can translate those words into immediate, effective action. This is where training and drills make all the difference, turning documented procedures into a genuine, reflexive capability for your crew.

I’ve seen it happen. Under the stress of a real emergency, even the best plans fall apart without practice.

The goal is to build muscle memory. In a crisis, people don’t rise to the occasion—they fall back on their level of training. You want your team so familiar with their roles that they act almost automatically, without fumbling for a manual. That confidence and competence are your greatest assets when a spill happens.

Designing an Effective Training Program

A solid training program isn't a one-and-done event; it's a continuous cycle of learning and reinforcement. It should mix different methods to keep the material from getting stale. A one-size-fits-all approach just doesn't work.

From my experience, a two-pronged approach is most effective:

- Classroom-Style Sessions: Start here. These sessions are perfect for walking through the plan itself. Review the notification call list, discuss who does what, and go over the Safety Data Sheets (SDS) for the fuels you handle. This is about understanding the "why" behind the "what."

- Hands-On Equipment Training: This is where theory meets reality. Get the spill kit out. Let everyone handle the gear. Show them how to properly unfold and connect sections of a containment boom. Let them get a feel for how sorbent pads work on a small, controlled sheen of water. This demystifies the equipment and builds crucial familiarity.

Remember, thousands of small spills happen in U.S. waters every year, often during routine things like refueling. As NOAA points out, even these minor incidents can cause serious harm. A well-trained crew is your best defense against a small mistake spiraling into a big problem.

The Power of Realistic Spill Drills

Drills are where your team, your plan, and your equipment all get tested at once. They are, without a doubt, the single most important part of making sure your fuel spill response plan is ready for prime time. And for them to be truly effective, they need to feel real.

I can't recommend this enough: run unannounced drills at least a couple of times a year. Yes, it might feel disruptive, but a surprise drill is the only way to get a true snapshot of your crew's readiness. Tossing an orange or a life ring into the water and yelling "Spill!" will tell you more about your response capability in five minutes than any scheduled meeting ever will.

During the drill, your job as a manager is to observe and take notes, not to jump in and lead. Watch for:

- Response Time: How long does it take for the team to react and start deploying equipment?

- Communication: Are the right people notified in the correct order? Is the communication clear?

- Equipment Deployment: Is the containment boom deployed correctly to isolate the simulated spill? Are sorbents used effectively?

- Safety Adherence: Is everyone wearing the proper PPE from the get-go?

The most critical step happens after any drill—announced or not. It's the debrief. Get everyone together immediately, while the experience is fresh. Ask what went well, what was confusing, and what could have been done better. This isn't about pointing fingers; it's about finding cracks in the system.

These post-drill huddles provide priceless feedback. Maybe the spill kit is in an awkward spot, or a particular boom connection is a pain to handle. Every lesson learned is a chance to make your plan stronger. Use these findings to update your procedures, tweak your equipment list, and focus your next training session. This cycle—drill, debrief, improve—is what creates a truly resilient response.

Got Questions About Your Fuel Spill Response Plan? We’ve Got Answers.

Even the most thorough guide can leave you with questions when it’s time to put pen to paper—or, more accurately, boots on the dock. I’ve seen it time and again: a great plan on paper doesn't always translate perfectly to the real world. That’s why the best plans are living documents, constantly tweaked and improved with experience.

Let’s dive into some of the most common questions I hear from marina operators and fuel dock managers. Getting these details right is what turns a basic, check-the-box plan into a safety strategy that actually works when you need it most.

How Often Should I Really Be Updating This Thing?

This one comes up a lot. People want a simple, set-it-and-forget-it answer, but it’s a bit more nuanced than that.

The absolute bare minimum? Review your plan once a year. Put it on the calendar. Make it a recurring team meeting where you read through the entire document, cover to cover.

But a yearly review is just your baseline. The real rule is to update your plan immediately after any significant change. Think of these as triggers for an instant refresh:

- You've changed the dock. Any modifications to your fueling setup, storage tanks, or the physical layout of the dock demand an immediate plan update.

- Your people change. Did your lead spill responder take a new job? You need to update names, roles, and contact information right away.

- You bought new gear. That new brand of sorbent pads or a different type of containment boom needs to be reflected in your inventory lists and deployment procedures.

- The regulations changed. State and federal rules don't stand still. Staying current is non-negotiable for compliance.

Here's the most critical piece of advice I can give you: The most important time to update your plan is right after you've used it. Whether it was a real-deal spill or just a training drill, you'll walk away with priceless lessons. Get those insights into the plan immediately so you don't repeat the same mistakes.

What Are the Most Common Mistakes to Avoid?

Learning from where others have stumbled is the fastest way to get ahead. After years in this field, I can tell you that most response failures boil down to a handful of critical, and surprisingly preventable, errors.

The single biggest mistake is a delay in reporting. It’s a natural instinct to try and control a spill before calling it in. This is a huge mistake. It almost always leads to bigger fines and worse environmental impact. Make the call first, then focus on containment. It's that simple.

Other classic blunders include:

- Forgotten and Failed Equipment: Pulling out a containment boom during an emergency only to find it's cracked and useless from sun damage is a nightmare scenario. Your equipment needs regular, hands-on inspection.

- Untrained Crew: A plan is just a binder on a shelf if your crew hasn't practiced their roles. Under pressure, people who are unsure what to do will either freeze or make things worse. Drills are everything.

- Confused Communications: Without a crystal-clear call list, chaos takes over. I’ve seen situations where three people call the same agency while a more critical contact gets missed entirely.

Who Exactly Do I Need to Call, and In What Order?

Your notification list is arguably the most critical page in your entire fuel spill response plan. It needs to be accurate, current, and easy to find in a panic.

Your first call, no exceptions, is to the National Response Center (NRC) at 1-800-424-8802. This is a federal requirement for any spill that leaves a visible sheen on the water.

After the NRC, your external call list must include:

- Your regional U.S. Coast Guard Sector Command Center.

- Your state’s environmental protection or emergency response agency.

- Local authorities like the harbormaster, fire department, or your city/county emergency management office.

Internally, you need a simple call tree for your own team. This gets management in the loop and mobilizes the right people on-site without confusion. For a more detailed breakdown, our comprehensive fuel spill response plan template has a great section that walks you through building these crucial contact lists from scratch.

I Run a Small Marina. Does My Plan Need to Be This Complicated?

Absolutely not. Your plan should be tailored to the size and risk of your specific operation. The plan for a small, private five-slip dock will look completely different from one for a massive commercial port fueling ships all day.

The core principles—risk assessment, equipment, procedures, training—are the same for everyone. But the complexity and scale should match your reality. A smaller marina will have less equipment to list, a much simpler command structure, and smaller potential spill sizes to plan for.

The key is relevance. A simple, practical plan that your team has actually rehearsed is infinitely more effective than a thick, complicated binder that just gathers dust.

At CLiX Fueling Solutions, we believe the best response plan is the one you never have to use. It all starts with prevention. By eliminating overfills and spills at the source, our automatic shut-off system helps you avoid the stress and cost of a cleanup. Protect your boat, your marina, and the environment by making every fueling a safe one. Learn more at https://clixfueling.com.