Think of a marine fuel transfer pump as the heart of your boat’s fuel system. Its job is simple but critical: to move fuel from your main storage tanks to where it's needed, like a day tank or directly to the engine. Without it, your vessel is dead in the water.

The Unsung Hero of Your Vessel's Fuel System

At its core, this pump is a specialized piece of equipment built to handle the tough marine environment. It's much more than just a motor—it’s a vital piece of gear that guarantees your engine gets a steady, clean supply of fuel, no matter the weather. This little workhorse is what stands between a full tank and a silent, starved engine.

Why Is This Pump So Important?

To really get it, picture your boat's fuel system like a circulatory system. The main storage tank is like the lungs, holding the fuel. The engine is the muscle that needs that fuel to do any work. The marine fuel transfer pump is the heart, tirelessly pumping fuel through the veins (your fuel lines) to power your journey.

This process is absolutely essential for a few key reasons:

- Engine Reliability: It keeps the fuel flowing smoothly and without air bubbles, which prevents engine stalls or damage. This is especially important in rough seas when fuel is sloshing around.

- Safety: True marine-grade pumps are built with ignition protection. They use robust materials designed to handle flammable liquids like gasoline and diesel safely, cutting down the risk of fires or dangerous leaks.

- Operational Efficiency: Moving fuel to a smaller day tank makes management easier. It also gives any water or sediment in the fuel a chance to settle out before it can reach your sensitive engine components.

A reliable fuel transfer pump isn’t a luxury; it's a fundamental requirement for safe and uninterrupted marine operations. It prevents engine starvation, which can leave a vessel powerless and adrift—a dangerous situation for any boater.

A Growing Market for Marine Reliability

The value of these pumps is easy to see in the industry's growth. The global marine pump market was valued at around USD 17.6 billion in 2023 and is expected to climb to USD 41.1 billion by 2031. This surge shows just how much demand there is for dependable equipment that keeps boats running right.

Of course, keeping a vessel in top shape involves more than just the mechanicals. Making sure you're protected with the right watercraft insurance provides peace of mind against the unexpected. A holistic approach to boat ownership means you're ready for anything, from routine maintenance to unforeseen trouble on the water.

How a Marine Fuel Pump Really Works

To get a real feel for your vessel, you have to look past the shiny parts and understand what makes it tick. The marine fuel transfer pump is one of those critical pieces of equipment that seems complicated at first glance, but it actually works on a pretty simple idea. Knowing how it operates isn't just for marine mechanics—it helps any boat owner spot trouble early and make smarter choices.

Think of the pump as a machine with a single job: creating a pressure difference. It needs to pull fuel from one place (your main tank) and push it to another (your day tank or engine). It does this by creating a low-pressure area, or a vacuum, at its inlet. Basic physics tells us that a vacuum wants to be filled, so the fuel naturally rushes in. Once inside, the pump's mechanics shove that fuel out the other side.

It's a lot like using a drinking straw. When you suck on the straw, you create a low-pressure zone inside it. The higher air pressure outside then pushes your drink up the straw. A fuel pump does the exact same thing, just with gears or diaphragms instead of your lungs.

The Inner Workings of Common Pump Designs

While the basic principle is the same across the board, different pumps use different methods to get the job done. The design really dictates what a pump is good at and where it should be used. Let's break down a few common types you'll run into.

-

Gear Pumps: Picture two gears meshed together inside a very snug housing. As they spin, their teeth separate on the inlet side, creating little pockets that trap fuel. This fuel gets carried around the outside of the casing until the teeth mesh together again on the outlet side, forcing the fuel out. It's a beautifully simple and reliable design that delivers a very steady flow.

-

Diaphragm Pumps: This pump uses a flexible membrane that moves back and forth, sort of like the plunger in a medical syringe. When the diaphragm pulls back, it creates a vacuum that sucks fuel into the chamber. Then, it pushes forward, squeezing the fuel out toward the engine. A huge advantage here is that many diaphragm pumps can run dry for a bit without destroying themselves, and they're great at self-priming—meaning they can pull fuel even if there's air in the lines.

-

Centrifugal Pumps: Imagine a spinning propeller (called an impeller) inside a circular case. It slings fuel outwards using centrifugal force, just like a salad spinner flings water off lettuce. This creates low pressure at the center, which pulls more fuel in, while the fast-moving fuel at the edge is directed out of the pump. These pumps are workhorses for moving a lot of fuel very quickly, but they often need to be primed to get started.

Translating Mechanics into Performance

Understanding how these pumps are built helps make sense of the technical terms you'll see. These aren't just buzzwords; they're practical measurements of what a pump can actually do for your boat.

The right pump isn't just about moving fuel; it's about moving it at the correct rate and pressure for your specific system, without fail, even in challenging conditions.

For example, the flow rate, measured in gallons per minute (GPM), tells you how fast the pump can move fuel. A big centrifugal pump will almost always have a higher flow rate than a small diaphragm pump.

Then you have head pressure. This is simply the pump's ability to push fuel uphill against gravity. If your day tank is mounted high above your main storage tank, you need a pump with enough head pressure to make that climb without struggling.

Finally, the pump's design affects how well it handles different fuel viscosities (thickness). Heavy diesel oil flows very differently from gasoline, and a gear pump, with its positive displacement action, is often much better at moving thicker liquids than a centrifugal pump is. At the end of the day, the mechanics directly determine how the pump will perform on your vessel.

Comparing Different Types of Fuel Pumps

Picking the right marine fuel transfer pump isn't a one-size-fits-all deal. The best choice for you boils down to your boat's size, its electrical setup, and what you need the pump to do. You wouldn't use a garden hose to fight a fire, and you certainly wouldn't put a small recreational pump on a commercial tanker.

The easiest way to start narrowing down your options is by looking at their power source. This simple distinction usually tells you a lot about their performance, toughness, and where they work best.

Electric DC Pumps: The Go-To for Recreational Boaters

For most folks with recreational boats—from small fishing skiffs to mid-sized cruisers—a 12V or 24V DC electric pump is the industry standard. These pumps are designed to hook right into your boat’s battery system, which makes them incredibly convenient and straightforward to install. No complex wiring needed.

They hit the sweet spot between performance and price. A good DC pump will give you more than enough flow to move fuel between tanks or fill a day tank, keeping your engine happily supplied. Plus, they're compact, relatively quiet, and built for the unique demands of a smaller vessel.

Heavy-Duty AC Pumps: Powering the Commercial Fleet

When you jump up to larger yachts, commercial fishing boats, or workboats, the power game changes entirely. These vessels typically have powerful onboard generators cranking out AC power (110V or 220V), which is needed to drive much bigger, more powerful pumps.

AC-powered pumps are the heavy lifters of the marine world. They're built for constant, high-volume work and can move hundreds of gallons of fuel every minute. This kind of muscle is non-negotiable for managing the huge fuel loads on commercial ships, where refueling has to be fast and flawless every single time.

Manual Hand Pumps: The Ultimate Backup Plan

No matter how slick your primary pump system is, every smart mariner keeps a manual hand pump on board. Think of this simple, bombproof device as your ultimate safety net. If you ever face a complete electrical failure miles from shore, a manual pump might be the one thing that can get fuel to your engine and get you moving again.

These pumps are cheap, need no electricity, and are incredibly tough. They're perfect for emergencies, for priming a stubborn fuel line, or for carefully drawing fuel from the bottom of a tank to check for water or gunk.

A manual pump is like a fire extinguisher for your fuel system. You hope you never have to use it, but you'll be incredibly grateful it’s there when you do. Having one is a cornerstone of responsible seamanship.

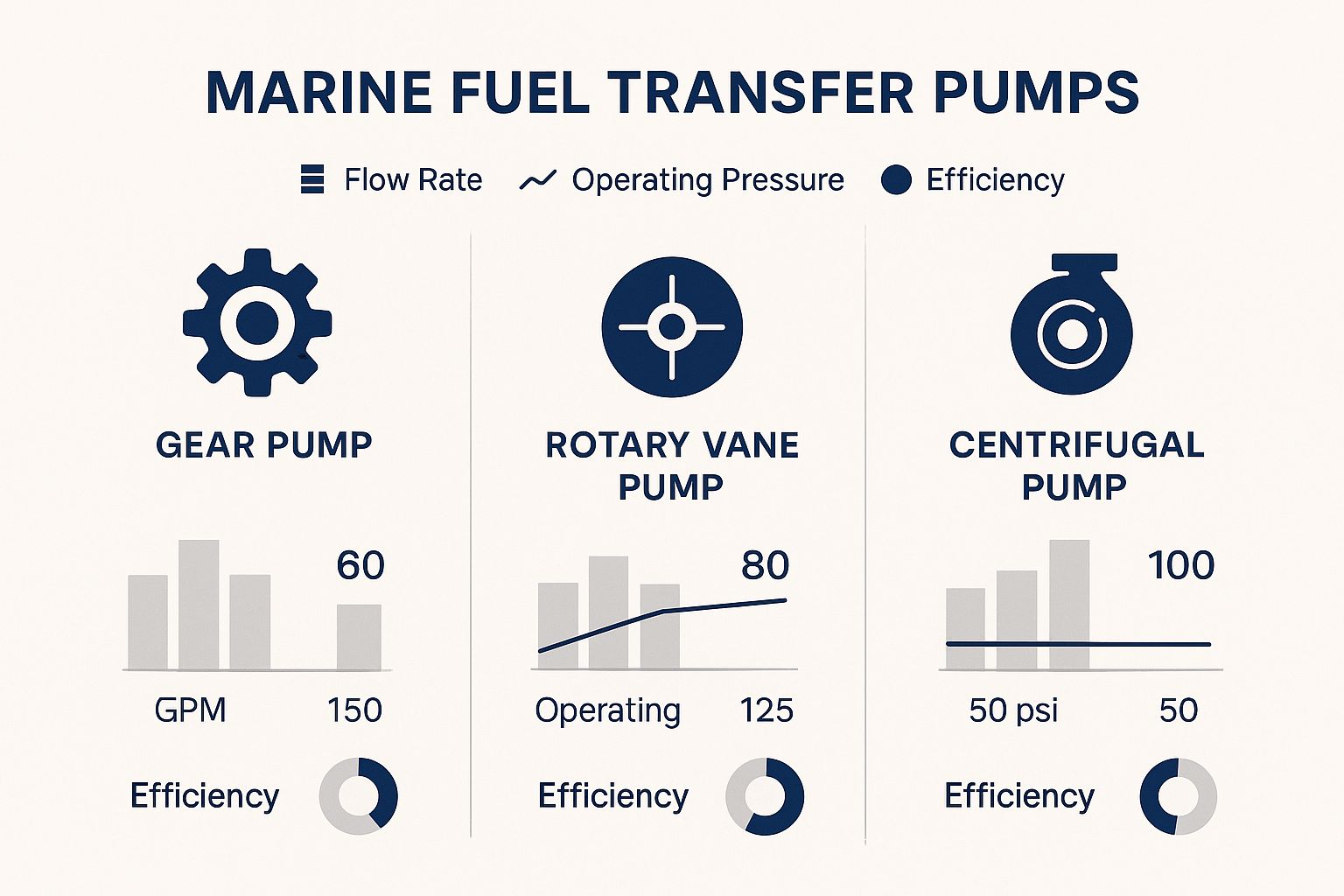

This image shows how different pump designs stack up in terms of performance, giving you a clear visual on how the mechanism affects flow rate, pressure, and efficiency.

As you can see, centrifugal pumps are kings when it comes to high-volume flow, while gear and vane pumps deliver the pressure and control needed for more precise transfers.

Comparison of Marine Fuel Transfer Pump Types

To make things even clearer, here’s a quick-glance table comparing the most common pump types. It breaks down what makes each one tick and where it shines.

| Pump Type | Power Source | Best For | Key Advantage | Potential Drawback |

|---|---|---|---|---|

| DC Electric | 12V / 24V Battery | Recreational Boats | Easy integration, affordable | Lower flow rate than AC |

| AC Electric | 110V / 220V Generator | Commercial Vessels | High volume, continuous duty | Requires generator, more complex |

| Manual | Hand Power | Emergency Backup | Utterly reliable, no power needed | Very slow, labor-intensive |

| Diaphragm | Electric or Manual | Versatile applications | Can run dry, self-priming | Can have a pulsating flow |

| Gear/Vane | Mostly Electric | Precise fuel metering | Steady flow, efficient | Can be damaged by debris |

This table should help you quickly match a pump's core strengths and weaknesses to the job you have in mind.

A Look at Pump Mechanisms

Beyond the power source, it's the pump's internal guts—the mechanism—that truly defines how it works and what it's good at.

- Diaphragm Pumps: These are the all-rounders. Their biggest perk is the ability to run dry for short periods without burning up, which is a common killer of other pumps. They're also great at self-priming, meaning they can pull fuel up even if there’s a little air in the line. This makes them ideal for setups where the pump is mounted above the fuel tank.

- Gear Pumps: Known for being tough as nails and providing a steady, pulse-free flow, gear pumps are workhorses. They are a type of positive displacement pump, moving a fixed amount of fuel with each rotation, which is perfect when you need precise delivery. They have no problem handling thicker fuels like diesel.

- Vane Pumps: A close cousin to gear pumps, rotary vane pumps also deliver a very consistent flow. They are typically self-priming and are excellent at moving thinner liquids like gasoline. Their efficiency makes them a popular choice, especially in portable systems. If that sounds like what you need, our guide on the top portable fuel transfer pump options dives deeper into these handy tools.

At the end of the day, choosing the right marine fuel transfer pump is about balancing power, design, and your specific needs on the water. By understanding these key differences, you can pick a pump that will serve you reliably and safely for years to come.

How to Choose the Right Fuel Transfer Pump

Picking the right marine fuel transfer pump is a lot more than just finding one that screws onto your fuel line. Think of it like choosing the right heart for your boat's circulatory system—it dictates how reliably, safely, and efficiently fuel gets where it needs to go. A smart choice here saves you from the massive headache of a mismatched or underpowered pump down the road.

This isn't just a concern for individual boat owners; it's a big deal for the entire maritime industry. The global market for marine fuel pumps was valued at roughly USD 1.2 billion in 2024 and is expected to climb to USD 1.9 billion by 2033. That growth is all about the constant push for more dependable, high-performance gear on the water.

Figuring Out Your Performance Needs

Before you even start browsing for pumps, you need to do a little homework on your boat’s specific needs. The two numbers that matter most are flow rate and head pressure. Get these right, and you’re setting yourself up for success.

1. Nail Down Your Flow Rate (GPM)

Flow rate, measured in gallons per minute (GPM), is simply how much fuel the pump can move in a minute. When you're just transferring fuel between tanks, you don't need a fire hose, but you also don’t want the job to take all afternoon. For most recreational boats, a pump that can move 5 to 15 GPM is a pretty good sweet spot.

2. Calculate Your Head Pressure

Head pressure is just a technical way of saying how high the pump needs to push the fuel. You’ll need to measure the vertical distance from where the pump sits to the highest point the fuel has to reach. Don't forget to account for friction from the hoses and fittings! A pump that can’t handle the head pressure will strain, struggle, and ultimately fail to get the job done.

Don't Skimp on Safety and Durability

Once you know the performance specs you're after, it's time to shift your focus to safety and longevity. Out on the water, these aren't just nice-to-haves; they're absolute necessities. The right materials and safety certifications protect your crew, your vessel, and the environment.

Of course, the pump is just one piece of the puzzle. To see how it all fits together, take a look at our complete guide to the boat fuel system.

Here are the critical things to look for:

- Fuel Compatibility: Make sure the pump's guts—the seals, gaskets, and diaphragms—are made to handle your specific type of fuel. What works great for diesel might get eaten alive by gasoline or ethanol blends.

- Ignition Protection: This is non-negotiable for any gasoline-powered boat. An ignition-protected pump is built to prevent its motor from creating a spark that could ignite fuel vapors. That’s a catastrophic risk you can’t afford. Look for pumps that are certified by the U.S. Coast Guard (USCG).

- Corrosion Resistance: The marine environment is brutal. Saltwater will destroy anything it can. A proper marine pump should be built from tough stuff like marine-grade stainless steel, bronze, or specialized polymers that just shrug off corrosion.

Choosing a pump without ignition protection for a gasoline boat isn't just a bad idea—it's a dangerous gamble. Always, always verify that the pump meets strict marine safety standards for your specific fuel.

By taking a methodical approach—first figuring out your performance needs and then zeroing in on material and safety features—you can pick a pump with confidence. This way, you're investing in a piece of equipment that will be reliable, safe, and efficient for years to come.

Fuel Pump Installation and Maintenance Tips

A high-quality marine fuel transfer pump is a great piece of gear, but its real-world performance comes down to how well you install and maintain it. Think of it like a finely tuned engine—the best design in the world won't matter without a proper setup and regular check-ups. A solid installation prevents dangerous leaks and keeps things running smoothly, while a simple maintenance routine can easily add years to its life.

This push for reliability is a huge deal in the marine world. The global market for these pumps was valued at around USD 1.71 billion back in 2021 and is expected to climb past USD 2.51 billion by 2030. That growth is all about the rising demand for tough, dependable equipment that boaters can count on. You can dig into these trends in Grand View Research's analysis.

Getting the installation right from day one is the single most important thing you can do. It's the foundation for years of worry-free fueling.

A Blueprint for Proper Installation

A rushed or sloppy installation is just asking for trouble, causing everything from poor performance to disastrous fuel leaks. Taking the time to do it right pays off every single time you need to move fuel. The main goals here are simple: accessibility, safety, and a secure, leak-proof system.

For a rock-solid installation, just stick to these guidelines:

- Pick a High and Dry Spot: Mount the pump somewhere with good ventilation, away from direct spray, and as dry as you can get it. Moisture and electronics are a bad mix.

- Make Sure You Can Reach It: Don't tuck your pump away in a spot you can’t get to. You’ll need to inspect it, change filters, and maybe even do a repair down the line.

- Use the Right Gear: This is non-negotiable. Always use marine-grade, fuel-rated hoses, clamps, and fittings. Automotive parts can't handle the harsh marine environment and will break down, creating a serious safety hazard.

- Secure the Mounting: Bolt the pump down securely to a solid surface. This cuts down on vibration, which can shake connections loose and wear out the pump’s internal parts over time.

Key Takeaway: Your installation is only as strong as its weakest link. A single automotive-grade hose clamp or a poorly sealed fitting can compromise the safety and reliability of your entire fuel transfer system.

Creating a Simple Maintenance Schedule

Preventative maintenance isn't about being a master mechanic. It’s about spotting small issues before they snowball into big, expensive problems that could leave you stranded. A consistent schedule of simple checks is all it takes to keep your marine fuel transfer pump in top shape. For a deeper dive into keeping your whole system healthy, check out our comprehensive boat fuel pump guide for selection and maintenance.

A smart maintenance routine can be broken down into three easy stages.

1. Daily Visual Checks (Before Each Use)

- Give the pump and the area around it a quick look for any signs of fuel weeping or leaks.

- Glance over the fuel lines to make sure they're secure and don't have any cracks or chafing.

2. Monthly Inspections

- Check and clean the pump's inline strainer or filter. A clogged filter forces the pump to work harder, which shortens its lifespan.

- Make sure all electrical connections are snug and free of corrosion.

- Run the pump for a moment and listen. Any weird noises, like grinding or a loud hum, could be a sign of internal wear.

3. Annual Service

- Take a close look at the pump's impeller or diaphragm for wear and tear. If it looks cracked or brittle, replace it.

- Double-check all the mounting bolts. A season's worth of vibration can loosen them up.

- To keep your pump running strong for years, it also helps to brush up on general tips for preventing fuel pump burnout.

By sticking to this simple plan, you’ll dramatically cut the risk of a surprise failure and ensure your pump is ready to go whenever you need it.

Your Top Questions About Marine Fuel Pumps Answered

Dipping your toes into the world of marine equipment can feel like learning a new language. And when it comes to something as vital as your fuel system, you need clear, no-nonsense answers to keep you safe and confident on the water.

Let's cut through the jargon and tackle some of the most common questions boaters have about their marine fuel transfer pump.

Can I Just Use an Automotive Fuel Pump on My Boat?

This is easily one of the most common—and most dangerous—questions we hear. The answer is a hard no. While it might seem like a fuel pump is a fuel pump, using one from a car on your boat is a recipe for disaster, especially with a gasoline engine.

Why? It all comes down to a lack of ignition protection. An automotive pump simply isn't sealed to prevent tiny electrical sparks from escaping the motor. In an enclosed boat engine room, where gas fumes can easily build up, just one of those sparks could trigger a catastrophic explosion. Marine-grade pumps are specifically built and certified to contain any internal sparks, and that’s a safety feature you absolutely cannot compromise on.

On top of the massive fire risk, car pumps are not designed to withstand the harsh, corrosive salt-and-spray environment of a boat. They'll rust out and fail in no time, leaving you dead in the water.

What Does Ignition Protected Really Mean?

"Ignition protected" isn't just a marketing term; it's an official safety standard, usually certified by groups like the U.S. Coast Guard (USCG). It guarantees that a piece of equipment has been engineered to operate safely in an environment where explosive vapors are present.

Think of it this way: an ignition-protected device is built so that it absolutely cannot light up any flammable fumes around it. For a fuel pump, this means the motor and all its electrical bits are completely sealed off, trapping any potential sparks safely inside.

This isn't just a good idea—it's the law for most gas-powered boats. When you're buying any electrical part for your fuel system, always look for that "ignition protected" label.

How Do I Prime a Fuel Pump That Lost Suction?

It's a frustrating moment: your pump is running, but nothing's happening because it's full of air instead of fuel. We call this losing its prime. Luckily, getting it going again is usually straightforward, especially if you have a self-priming pump.

If your pump needs a manual prime, here’s what to do:

- Safety First, Always: Turn off the engine and make sure the area is well-ventilated. It's smart to have a fire extinguisher within arm's reach.

- Find the Inlet: Locate the hose on the suction side of the pump—this is the line pulling fuel from the tank.

- Give it a Drink: You might need to disconnect the inlet hose at a high point and carefully pour a little fuel into it to fill the pump chamber. Some boats have a primer bulb (like on an outboard motor's fuel line) that you can squeeze a few times to manually pull fuel through the system.

- Button Up and Test: Reconnect the hose, making sure the connection is tight. Power up the pump, and it should now create suction and start moving fuel like it's supposed to.

What Are the Warning Signs of a Failing Pump?

A fuel pump doesn't usually just quit on the spot. It almost always gives you a few warning signs first. Learning to spot them means you can fix the problem at the dock, not when you're miles from shore.

Keep an ear and an eye out for these tell-tale symptoms:

- Weird Noises: A healthy pump has a steady, quiet hum. If you start hearing a loud whine, a grinding sound, or weird clicking, the motor or bearings could be on their way out.

- Sputtering Flow: Is the fuel delivery choppy or surging instead of smooth? That could point to a problem inside the pump, like a worn-out impeller or a failing diaphragm.

- Running Hot: If the pump casing feels unusually hot, it's straining. This is often caused by a blockage somewhere in the fuel line or an internal mechanical failure.

- Popping the Breaker: A pump that keeps tripping its circuit breaker is drawing way too much power. That's a serious red flag that the motor is about to fail completely.

At CLiX Fueling Solutions, we believe safety and convenience should go hand in hand. Our innovative system prevents dangerous fuel spills by automatically stopping the flow when your tank is full, protecting your boat and the marine environment. Discover a smarter, cleaner way to fuel up at https://clixfueling.com.