When you hear the term “floating fuel tank,” you probably picture a massive industrial storage facility sitting on the water. While that’s technically correct, for most boaters, the idea is much closer to home. It’s all about the principles of storing and handling fuel safely, both on your boat and at the marina.

What “Floating Fuel Tanks” Really Mean for Boaters

Let's start with the big guys. An industrial floating roof tank has a roof that literally floats on the surface of the fuel inside. As the fuel level changes, the roof moves with it, which drastically cuts down on vapor buildup and reduces environmental risks.

Now, bring that concept down to the scale of your own boat. You're not dealing with a floating roof, but the core principle is the same: managing fuel in a dynamic environment to prevent spills. It’s about avoiding those all-too-common, costly, and messy overflows at the fuel dock.

This guide bridges the gap between those massive industrial tanks and the everyday challenges you face. We'll look at everything from the tanks that supply your local marina to the system that powers your adventures, showing why being precise with your fueling is so critical.

A Boater's Take on Fuel Storage

For you, the "floating fuel tank" is the one built into your vessel. It’s specifically designed to hold fuel securely in a world of constant motion—rocking waves, vibrations, and changing angles.

These tanks are far from one-size-fits-all. They have to fit the unique layout of each boat, but a few things are always top of mind for builders and owners:

- Materials and Construction: Most tanks are made of high-density polyethylene, aluminum, or stainless steel. Each material offers a different balance of durability, weight, and resistance to corrosion from saltwater and fuel.

- Capacity and Range: Knowing your tank's exact volume isn't just for planning your trip. It's the most important piece of information you need to prevent a messy overfill at the pump.

- Built-in Safety: Your tank is a whole system. Vents, fuel gauges, and secure fill caps all work together to manage pressure and keep gasoline or diesel safely contained.

The big idea is this: whether it’s a million-gallon terminal tank or the 20-gallon tank on your center console, the goal is the same—secure and efficient fuel containment. A small spill from a recreational boat can cause just as much damage to the local marine life.

Ultimately, getting to know your boat’s fuel system is a core part of being a responsible skipper. Whether you're dealing with a main tank or a portable marine gas tank, every boater has a part to play in keeping our waters clean. This guide will give you the practical knowledge to fuel up with confidence every single time.

Understanding Different Marine Fuel Systems

To really get a handle on floating fuel tanks and their role in boating, it helps to zoom out and look at the entire marine fuel ecosystem. The term isn't just about one specific type of tank; it’s more of a concept that covers the secure storage of fuel all the way down the supply chain, from massive industrial terminals right into the hull of your boat.

Think about it: every drop of fuel you pump at the marina dock started its journey in a much, much larger container. These are the giant, industrial-scale floating roof tanks you might spot near a port—a brilliant piece of engineering based on simple physics.

From the Terminal to the Marina Dock

At the very top of the fuel supply chain are the true industrial floating fuel tanks. These tanks have a roof that literally rests on the surface of the fuel, rising and falling as the level changes. This clever design minimizes the empty space above the fuel where flammable vapors can build up, which is a massive safety feature when storing volatile liquids like gasoline.

First introduced way back in the 1920s, floating roof tanks completely changed the game for storing petroleum products. By letting the roof float on the liquid, they reduce the vapor space and can slash harmful volatile organic compound (VOC) emissions by up to 95% compared to traditional fixed-roof tanks.

From these huge terminals, fuel makes its way to your local marina, where it’s kept in smaller (but still pretty big) on-site storage tanks. These systems are all about keeping the fuel stable and clean right up until it hits the nozzle at the dock.

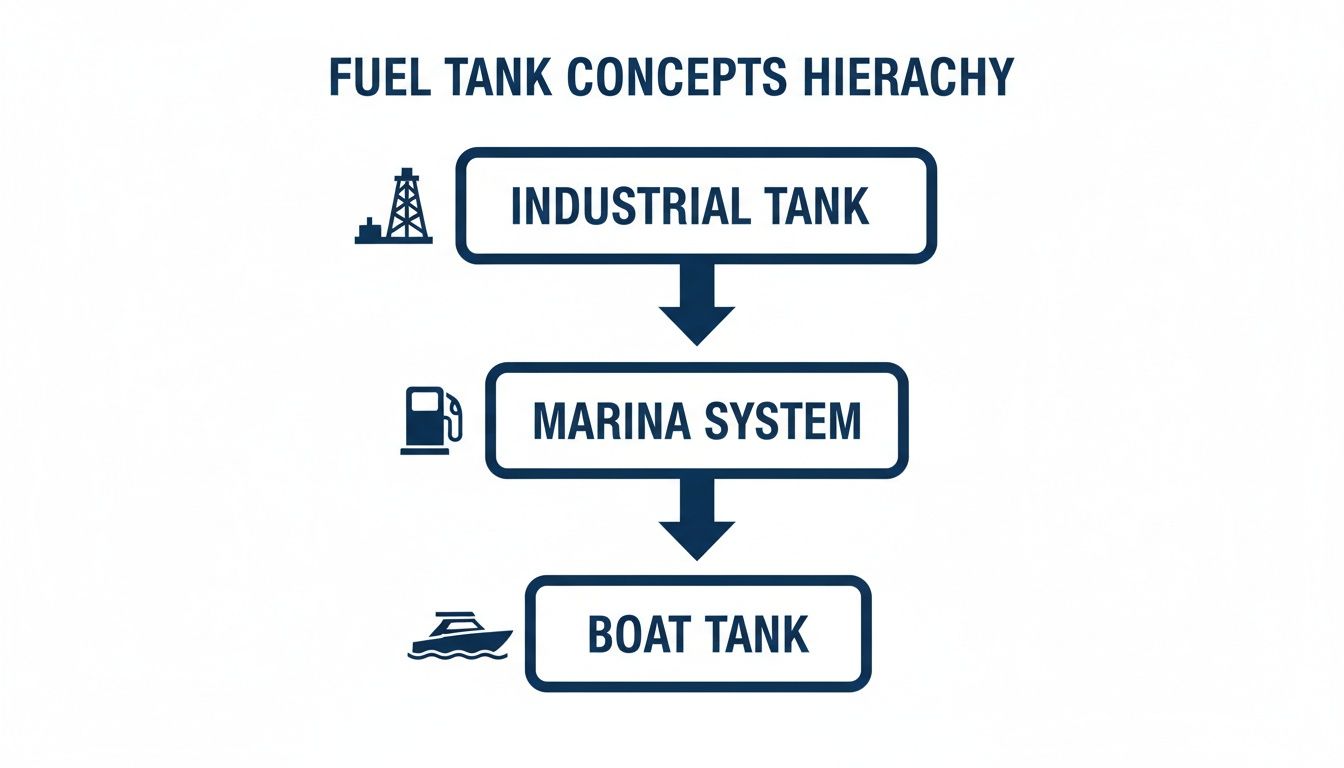

This whole journey, from the industrial source to your boat, is laid out in the chart below.

As you can see, the core principles of safe fuel handling stay the same—they’re just scaled differently for each environment.

The Fuel Tank Inside Your Boat

Once the fuel is at the marina pump, our focus narrows to the tank that matters most to you: the one on your boat. In a sense, your boat's tank is also a "floating fuel tank"—it's a self-contained system built to hold fuel safely while literally floating and moving on the water.

These on-board tanks are built tough to handle the unique challenges of a marine environment, like constant motion, engine vibrations, and the corrosive bite of saltwater. They are just one piece of a much larger puzzle, which you can learn all about in our guide to boat fuel systems.

To help you get familiar with what's out there, here's a quick rundown of the most common fuel storage systems you'll encounter as a boater.

Comparison of Marine Fuel Tank Types

| Tank Type | Primary Use | Advantages | Disadvantages |

|---|---|---|---|

| Industrial Floating Roof Tank | Large-scale bulk storage at refineries and terminals | Minimizes vapor loss, reduces emissions by up to 95%, enhances safety for volatile fuels | Not for mobile use, complex design, high initial cost |

| Marina Above-Ground Storage Tank (AST) | Holding fuel at marinas before it's dispensed | Easily accessible for inspection and maintenance, lower installation cost than underground tanks | Exposed to weather, can be an eyesore, potential for external damage |

| On-Board Polyethylene (Plastic) Tank | Fuel storage inside recreational boats | Lightweight, completely rust-proof, can be molded into custom shapes | Can degrade with UV exposure over time, susceptible to permeation |

| On-Board Metal Tank (Aluminum/Steel) | Fuel storage inside recreational and commercial boats | Extremely durable, puncture-resistant, long lifespan | Heavier, susceptible to corrosion (especially at welds), more expensive |

Ultimately, whether we're talking about a massive industrial tank or the one under your boat's deck, the fundamental goals are the same: safety, reliability, and preventing spills.

No matter the material or size, every single marine fuel system is built on the non-negotiable principles of safety and reliability. Getting to know how your on-board tank fits into this bigger picture is a great first step toward being a more confident and responsible boater.

Weighing Your Options: The Pros and Cons of Marine Fuel Tanks

When you're outfitting a boat, the fuel tank might not be the most glamorous component, but choosing the right one is critical. The decision really boils down to balancing durability, weight, and cost, and what's best for one boat might be all wrong for another.

For most recreational boats, you’ll run into three main materials: polyethylene (plastic), aluminum, and stainless steel. Each has its own personality when it comes to handling the tough marine environment, so let's break them down.

The Case for Plastic (Polyethylene) Tanks

There’s a reason you see so many plastic tanks in newer boats—they solve a lot of old problems. Their biggest selling point? They are 100% immune to corrosion. Rust and galvanic corrosion are the arch-enemies of metal parts on a boat, especially in saltwater, and plastic tanks simply don't have that problem.

This makes them a fantastic low-maintenance choice. They’re also a lot lighter than metal tanks, which can give you a nice little bump in fuel efficiency and overall performance. Plus, because they’re molded, manufacturers can get creative with the shapes, tucking them into odd spaces in the hull to maximize every last drop of fuel capacity.

Of course, no material is perfect. Plastic tanks have a few quirks to be aware of.

- Sun Sensitivity: If a plastic tank is exposed to direct sunlight for years on end, the UV rays can make it brittle.

- Fuel Odors: Some older, less advanced plastic tanks could allow a minuscule amount of fuel vapor to pass right through the material, a process called permeation. It's not a leak, but it can leave a faint fuel smell in the bilge.

- Toughness: While they're plenty strong for normal use, they are generally more vulnerable to a sharp impact or puncture than a heavy-gauge metal tank.

A Look at Metal: Aluminum and Stainless Steel

For years, aluminum was the king of boat fuel tanks, and for good reason. It's strong, durable, and a well-made aluminum tank can easily outlast the engine. Stainless steel is its tougher, more corrosion-resistant big brother, but it comes with a significantly higher price tag and a lot more weight.

The Achilles' heel for any metal tank is corrosion. The risk is always highest at the welds and in any little crevice where water can get trapped and sit against the metal—a classic problem in damp bilge areas. This can lead to pitting corrosion, which creates tiny pinhole leaks that are a nightmare to track down and fix.

The Bottom Line: The choice between plastic and metal often hinges on where you boat and how you maintain your vessel. Plastic gives you peace of mind against rust, while a properly installed and cared-for metal tank can offer unmatched structural strength for the long haul.

It's interesting to see how these material choices play out on a larger scale. The global market for portable fuel tanks is set to grow from $2.8 billion in 2024 to $4.6 billion by 2033, and plastic tanks already hold a 55% market share. Their popularity comes down to that same core benefit: corrosion resistance.

This principle is also at the heart of massive industrial floating roof tanks, which minimize air exposure to prevent rust and have helped cut global VOC emissions by 2-5 million metric tons annually since 2000. It all comes back to smart design preventing problems before they start. That’s exactly why modern fueling solutions that automatically stop the nozzle are so important—they're designed to eliminate wasteful and harmful overfills from happening in the first place. You can read more about these trends in the full report on floating roof tank analytics.

The Critical Safety and Environmental Risks You Can’t Ignore

Fuel is the lifeblood of any adventure on the water, but let's be honest—it's also the biggest hazard we manage. Modern floating fuel tanks are built tough, but the risks that come with handling gasoline or diesel are always there. Understanding these dangers isn't about being paranoid; it's about having a healthy respect for the power you're carrying.

The most common—and totally preventable—incident is a fuel spill. One distracted moment at the fuel dock can lead to an overfill, sending gas or diesel straight out of the fill pipe or vent. This is way more than just a messy cleanup; it's a serious threat.

The Real Dangers of Spills and Overfills

A fuel spill, no matter how small, triggers immediate and expensive problems. Even a few ounces of gas creates that tell-tale sheen on the water, which can bring hefty fines from environmental agencies. Fuel is also incredibly corrosive. It can permanently damage your boat’s gelcoat, strip away wax, and eat at non-skid surfaces, leaving you with a hefty repair bill.

But the financial cost pales in comparison to the extreme risk of fire. Gasoline vapors are heavier than air, meaning they sink and collect in low spots like your boat's bilge or engine compartment. All it takes is a single stray spark from a bilge pump, a battery connection, or a hot exhaust manifold to ignite those fumes and cause a devastating explosion.

It's hard to overstate the danger. A single cup of spilled gasoline has the explosive power of 15 sticks of dynamite. Think about that concentrated in the enclosed space of your boat.

This is exactly why spill prevention isn't optional—it's a core part of responsible boating. And if a spill does happen, you need to know exactly what to do. For a step-by-step guide, check out our article on fuel spill cleanup procedures and expert response.

The Hidden Risk: Thermal Expansion

Here’s a sneaky one that catches even experienced boaters off guard: thermal expansion. You finish fueling, leave what you think is a safe amount of room in the tank, and head out. An hour later, you notice fuel trickling from your vent line. What happened?

The fuel stored in cool, underground marina tanks warms up significantly once it's in your boat's tank, baking in the sun. As the fuel’s temperature rises, it expands. If your tank is already close to full, that expanded fuel has nowhere to go but out the vent. It’s a quiet, unexpected spill that happens long after you've left the dock.

A good rule of thumb is to fill your tank to about 90% capacity. That little bit of extra space gives the fuel room to expand without causing a problem.

How Fuel Safety Has Evolved

The challenge of managing fuel vapors and preventing spills has been around for over a century. In the industrial world, the Chicago Bridge & Iron Company introduced the floating roof tank way back in 1919 to stop vapor buildup and reduce fire risks. The design was a game-changer, slashing explosion incidents by a whopping 70% in facilities that adopted it by the 1930s.

Today, the market for advanced storage tanks is a $7.83 billion industry. Floating roofs are still leading the way, driven by environmental rules like the U.S. Clean Air Act, because they can cut evaporation losses by up to 98%. This history lesson proves a simple point: controlling fuel and its vapors has always been the key to safety.

For us recreational boaters, that same principle applies directly to preventing overfills at the pump. Modern solutions are engineered to solve this exact problem, creating a reliable defense against spills and making the whole fueling process safer for you, your boat, and the environment.

Essential Fuel System Maintenance and Inspections

When it comes to your boat’s fuel system, an ounce of prevention is truly worth a pound of cure. Think of it as your boat's circulatory system—a small clog or leak in a fuel line can quickly lead to a massive headache out on the water. The good news is that you don't need to be a master mechanic to stay ahead of trouble. A simple, proactive inspection routine is all it takes.

Turning fuel system care into a regular habit transforms it from a stressful chore into a confidence-boosting part of your pre-launch ritual. For boaters and marina operators alike, these checks are the bedrock of a safe, enjoyable day on the water.

Your Pre-Departure Fuel System Checklist

Before you even think about untying the dock lines, make it a habit to run through this quick visual inspection. It only takes a few minutes but can save you from a ruined trip or a dangerous situation.

-

Give the Tank a Once-Over: Start with the tank itself. If you have metal floating fuel tanks, look for any corrosion, paying close attention to welds, fittings, and straps where moisture loves to hide. On plastic tanks, check for chalkiness, discoloration, or fine cracks that signal sun damage.

-

Inspect the Fuel Lines: These are the arteries of your boat. Give them a gentle squeeze; they should feel firm but still have some flex. If a line feels mushy, brittle, or rock-hard, it’s well past its expiration date and needs to be replaced immediately to prevent a leak.

-

Check Clamps and Fittings: Make sure every hose clamp is snug and rust-free. Gently wiggle the fittings where lines connect to the tank, filter, and engine. Nothing should feel loose. Any sign of dampness around a fitting points to a small leak that's bound to get worse.

-

Clear the Fuel Vent: Your fuel tank has to breathe. Find the fuel vent on the outside of your hull and ensure it’s not plugged up with dirt, spider webs, or old wax. A blocked vent can starve your engine of fuel or, worse, create a dangerous pressure buildup in the tank.

-

Verify the Fuel Cap Seal: Pop open your fuel cap and take a look at the rubber O-ring or gasket. If it looks cracked, dried out, or is missing entirely, get a new one. A bad seal is a common way for water to contaminate your fuel and cause engine problems.

A routine check isn’t just about finding problems; it’s about building a deep familiarity with your boat. When you know what "normal" looks like, you'll be able to spot even the slightest change instantly.

Maintenance Tips for Marina Operators

As a marina operator, keeping your fuel docks and equipment in top shape isn't just good business—it's a critical safety and compliance issue. Your responsibility covers the entire fuel delivery system, from the tanks to the nozzles.

- Schedule Regular Audits: Walk the docks weekly to inspect all fuel hoses, nozzles, and emergency shut-off switches. Look for any wear and tear, drips, or signs of a malfunction.

- Keep Spill Kits Ready: Check that your spill kits are fully stocked, clearly marked, and easy to grab in a hurry. Just as important, make sure your staff knows exactly how to deploy them.

- Use Clear Signage: Post simple, easy-to-read fueling instructions and safety warnings at every pump. This helps boaters follow best practices and promotes a culture of safety throughout your facility.

Making these inspections a non-negotiable part of your operations dramatically cuts the risk of spills and equipment failures, ensuring your marina remains a safe harbor for everyone.

Staying Compliant and Fueling Smart

Knowing the ins and outs of your boat's fuel system is one thing. But putting that knowledge into practice to stay compliant on the water? That’s where responsible boating really starts. It's all about following the rules designed to protect the very environment we love to be in, and thankfully, it doesn't have to be a headache.

The guiding principle behind most rules from agencies like the Environmental Protection Agency (EPA) and the U.S. Coast Guard is simple: keep fuel in the tank. If you spill enough fuel to create a visible sheen on the water, it’s an illegal act that has to be reported. Those fines aren't a joke—they can turn a simple refueling mistake into an incredibly expensive problem.

Mastering the Art of Fueling

Following the rules becomes second nature when you build solid fueling habits. Think of these practices as your first line of defense against spills, turning a potentially messy job into a safe, clean, and predictable routine.

Make these steps a non-negotiable part of every trip to the fuel dock:

- Know Your Tank: Before you grab the fuel nozzle, have a clear idea of your tank's total capacity and how much fuel you actually need. Fuel gauges can be notoriously unreliable, so don't depend on them alone.

- Get Absorbent Pads Ready: Always have an absorbent pad wrapped around the fuel fill before you start pumping. It’s a simple trick that catches any stray drips that could stain your deck and pollute the water.

- Pay Attention: This is not the time to multitask. Put the phone away and focus on the task at hand. Listen closely for the gurgling sound a tank makes as it gets close to full—it’s the best cue to slow down and prepare to stop.

The Overfill Problem (And How to Solve It)

Even the most careful boater can fall victim to the most common fueling mistake: the overfill. It happens in a flash. One second you think you have plenty of room, and the next, fuel is spewing from the fill pipe or vent. It’s messy, dangerous, and illegal. This is the one major issue that good habits alone can’t always prevent.

Let's be honest—a split-second distraction is all it takes to cause a spill. This is exactly why finding a way to make a manual, mistake-prone process foolproof is so important for boating today.

This is where technology can step in to back you up. Modern solutions are designed to work directly with the fuel nozzle, automatically shutting off the pump the moment your tank is full. By tackling the overfill risk head-on, these systems make it practically impossible to cause a spill.

While we're focused on fuel, it's also smart to have a wider understanding of rules like the UK hazardous waste disposal regulations, which cover the bigger picture of environmental responsibility. When you combine smart technology with your own careful safety habits, you create a powerful system for fueling responsibly. It’s the best way to ensure a safe, spill-free experience every time, protecting your boat, your wallet, and the water.

Your Top Questions About Marine Fuel Systems Answered

Even with a good grasp of how your boat's fuel system works, real-world questions always pop up. Let's tackle some of the most common things I hear from boat owners about keeping their fuel systems safe and reliable out on the water.

How Often Should I Really Inspect My Boat's Fuel Tank?

You should give your fuel tank and lines a quick once-over every single time before you leave the dock. Think of it as part of your pre-flight checklist.

That said, a much deeper inspection is a must at least once a year. This is where you get in there and check every fitting, clamp, and the entire tank surface for any signs of wear and tear. If you have an older boat or spend your time in saltwater, I'd strongly recommend doing this deep dive twice a year. It's cheap insurance.

What's the #1 Cause of Fuel Spills?

Hands down, the most common reason for a fuel spill is overfilling the tank at the fuel dock. It happens all the time.

Boat fuel gauges are notoriously unreliable, so it's incredibly easy to misjudge how much room you actually have. One moment of distraction and fuel is gushing out of the vent or fill pipe. Not only is it bad for the environment, but it's a huge fire risk right there at the dock.

The tough part is, most of these spills are completely avoidable. An overfill usually comes down to a moment of inattention or just not knowing the tank's true capacity. This really underscores why we need better fueling habits and tools.

Is It Okay to Mix Ethanol and Non-Ethanol Gas?

You can, but I really advise against it. Ethanol is like a magnet for water, pulling moisture right into your fuel system, which is the last thing you want. It's also known to break down older fuel lines that weren't built to handle it.

If your engine runs happily on non-ethanol fuel, stick with it. If you're in a pinch and have to switch, try to do it when the tank is almost on empty. And do yourself a favor—add a good marine fuel stabilizer to help head off any problems before they start.

What Do I Do If I Spill Fuel at the Dock?

First things first: stop the flow of fuel immediately. Don't even think about starting your engine or turning on any electronics.

Your very next move should be to alert the marina staff. They have the training and the right equipment to manage the situation safely.

Here’s what you need to do:

- Contain it. Grab absorbent pads to soak up the fuel floating on the water.

- No soap! Whatever you do, never use dish soap or any other detergent. It just breaks the fuel down into smaller droplets that sink, which makes the environmental damage a whole lot worse.

- Make the call. If the spill creates any visible sheen on the water, you're legally required to report it to the National Response Center.

You can stop spills before they even have a chance to happen. CLiX Fueling Solutions has a simple, brilliant device that automatically shuts off the fuel nozzle the second your tank is full. It completely takes the risk of messy, dangerous overfills off the table. Find out how to make fueling stress-free.