Your boat's fuel system is a whole lot more than just a tank that holds gas or diesel. I like to think of it as the boat's circulatory system—a vital network that stores, cleans, and delivers the energy you need for every trip out on the water. Getting to know how it works is the first step to making sure your boat is safe and performs at its best.

Why Your Boat's Fuel System Is Its Lifeline

On the surface, the job seems simple: get fuel from the tank to the engine. But the journey that fuel takes is anything but a straight line. It has to be kept clean from contaminants, vented properly to avoid dangerous pressure, and filtered to catch any gunk that could kill an engine.

This whole network is the unsung hero of every good day on the boat. When it’s all working right, you probably don’t even think about it. But if just one part fails—a cracked fuel line, a clogged filter, a bad vent—you're in for a world of hurt. We’re talking about everything from a stalled engine miles from shore to a dangerous fuel leak.

More Than Just a Gas Tank

A healthy fuel system is about more than just propulsion; it's about protection. Think about all the things it’s doing behind the scenes:

- Keeps Fuel Clean: Filters are like the system's kidneys. They pull out water, dirt, and other junk that can wreck sensitive engine components.

- Ensures Safety: Vents and tight seals are crucial for managing explosive fuel vapors, keeping them from building up in places like the bilge.

- Promotes Engine Longevity: By feeding your engine a steady, clean supply of fuel, the system helps it run smoother and last a whole lot longer.

You can see just how critical these systems are when you look at the bigger picture. With global maritime transport carrying over 80% of the world’s trade, the need for reliable marine fuel is only going up. In fact, the market is expected to jump from $140.619 billion in 2025 to $171.494 billion by 2030. You can dig into the numbers yourself in the global marine fuel market report.

"A well-maintained fuel system is the foundation of a dependable boat. Neglecting it is like asking for trouble when you can least afford it."

At the end of the day, understanding your boat fuel systems is a non-negotiable for any responsible owner. It’s what separates a passenger from a true captain who knows exactly what’s happening below deck. That knowledge gives you the confidence to handle maintenance, fix small problems, and make sure every trip is a safe one.

Exploring the Core Parts of a Boat Fuel System

To really get a feel for how your boat runs, you have to look past the engine and dive into the system that keeps it fed. All the different parts of a boat fuel system have to work together perfectly, storing, cleaning, and moving fuel where it needs to go. Think of it like a finely tuned pit crew—every member has a specific job, and if one person falters, the whole operation grinds to a halt.

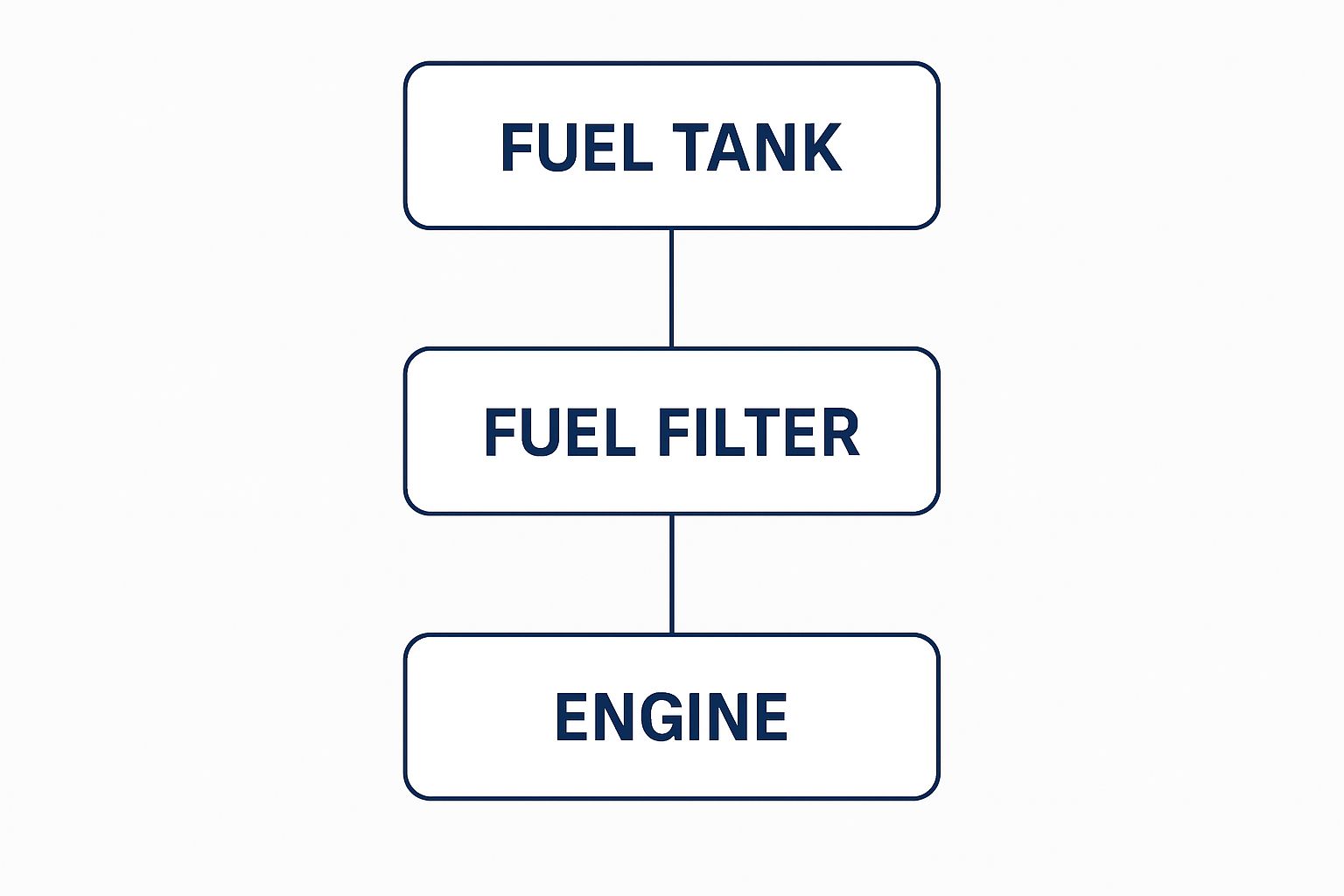

This simple graphic shows the basic path fuel takes from the tank to the engine.

As you can see, it's a straightforward journey. The filter stands as a critical guard, protecting the engine from what’s in the tank.

The Fuel Tank: The Reservoir

Everything starts with the fuel tank, where your gasoline or diesel is stored. These aren't just your average containers; marine fuel tanks are built tough to handle the constant motion, moisture, and temperature swings of life on the water. They’re typically made from high-density plastic, aluminum, or stainless steel, each offering different levels of durability and rust resistance.

Inside the tank, a fuel pickup tube sips fuel from the bottom, while a sending unit relays the fuel level to the gauge on your console. This setup ensures you always have a steady supply ready to go and, just as importantly, you know exactly how much you have left.

Fuel Lines: The Delivery Network

With the tank as the source, the fuel lines are the vital pipelines that get the fuel where it needs to go. These aren't just any old hoses. They are specifically engineered for safety and rated by the U.S. Coast Guard for fire resistance and their ability to contain fumes.

Different lines handle different jobs:

- Fuel Feed Lines: These carry fuel under pressure from the tank to the engine. In enclosed engine spaces, you'll need A1-rated lines for their superior fire resistance.

- Fuel Fill Lines: The wider hoses that run from the deck fill to the tank, making sure fuel goes in smoothly and safely.

- Vent Lines: These are crucial for letting air into the tank as fuel is used up and allowing vapors to escape. A clogged vent line is a classic culprit for an engine that stalls out from fuel starvation.

The Fuel Filter: The Engine's Bodyguard

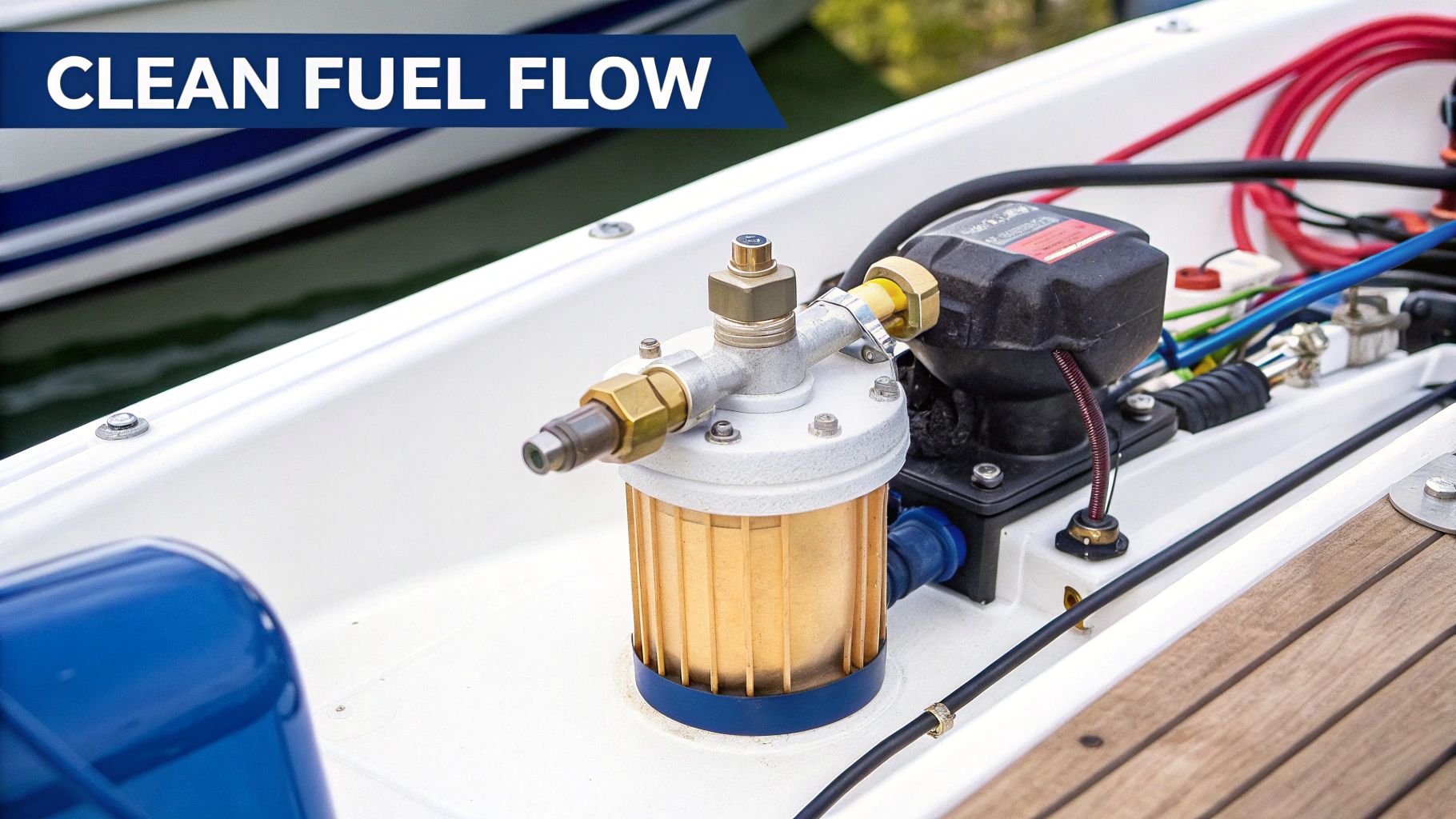

Before any fuel gets to the engine, it has to pass through the fuel filter. I always think of this as the engine's personal bodyguard. Its mission is to stop water, dirt, sediment, and that nasty microbial gunk from getting any further. Contamination is a huge issue in the damp marine world.

Most boats use a primary filter, usually a fuel-water separator, located between the tank and the engine. This is your first line of defense. There's often a smaller, secondary filter right on the engine for one last purification step before the fuel hits the injectors or carburetor. Keeping your filters clean is one of the most important things you can do for a healthy boat fuel system.

A clogged fuel filter is one of the biggest reasons for engine failure on the water. It only takes a tiny speck of debris to block a fuel injector and shut your engine down when you need it most.

Essential Supporting Components

A few other key parts keep the whole system running safely. You've probably used a primer bulb—that rubber squeeze bulb on outboard fuel lines that helps you manually pull fuel to the engine for an easier start. Another critical piece is the anti-siphon valve, which is required on most gas boats. It’s a safety device that stops fuel from leaking out if a line breaks.

Finally, the fuel pump is the heart of the operation, creating the pressure needed to push fuel from the tank, through the filters, and into the engine. Whether it's a mechanical pump driven by the engine or an electric one, it's what keeps the fuel flowing. For an even more detailed look, you can check out our comprehensive guide to the boat fuel system.

A Closer Look at the Key Components

Understanding what each part does is the first step toward good maintenance. Here’s a quick breakdown of the essential components, their jobs, and what to watch out for.

Key Components of a Boat Fuel System

| Component | Primary Function | Common Materials | Key Maintenance Tip |

|---|---|---|---|

| Fuel Tank | Safely stores the boat's fuel supply. | Polyethylene, Aluminum, Stainless Steel | Inspect annually for corrosion or damage; keep it at least partially full to reduce condensation. |

| Fuel Lines | Transport fuel and vapors between components. | Specialized Rubber, Plastic | Check regularly for cracks, stiffness, or soft spots; replace immediately if any damage is found. |

| Fuel Filter | Removes water and debris from the fuel. | Metal Housing, Paper Element | Replace according to the manufacturer's schedule, or at least once per season, to prevent clogs. |

| Fuel Pump | Pressurizes the fuel for delivery to the engine. | Metal, Composite | Listen for unusual noises; a whining pump may be a sign of impending failure. |

| Vent Line | Allows air to enter and vapors to exit the tank. | Specialized Rubber, Plastic | Ensure the vent opening is clear of debris or insect nests to prevent pressure issues. |

Keeping these parts in good shape isn't just about performance—it's about safety and peace of mind on the water. A little bit of preventative maintenance goes a long, long way.

Gasoline vs. Diesel Fuel Systems Explained

When you're looking at a boat, the choice between gasoline and diesel power goes way beyond just the engine. It shapes the boat’s entire personality and what it’s built to do. The boat fuel systems that feed these engines couldn’t be more different, each engineered specifically for the fuel they handle. Getting a handle on these differences is the first step to truly knowing your vessel.

I like to think of it as choosing between a sprinter and a marathon runner. A gasoline engine is the sprinter—it’s all about quick bursts of power, speed, and getting you on plane fast. On the other hand, the diesel engine is the marathon runner—built for endurance, steady power, and incredible efficiency over the long haul. Each of these athletes needs a completely different support system to perform at their peak.

The Gasoline Fuel System

Gasoline is a feisty fuel. It's highly volatile, and its fumes are incredibly flammable, which puts safety at the absolute top of the list for any gas fuel system. You’ll find these systems on most smaller recreational boats like runabouts, ski boats, and center consoles where zippy acceleration and high horsepower are the name of the game.

Because of the risk, every component has to be meticulously designed to prevent even the tiniest vapor leak. This isn’t just a suggestion; it's a requirement.

- You'll find anti-siphon valves that immediately stop fuel from pouring into the bilge if a line ever breaks.

- Anything in the engine bay that could create a spark, like the starter or alternator, must have ignition-protected components to avoid a disaster.

- The fuel lines themselves are special, usually A1-rated, which means they are highly fire-resistant and don’t let vapors escape—a must-have for enclosed engine spaces.

The way fuel gets to the engine is different, too. Gasoline engines typically use either carburetors or fuel injection systems that run at much lower pressures than their diesel cousins. The whole setup is designed to be lightweight and responsive, perfectly matching the high-revving, fast-paced nature of the engine it serves.

The Diesel Fuel System

Diesel is a different beast entirely. It’s far less volatile than gas but needs immense pressure to ignite, which results in a fuel system built for rugged power and durability. This is exactly why you see diesel engines in almost all larger vessels—from trawlers and sportfishers to large yachts and commercial boats where torque, range, and fuel economy are far more critical than getting a fast hole shot.

A diesel fuel system is noticeably more robust and, frankly, more complex. It operates under mind-boggling pressures, sometimes rocketing past 20,000 psi, just to atomize the fuel enough for combustion. This demands heavy-duty steel fuel lines and a seriously powerful high-pressure fuel pump.

One of diesel's biggest advantages is its lower volatility. This makes it a much safer fuel to store in large quantities on board, dramatically reducing the risk of an explosive vapor buildup. It’s a major reason diesel is the go-to for long-distance cruisers.

But diesel systems have an Achilles' heel: contamination. Water and microbial growth—the infamous "diesel bug"—are constant enemies. To combat this, diesel boat fuel systems are almost always equipped with a more sophisticated filtration setup, typically starting with a big primary fuel-water separator and followed by one or two secondary filters to protect the incredibly sensitive and expensive high-pressure injectors.

Comparing Key System Differences

The choice between gas and diesel really does impact everything, from how the boat performs on the water to how you maintain it. Here’s a quick rundown of how they stack up.

| Feature | Gasoline Fuel System | Diesel Fuel System |

|---|---|---|

| Primary Use | Smaller, high-speed boats (runabouts, ski boats) | Larger, long-range vessels (trawlers, yachts) |

| Safety Focus | Preventing explosive vapor leaks and ignition | Managing high pressures and preventing fuel leaks |

| Key Components | Anti-siphon valve, ignition protection | High-pressure pump, robust injectors, steel lines |

| Filtration Needs | Standard fuel filters are common | Advanced multi-stage filtration is critical |

| Operating Pressure | Lower (typically 40-60 psi) | Extremely high (often 20,000+ psi) |

At the end of the day, neither system is better than the other; they’re just engineered for completely different missions. Your gas-powered center console is built for fun, fast day trips. A diesel-powered trawler is built to cross oceans safely and efficiently. Understanding that core purpose helps you appreciate why your boat's fuel system is designed exactly the way it is.

Safe Fueling to Prevent Spills and Protect the Environment

https://www.youtube.com/embed/0PrgUOAG-fU

Refueling your boat might feel like a simple chore, but it’s one of the most critical moments you’ll face as an owner. One small mistake can lead to a dangerous fuel spill that damages your boat, pollutes the water, and poses a serious fire risk. Getting your fueling routine right isn't just about following rules—it’s about protecting your investment and the very waters you love to be on.

The whole process is loaded with potential hazards. When you pick up that fuel nozzle, you're dealing with a highly flammable liquid in a constantly shifting environment. One of the sneakiest dangers is static electricity. It can build up without you even noticing and discharge as a spark, which is all it takes to ignite fuel vapors with devastating consequences.

This is why proper technique is non-negotiable. Always, always keep the fuel nozzle in firm contact with your boat's fuel fill opening. This simple act creates a ground, preventing a static spark from ever having the chance to jump.

The Critical Role of Ventilation

Gasoline fumes are heavier than air. That’s a crucial fact to remember. Instead of floating away, they sink into the lowest parts of your boat, typically the bilge, creating an invisible, explosive pocket of vapor just waiting for an ignition source.

Proper ventilation is your best defense. Before you even think about turning the key after fueling, you have to get those fumes out.

- Open Everything Up: Pop open all hatches and portholes to let fresh air move through the entire boat.

- Run the Blower: Your bilge blower is an essential piece of safety equipment. Let it run for at least four to five minutes to actively pull fumes from the engine compartment.

- Trust Your Nose: Before starting the engine, do a quick "sniff test." Get down near the bilge and engine area. If you smell even a faint whiff of fuel, don't start that engine. Keep ventilating until the odor is completely gone.

Never underestimate the power of gasoline vapors. A single cup of spilled gasoline can create an explosive force equivalent to several sticks of dynamite when mixed with air in an enclosed space.

While preventing spills on your boat is paramount, it's also helpful to understand the general fire risks in vehicles. Broadening your safety knowledge helps build a more comprehensive and cautious mindset around any fuel-powered craft.

The Environmental and Financial Cost of Spills

A fuel spill is never just a simple mess. It’s a serious environmental problem with legal repercussions. Even a tiny amount of fuel can spread across a huge area of water, creating that tell-tale sheen that is toxic to marine life. You're legally required to report any spill that causes one.

The financial hit can be just as painful. Beyond any fines, the cost of fuel itself is a major expense. Owners of large superyachts might need over 50,000 gallons for a fill-up, pushing the fuel bill past $200,000. At those prices, every single spill is literally money poured into the water.

Modern Solutions for Spill-Free Fueling

For decades, boaters have relied on listening for a change in the gurgling sound from the fuel tank to guess when it's nearly full. It's an old, unreliable method and the number one reason for overfill spills at the fuel dock. Thankfully, we now have technology that takes the guesswork out of the equation.

Systems like CLiX Fueling Solutions are designed to make overfills a thing of the past. By creating a sealed, secure connection, these devices automatically shut off the fuel flow when the tank is full—just like the auto-shutoff feature on the pump at your local gas station. This technology prevents spills, stops toxic vapors from escaping, and makes the entire process remarkably stress-free.

This innovation turns a high-risk task into a clean, simple, and repeatable process. By removing human error from the equation, you protect your boat's finish, avoid harming the environment, and ensure every expensive drop of fuel gets where it belongs: in your tank. To build a truly solid safety plan, check out our guide on complete boat fueling safety.

Essential Maintenance and Troubleshooting Tips

When it comes to your boat, a reliable boat fuel system isn't something you can just set and forget. It needs consistent attention to stop small issues from becoming trip-ending disasters miles from shore. Think of proactive maintenance as your best insurance against engine trouble, making sure your boat is ready to go whenever you are.

This hands-on approach does more than just keep your engine humming; it protects you from the real dangers of a failing system. A few simple checks each season can save you a fortune in repairs and, more importantly, keep you safe out on the water.

Your Seasonal Maintenance Checklist

Before you kick off the boating season and right after you wrap it up, make a habit of running through these essential checks. This simple routine is the foundation of a healthy fuel system and will help you spot trouble long before it starts.

-

Inspect All Fuel Lines: Get in there and carefully check every inch of your fuel lines, from the tank all the way to the engine. You’re looking for any signs of cracking, brittleness, or spots that feel soft and mushy. A damaged fuel line is a serious fire hazard and needs to be replaced immediately.

-

Change Fuel Filters: Your fuel-water separator is the engine's main line of defense against gunk and water. Swap out the filter element at least once a season, or follow your engine manufacturer's advice. If you're sometimes forced to get fuel from questionable sources, you’ll want to change it even more often.

-

Check the Fuel Tank Vent: Find the tank vent on the outside of your hull and make sure it’s clear. It's a prime spot for dirt, debris, and even insect nests to build up. A blocked vent can create a vacuum in the tank, starving your engine of fuel and causing it to stall out at the worst possible time.

-

Treat Your Fuel: Today's fuels, especially those with ethanol, can go bad when left sitting. Always use a quality marine fuel stabilizer to stop water separation and prevent gunk from growing in your tank, which can clog up your filters and injectors.

Understanding and Maintaining Your Fuel Tank

The fuel tank is more than just a box that holds gas; it's where your entire system's health begins. Taking care of it is non-negotiable. For a much deeper dive, our boat fuel tank guide covers everything you need to know about choosing and maintaining this vital component.

One of the biggest culprits behind fuel problems is condensation. When a tank is only partially full, temperature swings cause water to form on the inside walls. This water sinks to the bottom, right where your fuel pickup is waiting to suck it into your fuel lines.

To fight condensation, try to store your boat with the fuel tank either almost full or nearly empty. A full tank leaves no room for moist air, while an empty one (properly fogged for winterization, of course) has no fuel to get contaminated in the first place.

This smart, proactive approach is right in line with where the marine industry is heading. In fact, marine fuel optimization technology is a booming sector, with its market size expected to jump from $12.01 billion in 2024 to $13.75 billion in 2025. These new technologies are all about boosting efficiency and cutting down on waste by giving boaters better monitoring and control over their fuel.

Quick Troubleshooting for Common Fuel Problems

When your engine starts sputtering or acting up, the fuel system is almost always the first place you should look. Here’s a quick-and-dirty guide to help you figure out what’s going on.

| Symptom | Potential Cause | What to Check First |

|---|---|---|

| Engine sputters or stalls | Fuel starvation or contamination | Check the fuel-water separator for water; inspect the tank vent for blockages. |

| Engine won't start | No fuel delivery | Squeeze the primer bulb. If it doesn't get firm, you might have a leak or a bad check valve. |

| Loss of power under load | Clogged fuel filter | The engine gets enough fuel to idle but chokes when you ask for power. Time to change the filter. |

| Strong smell of gasoline | Fuel leak | DANGER. Do not start the engine. Air everything out immediately and find the source of the leak. |

Having this knowledge lets you either handle the small stuff yourself or give a marine mechanic clear, accurate information to work with. A good description of the problem almost always leads to a faster, cheaper repair—getting you back on the water where you belong.

Answering Your Top Questions About Boat Fuel Systems

Even after you get the hang of how a boat fuel system works, questions are bound to pop up. Every boater, from the rookie to the seasoned sailor, runs into similar puzzles—from figuring out a maintenance schedule to diagnosing why the engine is acting strange. Getting solid, no-nonsense answers is the key to building confidence on the water.

This section gets right to the point, tackling the most common questions we hear from boat owners. We'll give you practical advice to help you solve problems and keep your vessel running like a dream.

How Often Should I Replace My Boat's Fuel Lines?

There's no one-size-fits-all answer here, but a good rule of thumb is to inspect your fuel lines every year and plan on replacing them every 5-10 years. The real-world lifespan really depends on the hose material and how much sun, heat, and fuel it’s exposed to.

Make sure you're always using USCG-approved hoses like Type A1-15 or B1-15, which are designed specifically for the tough marine environment. That said, the condition of the hose is far more important than its age. If you spot any of these red flags, replace the line immediately:

- Visible cracks or crazing on the surface.

- The hose feels unusually stiff or brittle when you bend it.

- You find soft, mushy, or swollen spots.

Putting off a fuel line replacement is a huge safety risk. A leak can cause a dangerous fuel spill or, far worse, a devastating fire.

What Is Fuel Polishing for Diesel Engines?

Think of fuel polishing as dialysis for your diesel fuel. It’s a proactive maintenance process that cleans the fuel while it’s still sitting in your tank. An external, high-powered filtration system circulates the fuel, pulling out water, sediment, and the nasty microbial growth often called the "diesel bug."

This is especially important for boats that sit idle for long stretches. When diesel fuel doesn't move, it’s a breeding ground for contaminants that can clog your filters and wreck sensitive, high-pressure injectors.

By polishing your fuel, you ensure it is pristine and ready for use, which is critical for reliability. It’s far better to remove contaminants in a controlled way at the dock than to have them clog your filters in rough seas.

Fuel polishing helps prevent sudden engine shutdowns and can save you from a massive repair bill for your fuel injection system. It's a smart move for any diesel boat owner who values dependability.

Can I Use Ethanol Fuel in My Marine Engine?

This is a classic "it depends" question. The answer really comes down to your boat's age and the design of its boat fuel systems. Most modern marine engines are built to handle gasoline with up to 10% ethanol (E10). For older boats, however, ethanol can cause some serious headaches.

Ethanol is hygroscopic, meaning it loves to absorb water right out of the air. This water can then separate from the gasoline and sink to the bottom of your tank, just waiting to get sucked into your engine. Ethanol is also a solvent, so it can break down older rubber fuel lines, gaskets, and even fiberglass fuel tanks, leading to leaks and system failures.

Here’s what you should do:

- Use ethanol-free gasoline whenever you can. It's the safest bet for any marine engine, no matter how old.

- If you have to use E10, always add a fuel stabilizer made to counteract ethanol's nasty side effects.

- Keep a close eye on your fuel system components for any signs of wear and tear if you regularly use E10.

What Should I Do If I Smell Gas on My Boat?

A strong gasoline smell is one of the most serious warnings you can get on a boat, and you need to act immediately and carefully. Gas fumes are heavier than air, so they sink and collect in the bilge—the lowest part of your boat—creating a ticking time bomb.

If you smell gas, follow these steps without skipping a beat:

- Don't Start Anything. No engine, no generator, no electrical devices. Don't even flick on a light or the bilge blower. A single spark is all it takes.

- Ventilate Immediately. Open every hatch, porthole, and canvas cover to get fresh air moving through the boat.

- Find the Source. Carefully trace the fuel system from the tank to the engine to find the leak. Common culprits are a cracked fuel line, a loose filter fitting, or a bad gasket on the fuel sending unit.

- Fix it Completely. Do not use the boat again until the leak is 100% repaired and the area is totally free of fumes.

Many common questions about boat fuel systems revolve around their components, especially the fuel tanks. For a deeper dive into specific details, you might find answers in these frequently asked questions about polyethylene tanks.

Tired of the stress and mess of overfill spills at the fuel dock? CLiX Fueling Solutions offers a simple, effective way to make every fill-up clean and safe. Our patented system provides a secure connection that automatically stops the flow when your tank is full, preventing dangerous and costly spills. Protect your boat, the environment, and your peace of mind by upgrading to a spill-free fueling experience. Learn more at https://clixfueling.com.