Emergency Response Fundamentals That Save The Day

When a fuel spill happens, the initial response is critical. These first few actions will often determine the scale of the incident and how effective the cleanup will be. Think of it as a medical emergency: quicker and more accurate initial actions greatly improve the chances of a full recovery. This involves a systematic approach, including assessment, security, and communication.

Initial Assessment and Security

Experienced response teams immediately assess the spill's severity. This means identifying the type of fuel, estimating the quantity spilled, and observing the surrounding environment. A diesel spill near a waterway, for example, demands a different approach than a gasoline spill on a paved road.

Securing the area is the next crucial step. This involves establishing a safe perimeter to protect people from fumes and stop the spill from spreading further. Much like a doctor isolates an infected wound, response teams contain the spill to limit its impact.

Communication and Regulatory Notification

Clear communication is essential throughout the entire response. Response teams contact relevant authorities, including local fire departments, environmental agencies, and, if needed, national response organizations. This prompt notification ensures everyone involved knows the situation and can work together effectively.

Understanding the required fuel spill cleanup procedures dictated by regulations is also vital. The fuel spill containment market provides important context. As of 2023, this market was valued at roughly USD 1.4 billion and is projected to reach about USD 2.3 billion by 2032. This growth highlights the importance of containment as a preventative measure against environmental damage.

Avoiding Common Mistakes

One frequent mistake is underestimating a spill's potential impact. Even small spills can have major consequences if not addressed correctly. Another pitfall is delaying notification of the proper authorities. Timely reporting is essential for effective coordination and regulatory compliance. Finally, failing to secure the area properly can expose both people and the environment to unnecessary risks.

These initial actions form the foundation of a successful cleanup. By prioritizing assessment, security, and communication, response teams can effectively manage the situation and pave the way for a controlled and efficient cleanup operation.

Containment Strategies That Actually Work

Containing a fuel spill effectively is paramount. It minimizes environmental damage and protects public safety. This involves a strategic approach tailored to the specific circumstances, not just using absorbent materials. Like a surgeon isolating an area before operating, response teams must consider the fuel type, terrain, and weather conditions.

Barrier Selection and Deployment

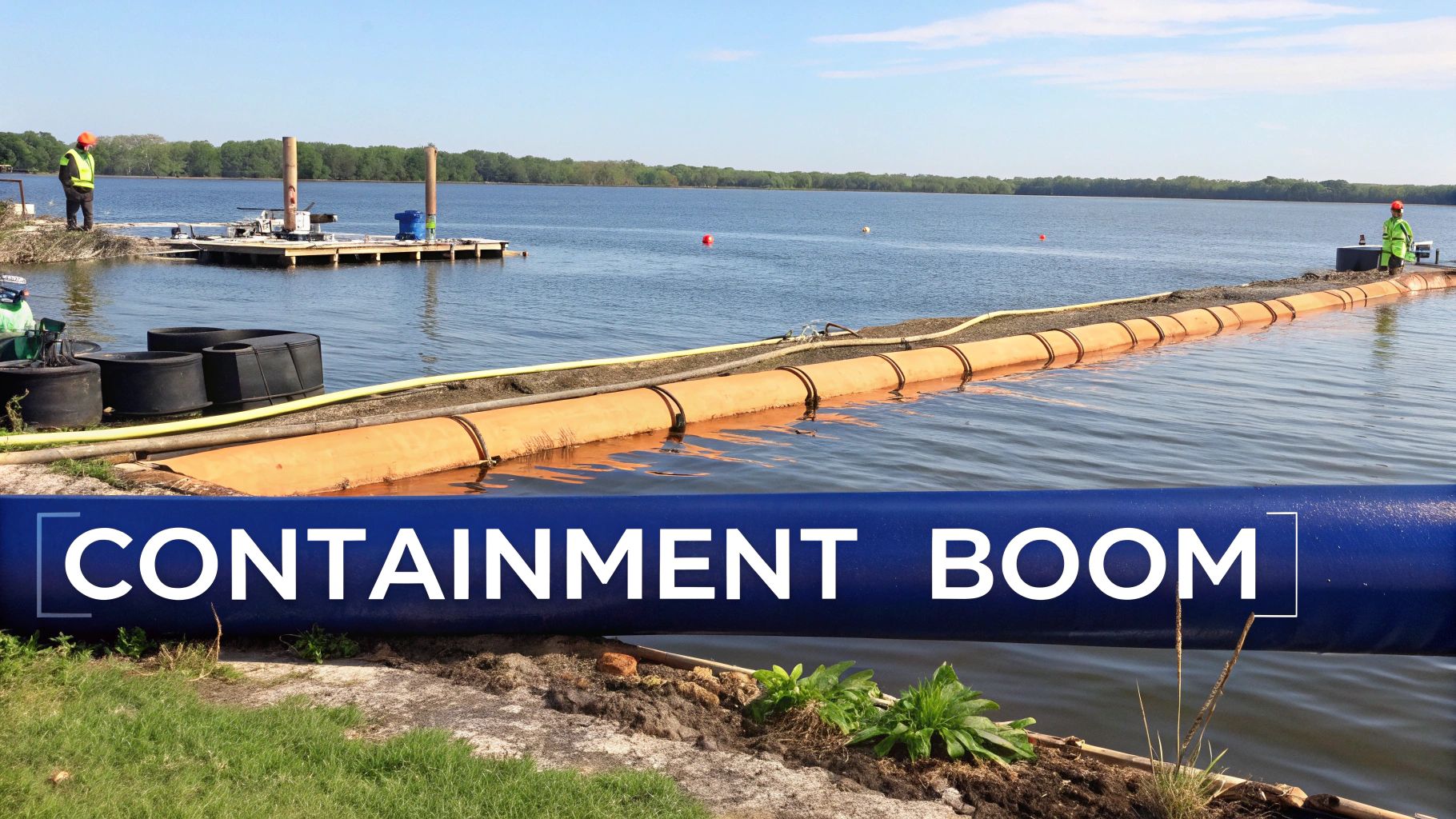

Choosing the right containment barriers is the first crucial step. Absorbent booms work well for spills on calm water surfaces. However, they might be less effective on land or in fast currents.

For challenging situations, advanced systems like polymer-based barriers may be necessary. These barriers adapt better to different terrains.

The infographic above highlights the importance of proper safety gear. Essential items include protective gloves, goggles, and a respirator. This gear minimizes exposure to hazardous materials and ensures worker safety during cleanup.

Establishing Effective Perimeters

After selecting the right barriers, response professionals strategically deploy them. This establishes an effective perimeter, the first line of defense against further migration. Think of it like building a dam to control floodwaters, redirecting the flow and preventing widespread damage.

Experienced teams consider several factors. Flow rates, soil permeability, and the proximity to water sources all play a role in establishing the perimeter.

Adapting to Changing Conditions

Fuel spill cleanup requires flexibility. Weather changes can significantly impact containment. Heavy rain can overwhelm barriers, and strong winds can spread fumes beyond the perimeter.

Response teams must continuously monitor and adapt. They may need to reinforce barriers, add more containment measures, or relocate the perimeter.

Let's take a look at the various containment methods available. The table below compares different strategies based on their best use cases, deployment time, effectiveness, and cost.

Fuel Spill Containment Methods Comparison

| Containment Method | Best For | Deployment Time | Effectiveness Rating | Cost Factor |

|---|---|---|---|---|

| Absorbent Booms | Calm water surfaces | Fast (minutes) | High for small spills, low for large or fast-moving spills | Low |

| Polymer-based Barriers | Land, uneven terrain, fast currents | Moderate (hours) | High | Medium |

| Containment Walls (metal or plastic) | Flat surfaces, channeling spills | Moderate to slow (hours to days) | High for controlled environments | High |

| Earthen Dams | Redirecting flow on land | Slow (days) | Medium, dependent on soil stability | Low to medium |

| Vacuum Trucks | Removing liquid spills from various surfaces | Fast for collection, slow for complete cleanup | High for removing bulk liquid | High |

This table summarizes various containment methods. Each method offers unique advantages and disadvantages based on the specific spill scenario. Choosing the right method is crucial for effective containment.

Equipment Limitations and Timing Decisions

Having the right equipment is vital, but understanding its limitations is equally important. Booms, for instance, have a finite absorption capacity. Deployment timing is also key. Delaying containment, even briefly, can allow the spill to spread, increasing cleanup difficulty and cost. Effective containment requires a rapid response and a well-defined procedure that addresses all potential challenges. This minimizes environmental impact and manages cleanup costs.

Cleanup Procedures That Match Your Fuel Type

Not all fuel spills are the same. Just as different medical conditions require different treatments, fuel spill cleanup needs to be tailored to the specific type of fuel. Understanding the properties of gasoline, diesel, aviation fuel, and heating oil is crucial for worker safety and effective remediation.

Gasoline Spill Cleanup

Gasoline is highly volatile, meaning it evaporates quickly, creating dangerous fumes. This requires immediate action, focusing on vapor control and proper ventilation for workers. Gasoline also spreads rapidly, so quick containment using absorbent booms or barriers is essential. For more information, check out this helpful resource: How to master gas spill cleanup. Often, bioremediation, using microorganisms to break down the fuel, is used for soil cleanup.

- Key Considerations: Vapor control, rapid containment, soil contamination.

- Best Practices: Vapor monitoring, absorbent materials, bioremediation for soil.

Diesel Spill Cleanup

Diesel spills present different challenges. Diesel is less volatile than gasoline, posing less immediate danger from fumes. However, its thick, viscous nature makes it difficult to contain and clean up. Diesel also persists in the environment longer, potentially contaminating soil and water. Mechanical removal, such as excavation or vacuuming, is often necessary, along with chemical treatments.

- Key Considerations: Environmental persistence, difficult removal, long-term contamination.

- Best Practices: Mechanical removal methods, specialized cleaning agents, groundwater monitoring.

Aviation Fuel and Heating Oil Spill Cleanup

Aviation fuel and heating oil spills share some similarities. Both require careful consideration of their unique properties. Aviation fuel’s high flash point is a major safety factor, while heating oil's tendency to solidify in cold weather means cleanup needs to happen quickly.

- Key Considerations: Specific fuel properties impacting safety and cleanup.

- Best Practices: Adapting procedures to the fuel and environmental conditions.

Adapting to Unique Circumstances

Standard procedures provide a good starting point, but real-world spills often require a flexible approach. Factors like terrain, weather, and proximity to sensitive areas (like waterways) influence cleanup methods. For instance, spills near water require extra containment measures to protect aquatic life. This highlights the need for trained professionals who can assess each situation and adapt procedures while prioritizing environmental protection.

| Fuel Type | Primary Concerns | Cleanup Approach |

|---|---|---|

| Gasoline | Volatility, rapid spread | Vapor control, rapid containment, absorbent materials |

| Diesel | Persistence, viscosity | Mechanical removal, specialized cleaning agents |

| Aviation Fuel | High flash point | Adapted procedures based on specific properties |

| Heating Oil | Solidification, viscosity | Adapted procedures based on specific properties |

This table summarizes key concerns and common cleanup approaches for various fuel types. Remember, each spill is unique and requires a tailored response plan.

Advanced Technologies Transforming Cleanup Operations

The fuel spill cleanup industry is constantly changing. New technologies are improving the speed, efficiency, and safety of cleanup procedures. These changes aren't just small steps forward. They represent a major shift in how spills are handled. For instance, automated response equipment is reducing human exposure to dangerous materials. This is a vital safety improvement.

It allows for faster initial responses and minimizes the risks faced by cleanup crews.

Bioremediation and Nanotechnology: Nature-Inspired Solutions

Bioremediation uses microorganisms to break down pollutants. It’s a process that's becoming increasingly sophisticated. Scientists are developing specialized microbes that can target specific types of fuel. This leads to more effective and environmentally friendly cleanup. Nanotechnology also provides exciting possibilities.

Imagine tiny, microscopic sponges designed to absorb specific fuel molecules. These sponges would leave other substances untouched. This level of precision allows for targeted cleanup and reduces waste.

Remote Monitoring and Data Analytics: The Power of Information

Real-time data is changing how we respond to fuel spills. Remote monitoring systems offer continuous information about the spill. They track its size, location, and movement. This constant flow of information allows response teams to adjust their strategies quickly. It also helps them use resources more efficiently.

Data analytics and predictive modeling are also becoming essential. By analyzing past spill data, weather patterns, and other factors, response teams can better predict a spill's behavior. This lets them optimize resource allocation, minimize cleanup time, and reduce costs. The oil spill management market, which includes cleanup procedures, is growing significantly.

This growth is due to increasing environmental concerns and regulatory pressure. In 2024, the market was valued at $149.93 billion. It's predicted to reach $156 billion in 2025, a 4.0% Compound Annual Growth Rate (CAGR). This growth is driven by advancements in detection, cleanup methods, and data integration. Learn more about this at Oil Spill Management Market Trends.

Emerging Innovations: A Glimpse into the Future

Several promising technologies are on the horizon. Autonomous robots equipped with sensors and cleanup tools can access difficult areas. This further reduces the need for human involvement. Advanced imaging techniques, like hyperspectral imaging, can quickly and accurately assess contamination levels. This even works below the surface.

These emerging innovations have the potential to transform fuel spill response. They will likely set new standards for cleanup procedures in the coming years.

Safety Protocols That Protect Your Team

Keeping your team safe during fuel spill cleanup requires careful planning and the right personal protective equipment (PPE). These protocols are crucial for preventing injuries and ensuring everyone's well-being, just like a surgeon meticulously prepares for an operation. It all starts with a thorough hazard assessment.

Hazard Assessment and Perimeter Establishment

Before any cleanup begins, assess the type of fuel, the spill size, and the surrounding environment. This information will determine the necessary safety measures. Establishing a safety perimeter is crucial for controlling the spread of fumes and preventing unauthorized access. This perimeter acts as a barrier, much like a quarantine zone contains the spread of a disease. For further information on preventing spills, consider reading this article: How to prevent marine pollution.

Air Monitoring and PPE Selection

Air monitoring is essential for identifying and measuring fuel vapor concentrations. This helps determine the appropriate respiratory protection. Selecting the right PPE is vital. The type of fuel spilled will influence the appropriate gloves, eye protection, and respirators. For some spills, basic respirators might be enough. Others may require full chemical suits for complete body protection.

Managing Common Hazards

Slip and fall hazards are common during fuel spill cleanups. Spilled fuel, combined with water and cleaning agents, creates slippery surfaces. Providing non-slip footwear and using absorbent materials are essential precautions. Vapor exposure is another serious risk. Continuous air monitoring and proper respiratory protection minimize inhalation risks.

Equipment-related injuries, such as those from pumps and hoses, can also occur. Proper equipment training and regular maintenance checks are vital. Furthermore, the global oil spill cleanup and remediation market is constantly evolving, driven by strict environmental regulations and growing public awareness. The use of advanced technologies like big data analytics and remote sensing is also important for future market growth. Learn more about this evolving market here. By implementing these safety protocols, fuel spill cleanup can be conducted effectively while protecting everyone involved.

Regulatory Compliance That Protects Your Organization

Navigating the regulatory landscape after a fuel spill can be daunting. Understanding the priorities of inspectors and agencies simplifies compliance. This section breaks down key federal, state, and local requirements governing spill response and cleanup, with a focus on documentation and reporting. When developing safety procedures, remember to consider the specific resources available to first responders, like those detailed in this guide on First Responder Benefits.

Understanding Regulatory Priorities

Regulatory bodies prioritize public safety and environmental protection. They want assurance that all necessary steps were taken to minimize harm. This requires meticulous documentation and prompt reporting. These aren't simply bureaucratic obstacles; they're essential for demonstrating responsible action and avoiding significant penalties.

Maintaining Compliance Records

Maintaining organized records is crucial. Document every stage of the fuel spill cleanup, from initial assessment to final site clearance. This comprehensive record should include the date and time of the spill, the type and quantity of fuel released, the containment and cleanup methods employed, and the disposal procedures for contaminated materials. Think of it as a detailed chronicle of the entire process.

Managing Inspector Relationships

A positive working relationship with inspectors is invaluable. Open communication and transparency are key. Be prepared to answer questions thoroughly and provide access to all necessary documentation. For further guidance on cleanup procedures, consider this resource: How to master gas spill cleanup procedures. A proactive approach demonstrates your commitment to compliance and can prevent misunderstandings.

Reporting Timelines and Documentation Formats

Different agencies have varying reporting requirements. Some mandate immediate notification, while others provide a short reporting window. Understanding these timelines is critical. Similarly, agencies often have specific documentation preferences. Some require electronic submissions, while others accept paper copies. Knowing these preferences in advance streamlines the process and avoids delays.

Avoiding Common Compliance Pitfalls

Inadequate documentation and missed reporting deadlines are common pitfalls. These oversights can result in substantial fines and legal ramifications. For instance, failing to report a spill within the designated timeframe can result in penalties of thousands of dollars per day. A well-organized system for tracking deadlines and ensuring comprehensive documentation helps prevent these costly errors.

The following table summarizes key regulatory milestones and required documentation:

Regulatory Timeline and Documentation Requirements

Key regulatory milestones and required documentation for fuel spill cleanup compliance

| Timeline | Required Action | Documentation Needed | Responsible Agency | Penalties for Non-Compliance |

|---|---|---|---|---|

| Immediately | Notify relevant authorities (fire, police, EPA) | Initial Spill Report, Incident Log | Varies by Location | Fines, Legal Action |

| Within 24 hours | Submit detailed spill report | Spill Volume, Containment Measures, etc. | Varies by Location | Fines, Legal Action |

| Ongoing | Regular updates on cleanup progress | Remediation Plan, Disposal Records | Varies by Location | Project Delays, Fines |

This table offers a general overview. Always consult your specific local and state regulations. Prioritizing regulatory compliance protects your organization from legal and financial risks, demonstrating a commitment to responsible environmental stewardship.

Key Takeaways

Effective fuel spill cleanup procedures are more than just a set of rules; they're a vital commitment to safety, environmental responsibility, and operational efficiency. This section highlights key takeaways from successful cleanup operations, providing a practical guide to improve your response capabilities. Building a robust spill response program requires proactive planning, thorough training, and continuous improvement.

Building a Prepared and Responsive Team

Preparation is the foundation of any effective response. This starts with comprehensive training programs that go beyond the basics. Your team needs hands-on experience with different spill scenarios, fuel types, and cleanup equipment. Regular response drills are essential for reinforcing training and pinpointing areas for improvement. Think of these drills like fire drills for fuel spills – they build muscle memory and ensure everyone knows their role in an emergency.

Maintaining equipment readiness is also critical. Regular inspections, maintenance, and calibration guarantee your equipment performs reliably when you need it. Just as a surgeon depends on sterile instruments, your team needs reliable tools to execute the cleanup effectively. Establishing vendor relationships beforehand streamlines procurement and ensures quick access to necessary resources.

Implementing Effective Procedures and Measuring Success

Developing clear, concise, and easy-to-understand fuel spill cleanup procedures is essential. These procedures should be tailored to your specific work environment, considering the types of fuel handled, potential spill locations, and environmental sensitivities. Regularly updating procedures based on lessons learned from drills and actual incidents ensures your response remains relevant and effective. Think of this like updating software – regular updates address bugs and improve performance. Protecting your assets is also important for regulatory compliance. Explore asset protection insurance strategies for more information on safeguarding your organization.

Measuring cleanup effectiveness isn't just about finishing the job; it’s about continually improving. Tracking key metrics, such as response time, containment success, and waste generated, provides valuable data for identifying areas for optimization. Establishing performance benchmarks and regularly reviewing them allows you to track progress and demonstrate a commitment to responsible spill management. This data-driven approach enables proactive adjustments and reinforces a culture of continuous improvement.

Practical Steps for Immediate Implementation

Here are some actionable steps you can take right now to strengthen your fuel spill cleanup procedures:

- Develop a comprehensive training program that includes hands-on exercises and regular drills.

- Create a detailed equipment checklist for regular inspections and maintenance.

- Establish pre-negotiated contracts with cleanup vendors and suppliers.

- Develop and regularly review spill response procedures specific to your facility.

- Implement a performance tracking system to measure cleanup effectiveness and identify areas for improvement.

By incorporating these key takeaways and practical steps, you can shift your fuel spill response from reactive to proactive, minimizing environmental impact, protecting your team, and ensuring regulatory compliance.

Ready for a truly spill-free fueling solution? Visit CLiX Fueling Solutions today and see how their innovative automatic shutoff system can transform your boating experience.