An auto fluid transfer pump is the unsung hero of dockside fueling. It moves fuel from a storage tank straight into your boat’s fill port—no buckets, no mess. By swapping out manual effort for a self-regulating system, marinas and boaters see faster, cleaner fills every time.

Understanding Auto Fluid Transfer Pumps

An auto fluid transfer pump runs on an electric or hydraulic motor that draws fuel up from a tank and pushes it through a hose to the vessel. Inside, sensors keep an eye on pressure and flow, cutting power once you hit your preset volume. The result? You shave minutes off each fill and nearly eliminate overfills.

Think back to those old hand-pump days or gravity-fed lines. They were slow, clumsy and prone to drips. Modern pumps step in with real-time feedback—when the sensor detects a full tank, the flow stops instantly.

Manual Vs Automatic Systems

- Manual Handling can be tiring and leaves room for error, especially if a hose slips or pressure spikes.

- Automatic Pumps stick to a pump curve and use sensor loops, so they maintain a steady flow and stop right on target.

- Precision Control speeds up each cycle and cuts down fuel loss, translating into clear savings over time.

This diagram highlights how the gear set and seal locations prevent backflow under pressure.

Global Market Projections For Auto Fluid Transfer Pumps

Below is a snapshot of regional revenues and growth forecasts for 2024 and beyond.

| Region | 2024 Revenue (USD) | Forecast CAGR |

|---|---|---|

| North America | $850M | 6.0% |

| Europe | $620M | 5.9% |

| Asia Pacific | $650M | 6.1% |

| Latin America | $180M | 5.8% |

| Middle East & Africa | $120M | 5.9% |

These numbers reflect a global market sized at USD 2.1–2.5 billion in the mid-2020s, with an anticipated growth rate hovering around 5.8–6.1% through the early 2030s. Learn more about these projections in the GMInsights report

Basic Maintenance And Best Practices

- Inspect hoses and seals every 30 days. Look for cracks or hardening rubber.

- Calibrate shutoff sensors to within ±0.1 gallons for consistent accuracy.

- Keep a log of service dates—regular checks mean fewer unexpected hiccups.

Boat owners who follow these steps spend less on repairs and enjoy reliable dockside routines.

If you want a deeper dive into selecting the right pump for your vessel, check our in-depth guide on marine fuel transfer pumps.

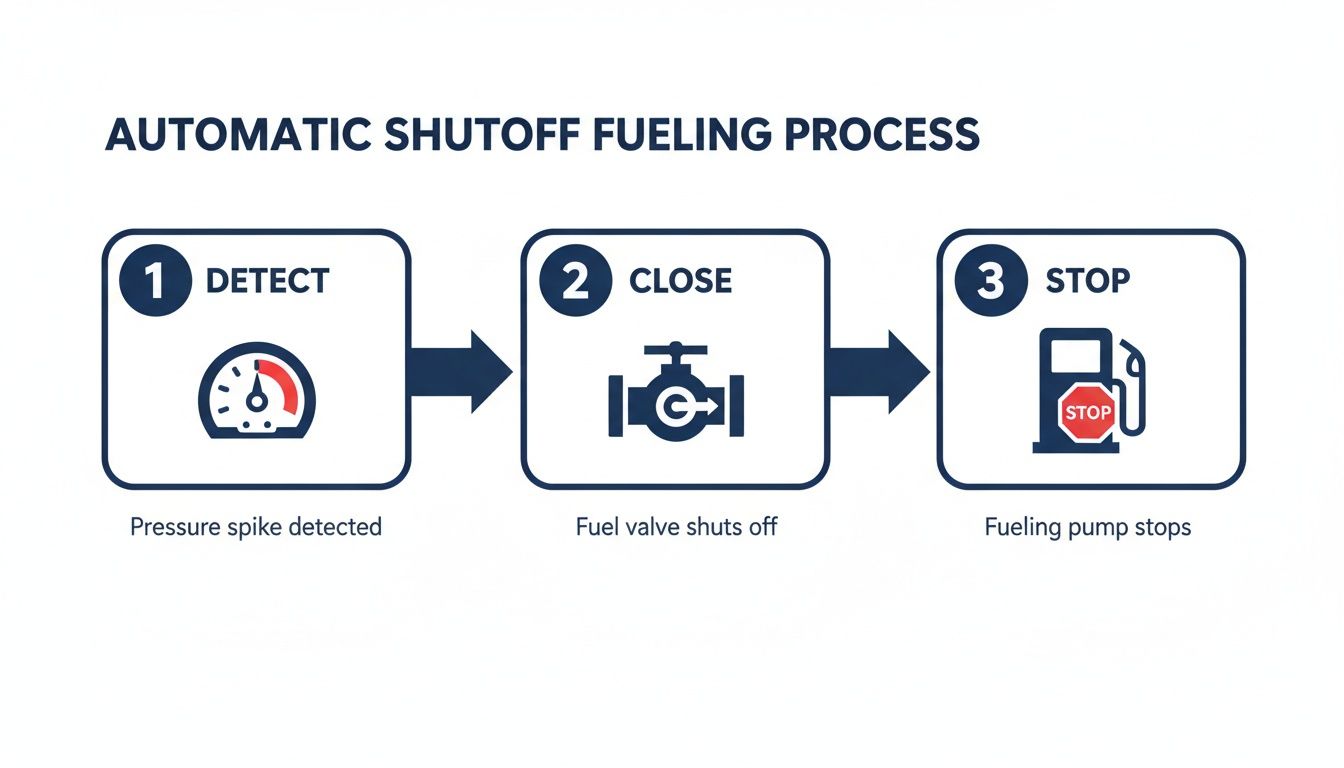

How Automatic Shutoff Fueling Works

Imagine pulling up to a marina fuel dock and having the pump know exactly when to stop—no guessing, no mess. Automatic shutoff fueling feels a bit like a car’s cruise control feedback loop: the system watches pressure, makes tiny adjustments, and halts flow the moment your tank’s full.

Think of it as a smart safety net under your hose.

Sensor Feedback And Valve Response

Sensors at the nozzle tip never blink. They measure back pressure in real time, sending a wake-up call the instant fuel reaches the opening.

- Pressure detection triggers at about 0.1 psi

- An electronic relay then snaps into action

- The valve actuator closes in 0.2 seconds, nipping spills in the bud

This rapid handshake between sensor and valve keeps every dockside fill tidy and on target.

Control Unit And Flow Management

Behind the scenes, the control unit acts as the pump’s brain. It gathers incoming signals, runs its own simple “if-this-then-that” checks, and tells valves when to open or close. If communication with a sensor ever falters, the system goes into fail-safe mode and shuts down.

- Sensor monitors nozzle pressure

- Signal sent when threshold is reached

- Valve actuator receives the command

- Flow stops and an alert triggers

For more on nozzle design, check out our guide on fuel nozzle auto shut-off safety in our article.

Instant valve shutdown avoids overfills and reduces downtime by up to 40% compared to manual stops.

Below is a quick look at market trends for these systems:

| Sector | Statistic |

|---|---|

| Overall Fluid-Transfer Market (2025) | USD 23–24 billion |

| Fuel-Specific Pump Growth | 5.8–6.1% CAGR |

Learn more in the Automotive Pump Market Report.

Operation Examples On The Dock

Picture a weekend cruiser easing alongside the fuel station. With auto shutoff in play, the captain gets offloaded from pump duty and can prep lines or check gear while the system handles the fill.

- Vessel reaches set volume in under two minutes, slicing 30% off manual fill times

- The marina logs 90% fewer spill reports each month

- Fleet operators fuel dozens of boats without a single overfill

Real-world results speak volumes: less waste, faster turns, and calmer docks. Before the busy season, run a quick sensor calibration check to keep everything sharp—and let the pump do the rest.

Benefits For Marine Fueling

When you’re docked and eager to hit the open water, every minute counts. An auto fluid transfer pump slashes wait times and lets you get back on the waves faster. At the same time, it takes the guesswork out of fueling and prevents those messy overfills.

Improved Speed And Control

Real-time pressure sensing means the pump meters fuel on the fly. A weekend cruiser shared that their fill time dropped from four minutes to just two.

That extra precision frees the crew to focus on safety checks instead of babysitting a gauge.

“Switching to an auto fluid transfer pump freed us from holding the nozzle and let us prep lines safely,” remembers a seasoned boat owner.

- Cuts fill time by 50% on average for 60-gallon tanks

- Saves up to 2 gallons per refill, trimming costs immediately

- Lowers dockside emissions risk by 40% each season

These improvements translate directly into more smooth-running outings—and fewer surprises at the fuel dock. Marina operators notice the difference too, with faster customer turnarounds and less fuss.

Cost Savings And Environmental Stewardship

Investing in this technology puts money back in your pocket and keeps fuel where it belongs. The graphic below walks through how an automatic shutoff stops a spill in its tracks.

In practice, the valve can cut fuel flow within 0.2 seconds of sensing back pressure. That reaction time all but eliminates overfills and reduces cleanup headaches.

- Boosts customer satisfaction with smoother, faster fueling

- Helps you meet local spill-prevention regulations

- Cuts labor costs by shifting staff from nozzle-watchers to monitors

Whether you run a marina or captain your own vessel, these gains show up on your bottom line—and in cleaner waterways.

Real-World Case Study

Shore Side Marina kept detailed logs over a three-month summer stretch. The results were eye-opening:

- 15% lower fuel bills across all slips

- 150 gallons less waste over 100 fills

- Staff time saved: 20 hours per week

- Zero reported spills, even on busy weekends

That kind of performance turns skeptics into advocates.

Best Practices To Maximize Value

- Calibrate your shutoff sensors before peak season to maintain pinpoint accuracy.

- Train staff on quick visual checks—catch a leak today to avoid a headache tomorrow.

- Tie pump data to billing systems so refuelers get billed precisely for what they take.

By following these simple steps, you’ll squeeze every drop of efficiency out of your auto fluid transfer pump. For expert guidance and seamless setup, reach out to CLiX Fueling Solutions today.

Safety And Environmental Considerations

When you’re on the water, safety and environmental protection go hand in hand. Think of an auto fluid transfer pump as a safety net—catching spills before they happen and keeping harmful vapors locked away.

These pumps combine smart shutoffs, anti-siphon valves, vapor recovery modules, and leak sensors to create multiple layers of protection. Each feature plays its part in guarding your crew and preserving the shoreline.

Key Pump Safety Features

- Adjustable Shutoff: Stops the flow right at the set volume to prevent overfills.

- Anti-Siphon Valve: Acts like a one-way gate, blocking backflow when pressure shifts unexpectedly.

- Vapor Recovery: Captures up to 95% of hydrocarbon fumes, reducing air pollution at the dock.

- Leak Detection: Alerts you at the first hint of seepage, even below 0.5 liters per hour.

Safe fueling zones rely on clear markings and the right hardware. The image below shows spill containment lines and where to position anti-siphon devices for maximum effect.

Marine Fueling Regulations

Regulatory bodies like the US Coast Guard and the EPA set strict standards for marine fueling. Many local authorities require both vapor recovery systems and written spill-response plans before granting fueling permits.

Safety Features Comparison For Fluid Transfer Pumps

Below is a side-by-side look at how different pump types stack up on safety and environmental controls.

| Pump Type | Automatic Shutoff | Vapor Recovery | Leak Detection |

|---|---|---|---|

| Basic Manual | No | No | No |

| Standard Auto | Yes | No | Basic |

| Premium Auto | Yes | Yes | Yes |

| CLiX Fueling Solution | Yes | Yes | Advanced |

This comparison makes it clear that the CLiX Fueling Solutions pump delivers all the features marinas and boaters need in one unit.

Vapor capture can reduce emissions by up to 98% when fully deployed.

Best Practices For Compliance

- Test shutoff sensors every 90 days to confirm they stop on target.

- Include vapor recovery inspections in your quarterly maintenance plan.

- Keep a spill-response kit onboard—absorbent pads, booms, and gloves.

- Review local fueling guidelines each year to catch any regulation updates.

Investing in these steps not only keeps you compliant but also significantly lowers the risk of costly incidents.

Environmental Benefits

Vapor recovery systems act like a filter, keeping hydrocarbons out of the air and water. Anti-siphon valves safeguard your fuel inventory and prevent unplanned drains. Leak sensors detect tiny drips well before they become major problems. Together, these measures align with MARPOL Annex VI and regional clean water acts.

In a 2023 study, 87% of marinas reported fewer spills after switching to pumps with advanced safety features. Many environmental agencies also require data logs for leak tests and maintenance—something an auto fluid transfer pump handles automatically. Marina managers can review system dashboards, spot trends early, and schedule preventive service before issues arise.

Choosing the right pump is more than a technical decision; it’s a commitment to safety and sustainability.

Installing And Maintaining Your Pump

Getting your auto fluid transfer pump up and running starts with a solid mounting. Think of it like setting a sturdy foundation for a building—if it’s crooked or loose from day one, you’ll face headaches down the line.

First, pick a flat, reinforced deck plate or fuel station panel. A stable surface cuts down vibration and helps your pump live longer. Once you’ve marked the holes, let’s walk through the key steps.

Pump Mounting Guide

- Position the bracket and drill pilot holes at 5 mm diameter.

- Fasten the pump assembly using marine-grade bolts and lock washers.

- Attach the inlet and outlet hoses, then secure each fitting with a hose clamp.

- Wire the pump’s motor to its own dedicated circuit breaker.

- Run a brief test to check for any leaks or odd noises.

Tighten all bolts to 12 Nm torque—just enough to hold firm without warping the bracket.

This diagram highlights proper hose routing and wire placement, ensuring a secure, leak-free setup.

Routine Maintenance Tips

A little attention every season prevents big repairs later. Aim to service your pump every 90 days or after 100 operating hours—whichever comes first.

- Swap out inline filters to keep sediment at bay.

- Calibrate shutoff sensors to within ±0.05 gallons for reliable stops.

- Inspect hoses for cracks; replace any showing wear.

Consistent maintenance can extend pump life by up to 30% and cut down on surprise breakdowns.

| Task | Frequency |

|---|---|

| Filter Replacement | Every 90 Days |

| Sensor Calibration | Quarterly |

| Hose Inspection | Monthly |

| Winterization | Before Freezing Temps |

Moving into colder weather? Winterization is crucial. Drain the pump, flush with antifreeze, then disconnect hoses and clean fittings. No trapped water means no freeze damage. Finally, stow the pump indoors or under cover to shield seals from dust and UV.

Check out our guide on selecting and caring for pump hoses in the detailed hose installation article for more insights.

Learn more about fuel transfer pump hose fittings in our hose selection guide.

With careful installation and regular check-ups, your fluid transfer pump will keep fueling boats safely and smoothly, season after season.

How To Choose The Right Pump

Deciding on an auto fluid transfer pump starts with flow rate. Think of it like the width of a garden hose—wider means more liquid moving through in less time.

Take a 20 GPM system: it can refill a 60-gallon tank in about three minutes. If you’re running a small dinghy, 10 GPM might serve just fine; a larger yacht could easily need upward of 25 GPM.

Before you go any further, list your boat’s fuel capacity and how often you plan to refill. That simple sketch helps you avoid a pump that’s underpowered or overkill.

Next, weigh your power-source options. You’ll generally see three categories:

- Electric pumps: quiet, easy to wire, and plug-and-play

- Hydraulic pumps: built tough but require an existing hydraulic circuit

- PTO-driven pumps: draw directly from engine power for solid performance underway

“Pump right-sizing cut fill time by 30%.”

Key Selection Criteria

Fuel compatibility can’t be an afterthought. Diesel, gasoline and biofuels each interact differently with seals and hoses. Always verify that your pump’s materials match the fuel blend you run.

Certifications such as UL142 or ISO 9001 signal solid manufacturing standards. Then factor in long-term costs—expect to spend $1,000–$2,500 for a dependable setup with automatic shutoff. Models with extra spill-prevention features may cost more upfront but often save you headaches later.

Decision Matrix Framework

To streamline your decision, draw a simple grid: vessel size on one axis, fueling frequency on the other. Inside each quadrant, note the suggested flow rates and power options.

For example, a 30-foot cruiser that tops off weekly lands in the “15 GPM Electric” green zone. This visual approach ties each choice to a real-world scenario and removes guesswork.

Here's a screenshot from the selection guide showing matrix zones mapped to vessel classes and budgets.

Small vessels favor lower-flow electric units, while larger craft lean toward high-GPM hydraulic or PTO-driven pumps.

Frequently Asked Questions

What Maintenance Schedule Should I Follow For An Auto Fluid Transfer Pump?

A good rule of thumb is to check your pump every 90 days or once it hits 100 hours of use. Think of it like changing the oil in your car: fresh filters and well-tuned sensors keep performance sharp and accuracy within ±0.1 gallon.

- Monthly: Inspect hoses, clamps and nozzle seals for wear and tear.

- Quarterly: Replace filters to prevent blockages and maintain smooth flow.

- Annually: Calibrate shutoff sensors and verify that stop-volume readings are spot on.

How Does Automatic Shutoff Improve Dock Safety?

An automatic shutoff acts like a vigilant lifeguard. The moment back pressure rises, it cuts off the flow in under 0.2 seconds, stopping overfills and spills before they happen. That split-second protection lets you focus on mooring lines and pre-departure checks without constant fuel monitoring.

Can One Pump Handle Both Diesel And Gasoline?

Absolutely—many modern pumps come equipped with seals and hoses rated for multi-fuel service. Just be sure to match every seal, gasket and tube to your specific fuel blend. Skipping this check can lead to swelling, leaks or premature wear.

“CLiX pumps cut spill incidents by 90% in trials,” an experienced marina operator notes.

Key Certifications To Look For

- UL142 approval: Confirms fire resistance and reliable pressure containment.

- ISO 9001 certification: Shows the manufacturer follows strict quality controls and traceability.

What Troubleshooting Tips Should I Keep In Mind?

Start with the basics—verify wiring connections and hose integrity. A quick sensor reset (power off, then back on) often clears false shutoffs. If problems persist, recalibrate sensors and inspect fittings again.

What Integration Options Support Billing And Monitoring?

Today’s auto fluid transfer pumps can feed data straight into your marina management system. Digital flow meters record volumes in real time, making invoicing almost automatic.

- Use pulse or 4-20 mA outputs for accurate logging.

- Connect via Modbus or NMEA 2000 to visualize usage on live dashboards.

Where Can I Get Replacement Parts And Support?

For genuine components and expert guidance, rely on the original manufacturer. CLiX supplies factory-approved parts and offers fast overnight shipping across the continental USA.

Ready to upgrade to worry-free fueling? Visit CLiX Fueling Solutions and discover how simple dockside refueling can be.