That satisfying 'click' you hear every time you fill up your car isn't magic. It’s a brilliant, yet surprisingly simple, piece of mechanical engineering. The fuel nozzle auto shut off is the unsung hero of the gas station, a crucial safety feature that stops fuel from flowing the second your tank is full. Without it, every fill-up would be a messy and dangerous guessing game.

The Science Behind That Familiar Click

So, how does the pump know exactly when to stop? The secret lies in a clever air pressure system built right into the nozzle.

Imagine you're drinking through a straw that has a tiny hole in it near the top. As you sip your drink, air flows through that little hole without any issue. But the moment the liquid level rises and covers the hole, the suction in the straw suddenly gets much stronger. You'd feel it immediately.

A fuel nozzle works on that very same concept. It's not just a spout for gasoline; it's a sophisticated sensor that uses air to detect when your tank is full.

How the Venturi Effect Works

Look closely at the tip of the nozzle's metal spout. You'll see a tiny hole near the end. This is the opening to a small sensing tube that runs all the way back up into the handle. As fuel rushes out, this tube is constantly sucking in a small, steady stream of air. This airflow keeps the pressure inside the nozzle stable, which holds a diaphragm and a set of levers in place, allowing the main valve to stay open.

The magic happens the instant the gasoline in your car's tank rises high enough to cover that little hole.

The moment the fuel blocks the sensing tube, the airflow is cut off. This creates a sudden vacuum inside the nozzle. That vacuum yanks on the flexible diaphragm, which instantly trips a lever mechanism. The lever snaps the main fuel valve shut, stopping the flow of gasoline in a fraction of a second.

That's the 'click' you hear—a purely mechanical response to a change in air pressure.

Why This Mechanism Matters

The fuel nozzle auto shut off is far more than a simple convenience; it’s a critical safety system. It prevents a whole host of problems:

- Costly Spills: Overfilling wastes expensive fuel and can easily damage your car's paint job.

- Environmental Contamination: Spilled gasoline is a serious pollutant that can contaminate soil and seep into groundwater.

- Vapor Release: By preventing overflows, the system dramatically reduces the amount of harmful gasoline vapors released into the air we breathe.

At the end of the day, this simple mechanical trick ensures every trip to the pump is safe, clean, and efficient.

Why This Feature Became a Global Safety Standard

The fuel nozzle auto shut off is more than just a handy feature—it’s a cornerstone of modern fueling safety. Its journey to becoming a non-negotiable standard really took off with two big changes: the move to self-service gas stations and a major push for stricter environmental rules.

Think about it. When self-service stations became the norm, the risk of someone getting distracted and overfilling their tank shot way up. An automatic shut-off was no longer a luxury; it became a crucial safety net to prevent dangerous and messy spills.

Regulations and a Growing Market

Around the same time, governments got serious about stopping fuel waste and preventing gas from contaminating soil and water. The fuel nozzle auto shut off was a perfect solution, quickly becoming a key part of building a safe fueling system that protects both people and the environment.

This focus on safety has driven major growth in the industry. The global market for these specialized nozzles is already worth about USD 1.5 billion and is expected to hit USD 2.5 billion by 2033. This isn't just a random spike; it's a direct response to tougher safety standards and a collective effort to reduce environmental risks. You can dig deeper into this growing market to see just how much these regulations shape technology.

The automatic shut-off is the unsung hero of the gas pump. It prevents overfills, cuts down on harmful vapor emissions, and stops pollutants from seeping into the ground. It’s a small device that does a massive job for responsible fueling.

A Simple Click for Universal Safety

In the end, the widespread use of this feature shows that everyone agrees on the importance of safety. That simple 'click' you hear when your tank is full is the sound of a powerful, standardized solution at work.

It prevents fires, protects your car's paint job, and keeps hazardous chemicals out of the ecosystem. It's a brilliant piece of engineering that delivers incredible peace of mind every time you fill up.

A Look Inside the Auto Shut Off Nozzle

Ever wondered about the magic behind that satisfying click when your gas tank is full? It’s not magic, but a brilliant piece of mechanical engineering. To really get how a fuel nozzle auto shut off works, we have to look under the hood, so to speak. It’s far more than a simple spout—it's a finely tuned system of parts working in perfect sync.

The whole process hinges on a few key components that execute a precise sequence. Think of them as a well-drilled team whose only job is to prevent messy and dangerous fuel spills.

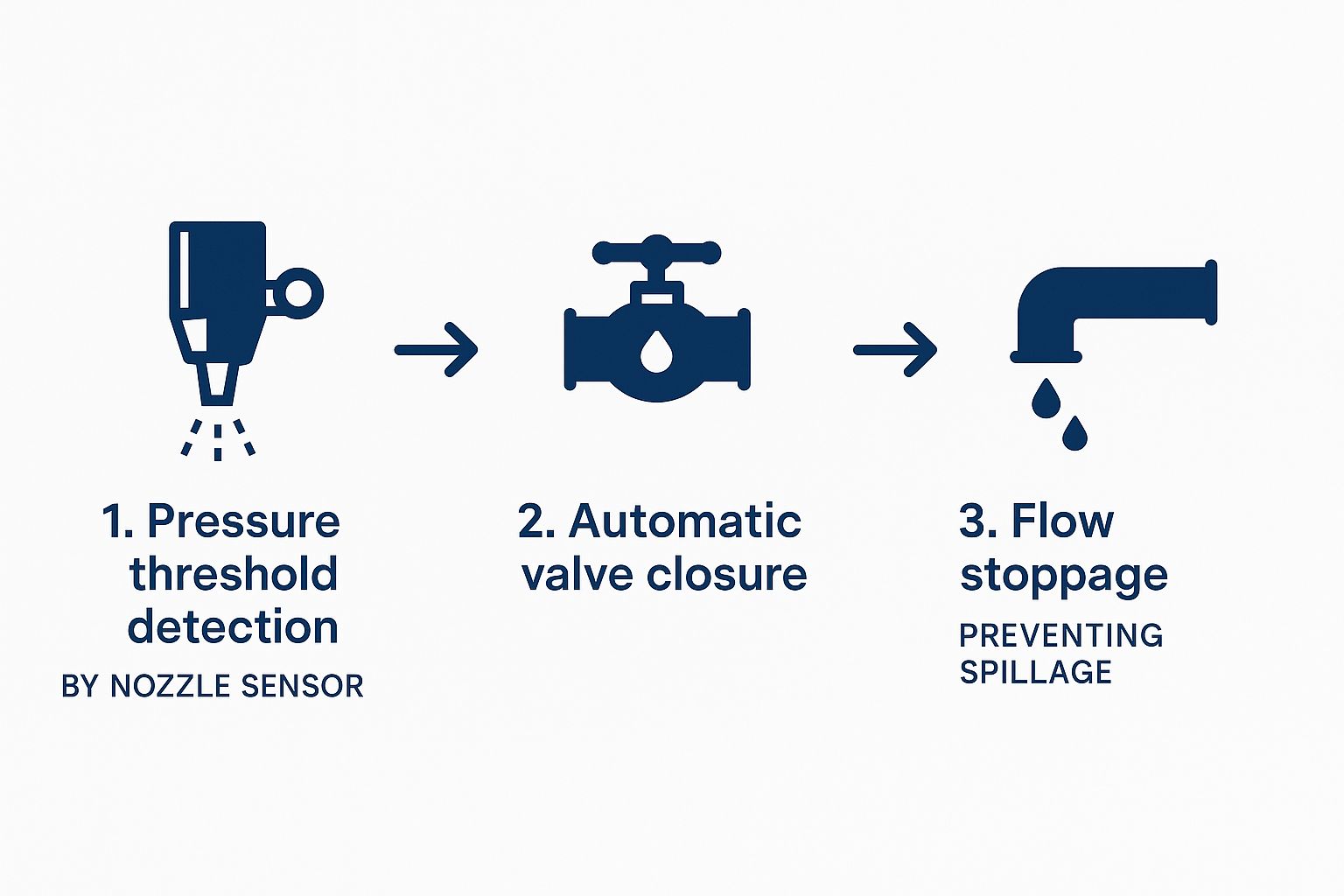

This infographic gives you a great visual breakdown of how the nozzle senses a full tank and triggers the shut-off.

As you can see, the entire chain reaction is kicked off by a simple change in air pressure. It's a surprisingly simple concept for such a critical safety feature.

The Core Mechanical Components

Let's meet the main players inside the nozzle that make this happen. Each part has a very specific job, and they all rely on each other for the automatic shut-off to work flawlessly.

- Main Valve: This is the big gatekeeper. When you squeeze the handle, this valve opens to let fuel flow. That click you hear is this valve slamming shut.

- Sensing Tube: This is a small, hollow tube running from the handle all the way down to that tiny hole near the tip of the spout. Its only job is to continuously suck in air while fuel is flowing.

- Flexible Diaphragm: Imagine a small, flexible disc, almost like a tiny trampoline, located inside the handle. The constant airflow from the sensing tube keeps it perfectly balanced. The moment that airflow stops, a vacuum yanks it out of position.

The final piece of this mechanical puzzle is the trip mechanism. When the diaphragm gets pulled by the vacuum, it knocks a few small steel balls out of place. These balls were holding back a poppet valve, and once they move, the poppet valve is released, which causes the main fuel valve to snap shut instantly.

This elegant little dance happens in a fraction of a second, much faster than a person could ever react. To dig even deeper into how these parts work together, check out our complete guide on automatic fuel nozzle systems.

To understand why maintenance is so critical, it helps to see what happens when just one of these parts fails. Here’s a quick comparison:

Functional vs. Faulty Auto Shut Off Nozzle

| Component | Normal Operation | Common Failure Mode |

|---|---|---|

| Sensing Tube | Constantly draws air, creating a balanced pressure system. | Becomes clogged with debris, preventing air from flowing. |

| Diaphragm | Remains flat due to steady airflow from the sensing tube. | A clog creates a false vacuum, causing the nozzle to shut off too early. |

| Main Valve | Stays open while fueling, then snaps shut when the trip mechanism is activated. | Worn springs or seals prevent it from closing fully, leading to drips or spills. |

As the table shows, a small bit of dirt or a worn-out spring can completely undermine the nozzle's safety features.

From Airflow to Instant Stop

So, let's put it all together.

As fuel is flowing out of the spout, air is simultaneously being pulled in through the sensing tube. This creates a state of equilibrium. The diaphragm stays flat, the steel balls stay locked in place, and the main valve remains wide open.

The second the rising fuel in your tank covers the tip of the spout, it blocks that little hole. Air can no longer get in, which instantly creates a vacuum in the tube. This vacuum pulls on the diaphragm, which trips the release mechanism, which dislodges the steel balls and shuts off the fuel. Click. Just like that.

How Global Regulations Shape Fueling Safety

You might assume every fuel pump in the world has an automatic shut-off feature, but that’s not quite the case. The use of the fuel nozzle auto shut off is deeply connected to a region's safety rules, environmental laws, and even its economic progress. This creates a patchwork of standards across the globe, with some areas leading the way and others playing catch-up.

In places like North America and Europe, these advanced nozzles have been the norm for decades. Strict environmental protection laws were put in place years ago to stop fuel vapor from polluting the air and prevent spills from contaminating the ground. As a result, the auto shut-off is a standard, expected feature at any gas station.

The Rise in New Markets

But the picture is changing fast. While North America has long been the dominant market, thanks to its massive automotive industry and tight regulations, the Asia-Pacific region is now the fastest-growing. This boom is fueled by huge industrial growth and a surge in vehicle ownership in countries like China and India. You can see the full picture of these market trends to understand the shift.

This global move toward safer fueling isn't just for cars. The same principles—preventing spills and protecting the environment—are even more critical in marine environments, where a single spill can devastate an entire ecosystem.

This growing demand for better fueling infrastructure is being driven by new government policies designed to cut down on pollution and stop fuel waste. As these economies add more cars, trucks, and commercial boats, the fuel nozzle auto shut off is becoming a must-have technology.

The same dedication to safety is just as important on the water. Our guide on boat fueling safety offers a complete protection playbook, explaining how spill prevention protects both your boat and the fragile marine world. In the end, whether you're on land or at sea, regulations are driving technology forward to make fueling safer for everyone.

Troubleshooting Common Fueling Problems

We’ve all been there. You’re standing at the pump with an empty tank, and the nozzle keeps clicking off every few seconds. It’s incredibly frustrating, but it usually doesn't mean the pump is broken. Most of the time, it's just a simple conflict between the gas pump and your car.

The most common reason for this is a pump that’s dispensing fuel too quickly. When the gasoline rushes into your car’s filler neck at high speed, it can splash back up. This splash-back hits the nozzle's sensor, fooling it into thinking the tank is full and triggering the fuel nozzle auto shut off.

Another possibility is your car's own vapor recovery system. This system is great for capturing gas fumes, but on some vehicles, its design can disrupt the flow of incoming fuel. This also creates that tell-tale splash-back that stops the pump prematurely.

Quick Fixes at the Pump

Thankfully, you don't have to just stand there and get frustrated. A few simple adjustments can usually solve the problem right away.

- Ease up on the handle: Instead of squeezing the pump handle all the way, try a lighter touch. A slower flow rate is far less likely to cause fuel to splash back.

- Reposition the nozzle: Try pulling the nozzle out just a little bit, maybe an inch or so. Changing its depth can completely alter the flow dynamics inside the filler neck.

- Give it a turn: If pulling it out doesn't do the trick, try rotating the nozzle to a different angle. Sometimes turning it 90 or even 180 degrees is all it takes to get the fuel flowing smoothly.

These quick fixes can make all the difference. But if you’re dealing with actual spills instead of just premature shut-offs, that's a more serious concern. Knowing how to handle cleaning gas spills with safe, effective methods is crucial for both your safety and the environment.

Got Questions? We’ve Got Answers About Fuel Nozzles

Even after you understand the basics, you might still have a few lingering questions about how these fuel nozzle auto shut off mechanisms work in the real world. Let's tackle some of the most common ones we hear.

Can I Always Trust the Auto Shut-Off Feature?

Mostly, yes. These nozzles are engineered to be incredibly dependable and are subject to strict safety regulations. But, like any piece of machinery, they aren't completely infallible. Failure is rare, but it can happen.

A tiny bit of debris clogging the sensing tube or a simple worn-out part can sometimes cause a problem. This is exactly why you should never leave the pump unattended while fueling. Think of your presence as the ultimate safety override.

While designed for exceptional reliability, no mechanical system is 100% perfect. Always stay with your vehicle during fueling to prevent spills, even with the latest nozzle technology.

Why Does the Pump Sometimes Shut Off Before My Tank Is Full?

This is a common frustration, but there's a simple explanation. It's usually caused by fuel splashing back up your car's filler pipe. When the fuel flows too quickly, it can surge back and prematurely cover the nozzle's sensing hole, fooling the system into thinking the tank is full.

The fix is usually pretty simple: try not squeezing the handle at full blast to slow the flow. Sometimes, just changing the angle of the nozzle slightly can solve the problem.

Is It Really That Bad to "Top Off" My Tank After the First Click?

Yes, it is. When you hear that first click, it’s time to stop. That's not just a suggestion; it's a signal that the fuel nozzle auto shut off has done its job correctly, leaving the right amount of empty space in your tank. This space is crucial for allowing fuel vapor to expand, especially as temperatures change.

Forcing more fuel in can push liquid gasoline into your vehicle’s evaporative emissions (EVAP) system, which is only designed to handle vapor. This can saturate and ruin expensive parts like the charcoal canister, leading to engine trouble and a hefty repair bill. The best rule of thumb? When it clicks, you're done.

Tired of the fueling guessing game and the messy, dangerous spills that can happen with boats? The CLiX Fueling Solutions system removes all the stress by automatically stopping the nozzle when your tank is full. It's designed to prevent costly spills, every single time. Discover a spill-free fueling experience at clixfueling.com.