You've seen the difference between a garden hose and a fire hose, right? One is a trickle, and the other is a torrent. That's the best way to think about a high-flow, or 'high flo,' fuel pump. It’s designed to move a massive amount of fuel, fast, slashing the time you spend at the fuel dock.

This speed is a game-changer for everyone, from recreational boaters eager to get back on the water to busy marina operators juggling a lineup of thirsty boats.

What Is a High Flo Pump and Why Do You Need One?

Simply put, a high flo pump is built for speed and volume. Your average fuel pump at the dock might dribble out 10-15 gallons per minute. A true high flo pump, on the other hand, can push 25, 50, or even 100+ gallons per minute (GPM).

That kind of power turns a long, frustrating fueling stop into a quick pit stop. It means more time enjoying the water and less time watching the numbers on the pump slowly creep up. For a marina, that efficiency is pure gold.

The Power of High Flow Rate

The number that matters most here is the flow rate, measured in GPM. It's the pump's spec sheet hero, telling you exactly how much fuel it can move in sixty seconds.

Let’s put it in real-world terms. Topping off a 200-gallon tank with a standard 10 GPM pump is a 20-minute job. With a 50 GPM high flo pump? You’re done in just four minutes. That’s a huge difference when you’ve got a full crew waiting or other boats lining up behind you.

A high flo pump's real job is to eliminate wasted time. It moves so much fuel so quickly that it minimizes downtime for boaters and maximizes customer turnover for marinas. It turns the fuel dock from a bottleneck into a smooth, profitable part of the operation.

Key Benefits at a Glance

When you get down to it, the reasons for switching to a high flo pump are pretty straightforward. The impact is immediate, whether you're filling up your own center console or managing a commercial dock.

- Slash Your Fueling Time: This is the big one. We’re talking about spending minutes, not hours, at the pump.

- Boost Marina Efficiency: Serve more boats in less time. This clears up dock congestion, especially on a busy Saturday.

- Happier Customers: Nobody likes to wait. A fast, professional fueling experience brings boaters back again and again.

At the end of the day, a high flo pump solves the single biggest headache in marine fueling. It delivers the speed you need to make refueling a minor errand instead of a major event.

Trying to make sense of a pump's spec sheet can feel like you need an engineering degree. But once you get a handle on a few key terms, you'll be able to see right through the jargon and know exactly what you're looking at. When it comes down to it, just three numbers really tell you how a pump is going to behave at the dock.

We're talking about Gallons Per Minute (GPM), pressure (PSI), and head pressure. Each one paints a piece of the performance picture, and they all have to work together to get the job done right.

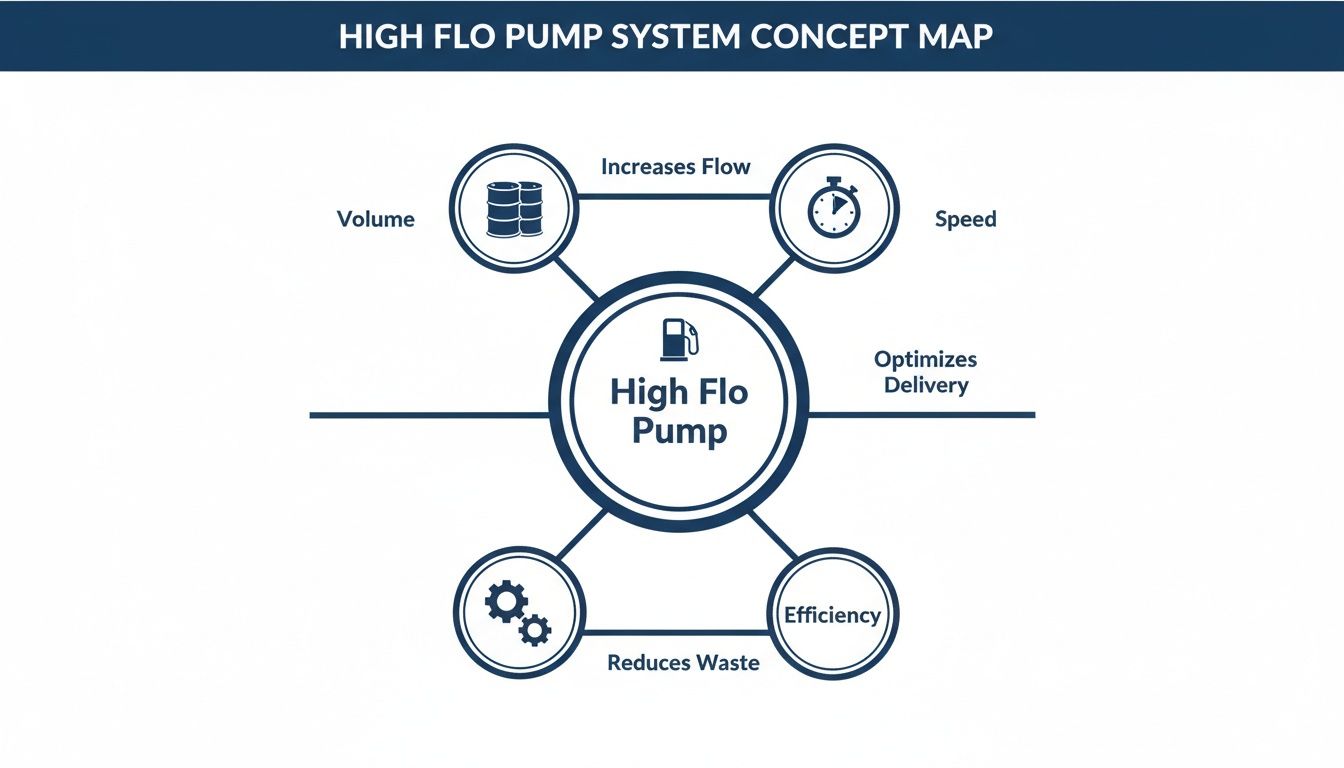

This quick visual breaks down why a high flo pump is so much better at its job.

As you can see, it's all about moving a high volume of fuel quickly and efficiently.

GPM: The Need for Speed

Gallons Per Minute (GPM) is the big one. This number tells you how much fuel the pump can theoretically move in one minute if everything is perfect. Higher GPM means faster fill-ups. It's that straightforward. But GPM is just the headliner; it can't perform without its backup singers, PSI and head pressure.

PSI and Head Pressure: The Muscle Behind the Flow

Pressure, measured in Pounds per Square Inch (PSI), is the raw force pushing the fuel. It's just like the water pressure in your house—too low, and you get a disappointing trickle; too high, and you've got a powerful jet. You need enough PSI to shove that fuel through long hoses, navigate tight corners, and overcome the friction inside the system.

Head pressure is a close cousin to PSI. It specifically measures how well the pump can push fuel upward. If your dock is lower than the boat's fuel tank, a pump with weak head pressure will struggle against gravity, slowing your flow to a crawl.

Here’s the bottom line: GPM, PSI, and head pressure are a team. A pump can boast a massive GPM rating, but if the PSI and head pressure aren't up to the task for your specific setup, you’ll never see that top speed. The fuel will lose its battle against hose friction and gravity every time.

To give you a better idea of the difference, let's look at some typical numbers side-by-side.

Standard vs High Flo Pump Performance Metrics

| Specification | Standard Fuel Pump | High Flo Pump |

|---|---|---|

| Flow Rate (GPM) | 10-25 GPM | 40-100+ GPM |

| Pressure (PSI) | 10-15 PSI | 25-50+ PSI |

| Head Pressure | Lower (Best for short, level runs) | Higher (Designed for long hoses & elevation) |

| Best For | Smaller recreational boats, simple setups | Large yachts, commercial vessels, busy marinas |

This table makes it clear: high flo pumps aren't just a little faster; they're in a completely different league when it comes to power and capability.

The need for pumps that can move huge volumes isn't just a marine thing. In water and wastewater management, for example, pumps that move over 2,000 GPM are seeing a huge surge in demand, with a projected growth of 5.30% CAGR between 2025 and 2034. These massive pumps are essential for supplying cities and treating industrial wastewater.

And if you want to know exactly how much fuel your boat is using out on the water, take a look at our complete guide on boat fuel flow meters for a precise reading.

The Real-World Benefits for Boaters and Marinas

It’s one thing to talk about specs and flow rates, but it’s another to see what a high-flow pump actually does for your day on the water. For everyone from recreational boaters to marina operators, the biggest advantage comes down to one simple, powerful thing: time. You can’t get more of it, and a high-speed pump helps you make the most of what you have.

For a boat owner, this is huge. It means you’re not stuck at the fuel dock while the best part of the day slips away. A quick, painless fill-up turns a chore into a quick pit stop, getting you back out on the open water with friends and family that much faster.

Transforming the Marina Fuel Dock

If you run a marina, those benefits translate directly to your bottom line and your reputation. We’ve all seen it: a beautiful weekend afternoon, and the fuel dock is a chaotic logjam of boats waiting to fuel up. A high-flow pump system can turn that frustrating bottleneck into a smooth, efficient operation.

By slashing the time it takes to refuel each boat, you can completely change the dynamic at the dock.

- Faster Customer Turnover: You can serve far more boats in the same amount of time.

- Less Congestion: It keeps boat traffic moving safely and clears up valuable dock space.

- Happier Boaters: Customers remember the places that get them back on the water quickly and without a hassle.

This isn't just about boosting fuel sales; it’s about building a name for yourself as a top-tier facility. Having the right equipment is a cornerstone of well-run marine fueling stations.

A high-flow pump does more than just move fuel. It completely elevates the customer experience. It shows boaters you respect their time and are serious about providing professional service, which is exactly what brings them back and gets them talking.

A Look at High-Volume Pumping

The idea of moving a lot of liquid in a hurry isn't just for fueling boats. Look at the industrial world, where high-power axial flow pumps held a massive 59.2% revenue share of a global market valued at USD 4,138.5 million in 2024. These are the workhorses used for everything from flood control to agriculture.

This just goes to show how critical high-volume fluid transfer is across many industries. You can find more details on the axial flow pump market at Grand View Research.

Choosing the Right Pump for Diesel or Gasoline

When you're picking out a high-flo pump, the single most important decision is matching the pump to the fuel. It's a dangerous—and potentially very expensive—mistake to think you can use any pump for either gasoline or diesel. These two fuels are completely different animals, and the pumps built to handle them are just as distinct.

Gasoline is incredibly volatile. What that means is it evaporates into a highly flammable vapor, even on a cool day. This creates a serious risk of fire or explosion if you don't handle it with the right gear. Because of this, any pump built for gasoline has to meet some really strict safety standards.

The Gasoline Pump Safety Checklist

A pump designed for gasoline has one primary job beyond just moving fuel: preventing sparks. It’s not just a nice feature; it's a non-negotiable safety requirement to prevent a catastrophe at the fuel dock.

Here's what makes a gas-rated high-flo pump safe:

- Explosion-Proof Motors: Think of these as completely sealed units. Any electrical spark created inside the motor stays inside, safely away from flammable gas fumes.

- Specialized Seals and Gaskets: The internal parts are made from materials that can stand up to the harsh additives in gasoline without breaking down and causing a leak.

- Thermal Overload Protection: If the motor starts to get too hot, this feature acts like a circuit breaker and shuts it down automatically, which is another crucial layer of safety.

Using a pump that isn't rated for gasoline is like walking into a room filled with gas fumes while flicking a lighter. It’s not a question of if something will go terribly wrong, but when.

Understanding Diesel Pump Requirements

Diesel, on the other hand, is a much heavier, oil-based fuel. It’s far less volatile and doesn't really produce explosive vapors at normal temperatures. While the explosion risk is almost non-existent, diesel has its own set of challenges.

Its thicker, oil-like consistency means you need a pump built with enough muscle to move a heavier liquid without burning itself out. A diesel pump is designed for durability and power, but it doesn't have the sophisticated (and expensive) explosion-proof parts you find in a gasoline pump.

Never, ever use a pump designed for diesel to move gasoline. A standard motor can create small sparks during normal operation. With diesel, that’s no big deal. With gasoline vapors, those same sparks can trigger a devastating explosion.

Making the Right Choice for CLiX Fueling Solutions

Getting this choice right is all about safety, performance, and staying compliant. For anyone using a system like CLiX Fueling Solutions, picking the correct pump is fundamental to making the system work properly. It's simple: a gasoline-rated pump must be paired with the gas model of CLiX, and a diesel pump must be used with the diesel model.

Matching the pump to the fuel and the system ensures everyone at the dock stays safe and your entire fueling setup runs smoothly for years. Always double-check that your high-flo pump is explicitly rated for the type of fuel you're handling. It’s a simple step that protects your boat, your property, and most importantly, the people around you.

Proper Installation and System Integration

Getting the most out of your high flo pump isn’t just about picking the right model; it’s about setting it up correctly. A flawless installation means you get every drop of performance you paid for. On the other hand, a botched setup can choke its output, leaving you with frustratingly slow fueling speeds.

It’s a bit like putting a high-performance engine in a car. If the fuel lines are too small or the electrical system can’t keep up, you’ll never feel its true power. The exact same idea applies here. For a high flo pump to hit its maximum GPM, every part of the system has to be up to the task.

Pre-Installation Planning Checklist

Before you even touch a wrench, a little bit of planning goes a very long way. Running through a quick checklist helps you sidestep the common mistakes that can bottleneck your entire system and cause major headaches down the road.

- Correct Power Supply: Does your electrical circuit actually match the pump's voltage and amperage needs? An undersized circuit will starve the motor, causing it to run hot or seriously underperform.

- Appropriate Hose Diameter: Using a hose that’s too narrow is like trying to force a fire hose’s worth of water through a tiny garden hose. It creates a ton of friction and absolutely kills your GPM.

- Secure Mounting: A high flo pump generates a lot of force. You need to mount it securely to a solid surface to cut down on noise and vibration, which can wear out fittings and connections way too fast.

- System Compatibility: Make sure the pump will play nice with your existing setup, especially if you're using advanced fuel transfer systems.

A high flo pump is only as strong as its weakest link. Proper installation ensures that every part of your fueling system—from the electrical wiring to the hose nozzle—works together to support maximum flow rate, not hinder it.

Integrating with CLiX Fueling Solutions

A huge part of a modern setup is making sure your new pump works perfectly with solutions designed to boost safety and stop spills. For boaters and marinas using CLiX Fueling Solutions, this integration is simple but absolutely critical. The pump gives you the speed, and the CLiX system provides the safe, automatic shut-off. Together, they create a powerful and responsible way to fuel up.

The demand for high-performance gear like this isn't just in the marine world. The wider high-pressure pumps market is expected to jump from USD 3.0 billion in 2025 to USD 4.4 billion by 2035. This trend really shows how much major industries are relying on powerful, efficient pumps. You can learn more about the trends in the high-pressure pumps market.

Simple Maintenance for Lasting Performance

A high-flow pump is a serious investment in your marine operations. And like any powerful piece of equipment, it needs a little TLC to keep performing at its best. Staying on top of maintenance is always easier and cheaper than dealing with a breakdown later.

Think of it like the engine in your boat—you wouldn't ignore a strange noise or a warning light, right? A simple, routine check-up can catch minor wear and tear before it snowballs into a costly failure that shuts down your fuel dock on a busy holiday weekend.

Your Routine Maintenance Checklist

The secret to a long-lasting pump is a consistent schedule. This doesn’t have to be complicated. A few quick checks are usually all it takes to keep things running smoothly.

- Clean the Filters: A clogged filter is public enemy number one for flow rates. Check and clean them regularly to prevent blockages that put unnecessary strain on the motor.

- Inspect Hoses and Fittings: Give your hoses a quick once-over. Look for any visible cracks, bulges, or signs of wear. Make sure every fitting and connection is snug to prevent leaks and stop air from getting into the system.

- Listen for Unusual Noises: Your ears can be your best diagnostic tool. Any new grinding, whining, or rattling is an early warning that something might be wrong inside, like a worn bearing.

A proactive approach to maintenance is your best defense against unexpected downtime. Addressing small issues like a dirty filter or a loose fitting immediately can prevent over 90% of common pump failures.

If you do run into electrical problems, getting professional commercial electrical repairs handled quickly is the best way to minimize downtime and keep your pump working safely and efficiently.

Troubleshooting Common Pump Problems

Even with perfect maintenance, things can still go wrong. Knowing how to spot and diagnose the usual suspects can save you a ton of time and money.

- Sudden Drop in Flow Rate: If your GPM takes a nosedive, always start with the simple stuff. It's almost always a clogged filter or a kinked hose.

- Pump Won't Prime: This usually points to an air leak somewhere on the suction side. Carefully check every connection from the fuel tank all the way to the pump for any loose fittings.

- Motor Overheating: An overheating motor could mean there's a blockage creating too much back pressure. It could also signal an electrical issue that needs a closer look.

By following these simple steps, you can confidently stay on top of your high-flow pump’s upkeep. This hands-on approach keeps your fueling operations efficient and protects your investment for the long haul.

Got Questions About High Flo Pumps? We've Got Answers.

Even after getting the basics down, you probably still have some practical questions about making the switch to a high-flow pump. That's completely normal. Let's tackle some of the most common things we hear from boat owners and marina managers to help you get the clarity you need.

So, How Much Faster Are We Talking?

The difference isn't just noticeable—it's night and day. Your average, everyday pump chugs along at about 10-15 GPM (gallons per minute). A high-flow pump, on the other hand, can roar to life at 25-100 GPM, and sometimes even more.

Let's put that in real-world terms. Imagine you're filling a 200-gallon tank. With a standard pump, you're stuck at the dock for the better part of 20 minutes. With a high-flow setup, you’re done and heading out in just 2 to 5 minutes. It completely changes the whole fueling game.

Can I Just Use the Same Pump for Diesel and Gas?

Absolutely not. Unless a pump is specifically built and certified for both—which is incredibly rare—you cannot swap them. Gasoline is far more volatile than diesel and demands a pump with an explosion-proof motor and special seals to prevent a catastrophic fire.

Safety First: Pumping gasoline with a diesel pump is a serious gamble. A simple spark from a standard motor can ignite gas fumes instantly. Always, always match the pump to the fuel. It’s the single most important rule of dock safety.

What Are the Telltale Signs That My Pump Needs a Check-Up?

Your pump will usually give you a heads-up before it decides to quit on you. The trick is knowing what to look and listen for.

Here are the most common red flags:

- Slower Flow: The most obvious sign is a pump that just isn't pushing fuel as fast as it used to.

- Strange Noises: If you hear any new grinding, whining, or rattling sounds, it's time to investigate.

- Slow to Start: Is the pump taking longer to prime and get the fuel moving? That’s a clear signal it’s struggling.

A little preventative care goes a long way. Regularly inspecting your hoses for cracks and making sure all the fittings are snug can head off the majority of problems. Catching these little things early saves you a world of headaches and expensive downtime later.

Ready to eliminate spills and make every fueling stop safer and faster? Discover how CLiX Fueling Solutions can modernize your marine fueling setup. Visit the CLiX Fueling website to learn more.