A marine fueling station is a lot more than just a gas pump on a dock. It's a critical lifeline for everything that moves on the water, from the smallest fishing boat to the largest container ship. Think of them as the essential pit stops that power the entire maritime world.

The Critical Role of Marine Fueling Stations

Without these fueling hubs, global logistics would grind to a halt, and a simple weekend on the lake would be impossible. They are the indispensable link in the chain, ensuring every vessel has the fuel it needs to get where it's going, safely and on time.

Their role is fundamental, whether it's a small fuel dock at a local marina or a massive bunkering terminal in a busy port. Just how important are they? Consider that maritime shipping is responsible for moving over 80% of the world's trade volume. None of that happens without reliable fuel.

Powering Global and Local Economies

The economic footprint here is enormous. The global marine fuel market was recently valued at around USD 140.6 billion, with projections showing it could hit USD 171.5 billion by 2030. That growth is a direct reflection of expanding global trade and the demand for efficient, clean-burning fuels.

But it's not just about massive cargo ships. On a local level, a marina's fuel dock is a key service that brings in boaters, boosts tourism, and creates revenue for the whole community. For any recreational boater, a dependable fuel dock is a major reason to choose one marina over another. Even something as simple as a well-maintained https://clixfueling.com/blogs/news/boat-fueling-system can set a marina apart.

At its heart, a marine fueling station is an energy transfer point. Its primary job is to move large volumes of a volatile liquid from a secure storage tank into a vessel's fuel tank—safely, efficiently, and without harming the environment.

That might sound straightforward, but it's a complex dance involving specialized equipment, strict safety rules, and careful planning. The scale of these operations varies dramatically, as you can see below.

Quick Overview of Marine Fueling Station Types

To better understand the landscape, here's a quick breakdown of the common types of marine fueling stations you'll encounter. Each one is designed to serve a very different kind of customer.

| Station Type | Primary Users | Common Fuel Types | Key Feature |

|---|---|---|---|

| Recreational Marina | Pleasure craft, fishing boats, yachts | Gasoline, Marine Diesel | User-friendly, convenient access for boat owners |

| Commercial Port | Cargo ships, tankers, cruise liners | Heavy Fuel Oil (HFO), Marine Gas Oil (MGO) | High-volume "bunkering" via barge or terminal |

| Floating Station | Vessels in remote areas or open water | Diesel, Gasoline | Mobile and flexible, often on a dedicated barge |

| Private Fuel Dock | Yacht clubs, government agencies, fleets | Diesel, Gasoline | Restricted access for specific users or fleets |

As the table shows, from a small marina serving weekend boaters to a bustling commercial port refueling the giants of the sea, the core purpose remains the same. They are all there to provide the reliable power that keeps our waterways alive and moving.

What's Under the Hood? A Look at the Core Components

To really get a handle on marine fueling stations, you have to look past the dock and see what makes them tick. A modern station isn't just a tank and a hose; it's a sophisticated system. Every single part has to work together perfectly to move fuel safely, accurately, and without harming the environment.

I like to think of it as a body's circulatory system. The tanks are the heart, the pipes and hoses are the arteries, and the dispensers are the hands that deliver the energy. From the massive storage tanks buried underground to the software tracking every last drop, each piece has a critical job to do.

Let's break down the anatomy of a typical marine fueling system.

The Heart of the Operation: Fuel Storage Tanks

Everything begins with the fuel storage tanks. These are the giant containers holding the station's entire fuel supply, the main reservoir for the whole operation. You'll generally find them in one of two setups:

- Above-Ground Storage Tanks (ASTs): These are the tanks you can see, usually sitting in a secure, diked area. The big advantage here is that they're easy to inspect and maintain. The trade-off is they need serious physical protection and secondary containment walls in case a spill ever happens.

- Underground Storage Tanks (USTs): Tucked away beneath the marina, these tanks are great for saving space and are naturally protected from things like vehicle collisions. Installing them is a bigger job, though, and they depend on advanced monitoring systems to catch any potential leaks before they become a real problem.

No matter where they're located, today's tanks are built tough. Most have double-wall construction and are made from corrosion-resistant materials to meet strict environmental rules.

Arteries and Veins: Pipes and Hoses

Once fuel leaves the tank, it travels through a whole network of pipes and hoses. This is the plumbing of the system, the crucial link between storage and the dispenser on the dock.

The permanent piping is usually made from stuff that won't corrode, like fiberglass or specially coated steel. Think of these as the main arteries running from the tanks to the docks. From there, flexible fuel hoses take over, giving you the reach you need to connect right to a boat's fuel intake. Getting the details right, like the specific hose assembly requirements, is absolutely essential for keeping the whole system safe and efficient.

Key Insight: You can't overstate the importance of high-quality pipes and hoses. A single weak point or a bad connection can cause a catastrophic failure. That's why regular, thorough inspections aren't just a good idea—they're a non-negotiable part of running a station.

The Brain: Fuel Management and Pumping Systems

The pump provides the muscle to move the fuel, but the fuel management system is the brain that runs the show. This digital command center is what truly separates a modern fueling station from an old-school gas pump.

It does everything—authorizing sales, tracking inventory down to the gallon, monitoring for leaks, and making sure the pumps are dispensing accurately. Marina operators get real-time data on fuel levels, sales figures, and overall system health, giving them precise control. The pumps themselves are high-flow units, built to move a lot of fuel fast and get big boats on their way.

This focus on precision isn't just happening at the dock. As fuel costs and emissions standards climb, the technology inside a ship's engine is getting smarter, too. The market for marine fuel injection systems—a key part of engine efficiency—was valued at USD 5.11 billion and is expected to hit USD 6.45 billion by 2030. You can explore the full marine fuel injection systems market analysis to see just how big this trend is.

The Final Touchpoint: Dispensers and Nozzles

Finally, you have the dispenser and nozzle—the parts the boater actually touches. The dispenser is the box on the dock that holds the meter, the display showing gallons and cost, and the credit card reader.

The nozzle is that last piece of the puzzle. It's designed to create a secure, snug fit with the boat's fuel tank to prevent any spills during refueling. It’s the handshake that completes the entire process.

The Bunkering Process from Start to Finish

Ever wondered how a massive cargo ship or even a large yacht gets its fuel? It’s not as simple as pulling up to a pump. The entire procedure, known in the commercial shipping world as bunkering, is a carefully choreographed operation that demands precision, constant communication, and a deep respect for safety.

Think of it less like filling up your car and more like a carefully planned aerial refueling for a jet. Every step is calculated and double-checked to ensure the safe and efficient transfer of what can sometimes be millions of gallons of fuel. Let's walk through what a typical refueling operation looks like, from the first radio call to the final sign-off.

Step 1: Making Contact and Arrival

The process starts long before the vessel even sees the fuel dock. The ship’s agent gets in touch with the marine fueling station or the bunkering provider to schedule a time, lock in the type and quantity of fuel needed, and agree on the price. This isn't a spontaneous decision; it's a planned logistical event.

As the vessel approaches the port or marina, the ship's captain and the dock master begin communicating directly. They’ll coordinate the approach, factoring in tides, currents, and other boat traffic. Once the ship is ready to moor, lines are cast and secured, holding the vessel firmly in place. This is critical—even slight movements during fueling can put dangerous stress on the hoses.

Step 2: The Pre-Transfer Safety Dance

Before a single drop of fuel flows, safety becomes the sole focus. This phase is governed by a strict pre-transfer checklist, a document that both the ship’s chief engineer and the person in charge at the fueling station must review and sign together.

This isn't just paperwork; it’s a critical safety agreement. The checklist confirms key details like:

- Emergency Procedures: Both parties agree on shutdown signals and emergency contact information.

- System Integrity: All connections, hoses, and valves are visually inspected for wear and tear.

- Spill Containment: Spill kits are on standby, and for larger transfers, a containment boom is often deployed around the vessel.

- No Ignition Sources: Smoking is strictly forbidden, and any work nearby that could create a spark is halted.

A pre-transfer inspection is the single most important moment for preventing accidents. It’s a formal "time out" where both the vessel and the station confirm they are fully prepared for a safe operation, establishing a shared responsibility for what happens next.

Step 3: Connecting and Monitoring the Flow

With all safety checks complete, the heavy-duty bunkering hoses are carefully lifted—sometimes by crane, sometimes by crew—and connected between the dock and the ship's fuel intake manifold. The connection is meticulously tightened and checked for a perfect seal. Once secure, the dock operator and the ship's engineer do one last cross-check.

The pumping starts slowly. This initial low flow rate gives everyone a final chance to check for leaks. If all connections are tight, the flow rate is gradually increased. Throughout the entire process, which can last for hours, both crews keep a constant watch on pressure gauges, flow meters, and the ship's tank levels.

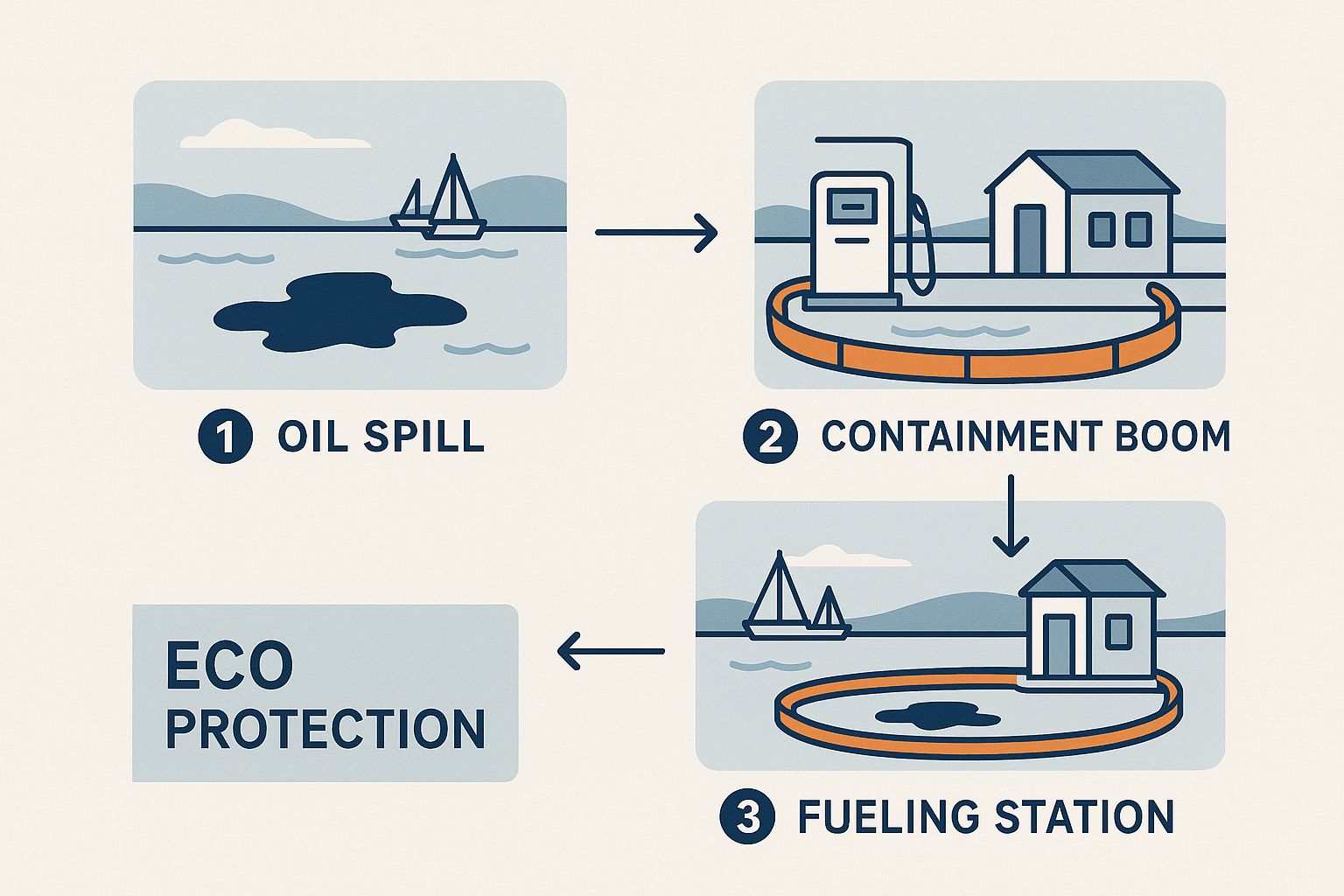

This image shows how environmental protection measures, like containment booms, are an integral part of the process at modern marine fueling stations.

It’s a great illustration of how eco-protection isn't an afterthought but a primary consideration, creating a physical barrier to protect the surrounding water.

Step 4: Finalizing the Operation

As the ship’s tanks get close to their target level, communication becomes even more frequent. The engineer will tell the dock operator to slow the pumping rate to avoid a high-pressure surge that could cause an overfill. Topping off a ship's tank is a delicate process that requires careful management to prevent any spills.

Once the exact amount of fuel is on board, the pumps are shut down. The lines are then carefully purged with air to push any remaining fuel from the hose into the ship's tank. This ensures an accurate delivery and minimizes dripping when the hose is disconnected. After disconnecting, the hose is capped, all valves are closed, and a final inspection makes sure no fuel has leaked onto the deck or into the water. Only then is the paperwork signed, officially closing out the bunkering operation.

Putting Safety and Environmental Protection First

When it comes to marine fueling stations, safety and environmental stewardship aren’t just boxes to tick—they’re the foundation of the entire operation. We’re talking about handling huge volumes of flammable liquid right next to fragile marine ecosystems. This demands a level of care and precision where a small mistake can create massive problems for people and the planet.

Think of a modern fuel dock less like a gas station and more like an operating room. Every single piece of equipment and every step in the fueling process is meticulously designed to create a tightly controlled environment that keeps risk at an absolute minimum. It’s all about layering systems—both proactive and reactive—to prevent an incident or, if one happens, to contain it immediately.

The stakes couldn't be higher. A fuel spill, even a small one, can wreak havoc on local wildlife, contaminate shorelines, and poison the water. On the other hand, a fire on a fuel dock is an immediate threat to life and property. That's why the regulations for these facilities are so strict and unforgiving.

Proactive Safety Systems

The best way to handle an emergency is to stop it from ever happening. That's why modern marine fueling stations are packed with advanced safety features designed to get ahead of any potential problems. These systems are the unsung heroes, working quietly in the background to make every fuel transfer as safe as possible.

Some of the key preventive measures you'll find are:

- Leak Detection Sensors: These are the dock's silent watchdogs. Using pressure sensors and electronic probes, they constantly monitor tanks and pipes for the slightest hint of a breach.

- Corrosion-Resistant Materials: Everything that comes into contact with fuel, from double-walled fiberglass tanks to specialized piping, is built to survive the harsh salt-and-sun environment without breaking down.

- Grounding Systems: Static electricity is a huge, invisible fire risk. To counter it, all equipment is thoroughly grounded to safely discharge any static buildup during fueling.

Emergency Response and Containment

Even with the best planning, you have to be ready for the unexpected. This is where emergency response equipment takes center stage. These tools are designed for one thing: rapid deployment to get a bad situation under control fast.

The golden rule of emergency response is instant action. The goal is to shut down the source of the problem and contain the damage in seconds, not minutes. That speed is what turns a potential catastrophe into a manageable incident.

The most critical emergency systems include:

- Emergency Shutdown (E-Stop) Buttons: These are the big red buttons you see around the dock. Anyone can hit one to instantly cut power to all fuel pumps.

- Fire Suppression Systems: Docks are armed with specialized fire extinguishers built to handle fuel fires. Larger facilities often have automated foam or chemical systems that can smother a fire in moments.

- Spill Containment Booms: These are floating barriers that can be quickly thrown into the water to encircle a boat or the dock itself. They trap spilled fuel on the surface, keeping it from spreading into the open water.

At a well-run facility, safety and environmental protection are two sides of the same coin. The measures that protect people and equipment often directly protect the surrounding ecosystem. The following table breaks down how these systems serve both purposes.

Key Safety vs Environmental Measures at Fueling Stations

| Measure Category | Safety Focus (Personnel/Asset) | Environmental Focus (Ecosystem) |

|---|---|---|

| Leak Detection | Prevents fuel from pooling on the dock, reducing fire and slip hazards. | Stops contaminants from seeping into the ground or water before a major spill occurs. |

| Emergency Shutdown | Immediately stops the flow of fuel during a hose rupture or fire, protecting people nearby. | Minimizes the total volume of a potential spill, drastically reducing environmental impact. |

| Spill Booms | Help contain flammable liquid on the water surface, making it easier to manage and reducing fire risk. | The primary tool for physically containing a spill to a small area for cleanup. |

| Double-Walled Tanks | Provides a secondary containment layer, preventing a catastrophic fuel release if the inner wall fails. | Protects groundwater and soil from contamination by ensuring any tank leak is captured. |

Ultimately, the goal is a seamless system where protecting people, property, and the planet are all part of the same operational mindset.

Learning how to guard our waters is a shared responsibility. You can find out more by exploring these simple ways to prevent marine pollution and protect our oceans. Protecting the environment also means looking at the bigger picture. To truly manage the footprint of marine fueling, it helps to understand the broader carbon impact of shipping and logistics. It’s this combination of local action and global awareness that will safeguard our marine worlds for generations to come.

Navigating the Future of Alternative Marine Fuels

The world of marine fuel is on the cusp of some big changes. Driven by tightening environmental rules and a worldwide push for cleaner energy, the familiar landscape of diesel and gasoline is starting to look different. This evolution is completely reshaping what we need from our fueling stations.

Think about what's happening on our highways. Gas stations are starting to install EV chargers right alongside the regular pumps. It’s the same idea on the water. Marine fueling stations are gearing up to become multi-fuel hubs, ready to serve a new generation of vessels running on cleaner alternatives. This isn't science fiction; it’s happening right now.

The Rise of Cleaner Marine Fuels

For decades, the choice was pretty straightforward. Now, a wave of new fuels is joining the conversation, and each one has the potential to seriously slash emissions. While the initial focus is often on massive commercial ships, the technology and infrastructure being developed today will eventually trickle down to the entire marine industry.

Here are the top contenders you'll start hearing more about:

- Liquefied Natural Gas (LNG): Right now, LNG is the frontrunner. It's simply natural gas that has been cooled into a liquid, and it dramatically cuts down on sulfur oxides, nitrogen oxides, and particulate matter. You’re already seeing it adopted by large cargo ships and cruise liners.

- Methanol: This is a simple alcohol that can be made from natural gas or even renewable sources like biomass. A big plus is that it's a liquid at normal temperatures, which makes it much easier to handle and store on a boat compared to LNG.

- Ammonia: When it's produced using renewable energy—so-called "green ammonia"—it's a completely carbon-free fuel. The trade-off? It comes with some serious challenges, especially around its toxicity and how to store it safely.

The push toward these fuels is a direct response to global targets to decarbonize the shipping industry. For the fueling stations, this means investing in new types of storage tanks, specialized hoses, and intensive training for their crews to handle these very different substances safely.

Building the Infrastructure for Tomorrow

This shift isn't just about pouring a new liquid into a tank; it requires a ground-up rethinking of our fueling infrastructure. The market for marine LNG fuel gas supply systems (FGSS) is a perfect example of this investment in action. It was valued at USD 2.5 billion and is expected to explode to USD 6.7 billion by 2033, showing a serious industry commitment.

As marine fueling stations evolve, understanding how robust energy infrastructure works becomes critical. For instance, knowing how utility-scale energy storage can support massive power demands is key, especially when you consider future solutions like shore power or hydrogen that will place new strains on local grids.

The road ahead is a complex one, with every alternative fuel bringing its own pros and cons to the table. But the direction is crystal clear. The marine fueling stations of the future will be more diverse, more technologically advanced, and fundamentally cleaner, ensuring that boating remains both powerful and sustainable for years to come.

Choosing the Right Marine Fueling System

Picking out and installing a new fueling system for a marina or port is a massive undertaking. It’s a decision that will shape your efficiency, profits, and environmental standing for decades to come. To get it right, you have to look past the surface-level specs and start asking the hard, practical questions from day one.

Think of it like laying the foundation for a new house. You have to get it right from the start because everything else rests on it. This means you need to meticulously analyze your specific needs, work through a maze of regulations, and try to plan for a future that isn't entirely clear. It’s a job that requires real foresight and a solid strategy.

Assessing Your Unique Operational Needs

First things first, you need to build a detailed profile of your customers and your operational reality. A one-size-fits-all solution just won't work here. The system you choose has to be built for the boats you service right now and the ones you hope to attract down the line.

Start with these fundamental questions:

- Who are you serving? Is your dock filled with small recreational boats that need gasoline? Or are you catering to large yachts and commercial fishing boats that demand high-flow diesel pumps? This single answer will drive decisions on everything from dispenser speed to the length of your fuel hoses.

- What is your projected volume? You need a solid estimate of your daily, weekly, and seasonal fuel demand. If you guess too low, you'll have long, frustrating lines and lose business. Guess too high, and you'll have tied up a ton of cash in oversized tanks and equipment you don't need.

- What are your site constraints? Take a hard look at your physical location. Do you have room for above-ground tanks, or will you need to bury them? What about access for the fuel delivery trucks?

Answering these questions honestly gives you the blueprint for a system that fits your operation perfectly. It’s what separates a merely functional fuel dock from a highly profitable one.

The most successful marine fueling stations are those that deeply understand their clientele. The system's design should be a direct response to boater behavior, vessel size, and peak demand periods.

Navigating Permits and Choosing Equipment

Once you have a clear picture of your needs, the next stage runs on two parallel tracks: securing permits and selecting your equipment. The permitting process can be notoriously complicated and often involves local, state, and sometimes even federal agencies. My advice? Start talking to regulators early to sidestep expensive delays.

At the same time, you'll start looking at equipment suppliers. Your budget is obviously a huge factor, but don't ever sacrifice durability and compliance just to save a few bucks upfront. Modern systems come with incredible tools for managing every single gallon. For a closer look at these advanced features, a complete guide on the modern boat fuel management system can show you what’s possible with tracking, security, and reporting. This tech is absolutely key for accurate inventory and stopping fuel theft.

When you’re picking out the core components, focus on these three things:

- Tank Type and Size: You'll choose between above-ground (AST) or underground (UST) tanks. This depends on your available space, local rules, and how you want to handle maintenance. Size them to meet your peak demand with a bit of a reserve.

- Pumps and Dispensers: Match the pump flow rates to the boats you serve. High-speed diesel pumps are a must for bigger vessels, while standard-flow gasoline is fine for the smaller weekend boats.

- Hoses and Nozzles: This isn't the place to cut corners. Invest in high-quality, tough hoses and nozzles. Features like automatic shut-offs aren't just nice to have—they are essential for preventing spills and keeping everyone safe.

The installation itself is the final, critical step. Always, always hire experienced, certified contractors who specialize in marine fueling stations. A perfect installation is your single best defense against future leaks, system failures, and environmental headaches, making sure your investment is safe, compliant, and ready to serve boaters for years.

Got Questions? We've Got Answers

Stepping into the world of marine fueling can feel a little confusing at first. There's a lot of unique lingo and different ways of doing things, but once you break it down, it's all pretty straightforward. We've pulled together the most common questions we hear to give you clear, simple answers.

Let's clear up some of the key things that boaters and curious onlookers often wonder about.

Bunkering Versus Regular Fueling

People often use these terms like they mean the same thing, but they really describe two different scales of fueling.

"Bunkering" is a term reserved for the big leagues—think refueling massive commercial vessels like cargo ships and cruise liners. This is a heavy-duty operation involving specialized barges or dedicated terminals that pump huge volumes of fuel, like Very Low Sulphur Fuel Oil (VLSFO).

"Marine fueling" is the everyday term that covers everything else. It includes bunkering, but it also describes what most of us do: pulling up to the fuel dock at a marina to fill our recreational boats and yachts with gasoline or marine diesel.

How Stations Prevent Fuel Spills

Modern fuel docks have a lot of built-in smarts to keep fuel in the tank and out of the water. It’s a layered approach, starting right with the infrastructure itself—things like tough, double-walled tanks and pipes that resist corrosion and are often rigged with electronic leak detectors.

When you're actually pumping the fuel, a few key pieces of gear do the heavy lifting:

- Dry-break couplings are special hose fittings that seal tight to prevent drips when you connect or disconnect.

- Automatic shut-off nozzles work just like the ones at a gas station, sensing back-pressure to stop the flow when the tank is full, which is your best defense against overfills.

- Emergency shutdown systems, usually big red buttons on the dock, let anyone kill power to all the pumps instantly if something goes wrong.

For larger fueling jobs, you’ll also see stations deploy floating spill containment booms in the water around the boat. These act like a floating fence, trapping any spilled fuel on the surface so it can be cleaned up quickly and efficiently.

Understanding Different Fuel Grades

You bet. Just like at a car gas station, there are different grades, but they’re specifically for marine engines. At your local marina, the choice is usually simple: you'll find marine-grade gasoline (often ethanol-free, which is much kinder to boat engines) and marine diesel.

Commercial ports are a different story. They offer a whole menu of fuels to meet the demands of different engines, vessel sizes, and global emissions rules. This includes things like:

- Marine Gas Oil (MGO)

- Very Low Sulphur Fuel Oil (VLSFO)

- Heavy Fuel Oil (HFO), which is becoming less common due to stricter regulations.

More and more, you're also seeing commercial ports add alternative fuels like Liquefied Natural Gas (LNG) and biofuels to their lineup as the industry moves toward cleaner energy.

Can Any Boat Use Any Station?

Not quite. It really boils down to two things: the type of fuel your boat needs and the physical size of the station. A big yacht that requires high-speed diesel pumps can't just pull up to a small dock built for little gasoline outboards.

Commercial bunkering terminals are in a league of their own. They are built specifically for huge ships and are totally off-limits to recreational boaters. In the same way, a ship with a deep draft can't get anywhere near a shallow-water marina. It’s all about matching the boat to the right dock.

For any boater who wants a foolproof way to prevent dangerous and expensive fuel spills at the dock, CLiX Fueling Solutions has a simple, brilliant device. Our system automatically stops the fuel flow the moment your tank is full, giving you peace of mind and protecting both your boat and the water. See how you can make every refueling safer.