At its most basic, a fuel transfer system is what gets fuel from a storage tank to where you actually need it—whether that's an engine, a generator, or another container. Think of it as the circulatory system for your equipment, making sure a steady and clean supply of energy is always on tap. These systems are absolutely essential for keeping fuel pure and operations running without a hitch.

What Is a Fuel Transfer System?

Picture this: you’re trying to refuel a combine harvester in the middle of a massive field, and all you have is a 55-gallon drum. Tipping that drum to pour is not just impractical—it’s dangerous and incredibly messy. This is exactly the kind of problem a fuel transfer system was designed to solve.

These systems give you a controlled, safe, and efficient way to move flammable liquids from point A to point B. They aren't just a matter of convenience; they are the backbone of countless modern industries. From construction sites and farms to airports and marinas, the ability to transfer fuel safely and cleanly is a must-have. Without them, work would grind to a halt.

The Role in Preventing Contamination and Ensuring Supply

One of the most critical jobs of a fuel transfer system is to protect the quality of your fuel. When fuel sits in a storage tank, it can easily pick up water, sediment, and other gunk that will wreak havoc on an engine. A properly designed system includes filters and water separators that clean the fuel as it's being transferred.

This simple step ensures that only pure fuel reaches your valuable equipment, saving you from expensive repairs and frustrating downtime. It's the difference between an engine that runs like a top for years and one that constantly suffers from clogged injectors or internal corrosion. In marine environments, for instance, a clean fuel supply isn't just important—it's vital. You can find out more about the specific needs of a https://clixfueling.com/blogs/news/marine-fuel-transfer-pump in our detailed guide.

A reliable fuel transfer system acts as a gatekeeper, ensuring that only clean, usable fuel reaches its destination. This simple function protects expensive machinery and maintains operational uptime, making it a vital investment for any fuel-dependent operation.

To get a sense of just how important these systems are, take a look at the broader fluid handling market. Valued at USD 71.35 billion, it's projected to climb to USD 113.59 billion, which shows just how much demand there is across industries for reliable fluid management.

Specialized applications often require more advanced setups. For a great example of this in action, check out how mobile fueling trucks deliver on-site refueling solutions for entire fleets of vehicles and heavy machinery.

To really nail down their importance, let's break down the essential jobs these systems perform.

Core Functions of a Fuel Transfer System

| Function | Description | Primary Benefit |

|---|---|---|

| Bulk Transfer | Moves large volumes of fuel from a primary storage tank to a smaller day tank or directly to equipment. | Efficiency. Quickly refuels large machinery or vehicles, minimizing downtime. |

| Fuel Filtration | Removes contaminants like water, dirt, and rust from the fuel before it enters an engine. | Protection. Prevents costly engine damage and extends the life of your equipment. |

| Metering & Monitoring | Accurately measures the amount of fuel being transferred for inventory and cost tracking. | Control. Provides precise data for fuel management and helps detect leaks or theft. |

| Safety Management | Incorporates features like automatic shut-offs, emergency stops, and spill containment measures. | Safety. Reduces the risk of fires, spills, and environmental contamination. |

Ultimately, a well-designed system isn't just moving liquid; it’s providing clean, measured, and safe energy right where you need it.

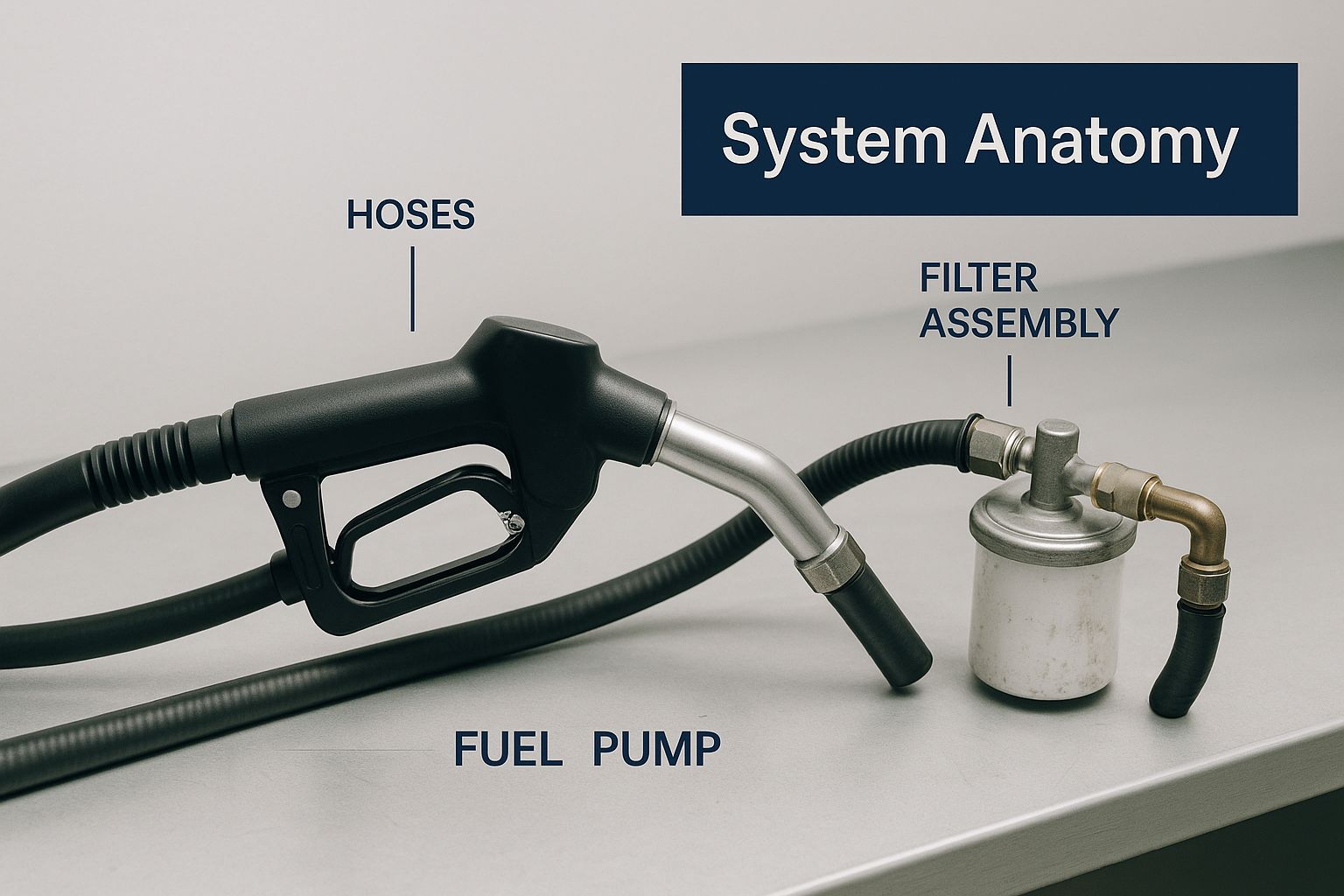

The Anatomy of a Fuel Transfer System

Think of a fuel transfer system like the circulatory system in your own body. Every single part has a specific role, and they all have to work in perfect harmony to move fuel from point A to point B safely and without a hitch. Getting to know these core components really helps you understand how these systems keep your expensive equipment running smoothly.

This infographic breaks down the essential parts that make up a complete fuel transfer system.

As you can see, the pump, hoses, and filter assembly are right at the center of the action, making sure fuel gets where it’s going cleanly and efficiently. Let's take a closer look at what each of these pieces does.

The Pump: The Heart of the Operation

At its core, the pump is the engine of any fuel transfer system. Its one and only job is to create the pressure and flow needed to pull fuel out of a storage tank. If your pump isn't working, nothing else is.

Pumps come in all shapes and sizes, built for different tasks. For example, a farmer out in a remote field might use a portable 12V DC pump that hooks right up to a tractor's battery. On the other hand, a bustling marina fueling up boats all day would need a heavy-duty, stationary 120V AC pump to handle the high volume and constant use.

It all comes down to matching the pump to the job. This is the component doing all the heavy lifting, so choosing the right one is probably the most critical decision you'll make.

Hoses and Pipes: The Arteries and Veins

If the pump is the heart, then the hoses and pipes are the arteries and veins. These are the channels that safely carry the fuel. It's absolutely critical that they are made from materials that won't break down or degrade when exposed to the corrosive properties of gasoline or diesel.

Just think about the different needs. A flexible hose is perfect for reaching a vehicle's fuel tank. But for a permanent setup, you might see rigid steel pipes running underground from a massive storage tank to a dispensing station. The integrity of these lines is non-negotiable for preventing leaks and keeping things safe.

The Nozzle: Precision Delivery

The nozzle is where you have direct control. It lets you start, stop, and manage the flow of fuel with real precision, preventing spills and making sure every last drop goes where it’s supposed to.

Many modern nozzles even have an automatic shut-off feature. It senses when a tank is full and cuts the flow, which is a lifesaver for preventing messy and dangerous overfills. This small part plays a huge role in both safety and efficiency, acting as your direct interface with the whole system.

Filters and Meters: The Kidneys and Brain

Fuel is almost never perfectly clean. Water from condensation, rust particles, and other gunk can build up in storage tanks. The filter acts as the system's kidneys, trapping all those contaminants before they can get into your engine and cause serious damage. A single clogged injector can cost thousands to fix, which makes a simple filter a very smart investment. To see just how important this is, you can learn more about the role of a fuel water separator filter in keeping fuel pure.

Even a tiny bit of water or debris in a fuel line can cause major engine problems and lead to some seriously expensive repairs. A good filter is your first line of defense against contaminated fuel.

Finally, the meter acts as the brain of the operation, accurately measuring and showing you exactly how much fuel is being transferred. This is vital for tracking inventory, billing customers, or just making sure you’re dispensing the right amount. More advanced systems might use sophisticated sensors for even greater precision. For those curious about the tech behind this, exploring LVDT sensor applications in fuel control systems provides a fascinating look under the hood. Together, all these parts work as a single, cohesive unit to make modern fueling possible.

Gasoline vs. Diesel Transfer Systems

While they both power engines, gasoline and diesel are two completely different beasts. Think of it like trying to pump water versus honey—you wouldn't use the same setup. A fuel transfer system has to be built specifically for the liquid it’s moving. Trying to swap them isn't just a bad idea; it's incredibly dangerous.

The whole game changes because of two properties: volatility and viscosity. Gasoline is extremely volatile, meaning it turns into a flammable vapor very easily, even at cool temperatures. Diesel, on the other hand, is thicker (more viscous) and far less volatile, acting more like a light oil.

These differences dictate everything about the system's design, from the rubber seals to the pump motor. Getting this right is the first step to running a safe and reliable fueling operation.

Why Gasoline Systems Demand Explosion-Proof Designs

The biggest danger with gasoline is its volatility. Those vapors it produces are just waiting for a single spark to ignite. That spark could easily come from the internal brushes of a standard electric motor, creating a massive fire risk. This is why regulations are so strict about the equipment used for gasoline.

Any gasoline transfer system absolutely must have an explosion-proof motor. These units are completely sealed, trapping any internal sparks so they can't ignite the fumes in the air.

It doesn't stop there. The entire system has to be designed to handle static electricity. As fuel rushes through a hose, it builds up a static charge. If that charge finds a way to arc, you've got an explosion. That's why gasoline hoses are conductive and need to be properly grounded, giving that static buildup a safe path to dissipate.

"Never underestimate the danger of gasoline vapors. A system that isn't rated for gasoline is a serious fire hazard waiting to happen. The right equipment isn't a recommendation; it's a requirement."

This is why you'll always see components labeled "UL-listed for gasoline." It's not just a sticker; it's a certification that the equipment meets the tough safety standards needed to handle this fuel.

How Diesel Systems Tackle Viscosity and Contaminants

Diesel brings its own set of problems to the table. Being thicker and oilier, it demands a more powerful pump to move it around, especially when it gets cold and even more sluggish. A pump designed for thin, easy-flowing gasoline would strain and likely burn itself out trying to push diesel.

Because of this, diesel pumps are built for torque, not speed. They often have beefier gears or vanes that can generate the higher pressure needed to overcome the fuel's resistance.

Diesel is also prone to contamination, especially from water. Water in a diesel tank can lead to microbial growth—the infamous "diesel bug"—which creates a nasty sludge that clogs filters and ruins expensive injectors. To combat this, diesel transfer systems almost always include more advanced filtration, like water-separating filters, to protect the engine.

The market for these systems highlights their specialized nature. Gasoline-powered pumps, for instance, hold a dominant market share of over 60%, which is expected to grow past USD 2 billion. Within that, electric pumps account for over half of the market, driven by the auto industry’s demand for efficient technology. You can find more data on automotive fuel transfer pump trends to see how designs are tailored for each fuel type.

To really nail down the differences, let's look at them side-by-side.

Gasoline vs. Diesel Transfer Systems Key Differences

The table below breaks down the distinct requirements for handling gasoline versus diesel, showing why you can't just use one system for both fuels.

| Feature | Gasoline System Requirements | Diesel System Requirements |

|---|---|---|

| Pump Motor | Must be explosion-proof (UL-listed) to prevent ignition of flammable vapors. | Standard-duty motor is acceptable, but it must have enough torque to handle higher viscosity. |

| Hoses & Seals | Made from materials like Buna-N or Viton that resist gasoline's corrosive properties. Hoses must be conductive for grounding. | Materials must withstand diesel's oily composition. Often more robust to handle higher pressures. |

| Safety Concerns | The primary concern is fire and explosion from static discharge or sparks igniting vapors. | The main concerns are spills and contamination, especially from water and microbial growth. |

| Filtration | Focuses on particulate matter. Often a simple screen or particle filter is sufficient. | Requires robust filtration, typically including a water separator to prevent engine damage and sludge. |

| Flow Rate | Pumps are designed for lower viscosity, often providing a faster flow rate (GPM) with less power. | Pumps need more power to move the thicker fluid, which can result in lower GPM for the same motor size. |

As you can see, the design philosophy for each system is driven by the unique chemical and physical properties of the fuel it's meant to handle. It's all about matching the equipment to the job to ensure safety and efficiency.

How to Choose the Right Fuel Transfer System

Picking the right fuel transfer system can feel like a big decision, but it boils down to answering a few straightforward questions. It’s all about matching the hardware to the job you need to do, ensuring you get something that’s effective, safe, and doesn't break the bank.

Think of it like choosing any other tool for your workshop or vehicle. You wouldn't use a sledgehammer to hang a picture frame, right? In the same way, the simple setup a farmer needs to top off a tractor is a world away from the high-volume system a busy marina requires to service dozens of boats a day.

Getting this right means you won't overspend on features you don't need or, even worse, find yourself stuck with a system that can't keep up. Let's walk through the three most important things to consider.

Determine Your Required Flow Rate

First things first: how fast do you really need to move that fuel? This is measured in GPM (Gallons Per Minute), and it’s the single biggest factor that will guide your choice of pump. A higher GPM gets the job done faster, but it also means a bigger price tag and more power consumption.

To nail down the right GPM for you, just think about what you're filling up:

- Small Equipment: For smaller tanks on things like generators or jet skis (usually under 25 gallons), a pump that delivers 8-10 GPM is perfect. It's plenty fast without being difficult to control.

- Heavy Machinery: If you’re refueling construction equipment, farm tractors, or bigger boats with 50-100 gallon tanks, stepping up to a 15-25 GPM system will save you a ton of time waiting around.

- Bulk Transfer: For the really big jobs, like moving fuel between large storage tanks or for high-turnover commercial fueling, you’ll need a heavy-duty pump that can push 25 GPM or more.

It's a bit of a balancing act. Go too slow, and you’re wasting time that could be spent on something else. But go too fast with a small tank, and you’re asking for splashes and messy overfills.

Select the Right Power Source

Once you've figured out your speed, you need to think about how you'll power the pump. This decision really comes down to where you'll be doing the refueling. You've got three main options.

-

AC (Alternating Current) Power: These are your stationary workhorses. They plug into a standard wall outlet (120V or 240V) and are ideal for a workshop, garage, or a fixed fueling dock. AC pumps provide consistent power and can handle the higher GPM rates needed for serious, repetitive work.

-

DC (Direct Current) Power: Running on battery power (usually 12V or 24V), DC pumps are built for life on the go. You can hook them right up to a truck or boat battery, giving you the freedom to refuel absolutely anywhere. They're the go-to for mobile and off-grid applications.

-

Manual Pumps: The old-school, reliable option. These hand-cranked pumps need zero electricity. Sure, they're much slower, but they are incredibly dependable, easy to carry, and a lifesaver for small jobs or as a backup when you can't get to power.

For example, a construction fleet manager might install a powerful AC pump at the main depot for overnight refueling, while each of their service trucks would carry a 12V DC pump for topping off equipment out on the job site.

A fuel transfer system is a long-term investment in your operation's efficiency and safety. Taking a moment to think through your specific needs—from the type of fuel to where you'll be working—ensures you end up with a system that will do its job reliably for years.

The demand for these systems is growing fast, which tells you just how critical they are. The global fluid transfer system market was valued at around USD 2.70 billion and is projected to hit USD 6.77 billion as more industries look for efficient ways to handle fluids. You can discover more insights about this expanding market and its components.

Ensure Fuel Compatibility and Safety

This last point is the most important one: you have to make sure every single part of the system is rated for the specific fuel you're handling. As we covered earlier, gasoline and diesel systems are built differently and are not interchangeable. Trying to pump gasoline with a diesel-rated setup is a serious fire hazard, period.

Always check for certifications, like a UL listing. This mark means the equipment has been independently tested to meet strict safety standards for flammable liquids. This isn't just a nice-to-have feature; it's a non-negotiable for keeping you and your property safe.

Essential Safety and Maintenance Practices

Let's be blunt: working with gasoline or diesel demands your full respect. A fuel transfer system is an incredibly useful tool, but it's only as safe as the person using it. Following the right safety steps isn’t just about checking a box for regulations—it’s about protecting yourself, your expensive equipment, and the environment from a completely avoidable disaster.

Think of safety and maintenance as two sides of the same coin. Keeping your pump and hoses in good shape doesn't just make them last longer; it's your first and best defense against dangerous leaks, spills, and sparks. If you cut corners on either, you're setting yourself up for costly downtime or, even worse, a serious accident.

Non-Negotiable Safety Protocols

Safety begins long before you flip the pump's switch. The single most critical thing to manage with gasoline is the risk of static electricity. It’s a simple fact of physics: as fuel rushes through a hose, it can build up a static charge. One tiny spark is all it takes to ignite those flammable vapors.

To stop that from happening, you absolutely must ensure your system is properly grounded. Grounding gives that static charge a safe path to travel, dissipating harmlessly into the earth.

Beyond grounding, make these habits second nature:

- No Smoking or Open Flames: This one’s a no-brainer, but it’s the golden rule for a reason. Keep any and all ignition sources far away from your fueling station.

- Get Some Airflow: If you're working inside a garage or shed, open the doors and windows. Good ventilation prevents a dangerous concentration of fuel vapors from building up.

- Use Explosion-Proof Motors: When you're pumping gasoline, your pump motor must be UL-listed and officially rated as explosion-proof. This is not a suggestion; it’s a requirement.

- Wear Your PPE: At the very least, put on some safety glasses and a pair of fuel-resistant gloves. A splash of fuel in the eye is no joke.

A fuel spill isn't just a messy cleanup. It's a serious safety hazard and an environmental nightmare. A single gallon of spilled gasoline can contaminate thousands of gallons of groundwater. Being careful is your best prevention tool.

Creating a Simple Maintenance Checklist

Catching small problems before they become big, expensive ones is what regular maintenance is all about. A quick look-over before every use and a more detailed check once a month can save you a world of hurt. The whole point is to keep every part of your fuel transfer system in peak condition.

Treat it like a pilot’s pre-flight check. It's a simple routine that gives you confidence that everything is ready to go and working exactly as it should.

Here’s a straightforward checklist to get you started:

-

Inspect Hoses for Damage: Run your hand along the hoses and look for any cracks, bulges, or mushy spots. A weak hose is just a leak waiting to happen. If you see any wear, replace it immediately.

-

Check All Connections: Give all the fittings, clamps, and connections a quick wiggle and a twist. They should be rock solid. A loose fitting is probably the most common cause of a slow, nagging leak.

-

Examine the Nozzle: Squeeze the nozzle trigger to make sure it moves smoothly. If it has an automatic shut-off, double-check that it’s working right.

-

Clean or Replace the Filter: Your fuel filter is what protects your engine from gunk. Check it every month and swap it out based on the manufacturer's recommendation, or sooner if you notice the pump's flow rate seems sluggish.

This hands-on approach keeps your system safe and makes sure it runs reliably for years. For anyone working around water, these checks are even more important. You can learn more by reading our complete guide on boat fueling safety to keep your vessel protected. Make these practices a habit, and you’ll protect your investment while ensuring your fuel transfer system is always ready to work safely and efficiently.

Understanding the Installation Process

Setting up a new fuel transfer system can feel like a big job. But when you break it down into a few clear stages, it's far less daunting.

This guide isn't meant to replace the manufacturer's manual or a pro's advice, of course. Think of it as a roadmap. It'll give you the confidence to either handle a simple installation yourself or know exactly what to ask for when you hire an installer. The goal is always the same: a secure, leak-proof, and efficient fueling setup.

Preparing the Site and Mounting the Pump

First things first, you need to pick the right spot. Look for a stable, level surface that can handle the weight of the pump and tank. You’ll want it out of the way of vehicle traffic to avoid accidental bumps. Good ventilation is also a must, especially with gasoline, to keep flammable vapors from building up.

Once you have your location, the next step is crucial: mounting the pump securely. A pump that vibrates or shifts around is asking for trouble. That movement puts a ton of stress on the fittings and hoses, which is a common cause of leaks down the road. Most pumps have pre-drilled holes in the base, making it straightforward to bolt them down to the tank, a concrete slab, or a heavy-duty bracket.

Connecting Hoses and Electrical Components

With the pump locked down, it's time to connect the plumbing. This is where attention to detail really pays off. Always use a thread sealant—like Teflon tape or pipe dope—that’s specifically made for the fuel you’re pumping. This is your best defense against leaks at the threaded connections.

One of the most common mistakes I see is a cross-threaded fitting. If you have to force it, something is wrong. Damaged threads are a guaranteed leak. Always start threading fittings by hand to make sure they screw in smoothly before you even think about picking up a wrench.

After the hoses are on, the last piece of the puzzle is the electrical hookup. For a DC pump, you’ll connect the positive and negative leads to your battery. For an AC pump, you'll be wiring it into your shop's electrical system.

Safety is everything here. If you have any doubt about what you're doing with the wiring, stop and call a qualified electrician. It’s always the right call.

A solid installation really just comes down to being patient and getting each step right. Prepare the site properly, mount the pump so it's rock-solid, and make clean, leak-free connections. Do that, and your system will serve you well for years to come.

Got Questions? We've Got Answers

When you're dealing with fuel transfer systems, a few questions always seem to pop up. Let's tackle some of the most common ones I hear, so you can feel confident you're getting things right.

What Does GPM Mean For a Fuel Pump?

GPM is short for Gallons Per Minute. Think of it as the pump's speed—it tells you how much fuel it can move in 60 seconds.

Getting the GPM right is all about efficiency. If you’re filling a massive tractor tank with a low-GPM pump, you’ll be standing there forever. But try to fill a small generator with a super-fast, high-GPM pump, and you risk a messy, dangerous spill. The sweet spot is matching the pump's GPM to the size of the tanks you fill most often.

How Often Should I Change the Filter?

This really depends on how clean your fuel is and how much you use the system. A good starting point is to give the filter a visual check every month and swap it out at least every six months.

If your pump suddenly seems slow or weak, a clogged filter is the most likely culprit. That's your system's way of telling you it's struggling to breathe.

If you know your fuel source tends to have a bit of gunk or water in it, you'll want to change that filter more frequently. When in doubt, always follow what the manufacturer suggests for your specific model.

Can I Use One Pump For Multiple Liquids?

Absolutely not. Unless the pump is specifically designed and advertised for multi-fluid use, you should never use it for anything other than its intended fuel. A pump built for gasoline just isn't made to handle water, oil, or chemicals.

Here's what can go wrong:

- Corrosion: Pumping water with a gasoline pump will cause its internal metal parts to rust and seize up in no time.

- Motor Burnout: Thicker fluids like oil will overwork a motor designed for thin gasoline, leading to a quick burnout.

- Contamination: Even tiny leftover amounts of one fluid can contaminate the next batch, which could spell disaster for an engine.

The best practice is to dedicate one pump to one type of liquid. It’s the safest way to protect your pump, your engines, and yourself.

At CLiX Fueling Solutions, we think fueling should be easy and clean—no guesswork, no spills. Our system automatically stops the flow once your tank is full, keeping your boat and the environment safe. See how we make refueling smarter at https://clixfueling.com.