Refueling a boat can be a real pain. It's often a clumsy, awkward process that risks spilling fuel into the water or all over your deck. A good fuel can pump completely changes the game, turning a frustrating chore into a quick, clean, and safe task.

These pumps come in all shapes and sizes, from basic manual siphons to powerful battery-powered units. The whole point is to move gasoline or diesel from your portable can into the boat's tank without making a mess. Picking the right one is your first step toward smarter, safer boating.

Choosing the Right Fuel Can Pump for Your Boat

There’s no single "best" pump for everyone. What works for a small fishing boat won't be ideal for a big cruiser. Your perfect pump depends on your boat, your fuel type, and how much time you spend on the water.

If you have a small skiff with a 6-gallon portable tank, a simple manual siphon pump is probably all you need. They're cheap, tough, and don't rely on batteries. They just work.

But if you're trying to fill a larger tank, a battery-operated pump is a lifesaver. Imagine trying to hoist and pour multiple 5-gallon jugs—it's exhausting and risky. A battery-powered pump delivers a steady, effortless flow, saving your back and getting you back on the water faster.

Material and Fuel Compatibility

This is the most critical part. You absolutely have to match the pump to your fuel type. Gasoline is incredibly corrosive and will eat through the seals and plastics of a pump not designed for it. Using the wrong pump isn't just a waste of money; it's a serious fire hazard.

Diesel is a different animal. It's thicker and less volatile, but it still requires a pump built to handle its specific properties. Always, always check the manufacturer's specs. A reputable brand will clearly label its pumps for gas, diesel, or both. For instance, CLiX Fueling Solutions offers distinct models for gas and diesel to ensure you're using a safe, compatible tool every time.

You might be surprised to learn how much engineering goes into these pumps. The automotive fuel transfer pump market was valued at $2.5 billion USD and continues to grow. This push for better, more efficient pumps in cars and trucks means we boaters get to benefit from that same technology.

Flow Rate and Control

It’s easy to assume faster is better, but when you're filling a boat tank, that's not always true. A pump that moves fuel too quickly can cause it to "burp" back out of the fill pipe, creating a dangerous spill.

The sweet spot is a flow rate you can easily manage, usually around 2-3 gallons per minute (GPM). This is quick enough to not waste your time but gives you enough control to stop the flow immediately if the tank is getting full.

Some of the best pumps have an auto-stop feature that shuts the pump off when the tank is full, which is fantastic for preventing overflows. To get a better feel for the options out there, our guide on the top boat fuel pumps for 2025 breaks down different models and their features.

How to Prepare for a Safe Fuel Transfer

A safe fuel transfer starts long before you even think about pumping. Honestly, taking a few minutes to set up a controlled environment is the best thing you can do to prevent a nasty spill or accident. I always think of it as my pre-flight check on the water.

Your prep should always start with a quick equipment inspection. Don't just grab your fuel can pump and head to the dock; give it a solid once-over. Check the hoses for any cracks, kinks, or signs of becoming brittle—any of these can mess with the fuel flow or, worse, spring a leak. Make sure every connection is tight and the seals look healthy.

A cracked hose or a worn-out seal is practically a guaranteed spill. If you see any damage, just replace the part. It’s not worth the risk.

Setting Up Your Fueling Station

Once you know your gear is good to go, turn your attention to the boat and the area around it. This isn't just for convenience; it’s about shutting down every possible risk.

-

Secure the Boat: First things first, get that boat tied up tight to the dock. A vessel that shifts unexpectedly while you're fueling can easily yank the nozzle out of the tank or knock over a fuel can.

-

Kill the Power: Shut down everything. That means all engines, electronics, and anything else that might create a spark. I’m talking bilge blowers, generators, even the stove in the galley. Gas fumes are heavier than air and can settle in low spots, making any spark a serious danger.

-

Get Good Airflow: Try to position your boat for good ventilation. Ideally, you want the wind carrying fumes away from both the boat and the dock. Open up all the hatches and ports to keep fumes from building up down below.

A huge part of being prepared is knowing your boat's own fuel system inside and out. Understanding the location and type of your marine fuel fill helps you place the can and hose just right, avoiding awkward angles that can lead to a messy transfer.

Final Safety Checks

With your gear and boat prepped, there are just two last things to grab. Don't even think about starting that pump until you have these within arm's reach.

You need a spill kit and a fire extinguisher. Your spill kit should have absorbent pads or pillows made specifically for fuel. Having them ready to go means you can stop a small drip from turning into an environmental headache.

And of course, your fire extinguisher. Make sure it's a marine-rated B-I or B-II type, which is what you need for flammable liquid fires. You hope you never have to use it, but being prepared isn't optional when you're handling fuel. Taking these few simple steps can turn a potentially dangerous chore into just another routine part of a great day on the water.

A Practical Guide to Pumping Fuel Without Spills

Alright, your boat is tied off and your gear is ready to go. Now for the main event: moving the fuel. This is where a good fuel can pump really shines, turning what could be a messy, frustrating chore into a clean and simple transfer. Getting it right just takes a little technique.

First things first, get a perfect seal between the pump and the fuel can. I can't stress this enough—a loose connection is the number one cause of dangerous vapor leaks and will make your pump struggle for suction. Thread it on straight and tighten it down until it's snug. You need an airtight fit. This is non-negotiable for safety and for the pump to work properly.

Once the pump is locked onto the can, go ahead and insert the nozzle into your boat's fuel fill. Don't just shove it in there. Make sure it's deep enough that it won't pop out if the boat rocks or the hose shifts. Trust me, a nozzle slipping out mid-transfer is a nightmare you don't want to live through.

Mastering the Fuel Transfer

With the nozzle in place, you can start pumping. I always recommend starting slowly. This gives you a moment to double-check that everything is flowing smoothly and there are no surprise leaks at any of the connection points. A steady, controlled pace is always better than rushing.

As the fuel is moving, just pay attention. You’ll often hear the sound of the pump change as the can gets low. It might start to sputter a bit or the motor's whine will change pitch as it begins to pull in air. That’s your signal to get ready to stop.

The pumps we use today are worlds away from older models. The global market for fuel transfer pumps was $1.87 billion and is projected to hit $2.45 billion in just five years, largely because of better safety features. Some of the high-end pumps can move 200 liters a minute with 99% accuracy, which shows you how serious manufacturers are about preventing spills. You can find more market growth insights at Research and Markets.

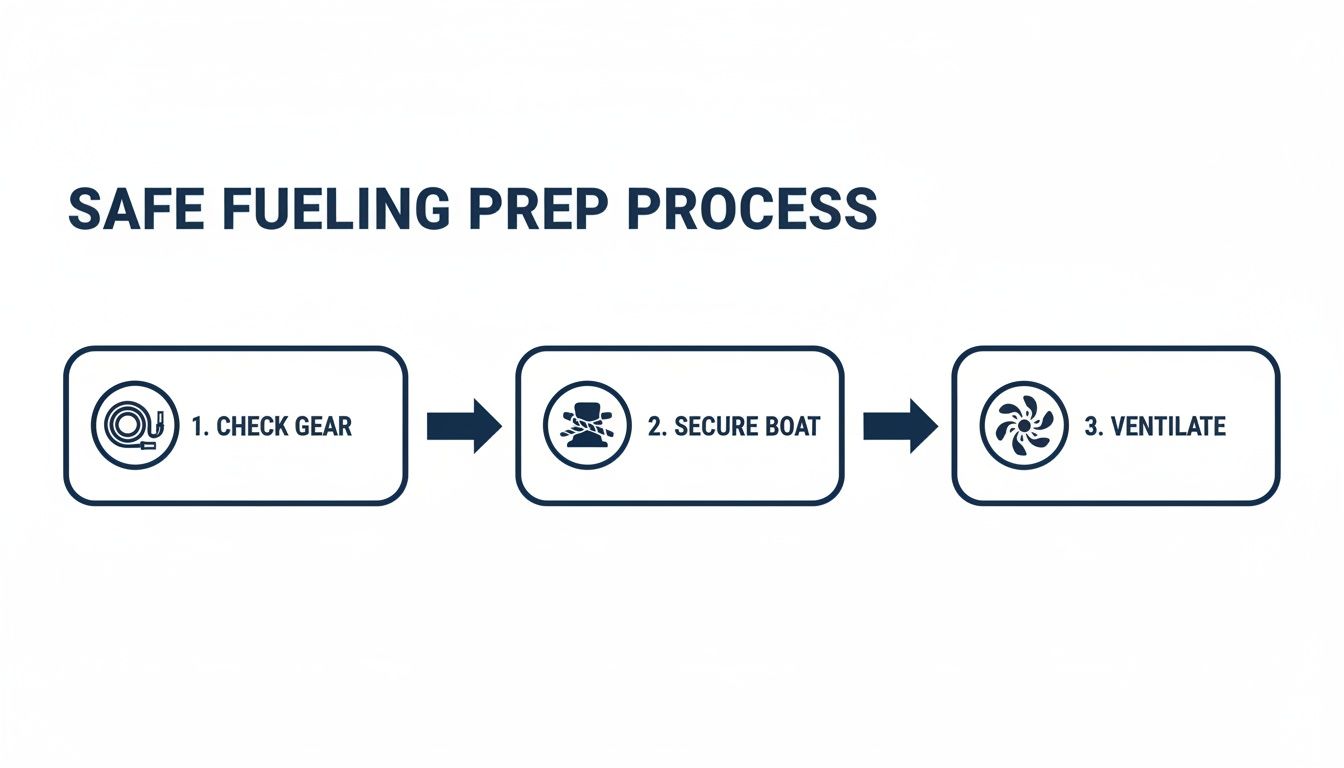

Thinking through the prep steps visually can help burn them into your routine so you do it right every time.

This simple flow—gear check, secure boat, good ventilation—is the foundation for a spill-free day on the water.

Finishing the Job Cleanly

The last few seconds of the transfer are prime time for spills. A little care here goes a long way.

When you hear the pump sputter as the can runs dry, stop the flow. I usually tilt the can to get that last bit of fuel pooled in one corner. This lets you get the very last of it out without sucking a bunch of air into the line.

A few quick tips for managing the hose can also save you a headache:

- Keep it Straight: Try to avoid any sharp kinks or bends. A kinked hose restricts flow and puts a lot of stress on the pump and connections.

- Support the Hose: Don't let the full weight of the hose just hang off the nozzle. Use your free hand to support it and take the strain off.

- Position for Success: Set your fuel can on the dock or deck where the hose can have a nice, gentle curve down to the tank. Don't stretch it tight.

When you're done, pull the nozzle out of the tank slowly. The key is to keep the tip pointed up as you lift it out. This lets any fuel left in the hose drain back into your boat's tank instead of all over your deck. It’s a small move that makes a huge difference.

Keeping Your Fuel Pump in Top Condition

Proper care is what separates a reliable fuel can pump from one that dies on you at the worst possible moment. A little bit of maintenance makes all the difference, giving your pump a long and effective life. Just think of it like any other critical piece of boating gear—it needs some attention to perform when you count on it.

The most important habit you can build is cleaning the pump after every single use. It's not complicated. Just pump any leftover fuel from the hose back into the can, then let the pump run dry for a few more seconds. This simple step purges the lines and prevents fuel from degrading the seals and hoses, which is what makes them brittle over time.

Your Routine Inspection Checklist

Before you pack it away, give your pump a quick once-over. This five-minute check can spare you a massive headache on your next trip out on the water.

Here’s what to look for:

- Check the Hoses: Run your hands along the entire length of the hose. You're feeling for any cracks, brittle sections, or weirdly soft spots. A bad hose is the number one reason these things fail.

- Inspect the Seals: Take a look at the seals where the pump connects to the can. They need to be soft and pliable, with no signs of cracking or wear.

- Test the Power: If you're using a battery-powered model, check that the batteries are good to go. Corroded terminals are a classic culprit for a pump that won't turn on, so keep them clean.

Don't forget that the pump is only part of the equation. You also need to be maintaining a clean fuel supply with a quality filter to ensure everything runs smoothly for the long haul.

It's no surprise that regular maintenance is so important, especially given the technology involved. The global fuel pumps market was valued at $8.242 billion and is projected to keep growing, largely thanks to new innovations in efficiency and safety.

Smart Storage for Longevity

Where you store your pump is just as important as how you clean it. Tossing it in a hot trunk or leaving it out in the sun is just asking for trouble. Heat and UV exposure will wreck the plastic and rubber components, leading to a much shorter lifespan.

The best spot for your fuel can pump is somewhere cool, dry, and well-ventilated—think a garage shelf or a dedicated storage locker. This keeps it safe from the elements and ready for your next adventure. Taking these small steps is just part of being a responsible boat owner.

For a deeper dive into all things fuel pumps, check out our complete boat fuel pump guide for more expert tips on selection and care.

Common Fueling Mistakes and How to Avoid Them

Even the most seasoned boaters have a story about a fueling mishap. It usually comes down to a simple distraction or a bad habit, but the results can be messy, dangerous, and bad for the environment. It's much better to learn from others' mistakes than to make them yourself.

One of the biggest culprits is overfilling the tank. You get distracted by a passing boat or a question from a guest, and suddenly fuel is spewing from the fill pipe. The only real defense here is your undivided attention. Never walk away or turn your back when the fuel can pump is running, even if you trust its auto-shutoff feature.

Overfilling and the Topping-Off Temptation

We've all felt that urge to "top off" the tank to get every last drop in. It feels like the right thing to do, but it’s a classic mistake that often leads to spills. Your boat’s fuel tank needs a little empty space for the fuel to expand as temperatures change throughout the day.

When you overfill, that expanding fuel has nowhere to go but out the vent line, creating a dangerous slick on the water and a serious fire hazard.

A single pint of spilled fuel can create a slick the size of an acre on the water's surface. This puts things into perspective—preventing spills isn't just about a clean boat; it's about protecting the water we all enjoy. Make it a habit to stop pumping at the first click or when the tank is about 90% full.

Another common pitfall is grabbing the wrong gear for the job. Using a pump built for diesel to transfer gasoline is a critical mistake. Gasoline is much more corrosive and demands specific materials for seals and hoses to prevent them from breaking down. Using the wrong pump is a recipe for leaks and a major safety risk. Always use dedicated, clearly labeled equipment for each type of fuel.

Poor Hose Management and Its Consequences

It might seem like a small detail, but how you handle the hose makes a huge difference. A tangled or kinked hose doesn't just slow things down; it restricts the flow and puts a ton of strain on the pump's motor. This can cause the pump to work harder, overheat, and burn out way too soon.

A messy hose is also a serious trip hazard on the dock or deck. One wrong step could pull the nozzle right out of the tank or send the entire fuel can tumbling, leading to a major spill in an instant.

Here’s a simple routine to avoid these problems:

- Lay It Straight: Before you even start pumping, lay the hose out so it has a clear, direct path from the can to the tank.

- Give It Slack: Never stretch the hose to its maximum length. Make sure there’s enough slack to handle any movement from the boat rocking in the water.

- Support Its Weight: Use your free hand to hold the hose, taking the weight off the nozzle. This gives you better control and prevents strain.

Turning these small actions into habits will make fueling a safe, routine part of your boating life. It’s all about being methodical and focused to ensure every fuel transfer is clean and completely spill-free.

Got Questions About Fuel Can Pumps? We've Got Answers

Even seasoned boaters run into questions when using new gear. Here are the answers to some of the most common things we get asked about using a fuel can pump. Hopefully, these clear, straightforward answers will help you fuel up safely and efficiently.

Can I Use the Same Pump for Both Gasoline and Diesel?

Absolutely not. Using one pump for both gasoline and diesel is a recipe for disaster. It's not just about cross-contaminating your fuel and potentially wrecking your engine; it's a massive safety risk.

Gasoline is far more corrosive than diesel and requires pumps made with specific seals and materials that can handle it. A pump that isn't rated for gas can quickly degrade, crack, and leak. The only way to do this safely is to have dedicated, clearly labeled pumps and cans for each type of fuel. No exceptions.

What’s the Best Way to Prevent Spills When a Can Is Almost Empty?

This is all about listening and being patient. As the can gets low, the sound of the pump’s motor will change—it'll often get higher-pitched or start to sputter as it pulls in air. That's your signal to slow things down.

My Go-To Trick: The moment I hear that sputtering sound, I gently tilt the fuel can to gather the last bit of fuel into one corner. This helps the pump get every last drop without sucking in a big gulp of air, which is what causes that final splash of fuel to spit out of the nozzle.

When you're ready to pull the nozzle out, do it slowly and keep the tip pointed up. This simple move lets any fuel left in the hose drain back into the tank instead of all over your deck.

How Should I Clean My Fuel Pump?

A quick cleanup after each use goes a long way in keeping your pump working for years. First, make sure you pump any fuel left in the hose back into the can or your boat's tank. Then, let the pump run dry for just a few seconds to clear the lines.

Give the outside of the pump and hose a good wipe-down with a clean, dry rag. A crucial point here: Never use water to clean the inside of the pump. You'll just introduce moisture that can cause serious engine trouble next time you fuel up. Store it in a cool, well-ventilated spot away from sparks and direct sunlight.

How Do I Legally Dispose of Old or Contaminated Fuel?

Getting rid of old fuel the right way is a big deal, both legally and for the environment. Never, ever dump it on the ground, into the water, or down a storm drain. It’s highly toxic, illegal, and causes incredible harm.

The proper way is to take it to a designated hazardous waste collection site. You’ll need to transport it in a clearly labeled, approved container. Check with your local marina, an auto parts store, or your county's waste management service—they can point you to a drop-off location. A quick online search for "hazardous waste disposal near me" will usually give you a few safe and legal options.

Ready to make fueling simple and spill-free for good? CLiX Fueling Solutions gives you total peace of mind with our genius auto-shutoff system. Check out our gas and diesel models and see just how easy safe fueling can be.