A gas hand pump is your trusty, no-frills tool for moving fuel from a can to your boat’s tank. It’s a simple, manually operated device that doesn’t need any electricity to work. Think of it as a powerful, portable lifeline—an essential piece of safety gear for any boater and a reliable backup when you're far from a modern fuel dock.

Understanding Gas Hand Pumps and Their Role in Boating

At its heart, a gas hand pump is a mechanical fix for a common headache: moving fuel safely when an electric pump isn't an option. For boaters, this is a situation we know all too well.

You might be moored at a remote slip, topping off the dinghy from a jerry can, or worse, running low on fuel miles from shore. In these moments, a manual pump is often the only thing that can get the job done. Its real value is in its sheer simplicity and reliability.

These pumps have been around forever, playing a quiet but vital role in small-scale fueling since the early 20th century, long before electric dispensers were everywhere. By the 1920s, basic piston pumps were a common sight for getting gasoline from drums into boats and cars, especially where there was no power grid. Even today, with over 11 million registered recreational vessels in the United States, thousands of boaters still count on these manual systems to top off their tanks.

Why Every Boater Needs a Manual Pump

Sure, modern marinas have great fueling stations, but a hand pump gives you independence and a critical safety net. You really see its value in a few key situations:

- Emergency Fueling: Running low on gas offshore can go from an inconvenience to a serious problem fast. A hand pump lets you safely transfer that spare fuel from a portable can into your main tank. Knowing what to do if you run out of gas at sea often starts with having the right tool on board.

- Remote Locations: We all love those secluded coves and private docks, but they rarely come with a fuel station. A hand pump means you can refuel from your own containers without having to motor all the way back to a busy marina.

- Fuel Management: They’re also perfect for practical tasks like moving fuel between tanks or siphoning out old, contaminated gas. Having that kind of direct control is a big part of maintaining healthy boat fuel systems.

Key Takeaway: The gas hand pump isn't just about convenience—it’s about self-sufficiency and safety. It gives you the power to handle fuel problems on your own, making sure a great day on the water doesn't get ruined by an empty tank.

Exploring Different Types of Manual Fuel Pumps

When you hear "gas hand pump," you might picture one specific tool. But the truth is, there's a whole family of them, each built differently and for different jobs. Knowing the ins and outs of each type is crucial for picking the right one for your boat—whether it's for routine fueling or an emergency on the water.

They generally break down into three main types: piston, rotary vane, and siphon pumps. Let's look at how each one works, and where they shine (or don't) in a marine setting.

Piston Pumps: The Classic Workhorse

The piston pump is probably the one you're imagining. It works just like a classic bicycle pump. You pull the handle up, and a piston inside a cylinder sucks fuel into the chamber. Push the handle down, and that fuel is forced out through the hose into your tank. Simple as that.

That straightforward push-pull motion is great for creating some serious suction and pressure. This makes piston pumps perfect for moving fuel over a short vertical distance—say, from a jerry can sitting on the dock up into your boat’s fuel intake.

The downside? The flow is choppy, matching your pumping rhythm, so it can feel a bit slow and strenuous compared to other options. Your effort directly dictates the speed.

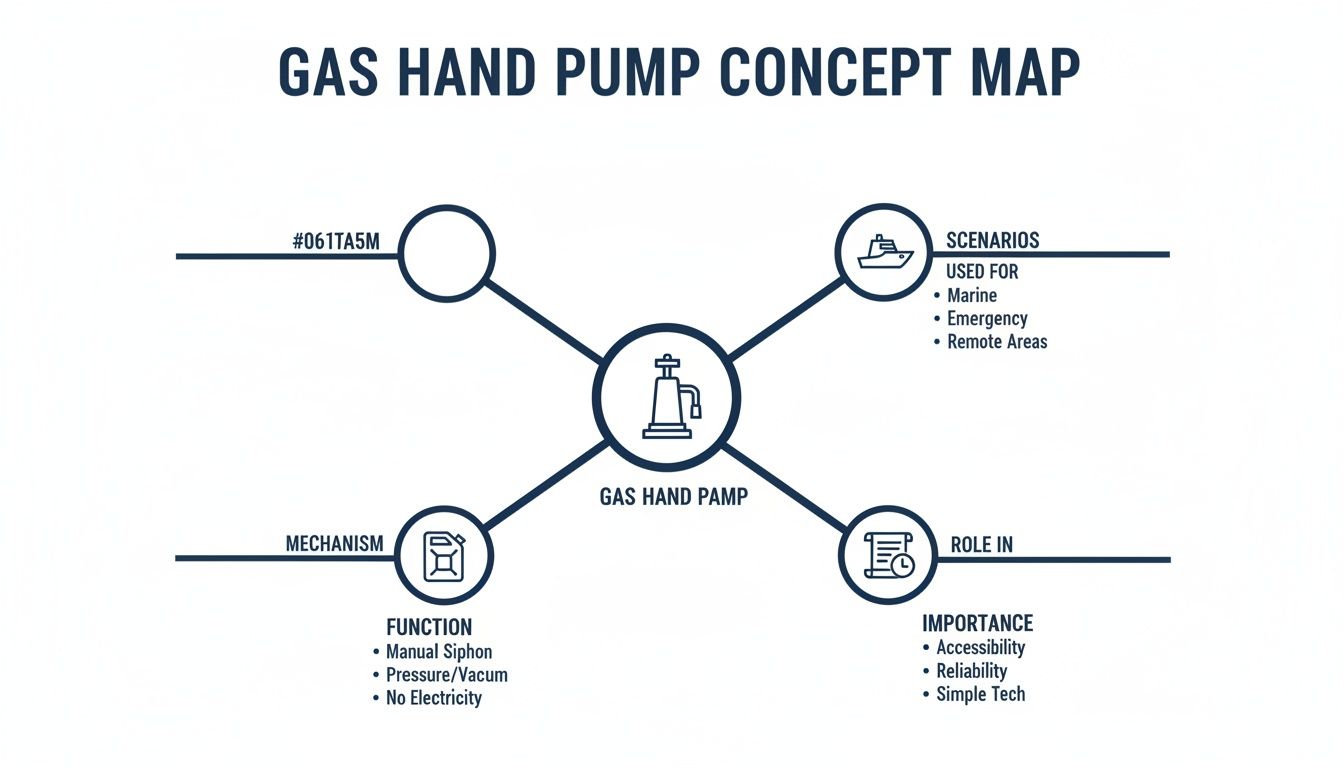

This concept map gives you a good visual of how different manual pumps fit into the boating world.

As you can see, the right pump really depends on what you're trying to do. That’s why it’s so important to know the difference.

Rotary Vane Pumps: Smooth and Steady Flow

Next up is the rotary vane pump. Think of this one less like a bike pump and more like a little water wheel. Inside the housing, there's a rotor with small, sliding vanes. When you turn the crank, this whole assembly spins, creating little sealed-off chambers that trap fuel, carry it around, and push it out the hose.

The result is a beautifully smooth, continuous stream of fuel. This is the big advantage here: a consistent flow rate. Unlike the stop-start action of a piston pump, a rotary pump keeps the fuel moving as long as you're turning the handle. It’s a much better choice for transferring larger volumes of fuel without wearing out your arm.

Key Insight: Rotary pumps are a favorite for their efficiency and ease of use, especially when you're dealing with more than a few gallons. They're a real step up for boaters who often transfer fuel by hand.

The trade-off is their complexity. With more moving parts, they can be more vulnerable to gunk and debris in the fuel, which means they need a bit more care and maintenance to keep running smoothly.

Siphon Pumps: Harnessing Gravity

Last but not least, we have the siphon pump—the simplest of the bunch. This type doesn’t really create mechanical pressure. Instead, you use a little squeeze bulb or a vigorous shake to get the fuel moving, and from there, gravity takes over.

For a siphon to work, your fuel source (the gas can) has to be higher than the destination (your boat’s tank). Once you get the flow started, the siphon effect kicks in, and fuel will continue to drain downhill all on its own.

Siphon pumps are dirt cheap and dead simple. They have almost no moving parts, so they're super reliable and easy to toss in a storage locker. But they come with some hard limits:

- Gravity Dependent: If you can’t get the source container above the tank, they’re completely useless.

- Less Control: Stopping the flow can be clumsy. You usually have to lift the hose out of the fuel, which makes spills a real risk.

- Slow Flow Rate: The flow is generally much slower than what you'd get from a piston or rotary pump.

Because of this, siphon pumps are really only good for small, non-urgent fuel transfers where you just need something simple that works.

To help you decide, here’s a quick breakdown of these three common pump types.

Comparison of Common Manual Fuel Pump Types

| Pump Type | Mechanism | Best For | Pros | Cons |

|---|---|---|---|---|

| Piston Pump | A piston moves up and down in a cylinder, creating suction and pressure. | Small to medium transfers, especially when lifting fuel vertically. | Simple, reliable, good suction. | Pulsed flow, can be tiring for large volumes. |

| Rotary Vane Pump | A crank turns a rotor with sliding vanes, creating a continuous flow. | Transferring larger volumes of fuel quickly and efficiently. | Consistent flow, less physical effort, faster. | More complex, more moving parts, can be damaged by debris. |

| Siphon Pump | Uses a squeeze bulb or shaking motion to start a flow, then relies on gravity. | Small, simple transfers where the fuel source is elevated. | Inexpensive, very few parts to break, highly portable. | Requires gravity, slow flow rate, messy to stop. |

Each pump has its place. Your choice really comes down to how much fuel you typically move, your physical setup on the dock or boat, and how much you value speed versus simplicity.

The Hidden Risks of Fueling with Hand Pumps

The simple convenience of a gas hand pump can sometimes hide its serious downsides. While they’re undeniably useful tools in many situations, their manual nature brings risks that every boater needs to take seriously. From environmental damage to fire hazards, understanding these dangers is the first step toward safer fueling on the water.

The biggest and most common risk? A fuel spill. It only takes a momentary distraction—a sudden wake, a dropped hose, or just misjudging how full the tank is—for gasoline to end up in the water. Unlike fuel docks with automatic shut-off nozzles, a hand pump puts all the control, and all the responsibility, squarely on your shoulders.

Environmental Impact of Fuel Spills

Even what looks like a small spill can wreck a marine ecosystem. Gasoline is highly toxic to aquatic life, and it doesn’t just disappear.

- Immediate Harm to Wildlife: A single gallon of gasoline can contaminate up to 750,000 gallons of water. It creates a film on the surface that blocks oxygen, essentially suffocating fish and other organisms.

- Long-Term Damage: The toxic chemicals in gasoline can sink into the sediment, poisoning the habitat for years and working their way up the food chain.

- Difficult Cleanup: Cleaning a fuel spill on water is a messy, expensive, and often incomplete job. The responsibility—and the hefty bill—can fall directly on the boat owner.

A small overfill might seem like just a few drops, but those drops quickly spread into that all-too-familiar rainbow sheen, a clear sign of environmental contamination. Responsible boating means doing everything you can to keep fuel in the tank and out of the water.

Knowing how to manage a spill is critical for minimizing the damage. If an accident happens, having a plan is essential. For a deep dive on this, check out our guide on cleaning gasoline spills.

Fire Hazards and Personal Safety

Beyond the environmental mess, manual fueling with a hand pump presents some serious fire risks. Gasoline is incredibly volatile. Its vapors are heavier than air, which means they can sink and collect in low, unventilated spaces like your boat’s bilge.

This creates the perfect recipe for a potential explosion. All it needs is a single spark.

Common Ignition Sources During Manual Fueling:

- Static Electricity: Fuel moving through a hose can build up a static charge. If you’re not properly grounded, that charge can jump from the nozzle to the tank opening, instantly igniting the fumes.

- Stray Sparks: A spark from a nearby electrical part, a dropped metal tool, or even a cell phone can be enough to set off a fire.

- Engine Heat: Never fuel near a hot engine or exhaust. The heat alone can be enough to ignite gasoline vapors.

On top of all that, a failing hand pump has its own set of dangers. A worn-out seal or a cracked hose can leak fuel all over your hands, the dock, or your boat, increasing both your exposure and the fire risk. If a pump suddenly starts making a whining noise or gets hard to crank, it’s telling you something is wrong. Continuing to use it is a gamble you don't want to take.

6. Keeping Your Hand Pump in Shipshape: Maintenance and Troubleshooting

A gas hand pump is a beautifully simple tool, but don't let that fool you. Its reliability hinges entirely on how well you look after it. Just like any other gear on your boat, a little preventative care goes a long, long way.

Ignoring your pump is a recipe for frustration. It can lead to annoying failures right when you need it, messy spills on your deck, and unsafe conditions at the dock. Good upkeep isn't complicated; it's just about staying ahead of the game.

A Simple Maintenance Routine That Works

The secret to keeping a hand pump working perfectly is consistency. You don't need to spend hours on it—just a few quick checks can catch small issues before they snowball into big problems.

Build this checklist into your fueling routine:

- Rinse After Use: If you can, run a small amount of clean fuel through the pump when you're done. This helps flush out any gunk or water, which is especially important in saltwater environments.

- Inspect Hoses and Seals: Give the hoses a quick once-over before and after you use the pump. Look for any cracks, kinks, or spots that feel brittle. The seals and gaskets at connection points are your primary suspects for leaks, so pay close attention to them.

- Feel for Smooth Operation: As you pump, notice how it feels. A healthy pump is smooth. If you feel any grinding, sticking, or weird resistance, that's a red flag that something inside needs a look.

- Store It Right: When you're done, find a clean, dry spot for it out of the sun. UV rays will absolutely destroy rubber and plastic over time. And whatever you do, don't coil the hoses too tightly—that's a sure way to cause permanent damage.

Pro Tip: Never, ever use water to clean the inside of a fuel pump. Even a tiny bit of leftover moisture can contaminate your next tank of gas and start causing corrosion inside the pump's guts.

What to Do When Things Go Wrong

Even the best-maintained gear has bad days. The good news is that most hand pump problems are pretty straightforward and easy to fix if you know what you're looking for.

If your pump starts acting up, don't panic. Just work through the possibilities logically. This handy chart covers the most common headaches and how to solve them.

| Symptom | What's Likely Happening | How to Fix It |

|---|---|---|

| No Suction or Weak Flow | There’s an air leak somewhere, probably from a loose connection or a worn-out seal. | Check that all fittings are snug. If that doesn’t do it, find the bad seal—it’ll likely be cracked or hard—and replace it. |

| Pump Handle Is Stiff or Stuck | Debris has gotten lodged in the mechanism, or the internal parts are dry. | Take the pump apart (check the manual!) and give everything a good cleaning. Apply a little bit of fuel-safe lubricant. |

| Fuel Leaks from Connections | The gaskets have had it, or a hose fitting is cracked. | Stop pumping immediately. You need to replace the bad part before you use the pump again, no exceptions. |

| Pumping Is Super Slow | The intake filter or the hose itself is clogged with gunk from the fuel can. | Pop the intake hose off and check the little filter screen. Clean off any sediment you find. |

Getting familiar with these common issues means you can fix them on the spot instead of letting them ruin your day. A well-cared-for hand pump is a tool you can count on; a neglected one is just an accident waiting to happen.

It's Time to Move Beyond Manual Pumping

After looking at all the risks and upkeep that come with old-school gas hand pumps, one thing is crystal clear: they leave way too much room for human error. It only takes a second of distraction, a failing seal, or a quick misjudgment to cause a dangerous and expensive fuel spill. That constant need to be on high alert can turn a simple refueling stop into a stressful chore. This is exactly why the marine industry has been looking for smarter, safer ways to get the job done.

The future of fueling your boat isn't about finding a more complicated hand pump. It's about using systems that have safety built right in from the start. These modern solutions all share one critical goal: stop spills before they ever happen by taking the guesswork out of the equation. They give you a level of protection that you just can't get with manual pumping, and that means more peace of mind on the water.

The Shift Toward Automated Fueling Safety

The pump market as a whole is massive—globally, the demand for all kinds of pumps is expected to climb to $89.2 billion by 2033. Zooming in on our world, the smaller niche of fuel transfer pumps is also growing, projected to reach $184 million by 2032, largely because of tighter regulations around safe fuel handling. You can dig into the numbers and trends yourself over on Grandview Research.

This trend is pushing a clear demand for smarter solutions that keep the simplicity of older methods but add modern safety nets, like an automatic shutoff. This isn't just about making things easier; it’s a direct answer to the real environmental and safety costs of manual fueling. The fix lies in tech that knows when a tank is full and cuts the flow for you, just like the pump at any gas station.

The Real Problem with Manual Pumping: No matter how careful you are, the shutoff mechanism is you. Modern systems take that job away from the user and give it to a reliable, automated process. You get a perfect fill every single time.

This kind of technology isn't just for big industrial operations anymore. Clever new products are bringing this precision and safety right to the recreational boater. Instead of trying to guess the fuel level by sight or sound, these systems give you a definite, automatic stop. This is a huge step up, even from the best electric portable gas pump options out there, which might be faster but still need you to be watching like a hawk.

Meet the Spill-Proof Fueling System

This is exactly the problem the CLiX Fueling system was built to solve. It was designed from day one to tackle the single biggest headache in marine fueling: the overfill. It’s not just a new pump or a different nozzle. It’s a complete system that works with your boat to make fueling foolproof and totally stress-free.

CLiX creates a direct, sealed connection between the fuel nozzle and your boat's tank. This seal is what allows the automatic shutoff on any standard gas pump nozzle to work just like it does when you fill up your car.

Here’s how easy it makes the process:

- Connect: The CLiX receiver gets installed on your boat’s deck fill.

- Click: You just click the fuel nozzle into the receiver. That's it—you’ve made a secure, sealed link.

- Fuel: Start pumping and relax. No more peeking into the tank or listening for that gurgle that means you're about to make a mess.

- Auto-Stop: The moment the tank is full, the nozzle clicks off automatically, instantly stopping the flow.

This simple, smart design makes it impossible for fuel to splash out of the fill opening. It protects your boat's gelcoat, your own health, and the water we all enjoy. It takes fueling from a high-stakes guessing game and turns it into a clean, simple, and safe task. With CLiX, the risk of an overfill is completely gone, giving you total confidence every time you head to the fuel dock.

Frequently Asked Questions About Hand Pumps and Fueling

We've covered a lot of ground, but you might still have a few questions rolling around. That's completely normal. Moving from old-school fueling habits to safer, modern methods is a big step. This final section answers the most common questions boaters and marina staff ask about hand pumps and better fueling practices.

Think of this as your quick-reference guide. The goal is to give you clear, straightforward answers to help you make the smartest, safest decisions for your boat.

Are Gas Hand Pumps Allowed at All Marinas?

This is a big one, and the short answer is a hard no. Whether you can transfer fuel from a portable jug using a hand pump depends entirely on the marina's rules. Many, if not most, modern marinas have strict policies against it, requiring all boats to refuel at the designated fuel dock.

Why the strict rules? It’s not about making your life harder—it’s about safety and environmental protection. The risk of a fuel spill or, even worse, a fire is just too high when you have dozens of boats packed together.

Pro Tip: Before you ever think about using a hand pump, walk over to the marina office and ask about their specific fueling policy. Ignoring the rules could get you a hefty fine or even kicked out of the marina. It’s a community, and safety is everyone’s job.

What Is the Best Way to Prevent a Fuel Spill?

When you’re using a traditional hand pump, preventing a spill is 100% on you. It takes your full, undivided attention. No exceptions.

To have any chance of avoiding a mess, you absolutely must:

- Use Absorbent Pads: Before you start, tuck an absorbent pad or a fuel bib around the deck fill. It’s your first line of defense against drips and splashes.

- Stay Glued to the Nozzle: Never, ever walk away while pumping. Don't try to prop the handle open or get distracted by a conversation.

- Pump Slowly and Listen Carefully: A slow, steady rhythm is key. As the tank fills, the sound of the fuel entering will change. This is your only clue that you're getting close to full.

But let's be honest—even the most careful boater can make a mistake. The only truly foolproof way to stop a spill is to use a system that shuts off the flow automatically. That's where modern technology takes human error completely out of the equation.

How Do I Know When to Replace My Hand Pump?

Knowing when to toss your old hand pump is critical for preventing a nasty failure. You should plan on replacing it at the first sign of trouble, not after it's already failed and dumped fuel on your deck.

Here are the tell-tale signs that it’s time for a new one:

- Visible Damage: Look for cracks, deep gouges, or any discoloration on the pump body or hoses. UV rays are brutal on plastic.

- Brittle Parts: If the seals, gaskets, or hoses feel stiff and hard instead of soft and flexible, they're toast.

- Any Leaks: Even a tiny drip from a hose connection is a huge red flag. Don't ignore it.

- Poor Performance: Is the pump losing suction? Does the handle feel gritty or require way more muscle than it used to? These are signs the internal parts are shot.

A new hand pump is cheap. The cost of a fuel spill—both financially and environmentally—is not. When in doubt, throw it out.

Can a System Like CLiX Be Used on Any Boat?

Yes, for the most part. The CLiX Fueling system was designed to be a nearly universal fit for the vast majority of recreational boats with standard deck fills, whether you run on gas or diesel.

The installation is simple and doesn't require major surgery on your boat’s fuel system. It’s engineered to work perfectly with the auto-shutoff nozzles you find at every modern fuel dock. That means you get a perfect, spill-proof fill-up every single time, no matter where you are.

Of course, it's always smart to double-check the manufacturer's specs against your specific boat model just to be certain. But the peace of mind that comes from knowing you'll never overfill your tank again is one of the best upgrades any boater can make.

Ready to make fueling your boat the safest, cleanest, and easiest part of your day? Say goodbye to spills, stains, and stress. The CLiX Fueling Solutions system provides a foolproof, automatic shutoff that protects your boat, the environment, and your peace of mind. Learn more and upgrade your fueling experience at https://clixfueling.com.