A flexible spout for your gas can is one of those simple upgrades that makes a world of difference. It replaces the old, rigid spouts that feel like they were designed to spill, turning a frustrating chore into a quick, clean, and safe task. With a flexible spout, you can finally navigate those awkward angles with total precision.

Why Old Gas Can Spouts Just Don't Cut It

Let's be honest—wrestling with a traditional gas can is an almost universal frustration. We’ve all been there. You're holding a heavy can, trying to pour gas into a tiny opening, and the fuel starts glugging and splashing everywhere. Old-school, rigid spouts are notorious for making messes.

The headaches are all too familiar. Inflexible designs force you into uncomfortable positions, and the result is almost always a spill. That's not just wasted money; it's a serious fire hazard and terrible for the environment. Factor in the clumsy, hard-to-use "safety" mechanisms on some cans, and a simple job like fueling a lawnmower becomes a dreaded chore.

The Push for a Better Design

All that shared frustration from people fed up with spills and inefficient designs really drove a change in the industry. People needed solutions that were easy to use, genuinely safe, and didn't waste fuel.

The market definitely responded. The dispensing spout market was valued at around USD 837.7 million in 2023 and is only expected to grow as more people seek out convenient, no-mess solutions. This is what led us directly to the modern flexible spout.

These newer designs solve the core problems of their rigid ancestors:

- Precision Pouring: The flexible neck lets you guide fuel right where it needs to go, even in tight or hard-to-reach spots on your boat or generator.

- Controlled Flow: Many new spouts have better venting and trigger controls, giving you a smooth, predictable pour. You can learn more about how this works in our guide to fuel nozzle auto shut-off features.

- Reduced Spills: By getting rid of awkward angles and giving you more control, you can practically eliminate spills. This protects your equipment, your skin, and the environment.

A flexible spout isn't just a minor convenience; it's a fundamental improvement in safety and efficiency. It turns a risky, messy task into a controlled, clean process.

Whether you're refueling a generator in the dark or topping off a boat on rocking water, the benefits are obvious. Swapping out that old spout for a flexible one is a small change that makes a huge difference.

How to Choose the Right Flexible Spout

Picking the right flexible spout for your gas can isn't just about grabbing the first one you see on the shelf. The difference between a good spout and a great one really comes down to the details—the material it's made of, whether it actually fits your gear, and features that genuinely make your life easier and safer. I've seen it time and again: a bad choice leads to frustrating leaks and dangerous spills, completely defeating the purpose of getting a better spout in the first place.

Think of it like choosing any other tool for a specific job. You wouldn't try to hammer a nail with a screwdriver, right? The spout you need for a small chainsaw is a world away from what you’d want for refueling a boat that's bobbing at the marina. Your choice here has a real impact on your safety and how efficiently you get things done.

Material and Durability

The first thing I look at is what the spout is made of, because that tells you everything about its lifespan and resilience. Most are made from High-Density Polyethylene (HDPE), a tough plastic that stands up well to chemicals and getting knocked around. For the most part, it’s a solid, affordable choice.

But not all plastics are created equal. I've seen cheaper spouts made from flimsy polymers get brittle and crack after a season of sun exposure or a cold winter. A well-made HDPE spout, on the other hand, will stay flexible in the cold and won't get weak in the summer heat, meaning it’ll work when you need it to for years to come.

The best flexible spouts are engineered systems, not just simple plastic tubes. Investing in quality materials like virgin HDPE prevents cracks and leaks, protecting both your engine and the environment from contamination.

Size and Compatibility

Next up is fit. This is where most people get tripped up, and it's the number one cause of frustrating, messy leaks. You have to make sure the spout fits both your can and whatever you're fueling.

- Thread Compatibility: Gas cans have all sorts of different thread sizes and patterns. Before you buy anything, double-check that the spout’s collar will match your can. Many of the better replacement spouts come with a few different adapter rings for a universal fit—that’s a fantastic feature to look for.

- Spout Length and Diameter: A longer spout is a lifesaver for reaching awkward fuel ports, like on a boat or a generator tucked into a tight spot. A wider diameter usually means a faster, smoother pour with less "glugging," but you have to be sure it will actually fit into the opening of the tank you're filling.

Advanced Features Worth the Investment

Beyond the basics, a few modern features can make a huge difference in your fueling experience. These aren't just gimmicks; they're smart solutions to common problems.

An auto-shutoff mechanism, for instance, is a game-changer. It automatically stops the flow when the tank is full, preventing messy overfills—especially helpful when you can't easily see the fuel level. Another great feature is a built-in debris filter or screen. This little mesh inside the spout catches any dirt, rust, or other junk before it can get into your engine and cause some seriously expensive damage.

Finally, look for a spout with a secure cap that’s tethered to the spout itself. A good cap keeps fuel from sloshing out during transport and stops vapors from escaping. Having it attached means you’ll never set it down and lose it again.

To help you sort through the options, I've put together a quick comparison table.

Flexible Spout Feature Comparison

This table breaks down the key features to look for when selecting the best gas can flexible spout for your needs.

| Feature | What to Look For | Why It Matters |

|---|---|---|

| Material | Virgin High-Density Polyethylene (HDPE) | Resists cracking from UV exposure and extreme temperatures, ensuring a long life. |

| Auto-Shutoff | A mechanism that stops fuel flow when the tank is full. | Prevents dangerous and wasteful overfills, especially in hard-to-see tanks. |

| Debris Filter | A fine mesh screen integrated into the spout tip. | Catches dirt and rust before it can contaminate your fuel and damage your engine. |

| Tethered Cap | A securely fitting cap that is physically attached to the spout. | Prevents fuel spills, vapor leaks during transport, and ensures the cap isn't lost. |

| Adapter Rings | Multiple threaded rings included in the package. | Ensures a tight, leak-proof fit on various gas can brands and models. |

| Flow Rate & Venting | A wide-diameter spout with a dedicated air vent. | Provides a fast, smooth, "glug-free" pour, making fueling quicker and cleaner. |

Taking a moment to evaluate these elements ensures you buy a gas can flexible spout that is safe, effective, and built to last. For a deeper dive into specific models and designs, you can check out our detailed guide on choosing the right fuel tank nozzles in 2025.

Getting a Safe, Spill-Free Pour Every Time

You've picked out the perfect flexible spout for your gas can. Now comes the real test: getting the fuel from the can into the tank without a single drop hitting the ground. It’s less about muscle and more about a smart, steady technique. A good pour saves you money on wasted fuel, keeps messy chemicals out of the environment, and is a whole lot safer.

Before you even think about unscrewing the cap, take 30 seconds to set the stage. First, make sure your gas can is on a solid, level surface. Trying to fuel up on a slope is just asking for trouble. Second, always work in an open, well-ventilated space. You don't want to be breathing in those fumes.

Here's a quick mental checklist I run through every single time:

- Ground the Can: If you're filling a plastic can at the gas station, always put it on the ground first. This simple step dissipates any static electricity buildup.

- Quick Gear Check: Give the spout a quick once-over. Look for any cracks or damage, and make sure the little rubber gasket inside the collar is sitting flat.

- Get Your Stance: Plant your feet and get into a comfortable, stable position before you lift that heavy can.

How to Attach the Spout Correctly

From what I’ve seen, the most common reason for a leak is a poorly attached spout. If you cross-thread that collar, you've created a tiny gap where fuel will absolutely find its way out. It’s a dangerous mess waiting to happen.

Here’s the trick to getting it right every time. Place the spout's collar onto the can’s opening and gently turn it backward (counter-clockwise) until you feel or hear a little "click." That's the sound of the threads seating perfectly. Now, you can tighten it clockwise by hand until it’s snug. No need to wrench it down—hand-tight is all you need.

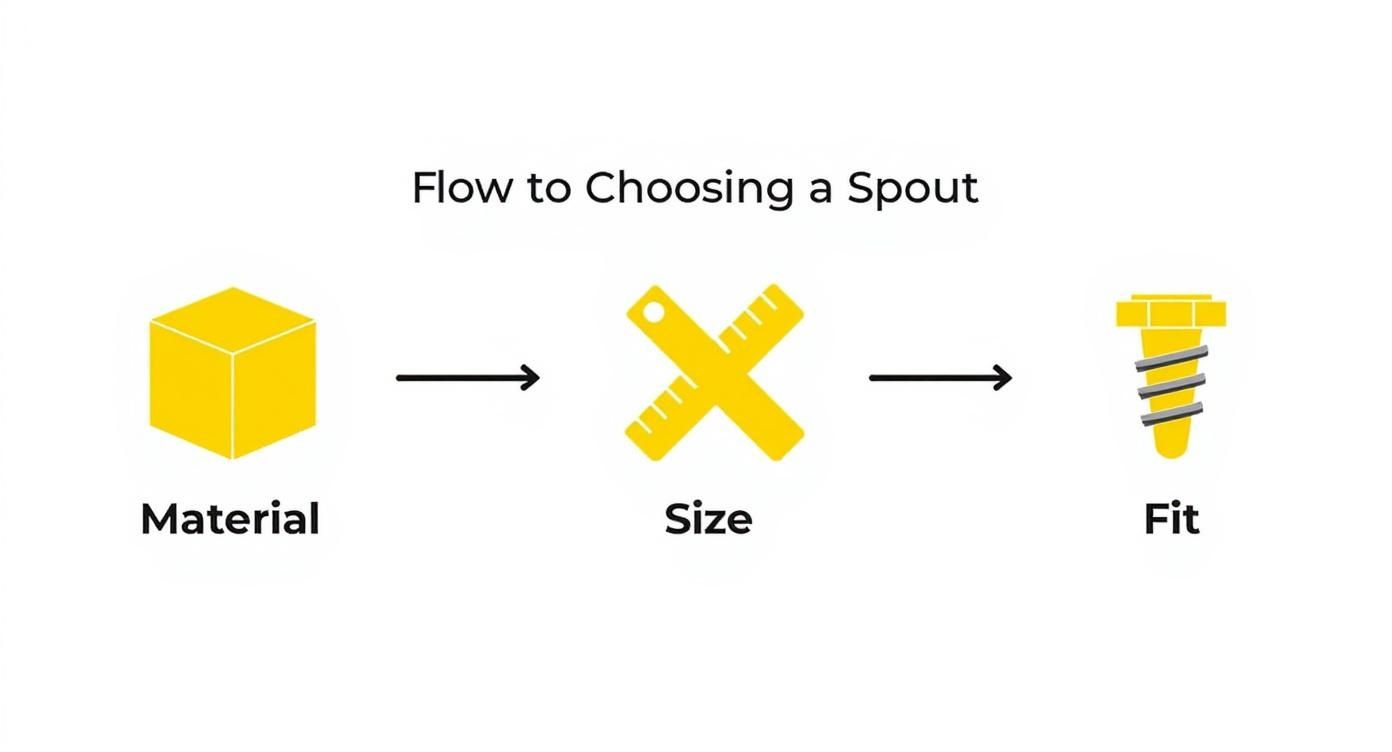

Getting the right spout from the start makes all of this easier. This little guide breaks down what to look for.

As you can see, it really comes down to the material, size, and fit. Nail those three things, and you're setting yourself up for a spill-free experience.

Mastering the Perfect Pour

With the spout securely on, you’re ready to pour. That flexibility is your best friend here.

Bend the spout and stick the tip deep inside the fuel tank opening before you start tilting the can. This one small action prevents that initial splash of fuel from going everywhere. As you tip the can, use the vent cap (if your can has one) to manage the flow. Popping it open lets air in, giving you a smooth, steady stream without any "glugging."

Pay attention to the sound. As the tank gets closer to full, you’ll hear the pitch change. That’s your cue to slow down. Stop pouring the moment you hit the right level to avoid a messy overfill. Understanding the principles of flexible fuel line safety gives you a much better appreciation for why these small steps are so critical for preventing spills and accidents.

Pro Tip: When fueling a boat at a marina, always keep the metal nozzle of the gas can spout in direct contact with the boat's fuel filler neck. This grounds the connection and prevents static sparks, which are a major hazard around fuel vapors, especially near water.

The demand for better, safer fuel-handling gear is on the rise. In fact, the global market for flexible gas hoses, which shares a lot of technology with a gas can flexible spout, was pegged at USD 1.2 billion in 2024. Experts predict it will grow by about 5.8% each year through 2033. It’s a clear sign that people are moving toward safer, more reliable solutions—and by using these techniques, you're doing the exact same thing.

Maintaining Your Flexible Spout for a Longer Life

A good gas can flexible spout isn't a throwaway item; it's a tool. And like any tool you rely on, a little care will ensure it gives you years of spill-free service. If you ignore it, you’re just asking for cracks, leaks, and clogs—the very headaches you bought a quality spout to avoid.

Think of it like any other essential piece of gear. You wouldn't let your wrenches rust or forget to change your engine's oil filter. Your spout deserves that same basic attention. These quick checks take less than a minute but can easily double its lifespan.

The Pre-Pour Inspection Routine

Make this a habit: before you even think about attaching the spout to the can, give it a quick once-over. This is the best way to catch a small issue before it turns into a big, messy problem.

- Check for Cracks: Gently flex the spout and look for hairline cracks or brittle spots. Pay close attention to the base and the tip, as these areas take the most abuse. UV rays from the sun and big temperature swings are the usual culprits.

- Inspect the Gasket: That little rubber ring inside the spout's collar is your first line of defense against leaks. Is it there? Is it sitting flat? Is it cracked or overly compressed? A missing or damaged gasket is hands-down the number one reason for fuel weeping out around the threads.

- Clear the Vent: If your spout has a vent, make sure it’s clear of gunk or debris. A blocked vent is almost always the cause of that annoying "glugging" that slows down your pour to a trickle.

Taking 30 seconds for a quick inspection can save you from a five-minute cleanup and, more importantly, a dangerous fuel spill. It’s a simple, effective habit that pays off every single time.

Smart Cleaning and Storage Habits

Once you're finished fueling, a little preventative care goes a long way. If you've got any fuel residue on the spout, wipe it down with a clean, dry rag. This keeps dirt and grime from building up and ending up in your fuel tank on the next fill.

When it comes to storage, the rules are simple but critical. Keep that spout out of direct sunlight. UV rays will break down the plastic over time, making it brittle and weak. The best place for it is in a cool, dry spot like a garage cabinet or a shed, away from extreme heat or cold that can make the material warp or stiffen up.

Troubleshooting Common Spout Problems

Even with the best care, things can still go wrong. Fortunately, most common spout problems are an easy fix and don't require you to run out and buy a new one.

- Slow Fuel Flow: The first thing to check is the vent. A tiny bit of debris is usually blocking the airflow. If the vent looks good, check the spout’s filter screen (if it has one) for any buildup.

- Leaks at the Collar: Nine times out of ten, this is a gasket problem. Pop the gasket out, clean both it and the groove it sits in, and put it back in place. If you still have a leak, the gasket is probably shot and needs replacing.

- Stiff Spout: If your spout has become rigid and hard to bend, especially in the cold, just bring it inside for a bit. Letting it warm up to room temperature will usually restore its flexibility. Whatever you do, don't try to force it when it's cold and stiff—that’s a great way to snap it.

Exploring Alternatives and Fuel Transfer Innovations

A good **gas can flexible spout** is a must-have for most jobs, but it's always smart to know what else is out there. Different situations sometimes call for different tools, and understanding the alternatives helps you build a complete fueling toolkit. Your go-to flexible spout is perfect for everyday tasks, but sometimes a unique job calls for a different approach.Take the classic funnel, for example. It's the oldest trick in the book—cheap, simple, and you can find one anywhere. The problem? You need two steady hands to use it without making a mess, which almost guarantees a dangerous spill. It kind of defeats the whole purpose of a controlled pour.

High-Volume and High-Tech Solutions

What if you need to move a lot of fuel, and fast? Think transferring gas from a 55-gallon drum into several smaller cans. This is where a battery-powered transfer pump really shines. These things can move gallons in just a few minutes with almost no physical effort.

Of course, there are a few trade-offs to consider:

- More Setup: They need a power source and take a bit more time to get going compared to a simple spout.

- Higher Cost: You're looking at a much bigger investment upfront.

- Maintenance Needs: With moving parts comes the need for upkeep and potential repairs down the road.

Another area of innovation is the all-in-one no-spill system. These are gas cans with integrated spouts, often featuring push-button controls and auto-shutoff features for a super clean fueling experience. This tech is a direct answer to people wanting safer, more dependable gear.

And the demand is huge. Recent data shows that major manufacturing hubs shipped over 39 million units of flexible spouts globally. Prices can range from $1.40 to over $130, depending on how advanced the design and safety features are. You can get a sense of this global market by checking out the pricing for gas can flexible spouts on Alibaba.com.

At the end of the day, any fueling tool should make the job safer, cleaner, and more efficient. While high-tech pumps and integrated systems have their place, the flexible spout is still the most practical and versatile choice for most of us.

These advanced systems show how we're still finding better ways to solve the age-old problem of handling fuel. They offer a great look at the full spectrum of tools available, from a basic funnel to a sophisticated pump.

For most boaters and homeowners, though, a reliable flexible spout hits that sweet spot of control, safety, and simplicity. If you've ever wondered about the trip fuel takes from the station to your equipment, we've got some great insights on the differences between gas pumps and gas cans.

Answering Your Top Questions About Flexible Spouts

Even with the right gear in hand, a few questions always pop up. I've heard just about all of them over the years, so let's walk through the most common ones. Getting these answers sorted out will help you fuel up safely and without the mess.

Can I Use the Same Spout for Gas and Diesel?

This is probably the number one question I get. While the high-density polyethylene (HDPE) plastic in most spouts can handle both gasoline and diesel, my advice is simple: don't do it.

Think of it as cheap insurance against very expensive engine problems. A little bit of gasoline in your diesel can lower its flashpoint, which is a serious safety hazard. On the flip side, even a trace of diesel in a small gas engine can lead to poor performance and a lot of smoke.

The best and safest approach is to have a dedicated can and spout for each fuel type. Label them clearly and never mix them up.

Are Universal Replacement Spouts Really Universal?

That's the million-dollar question, isn't it? The honest answer is no, not quite. Many replacement spout kits are fantastic and come with a few different adapter rings to fit various gas can threads. They cover most of the common brands out there.

However, you'll still run into older cans or off-brand models with unique threads that just won't seal properly. A bad seal at the collar is the main reason for those frustrating, messy leaks.

Before you buy a new spout, check the brand of your gas can. Matching the spout brand to the can brand is your surest bet for a perfect, leak-free fit right out of the package.

The word "universal" is more of a marketing goal than a guarantee. Your best bet is always to match brands or, at the very least, buy a quality kit with multiple adapters and test the fit before you head to the gas station.

How Do I Stop the Can from Glugging?

Ah, the classic "glug-glug-splash." That herky-jerky flow happens because a vacuum is forming inside the can as the fuel pours out. For fuel to flow smoothly, air needs to get in to replace it. When it can't, you get those messy surges.

Luckily, this is an easy fix. Modern spouts and cans are designed to prevent this in a couple of ways:

- Built-in Vents: Some spouts have a small, secondary tube running alongside the main one. This clever design lets air flow in while fuel flows out, creating a smooth stream.

- Rear Vent Caps: This is the most common and effective solution. Almost every gas can has a small vent cap on the back. You absolutely have to unscrew this cap before you start pouring.

Forgetting to open that rear vent is the single biggest mistake people make. Make it a habit: vent cap first, then pour. It will completely change your fueling experience from a splashy mess to a controlled, steady flow.

When you need a truly spill-proof solution, especially when fueling a boat at the marina, nothing beats a system designed for precision. CLiX Fueling Solutions offers an automatic shut-off device that completely prevents overfills, making the whole process effortless and safe. Discover how CLiX can transform your fueling routine.