If you’ve ever refueled your boat from a jerry can, you know the drill. You lug a heavy, sloshing can to the edge of the gunwale, try to get the spout into the fuel fill without scratching everything, and then tilt. The dreaded "glug-glug-glug" starts, fuel splashes onto your deck, and you’re left with an aching back and a smelly mess.

It’s a scene that plays out at docks and launch ramps everywhere. This old-school method is clumsy, slow, and frankly, a bit of a workout nobody asked for.

The Problem with the Old Way of Fueling

Let’s be honest: balancing a 40-pound can while trying to pour smoothly is a recipe for disaster. It’s not just inconvenient; it’s a genuinely frustrating part of a day that’s supposed to be about relaxing on the water.

This process is packed with issues we've all just learned to put up with:

- The Slow Drip (or Gush): The inconsistent flow turns what should be a quick top-off into a tedious, time-consuming task.

- The Physical Strain: Hoisting a full 5-gallon can at an awkward angle is tough on your back and shoulders. It's a real physical chore.

- The Inevitable Mess: That 'glug-glug' isn't just annoying; it’s the sound of fuel splashing out, wasting money and creating a hazard.

Spills Aren't Just Annoying—They're Costly

That spilled gasoline does more than just make your boat smell like a gas station. It can stain your gelcoat, eat away at non-skid surfaces, and damage your upholstery over time. Every drop that misses the tank is a waste of money, too.

And, of course, there's the environmental impact. As boaters, we’re stewards of the water. Even small, accidental spills add up, contributing to water pollution that harms the very environment we're out there to enjoy.

The bottom line is that traditional gas cans were never designed for the unique angles and challenges of refueling a boat. They make a simple job risky and turn it into a dreaded chore. We needed a better, more controlled way to get fuel from the can to the tank.

This isn’t just a niche problem; the technology behind moving fuel is a massive global industry. The entire pump market, including the big ones you see at gas stations, was valued at around US$57.0 billion. When you see the investment in that technology, it makes the old tip-and-pour method feel even more out of date. You can learn more about the global pump market outlook on oxfordeconomics.com.

This is exactly why a modern gas pump gas can system isn't just a gadget—it's a necessary upgrade for any boater who values their time, their boat, and their back.

Assembling Your Modern Fueling Toolkit

A clean, fast fuel transfer starts long before you ever get to the dock. It really comes down to having the right equipment on hand and ready to go. Forget the old, messy tip-and-pour method that almost guarantees a spill. A modern fueling system turns a dreaded chore into a quick, professional task by combining a few key components designed to work together perfectly.

At the center of it all is the universal connector, which is what creates a truly airtight seal on your gas can. This piece attaches to a high-flow hose, letting the fuel move quickly and consistently without any glugging. The final piece of the puzzle is an auto-shutoff vent that cleverly manages air pressure, stopping the flow the second your tank is full to prevent dangerous and messy overfills.

Choosing the Right Gas Can and Safety Gear

This kind of advanced setup works best with a modern, EPA-compliant plastic gas can. Why? Because these cans have the standardized threaded spouts you need for the universal connector to create that critical airtight seal. If you try to use older metal jugs or cans with weird, non-standard spouts, they just won't pair correctly, which completely defeats the purpose of the system's spill-proof design.

For a deeper dive, take a look at our guide on finding the best gas cans with a pump that are made to work with these modern systems.

Beyond the main kit, a few extra items are what I'd consider non-negotiable for safety and keeping things clean.

- Absorbent Pads: Always have these within arm's reach to catch any stray drips when you disconnect. A single pad can be the difference between a clean deck and a slick, smelly mess.

- Nitrile Gloves: Gasoline is nasty stuff on your skin. A good pair of durable nitrile gloves will protect your hands and give you a much better grip on everything.

Before you start, it’s a good idea to lay everything out. I like to use this quick checklist to make sure I haven't forgotten anything.

Essential Refueling Gear Checklist

| Item | Purpose | Pro Tip |

|---|---|---|

| CLiX Universal Connector | Creates an airtight seal on the gas can. | Double-check that it's screwed on tight before you start the flow. |

| High-Flow Hose | Allows for rapid and smooth fuel transfer. | Keep the hose as straight as possible to avoid kinks that can slow things down. |

| Auto-Shutoff Vent | Prevents overfills by stopping flow automatically. | Make sure the vent is properly seated in the boat’s fuel fill opening. |

| Absorbent Pads | Catches drips and small spills. | Place one directly under the fuel fill before you even begin. |

| Nitrile Gloves | Protects hands from fuel exposure. | Always put them on first and take them off last. |

Having all your gear organized makes the whole process faster and safer, letting you get back to what you'd rather be doing—enjoying your time on the water.

Think of it this way: you're preparing your tools for a seamless operation. With the right gas pump gas can setup, you're not just moving fuel; you’re executing a clean, controlled, and efficient transfer every single time.

This focus on preparation is a good habit for all aspects of boating. Beyond just having your fueling kit ready, it's wise to take a broader approach to preparedness by reviewing an ultimate boat safety equipment checklist to ensure you're covered for any situation on the water.

Your Step-by-Step Guide to Spill-Free Refueling

Alright, you've got your CLiX gear ready to go. Now, let's walk through how to actually use it. This whole process turns a chore I used to dread into something quick, clean, and honestly, pretty satisfying. We'll cover everything from getting your boat set up to the final, clean disconnect.

First things first: get your boat tied up securely to the dock. A stable boat is non-negotiable when you're moving fuel around. Place your full gas pump gas can on the dock or another sturdy surface that's higher than your boat's fuel tank inlet. We're letting gravity do the heavy lifting here. Before you start, pull on your nitrile gloves and keep an absorbent pad within arm's reach, just in case.

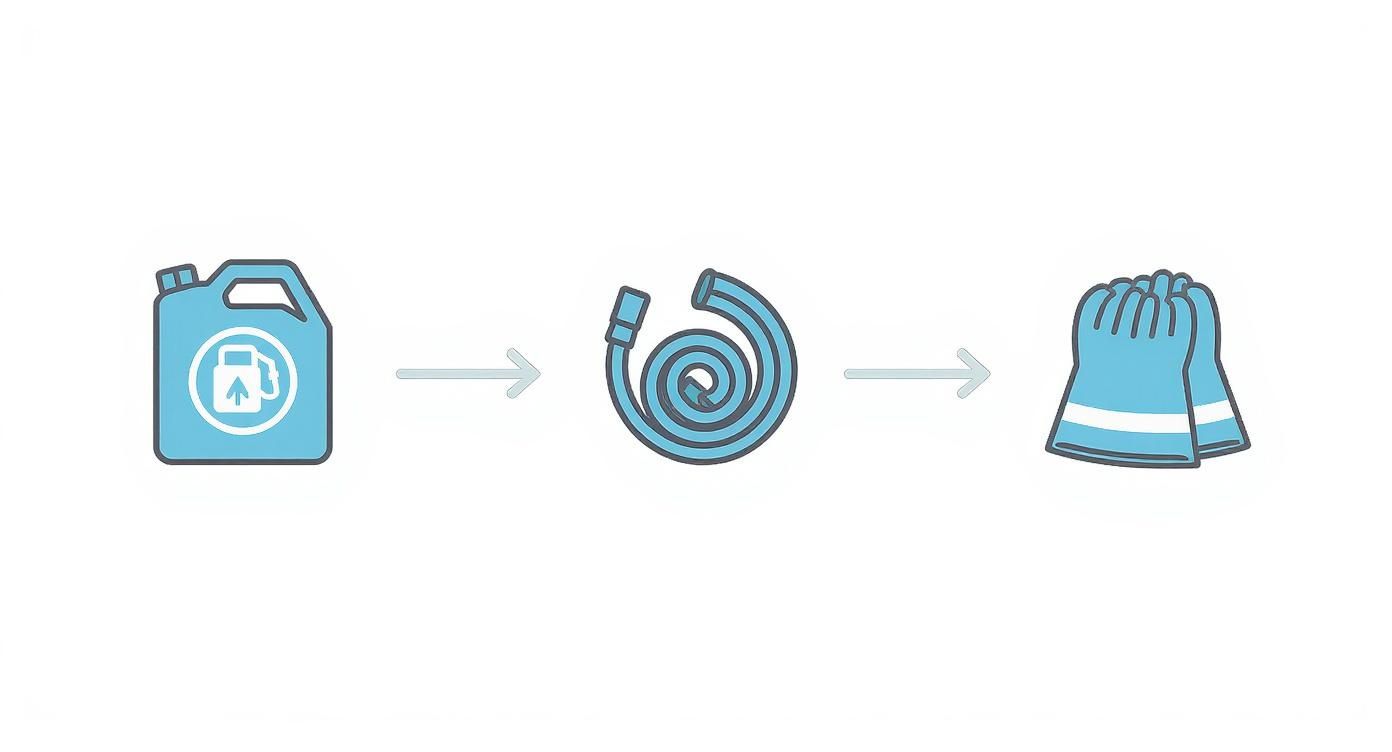

This image gives you a great overview of how all the pieces work together to create a foolproof system.

As you can see, the gas can, hose, and safety gear all combine to make spills a thing of the past.

Getting Connected and Starting the Flow

This is where the magic happens. Grab your CLiX universal connector and thread it onto your gas can's spout. You're aiming for a snug, hand-tight fit—that's what creates the crucial airtight seal.

With the connector on, snap the high-flow hose into place. You'll hear a very distinct ‘click’, which is your confirmation that it’s locked in and ready to go. No guesswork needed. That click means you have a solid, leak-proof connection.

Now, take the other end of the hose and the attached auto-shutoff vent and place them into your boat’s fuel inlet. Just make sure the vent is seated properly. All you have to do now is lift the gas can. Gravity takes over immediately, and the fuel starts flowing. No pumping, no button-holding, and no more of that annoying "glug-glug" surge.

You'll be amazed at how quickly and smoothly the fuel transfers. It’s a huge improvement over the old way of doing things. This kind of efficiency is becoming the standard, as the global market for better, more reliable gasoline fuel pumps continues to grow.

What to Do in Choppy Water

Let's be real—we don't always get to refuel on glassy-calm water. If there’s a bit of a chop, your focus needs to be on stability.

- Mind Your Footing: Make sure you and the can are on a stable surface that isn’t slippery.

- Ask for a Hand: If someone is with you, have them steady the boat or hold the can. It makes a big difference.

- Watch the Hose: Keep an eye on the hose line to make sure it doesn’t get caught or kinked as the boat rocks.

The best part about using a sealed system like this is the control it gives you. Because the connections are so secure, the fuel transfer stays contained from the can to the tank, even if the boat is moving around a bit.

The system is designed to be smart. As your boat’s tank gets full, the auto-shutoff vent senses the change in air pressure and instantly stops the flow. This completely eliminates the risk of overfilling and spilling fuel everywhere. To learn more about how this works at the tank, check out our guide on the boat fuel fill.

Once the flow stops, just lower the can, press the release button to disconnect the hose, and you're all set. No mess, no fumes, just a full tank.

Mastering the Finer Points of Fuel Transfer

Once you get the hang of the basics, a few small tweaks learned from experience can make a world of difference. These are the little details that take your refueling from just getting the job done to doing it perfectly. It's about more than just connecting the system; it’s about making the whole process faster, cleaner, and more precise.

Anyone can hook up a hose, but a seasoned boater makes it look effortless. It all starts with making gravity your best friend and paying attention to the details. With a couple of simple refinements, you can make every fuel transfer a smooth operation.

Use Gravity to Your Advantage for a Faster Flow

The height of your gas pump gas can makes a huge difference in flow rate. Sure, setting it on the dock works, but you can really speed things up by getting it higher. Try placing the can on a sturdy dock box or even a stable cooler. This can easily double the vertical drop, which kicks the fuel flow into high gear.

From my own experience, I've found that adding just an extra foot of height can easily shave 20-30 seconds off the time it takes to empty a 5-gallon can. It’s a simple trick, but it gets you back on the water that much faster.

The key is to create as much vertical distance as you safely can between the bottom of the gas can and the top of your boat’s fuel inlet. This maximizes gravity's pull and lets the system really do its job.

Listen for the Fill-Up Cues

The auto-shutoff feature is a lifesaver, but you can learn to anticipate it just by listening. As the fuel flows, you'll hear a consistent rushing or gurgling sound. Pay attention, because that sound changes right before the tank is full—it gets a bit higher-pitched, almost like an echo, as the last bit of air is pushed out.

Recognizing this subtle audio cue gives you a heads-up that the flow is about to cut off. This is super helpful when you're emptying multiple cans and want to be ready to swap in the next one without missing a beat.

- Steady Flow: You'll hear a consistent, deep "whooshing" or gurgle.

- Almost Full: The sound changes to a higher-pitched, hollower echo.

- The Cutoff: An abrupt silence tells you the vent has closed.

This little trick helps you stay one step ahead, putting you in complete control.

Nailing the Drip-Free Disconnect

The final move is to get a clean disconnect every single time. As soon as you hear the flow stop, immediately lower the gas can back down to dock level. Do this before you disconnect the hose. This simple action lets any fuel left in the hose drain back into the can instead of onto your deck.

Then, just press the release button firmly and lift the hose away. A quick, confident motion is the secret to a perfect, drip-free finish.

Keeping Your Fueling System in Top Condition

You've invested in a top-notch fueling system, and just like any quality piece of gear, a little care will keep it running smoothly for years to come. Think of it as a quick two-minute ritual after you're done fueling up.

After each use, give the hose and connectors a quick wipe-down with a clean, dry rag. This simple step prevents sticky fuel residue from building up, which can wear down the components over time.

Where you store your kit matters, too. Don't just toss it in a dirty dock box. Keeping it in a clean, dry spot protects the seals and makes sure it's ready to go the next time you head out on the water.

Routine Checks for Long-Term Reliability

Every so often, take a second to visually inspect the o-rings and seals. You’re looking for any signs of cracking, brittleness, or noticeable wear. These small parts are the key to a perfect seal, and catching a problem early saves you from a frustrating surprise at the dock.

A well-maintained fueling system is a safe fueling system. Spending just two minutes on a post-fueling clean and inspection is the best way to guarantee your gear will work flawlessly every time.

Taking care of your equipment is just one part of being a responsible boater. While our focus here is on your gas pump gas can, it’s interesting to see what’s happening in the broader energy market. For instance, global demand for natural gas is expected to grow by about 1.7%, which adds up to nearly 70 billion cubic meters year-on-year. You can find more global gas demand insights on datocms-assets.com.

Ultimately, understanding these simple maintenance practices is essential for anyone managing their own boat fuel system.

Got Questions? We've Got Answers

Whenever you're trying a new piece of gear, a few questions are bound to pop up. Let's walk through the most common ones we hear about modern fueling systems so you can top off your tank with total confidence.

Do These Work With My Old Metal Jerry Cans?

Probably not. These systems are engineered to create a perfect, airtight seal on the threaded spouts of today's EPA-compliant plastic fuel cans. Your trusty old metal can, or any can without that specific threading, just won't lock in securely.

For a spill-proof transfer every single time, you really need to stick with a modern, compatible plastic can. It's all about that perfect seal.

How Fast Are We Talking?

Seriously fast. If you get the gas pump gas can positioned higher than your boat's fuel tank, you can drain a full 5 gallons in under 90 seconds. The flow is steady and quick—a night-and-day difference from the old "glug-glug-stop" dance of a standard nozzle.

The auto-shutoff feature is the real magic here. It works on air pressure. As your boat's tank gets full, the back-pressure automatically trips a vent, and the fuel flow stops instantly. This is what prevents those dangerous and messy overfills.

What if I Get a Drip When I Disconnect?

If you disconnect quickly and cleanly, you should see little to no spillage at all. But, as any seasoned boater knows, it's always smart to be prepared.

I always keep a small absorbent pad handy and just place it under the connection point right before I unclip. It’s a simple pro habit that keeps the deck spotless and gives you peace of mind.

Ready to make refueling the easiest part of your boating day? See the spill-free difference for yourself with CLiX Fueling Solutions.