Yes, you can absolutely find a fuel transfer pump at Tractor Supply. The bigger question is, should you be using it on your boat?

While these pumps are fantastic for farm equipment and other land-based jobs, the marine world is a completely different beast. They often miss the critical safety features needed when you're dealing with volatile gasoline fumes hovering just above the water.

The Boater's Constant Struggle: Safe, Easy Fueling

Refueling your boat should be the easiest part of your day on the water, but we all know it’s rarely that simple. It's usually a clumsy dance with heavy, awkward fuel cans, trying to pour at just the right angle, all while praying you don't send a rainbow slick of gasoline or diesel across your deck and into the water.

It's a frustrating, high-stakes task. One slip-up can ruin your boat's finish, pollute the environment, and turn a great day sour. This is why ensuring safe and easy fueling is so critical for boat owners—it helps avoid common headaches, like running out of fuel mid-voyage and having to call for boat towing services.

That’s what usually starts the search for a better way, and a familiar name like Tractor Supply is often the first stop.

Why a Standard Pump Isn't the Whole Story

A good fuel transfer pump seems like the perfect answer. It promises a faster, cleaner, and less back-breaking process than wrestling with jerry cans or messing with a manual siphon. And for a lot of jobs on dry land, a pump from a big-box retailer is exactly what you need.

But the moment you're on a dock or a deck, the rules change. The risks get a lot higher, and the consequences of a fuel spill are much more severe.

Think about this: just one pint of spilled fuel can spread to create a slick covering nearly an acre of water. That really puts the need for caution into perspective.

This guide is here to answer the one question every boater should be asking: Is a general-purpose fuel transfer pump from Tractor Supply really built for the unique challenges of my boat? We'll dig into the key differences between a standard agricultural pump and a proper marine-rated system, focusing on the stuff that really matters:

- Ignition Protection: This is non-negotiable for preventing a stray spark from igniting gas fumes.

- Corrosion Resistance: Saltwater eats metal for breakfast. Your gear has to be built to survive it.

- Fuel Compatibility: You need to be certain the pump's internal seals and parts won't degrade when exposed to marine fuels.

It's About More Than Just the Pump

At the end of the day, a pump is just one part of the equation. The real goal is to get fuel from a can into your tank without spilling a single drop. That means you need to think bigger than just the pump—you need a complete, spill-proof fueling system.

We're going to introduce you to solutions designed to work with your pump to automatically shut off the flow and prevent tank overfills, which are the number one cause of fueling spills.

By looking at the whole picture—from picking the right kind of pump to adding smart, spill-stopping tech—you can finally take the stress out of refueling and get back to enjoying your time on the water.

How Fuel Transfer Pumps Work and Why You Need One for Your Boat

A fuel transfer pump is a pretty simple solution to a messy, age-old problem. Think of it as a powerful, controlled siphon. Instead of wrestling with a heavy, awkward fuel can and hoping gravity is on your side, a pump uses mechanical force to move fuel into your boat’s tank.

It’s a straightforward process. A motor—whether electric or manually operated—drives a mechanism like gears or an impeller. This creates a vacuum that pulls fuel from your container through an intake hose. The pump then pushes the fuel out through another hose and into your tank. It's the difference between bailing water with a leaky cup and using a high-pressure hose.

It's About More Than Just Convenience

Sure, not having to hoist a 40-pound gas can over your gunwale is a huge plus. No more strained backs or precarious balancing acts on a rocking dock. But the real game-changer for boaters is spill prevention. Every single drop of fuel that misses the tank can stain your gelcoat, eat away at your deck, and pollute the water.

A good pump gives you a sealed, contained system from the can to the tank, slashing the risk of accidental spills.

This isn't a problem unique to the marine world, either. Farmers and truckers rely on these pumps every day. A farmer might need a fuel transfer pump from Tractor Supply to fill up a combine in the middle of a field, miles from the nearest station. Trucking fleets use them to manage their own bulk fuel supplies.

The goal is always the same: get fuel from point A to point B without making a mess. But for boaters, the stakes are so much higher. In a fragile marine ecosystem, even a small spill can do serious damage.

The Growing Demand for Better Fueling

This push for smarter fueling isn't just a niche trend; it's a massive, growing industry. The global fuel transfer pump market was valued at US$1.8 billion in 2022 and is on track to hit US$2.6 billion by 2030.

Here in the U.S., the market is projected to reach US$780 million by 2030. While industries like agriculture (10% share) and transportation (30% share) are big players, this growth signals a wider shift toward safer, more efficient tech for protecting valuable assets—whether that’s a tractor or your boat. You can see the full breakdown in the research from DataM Intelligence.

This growth is driving innovation, which is why we have different pumps for different jobs:

- Centrifugal Pumps: These dominate with 40% of the market. They're built for high flow rates and continuous use, making them perfect for high-volume jobs like marina fueling stations.

- Diaphragm Pumps: With about 30% of the market, these are workhorses that can handle fluids of all kinds and are often used in portable setups.

This evolution in pump design highlights the need for smarter systems on the water. A basic pump gets the fuel moving, but it doesn’t solve the crucial "when to stop" problem. To learn more about what to look for, check out our guide on selecting a marine fuel transfer pump.

Why a Pump Is Only Half the Solution

So, a pump gets the fuel flowing, but it has no idea when your tank is full. That's the single most critical moment in the whole process, and it’s precisely where most spills happen. Without an automatic shutoff, you’re stuck guessing—listening for that gurgle or change in sound that means you're about to overflow. It’s a notoriously unreliable method.

This is why boaters need to think about the entire system, not just the pump. The best setup pairs the power of a dependable transfer pump with the intelligence of an automatic shutoff. That combination creates a complete, foolproof fueling process that protects your boat, saves you money, and keeps the water clean.

Choosing the Right Fuel Transfer Pump for Your Boat

Picking the right fuel transfer pump is about more than just moving fuel from point A to point B. It’s about doing it safely and reliably, especially in the harsh marine environment. While a standard fuel transfer pump from Tractor Supply is great for a farm, it often falls short of what’s needed on the water. Boaters deal with a whole different set of challenges, from corrosive saltwater to the ever-present danger of gasoline fumes.

The right choice goes way beyond a simple gallons-per-minute (GPM) rating. You need to think about the fuel you’re using, your boat's power supply, and what the pump itself is made of. Getting this right is critical for your safety, the lifespan of your gear, and the health of the water you enjoy.

Gasoline vs. Diesel Pumps

This is the big one. The single most important difference is whether a pump is designed for gasoline or diesel. Gasoline is incredibly volatile, and its fumes are explosive. Because of this, any pump used for gasoline in a marine setting must be ignition-protected.

- Ignition Protection: This is a non-negotiable safety feature. It means the pump's motor is completely sealed to prevent any internal sparks from igniting fuel vapors in the air. A standard pump from a hardware store probably doesn't have this, making it a serious fire hazard on board.

- Diesel Pumps: Diesel is far less volatile, so ignition protection isn't as critical. That said, diesel pumps often have seals and gaskets that can be eaten away by the additives in gasoline, leading to leaks and pump failure.

Always look for a "USCG Approved" or "ISO 8846" certification for ignition protection if you're pumping gasoline. Using a non-compliant pump isn’t just a bad idea—it’s a dangerous gamble with your boat and your life.

Power Source: AC, DC, or Manual

Your boat's electrical setup will probably steer you toward a specific power source. For most of us with recreational boats, a 12V DC pump is the most practical choice by a long shot.

- 12V DC Pumps: These hook right up to your boat's battery. They're portable, convenient, and perfect for refueling from jerry cans on deck or at a dock without shore power.

- AC Pumps: These need a standard 110V wall outlet, so they're best suited for marina docks or larger vessels that have an onboard generator. They usually pump faster but you can't take them with you.

- Manual Pumps: Good old-fashioned hand-crank or siphon pumps are simple, bulletproof, and don't need any power. They're slow, but they make a fantastic backup and are great for small jobs where speed doesn’t matter.

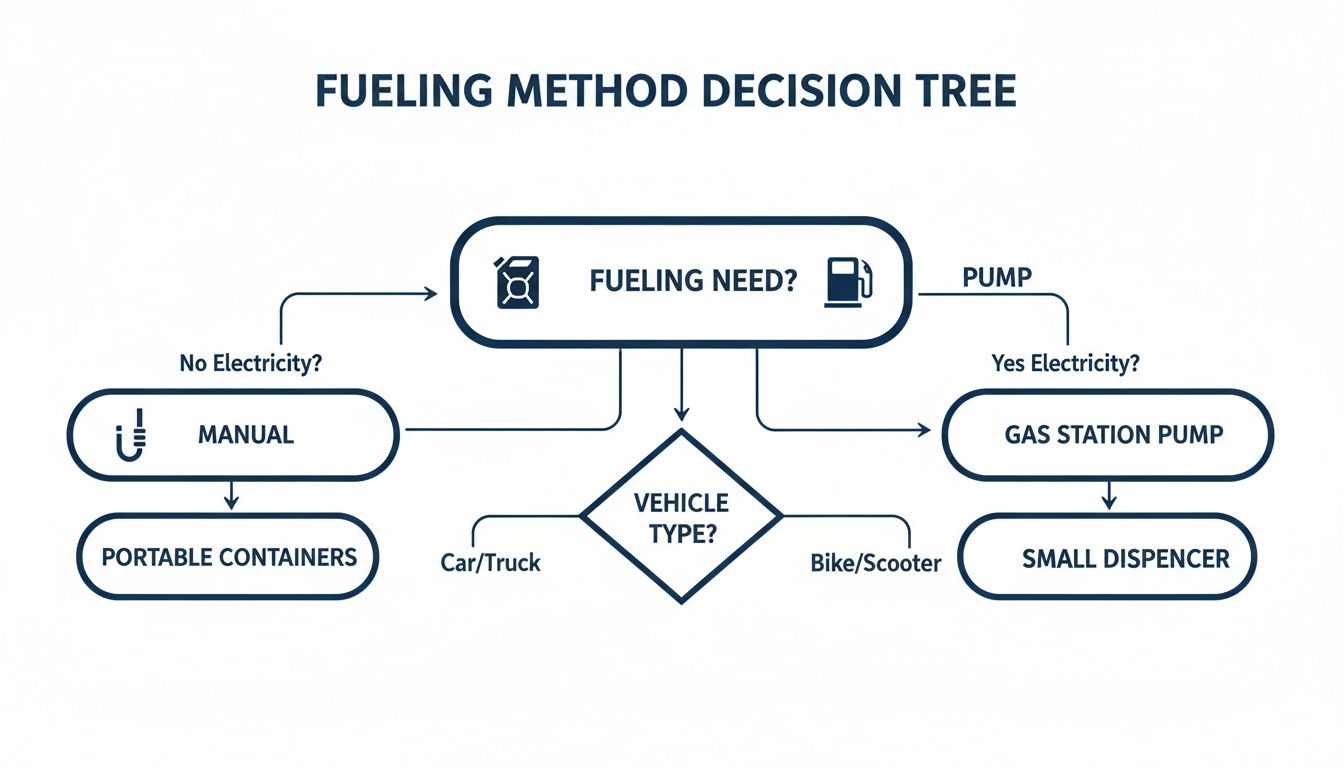

This decision tree gives a quick visual of how to think about your fueling options.

As the chart shows, while you can use a manual siphon, a dedicated pump gives you far more control and efficiency for most fueling jobs on a boat.

To make things even clearer, let's break down the common pump types boaters use.

Fuel Transfer Pump Feature Comparison for Boaters

This table compares the most common pump types to help you match their features to your specific needs on the water.

| Feature | 12V DC Electric Pump | Manual Hand Pump | AC Electric Pump |

|---|---|---|---|

| Best For | Most recreational boats, on-the-go refueling | Small jobs, emergency backup, non-powered boats | Marinas, large vessels with generators, fixed locations |

| Power Source | Boat's 12V battery | Your own muscle power | 110V AC outlet (shore power or generator) |

| Portability | Excellent. Can be used anywhere on the boat. | Excellent. Lightweight and simple. | Poor. Tethered to a power cord. |

| Flow Rate | Moderate (typically 8-15 GPM) | Slow. Depends on how fast you can crank or pump. | High. Often the fastest option. |

| Ignition-Protected | Yes, models for gasoline are readily available. | Yes. No motor means no sparks. | Yes, marine-rated models are available. |

| Ease of Use | Very easy. Flip a switch. | Simple, but requires physical effort. | Very easy, but requires an AC power source. |

Choosing between these really comes down to convenience, portability, and how much fuel you're typically moving. For the average boater, a 12V DC pump strikes the perfect balance.

Flow Rate and Material Construction

Flow rate, measured in gallons per minute (GPM), is all about speed. A higher GPM fills your tank faster, but it can also be harder to handle, which raises the risk of a messy overfill if you're not careful. For most recreational boats, a rate between 8-15 GPM is the sweet spot—fast enough but still manageable.

Just as crucial are the materials the pump is made from. The marine world is tough on equipment. Look for pumps built with corrosion-resistant materials like stainless steel, bronze, or marine-grade polymers that can stand up to saltwater. The hoses and seals are just as important; they must be rated for the specific fuel you use to keep them from getting brittle and causing a dangerous leak.

It's no surprise that the demand for tough, portable pumps is growing. North America currently holds a 43.9% share of the DC fuel transfer pump market, driven by people who need reliable off-grid fueling—from farmers to boaters. This trend points toward a bigger shift to safer and smarter fueling, where features like auto-shutoff nozzles and digital meters are becoming the new standard. You can explore more about these market trends and their impact on pump technology to see where the industry is headed.

Best Practices for Marine Fuel Transfer Safety

Having a high-quality fuel transfer pump is a great start, but it’s only half the battle. Real safety on the water comes from pairing the right gear with smart, consistent habits. Think of your pump as a powerful tool; your safety checklist is what guarantees you use it perfectly every single time.

Following a proper routine isn’t just about ticking boxes—it's about preventing dangerous situations before they even have a chance to develop. From grounding your equipment to doing a quick pre-fueling inspection, these steps turn a potentially hazardous job into a stress-free part of your day. For the sake of your boat, your crew, and the environment, these practices are non-negotiable.

Prepare Your Fueling Environment

Before you even think about moving fuel, your first job is to create a safe zone. This is especially crucial with gasoline, whose invisible fumes are heavier than air. They can quietly pool in low spots like the bilge, creating a ticking time bomb.

Make this pre-fueling checklist second nature. Start by having all passengers step off the boat and then kill every possible source of ignition. That means engines, generators, galley stoves, and even small electronics or cabin fans need to be off.

Next, get the air moving. Open every hatch, porthole, and door to help any stray fumes dissipate. If your boat is equipped with a blower, run it for at least four to five minutes before you start pumping and leave it running throughout the entire process.

It's easy to treat a fuel transfer pump from Tractor Supply like any other piece of equipment, but when it’s moving gasoline near the water, it demands serious respect. Good ventilation isn't just a suggestion—it's your best defense against a catastrophic fire.

Grounding and Equipment Inspection

Static electricity is the unseen enemy during fueling. The simple act of fuel rushing through a hose can build up a static charge, and the resulting spark is more than enough to ignite gas vapors. This is precisely why proper grounding is a must-do, not a maybe.

Before pumping, make sure the metal fuel nozzle is pressed firmly against the metal of your boat’s fuel fill pipe. This small action creates a ground, safely neutralizing any static electricity before it becomes a problem. Keep that contact throughout the entire fueling process.

Your equipment also needs a quick once-over before every use. A tiny crack in a hose or a loose fitting can turn a simple top-off into a dangerous spill in a heartbeat.

- Hoses: Feel along the entire length for any cracks, brittle sections, or soft spots.

- Connections: Wiggle the fittings at the pump and nozzle to ensure they are tight and secure.

- Power Cord: On an electric pump, look for any frayed wires or damage to the protective casing.

- Filter: A clogged filter makes the pump work harder, which can lead to overheating or failure.

This check takes less than a minute, but it can prevent the vast majority of equipment-related accidents. If you want to dive deeper, our guide on the essentials of a safe marine fuel fill has even more great info.

During the Fuel Transfer

Once the pump is running, your full attention is required. Never, ever walk away from the nozzle or try to wedge the handle open. You need to be in control from the first drop to the last.

Keep an absorbent, oil-only spill pad or a rag within arm's reach. That way, you’re ready to catch any drips from the nozzle the moment you pull it out of the fill pipe.

Finally, use your ears. As the tank gets close to full, the sound of the fuel entering the tank will change. That gurgle is your signal to slow down and prepare to stop. Preventing overfills—the most common cause of fuel spills—is less about fancy gadgets and more about paying close attention. Your pump is the tool, but your careful procedure is what truly keeps things safe.

Preventing Spills with Automatic Shutoff Technology

Even with the best pump and a careful routine, every boater faces the same nagging question: when is the tank actually full? We’ve all been there, listening for that gurgle from the fill pipe, trying to time the cutoff just right. A moment of distraction is all it takes for fuel to start gushing out.

This is the fundamental weakness of most fueling setups. A pump is great at moving fuel, but it has no idea when to stop. Without a way to automate that final, critical step, the risk of an overfill is always there—threatening your boat, your wallet, and the water.

The Gas Station Analogy

Think about filling up your car. You stick the nozzle in, lock the handle, and it just… stops. The pump clicks off automatically the second the tank is full. No guesswork, no watching, no stress.

That’s the simple power of automatic shutoff technology. It takes human error completely out of the equation.

An automatic shutoff system is like a foolproof guardian for your fuel tank. It physically senses when fuel reaches the nozzle and instantly cuts the flow, preventing a spill with 100% reliability.

This isn’t just a nice feature; it’s a total game-changer for fueling safety. It turns a manual, high-stakes chore into a simple, worry-free process. To see exactly how it works, check out our guide on the mechanics of a fuel nozzle auto shut off.

How Automatic Shutoff Elevates Your Fueling System

Adding this technology to your existing pump creates a truly complete, spill-proof system. It gives your pump’s brawn the brains it's missing, creating a setup that solves every boater’s worst fueling nightmare.

The benefits are immediate:

- Protect Your Investment: Fuel spills can cause thousands of dollars in damage. They stain gelcoat, eat through deck materials, and destroy striping. An automatic shutoff is the best insurance you can buy against this kind of damage.

- Stop Wasting Money: Every drop of fuel that goes into the water is money thrown away. Preventing overfills means every cent you spend goes directly into your tank, where it belongs.

- Eliminate Environmental Harm: As boaters, we have a duty to protect our waterways. An automatic shutoff is the single most effective way to stop fuel pollution right at the source.

The automotive fuel transfer pump market, already valued at USD 2.1 billion, is expected to hit USD 3.4 billion by 2032, driven by demands for better efficiency and safety. We're seeing the same trend on the water, as boaters look for this level of precision to prevent overfills—the cause of an estimated 20-30% of on-water spills.

A farmer might grab a fuel transfer pump from Tractor Supply to get the job done quickly, but a boater needs auto-stop tech to get it done safely.

When you add an automatic shutoff, you’re getting more than just a piece of hardware. You're adopting a system that delivers total peace of mind and makes fueling safer, cleaner, and more economical. It’s the final piece of the puzzle for a perfect fueling routine.

On-the-Dock Questions About Marine Fuel Pumps

It's one thing to read a guide, but it's another to be standing on the dock with a pump in hand. Practical questions always pop up. Let's tackle some of the most common ones we hear from boaters about choosing and using a fuel transfer pump.

Can I Just Use a Pump from Tractor Supply for My Boat?

This is probably the most frequent question we get. While you can definitely find a solid fuel transfer pump at Tractor Supply, it's almost certainly the wrong pump for your boat, especially if you're pumping gasoline.

The reason boils down to one critical feature: ignition protection. Marine-grade pumps built for gasoline are completely sealed. This design prevents any internal sparks from the motor from coming into contact with flammable fuel fumes—a major hazard in the confined spaces of a boat. Your standard farm or utility pump just isn't built that way. Using one with gasoline in an engine compartment or bilge is rolling the dice with a fire or explosion.

For diesel, the immediate risk is lower since it's less volatile. However, you'd still need to make absolutely sure the pump's components can stand up to constant exposure to saltwater without corroding.

The bottom line is simple: If a pump isn't clearly marked as "Ignition Protected" or "Marine Grade," it has no business being on your boat with gasoline. The convenience of a cheaper pump is never worth that kind of catastrophic risk.

What's the Single Most Important Safety Feature to Look For?

Hands down, it's ignition protection. For any pump that will ever touch gasoline, this isn't just a good idea—it's a non-negotiable safety standard required by the U.S. Coast Guard.

Beyond that, you want a pump that's built to last in a marine environment. That means a sturdy body made from corrosion-resistant materials and high-quality, fuel-rated hoses that won't crack or leak after a season in the sun and salt.

How Do I Pick the Right Flow Rate (GPM)?

Flow rate, measured in Gallons Per Minute (GPM), is all about how quickly the pump can move fuel from point A to point B. It's easy to think that faster is always better, but that’s not necessarily true at the fuel dock. A pump with a sky-high GPM can be tough to handle, and the fuel can rush in so fast that you overfill the tank before you even realize it's full.

For most recreational boats, a pump in the 8 to 15 GPM range is the sweet spot. It's quick enough that you're not spending your whole afternoon fueling up, but it gives you enough control to ease off as the tank gets close to full.

How Does an Automatic Shutoff System Fit in with My Pump?

Think of an automatic shutoff system, like the one from CLiX Fueling Solutions, as the smart accessory that works with your transfer pump to stop spills before they happen. It’s an adapter that sits between your pump's nozzle and your boat's fuel fill.

Here’s the breakdown of how it works:

- First, you connect the CLiX device to your boat's fuel fill.

- Next, you insert your pump’s nozzle right into the CLiX adapter.

- As you start pumping, the system keeps an eye on the fuel level rising in the fill pipe.

- The instant the tank is full, it mechanically shuts off the flow. This causes the pump nozzle to click off automatically, just like the ones at a roadside gas station.

It essentially gives your pump the "brain" it's missing, guaranteeing a perfect fill without a single drop spilled.

Ready to make fueling spills a thing of the past? CLiX Fueling Solutions offers a foolproof system that pairs with your pump to prevent messy overfills and protect our waterways. See how CLiX works and take the guesswork out of fueling.