For any boater who doesn't refuel at a marina fuel dock, a fuel barrel pump is one of the most important tools you can own. It's a simple device designed for one crucial job: moving fuel safely and cleanly from a large barrel or drum straight into your boat's tank.

This pump completely gets rid of the back-breaking, often messy chore of trying to lift and pour a heavy fuel container. No more spills, no more wasted fuel, just a straightforward and manageable process.

Why Every Boater Needs a Reliable Fuel Barrel Pump

Picture this: you're down at the dock with a 55-gallon fuel barrel next to your pride and joy. Now comes the hard part—a sketchy balancing act where you try to pour the fuel without getting it all over your boat's deck or, even worse, into the water. It's a stressful situation many boaters know all too well, but it doesn't have to be that way.

A good fuel barrel pump turns this risky job into a clean, controlled task. It acts as a secure bridge between your bulk fuel supply and your boat's tank. This isn't just about convenience; it's about being safe, efficient, and having one less thing to worry about.

From Risky Chore to Simple Process

Trying to refuel without a proper pump is just asking for trouble. Spills can damage your boat's finish, leading to expensive repairs, not to mention the potential for environmental fines. And let's not forget the risk of straining your back or worse by wrestling with a heavy barrel.

A dedicated pump solves all of these problems at once.

- No More Spills: The controlled flow means fuel goes where it's supposed to—in your tank. This protects your boat and the water around it.

- Greater Safety: We all know how carefully you have to handle gasoline or diesel. A pump minimizes your direct contact with the fuel and cuts down on vapor exposure.

- Saves Time and Effort: What used to be a tough physical job becomes quick and easy. You’ll be back on the water in no time.

A Long History of Getting It Right

The idea of moving liquids safely isn't new. People have been working on better ways to do it for a long, long time. In fact, the world's very first electric drum pump was invented and patented way back in 1950, and it completely changed the game for handling fluids.

This 70-year history shows just how important reliable pumps are, especially when dealing with flammable liquids. To get the full picture on keeping your fuel secure, it’s worth looking into different fuel storage solutions as well.

At the end of the day, it doesn’t matter if you have a small fishing skiff or a big cruiser—having the right gear is essential. To dive deeper, check out our guide to the different types of fuel pumps for boats at https://clixfueling.com/blogs/news/fuel-pumps-for-boats.

Picking the Right Tool for the Job: Fuel Barrel Pump Types

Choosing a fuel barrel pump is all about matching the tool to your specific needs. You wouldn't use a sledgehammer for a finishing nail, and the same logic applies here. Each pump is designed with a different purpose in mind, balancing things like flow rate, power source, and sheer convenience. Getting this choice right is the first step toward making refueling a safe, clean, and hassle-free part of your boating life.

Believe it or not, the core ideas behind modern pumps—safety and ease of use—have been around for a long time. The journey started with Sylvanus Bowser, who invented the first gasoline pump way back on September 5, 1885. Within 20 years, he'd added a hose and key safety features, laying the groundwork for the equipment we rely on today. You can get a glimpse of this fascinating journey by reading up on the history of the gasoline pump.

Manual Fuel Barrel Pumps

Manual pumps are the old reliable of the fueling world. They run on elbow grease, which makes them perfect for those times when you're far from a power outlet or just need a simple, bulletproof solution. Think of them as the trusty hand tools in your marine kit—they just work.

You'll generally find two main flavors of manual pumps:

- Rotary Pumps: Picture a small paddlewheel inside the pump housing. As you turn the crank, the vanes catch the fuel and push it along in a smooth, continuous stream. This design is fantastic for moving a good amount of fuel relatively quickly without breaking your back.

- Piston Pumps (Lever Action): These operate just like an old-fashioned well pump or a bicycle pump. Pull the handle up, and it sucks fuel into the chamber. Push it down, and it forces the fuel out the hose. The flow comes in pulses, but this design can build up a lot of pressure, which is great for thicker fluids or when you need to be very precise.

These are your go-to pumps for smaller boats, topping off tanks in remote spots, or just having a dependable backup that never needs a battery.

Electric Fuel Barrel Pumps

When you need to move a lot of fuel and time is a factor, nothing beats an electric pump. They do all the heavy lifting for you, turning a potential chore into a quick, simple task. For boaters with larger tanks or who refuel often, these are a game-changer.

The main difference comes down to their power source:

- AC Powered Pumps: These are the heavyweights. They plug into a standard 110/120V wall outlet, giving you the best possible flow rate. They’re the perfect setup for a dock, boathouse, or any marina slip with shore power. An AC pump is a serious tool for serious refueling.

- DC Powered Pumps: Built for life on the go, these pumps hook up to a 12V or 24V battery—like the one right on your boat. They might not be quite as fast as their AC cousins, but their portability is unbeatable. You can refuel at anchor, on a mooring, or anywhere your boat can take you.

The real win with an electric pump is the time and effort you save. A refueling job that might take 10-15 minutes of cranking a manual pump can be done in just a couple of minutes, which also means less time exposed to fumes and a lower chance of spills.

Siphon Pumps

Siphon pumps are the most basic option out there, using a little help from physics to get the job done. You start the flow with a squeeze bulb or a plunger, and as long as the fuel barrel is higher than your boat's tank, gravity handles the rest.

They're incredibly simple and cheap, with no real moving parts to break. But the trade-off is a very slow transfer rate and almost no control once the fuel is flowing. Siphons are fine for an emergency or moving a tiny amount of fuel, but for regular, safe refueling, you'll be much better off with a proper manual or electric pump.

Comparing Fuel Barrel Pump Types for Boaters

To make the choice easier, here's a quick look at how these pumps stack up for marine use.

| Pump Type | Power Source | Flow Rate | Best For | Key Limitation |

|---|---|---|---|---|

| Manual (Rotary/Lever) | Human Power | Low to Moderate | Backup use, small boats, remote locations without power | Requires physical effort; can be slow |

| Electric (AC) | Wall Outlet (110V) | High | Dockside refueling, large tanks, frequent use | Requires access to a standard power outlet |

| Electric (DC) | Battery (12V/24V) | Moderate to High | On-the-water refueling, portability, convenience | Relies on battery power; slightly lower flow than AC |

| Siphon | Gravity | Very Low | Emergencies, transferring very small amounts | Slow, lacks control, requires height difference |

Ultimately, the best pump is the one that fits your boat, your location, and your refueling habits.

How to Choose the Right Pump for Your Boat

Picking the right fuel barrel pump isn’t just about getting fuel from point A to point B. It’s about safety, efficiency, and finding what works for your boat. The pump that’s a perfect fit for a small fishing skiff could be completely wrong for a larger cruiser tied up at the marina. Nailing this decision upfront saves you a ton of headaches down the road and makes every refueling stop a smooth, predictable process.

Think of it like choosing any other tool for a job. You need to consider the type of fuel, how much you’re moving, where you’ll be doing it, and what power you have available. Each of these factors will help narrow down the options until you find the one that’s just right.

Fuel Type and Material Compatibility

This is the big one, the first question you have to answer: what kind of fuel are you pumping? Gasoline and diesel are very different beasts, and using a pump designed for one with the other is asking for trouble.

- Gasoline: It’s incredibly volatile and flammable. Any pump you use for gasoline must have an explosion-proof motor and be built with materials that won’t create a spark. Never, ever use a pump meant only for diesel to move gasoline.

- Diesel: While it's less volatile, diesel still requires a pump made of tough, compatible materials. The seals and hoses have to be rated for diesel to prevent them from breaking down and causing leaks.

Seriously, using the wrong pump is a major safety hazard. Always double-check the manufacturer's specs to be absolutely sure the pump is rated for your fuel.

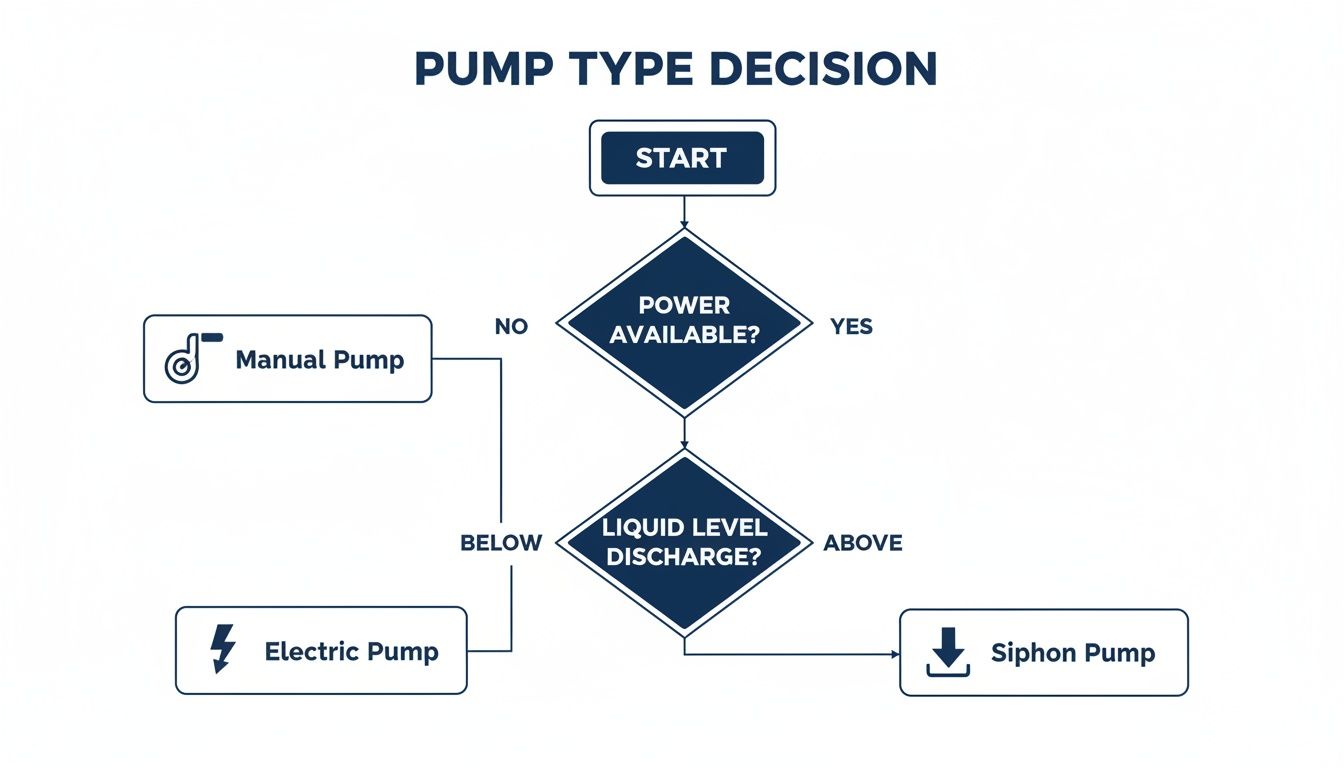

This decision tree can help you visualize how to narrow things down based on power and location.

As you can see, having a power source opens up the world of convenient electric pumps, but a good old manual pump is a reliable backup for any situation.

Assessing Your Power Source and Location

Where do you typically refuel? The answer will point you directly to the right kind of pump. Are you at a dock with outlets, or are you out on the water?

If you’re usually at a dock with shore power, a powerful AC electric pump is a fantastic choice. These models offer the fastest flow rates and will make quick work of filling even the largest tanks.

For those times you’re away from the dock—maybe at a mooring, anchored out, or transferring from a barrel you keep on board—a DC electric pump is your best bet. They hook right up to your boat’s 12V or 24V battery system, giving you incredible portability without needing to find a wall socket. For a deeper dive, you can learn more about selecting the right marine fuel transfer pump in our complete guide.

And of course, there’s the manual fuel barrel pump. It’s the ultimate fallback plan. No power required, which makes it a dependable solution for any scenario, especially if you’re in a remote spot or dealing with an emergency.

Flow Rate and Boat Size

So, how fast do you need to get the job done? This really comes down to your boat’s tank size and your personal patience level. A pump's speed, or flow rate, is measured in gallons per minute (GPM).

A higher GPM means faster refueling. This is a huge plus for boats with large fuel tanks (50+ gallons). For a 100-gallon tank, a 10 GPM pump will be done in 10 minutes, while a 2 GPM pump would take almost an hour.

Here are a few general rules of thumb:

- Small Boats (under 25 feet): A simple manual pump or a small DC electric pump with a lower GPM is usually all you need.

- Mid-Size to Large Boats (over 25 feet): An AC or a higher-GPM DC electric pump is well worth the investment. It will save you a significant amount of time and effort.

Putting your money into a quality pump is a smart decision. The global barrel pump market was valued at USD 504.7 million in 2022 and is still on the rise, which shows a huge demand for better, safer ways to handle fluids. For boaters, this trend is great news—it means we have access to more reliable and efficient equipment than ever before.

Mastering Safe Fueling and Spill Prevention

Switching to a fuel barrel pump is a huge improvement over wrestling with heavy cans, but safety doesn't stop there. Let's be honest: handling fuel always comes with risks, from fire to environmental spills. That's why every boater needs a solid, repeatable fueling routine.

Think of it like a pilot’s pre-flight check. It’s a simple process that helps you catch small problems before they blow up into big ones. This approach turns fueling from a chore into a professional procedure that protects you, your boat, and the water we all love.

Your Pre-Fueling Safety Checklist

Before a single drop of fuel moves, a quick but thorough inspection is your best friend. Spending just a minute or two checking your gear can prevent the vast majority of accidents. This is what separates simply owning a fuel barrel pump from using it like a pro.

Make this checklist second nature—run through it every single time you fuel up.

- Inspect All Hoses and Connections: Give the hoses a once-over. Are there any cracks, brittle spots, or kinks? Make sure all the fittings are snug. A loose connection is a leak waiting to happen.

- Ensure Proper Grounding: Static electricity is a real and silent danger. If your pump has a grounding wire, double-check that it’s securely connected to both the barrel and your boat to bleed off any static charge.

- Extinguish All Ignition Sources: This one is non-negotiable. Kill the engine, shut down all electrical gear, and put out any open flames (like a galley stove). And of course, no smoking for anyone in the vicinity.

- Prepare Your Spill Kit: Never, ever start fueling without a spill kit within arm’s reach. It should be ready to go with absorbent pads, booms, and gloves. If a spill happens, you need to be able to act instantly.

Step-by-Step Safe Fuel Transfer

With your prep work done, it's time to transfer the fuel. The key here is to stay focused and in control. Don't rush it, and don't get distracted.

First, insert the pump’s suction tube firmly into the fuel barrel. Then, get the nozzle seated securely in your boat's fuel intake. Only after both are in place should you start pumping.

Critical Safety Reminder: Never walk away from a running pump. Not even for a second. A moment's distraction is all it takes for a dangerous overfill and a messy spill. Stay with the pump from start to finish.

Pay attention to the sounds of the pump and the fuel going into the tank. You’ll often hear the tone change as the tank gets close to full. This is your cue to slow the flow to avoid a sudden splash-back.

The Dangers of Topping Off

It’s so tempting to squeeze in that last little bit of fuel to round up the number or maximize your range. But "topping off" is a bad habit that can cause real headaches for your boat and the environment.

Your boat's fuel tank needs a little empty space at the top. This air gap gives the fuel room to expand when it heats up during the day.

- System Damage: Overfilling can shove liquid fuel into the vapor recovery system, which is only designed to handle fumes. This can wreck expensive parts like the charcoal canister and lead to engine problems.

- Environmental Harm: When the fuel in an overstuffed tank expands, it has to go somewhere—usually right out the vent line and into the water. It doesn't take much fuel to create a nasty sheen.

- Wasted Money: At a commercial fuel dock, the nozzles have vapor recovery systems. If you keep clicking the handle after it shuts off, you might be paying for fuel that's just getting sucked right back into the station’s pump.

Once you're done, remove the nozzle carefully, wipe up any drips, and screw your boat's fuel cap on tight. Store your pump and hoses properly, away from direct sunlight and heat. Following these simple steps makes every refueling a safe, clean, and professional job.

A Smarter Way to Prevent Fuel Spills

Even when you've got the best fuel barrel pump and double-check all your connections, there’s always that nagging question: how do you know exactly when to stop? We've all been there, listening intently for that gurgle or change in pitch from the fuel fill, trying to avoid a messy, dangerous overflow.

A moment's distraction is all it takes for fuel to pour onto your deck and into the water. This guesswork is the biggest vulnerability in the whole process. Your pump gives you control over the flow, but it can't tell you when you're about to hit the tank's limit. This uncertainty often means we either stop too soon and cut our range short, or we push it a little too far and end up with a spill.

But there’s a much better way to handle this final, critical step.

Taking the Guesswork Out with Automatic Shut-Offs

What if your fuel nozzle was smart enough to know when the tank is full and could shut itself off, just like the pump at your local gas station? That’s the simple but brilliant idea behind an automatic shut-off system like CLiX Fueling Solutions.

Think of it as a smart link between your fuel nozzle and your boat's tank. It's engineered to cut the fuel flow at the perfect moment, stopping an overflow before it has any chance to happen. It completely removes the need for human guesswork and timing.

By automating that last step, you create a system that's virtually foolproof. This is more than just a convenience—it’s a powerful layer of safety and environmental protection that a standard pump and nozzle just can't offer on their own.

This kind of technology transforms fueling from a tense, hands-on chore into a predictable, stress-free routine.

What This Means for You on the Water

Adding an automatic shut-off system to your setup brings real, practical benefits that any boat owner will immediately appreciate. It’s the next logical step toward total confidence at the pump.

Here’s a look at what it does for you:

- No More Ugly Fuel Stains: Spilled fuel, especially diesel, can permanently stain your boat’s beautiful gelcoat and non-skid surfaces. An automatic shut-off is a great way to protect your boat’s finish and keep its value high.

- Zero Environmental Harm: Even a tiny spill creates a large, damaging sheen on the water. This can harm marine life and even lead to hefty fines. The best way to be a responsible boater is to prevent spills from happening in the first place.

- Total Peace of Mind: You can finally say goodbye to that fueling anxiety. You'll have the confidence of knowing the system will stop precisely when it's supposed to, every single time.

Of course, being proactive also means being prepared. Keeping a supply of oil spill absorbent pads on board is just plain smart seamanship. While new tech helps prevent spills, you should always be ready for the unexpected. You can also explore other fueling innovations that make life easier, like the advantages of drop-in fuel systems for modern boaters.

Simple Maintenance to Keep Your Pump Running Smoothly

A fuel barrel pump is a fantastic tool for convenience and safety, but just like any critical piece of boat gear, it needs a bit of attention to keep it working properly. A little neglect can lead to big problems—frustrating clogs, dangerous leaks, or a pump that dies right when you're counting on it. A simple maintenance routine is all it takes to make sure your pump is always ready to go.

It all starts with a solid installation. The most important thing is getting a tight, secure seal where the pump meets the fuel barrel. Any looseness there can let dirt and water in or allow fuel vapor to escape. Double-check that all your hoses are clamped down tight and, for electric pumps, that the electrical connections are clean and corrosion-free. A bad connection means an unreliable power source.

Your Simple Pump Maintenance Schedule

You don’t need to be a marine mechanic to keep your pump in prime condition. Just think of it as a quick pre-flight check before you start fueling. A few seconds of inspection can save you a world of trouble down the line.

Here’s a straightforward schedule to catch small problems before they become big ones:

- Before Every Use: Give the hose a quick once-over. Look for any cracks, kinks, or brittle spots. Wiggle the connections to make sure they’re still nice and snug.

- Monthly Check: Take a closer look at the pump body and fittings, especially if you’re in a saltwater environment. Corrosion is your enemy. If you have a filter or strainer, pull it out and see if it's clogged with debris. Clean it out based on what the manufacturer recommends.

- End-of-Season Storage: Before you pack it away for the winter, run the pump dry for just a few seconds to clear out any leftover fuel. Find a clean, dry spot to store it, and keep it out of direct sunlight, which can destroy hoses over time.

A well-maintained pump is a reliable pump. Consistent checks prevent the most common failure points—degraded hoses and clogged filters—which account for a significant portion of pump issues.

Listen for Warning Signs

Your pump will often give you clues when something’s amiss. Is it making a new high-pitched whine? That could mean the motor is straining against a clog. Has the flow rate dropped off, or does the pump sound like it’s working way harder than it used to? That’s a clear signal to stop and investigate.

Catching these little warnings early is the key to getting a long life out of your fuel barrel pump. It's a proactive approach that saves you from buying a replacement and, more importantly, ensures you have a safe, spill-free refueling every single time.

Got Questions? Let's Talk Fuel Barrel Pumps

Even after you get the hang of your fuel barrel pump, real-world questions always pop up. Knowing the answers is the key to feeling confident and staying safe out on the water. Let's dive into some of the most common things boaters ask.

Can I Use the Same Pump for Gasoline and Diesel?

This is a big one, and the answer is a firm no—unless the manufacturer specifically designed and rated the pump for both. The reason is simple: safety.

Gasoline is much more volatile than diesel. Any pump handling gasoline needs an explosion-proof motor and special components to prevent static electricity from creating a spark. Using a pump built only for diesel with gasoline is asking for a fire.

On the flip side, you could technically use a gasoline-rated pump for diesel, but you'd be running a huge risk of cross-contamination. A little bit of gasoline in your diesel fuel can lower its flashpoint and make it dangerously combustible. The best and safest approach is to have a dedicated pump for each type of fuel. No exceptions.

How Do I Pick the Right Flow Rate?

Flow rate, measured in gallons per minute (GPM), is all about how fast you want to get the job done. The right GPM really just comes down to the size of your boat's fuel tank and how much time you want to spend at the barrel.

Here's a quick breakdown:

- Smaller Tanks (under 25 gallons): A simple manual pump or a basic electric pump pushing 2-5 GPM will work just fine. No need to overdo it.

- Larger Tanks (50+ gallons): This is where a higher-flow electric pump (8-15 GPM) really shines. For example, a 10 GPM pump will fill a 100-gallon tank in about 10 minutes. That's a huge time-saver.

Think of it this way: matching the flow rate to your needs saves a ton of frustration. A pump that’s too slow for a big tank will feel like it takes forever. A pump that’s too fast for a small tank can easily cause a messy, dangerous splash-back if you're not careful.

What's the Safest Way to Store Everything?

Storing your pump and barrel correctly is just as important as using them correctly. Good storage habits protect your gear and prevent accidents.

When you're done with your pump, store it in a spot with good airflow, out of direct sunlight, and far away from anything that could ignite fuel vapors. The sun’s UV rays can break down hoses over time, making them brittle and likely to leak.

As for the fuel barrel itself, make sure it’s sitting on a flat, stable surface where it can’t be knocked over. Keep it clear of walkways or any high-traffic zones. And don't forget to check your local or marina regulations—there are often specific rules about how much fuel you can store and where.

Ready to take the guesswork out of fueling and stop spills before they happen? With CLiX Fueling Solutions, you get a perfect, automatic shut-off every time. Protect your boat and our waterways by visiting https://clixfueling.com to see how it works.