Ever tried to get fuel from a jerry can into your boat's tank without making a mess? That's where a fuel transfer hand pump comes in. Think of it as a purpose-built, super-efficient straw for moving fuel—no electricity needed. It’s a straightforward, portable tool for one of the most fundamental jobs in boating.

How a Fuel Transfer Hand Pump Works

It might look simple, but a manual fuel pump is a clever bit of physics in action. Its entire job is to create a pressure difference. By creating a low-pressure zone inside the pump and hose, it lets the normal atmospheric pressure outside do all the heavy lifting, pushing the fuel from your can right into your tank.

The principle is identical to using a drinking straw. When you sip, you reduce the air pressure inside the straw, and the higher pressure on the surface of your drink pushes the liquid up. A fuel pump just gives you a mechanical way to do the same thing, but for fuel.

The Core Mechanism: Suction and Displacement

No matter what kind of hand pump you're using—whether it's a crank, a piston, or a squeeze bulb—it all comes down to two simple steps:

- Creating a Vacuum: Your first pump, crank, or squeeze forces air out of the pump's chamber. This creates a pocket of low pressure, essentially a partial vacuum.

- Fuel Displacement: Nature can't stand a vacuum. The higher atmospheric pressure pushing down on the fuel in your jerry can forces the liquid up the hose to fill that empty, low-pressure space. With each pump, you keep this process going, drawing more fuel through the pump and into your boat.

It's a common misconception that the pump "pulls" the fuel. In reality, the pump creates the perfect environment for atmospheric pressure to push the fuel exactly where you need it.

This brilliantly simple mechanism is what makes these pumps so dependable out on the water. There are no finicky electronics or motors to break down—just pure, reliable mechanical action. Once you get your head around this basic push-and-pull of pressure, you'll be able to handle any manual fueling task with confidence.

Choosing the Right Manual Fuel Pump for Your Boat

Picking the right fuel transfer hand pump isn't a one-size-fits-all deal. The best pump for you really boils down to your boat, your typical fueling needs, and the specific job you're trying to tackle. Getting this match right means more efficiency, better safety, and a whole lot less frustration at the dock.

Let's walk through the most common types of manual pumps out there. Each works a little differently, making it the perfect tool for some jobs and the wrong one for others. It’s like picking between a hammer and a mallet—they both hit things, but you wouldn’t use a sledgehammer to tap in a small finishing nail.

The Workhorse: Rotary Vane Pumps

Picture a small, hand-cranked paddle wheel spinning inside a tight casing. That's the basic idea behind a rotary vane pump. As you turn the handle, a set of little blades (the vanes) rotate, grabbing fuel and pushing it smoothly out the hose.

This design is a real powerhouse for moving a decent amount of fuel pretty quickly. If you need to get 10 to 20 gallons out of a drum or a big jerry can and into your boat's main tank, the rotary pump is your go-to. They give you a continuous, steady flow that makes bigger refueling jobs feel much less like a chore. The only downside is they can be a bit bulky and are often overkill for just topping off a small tender.

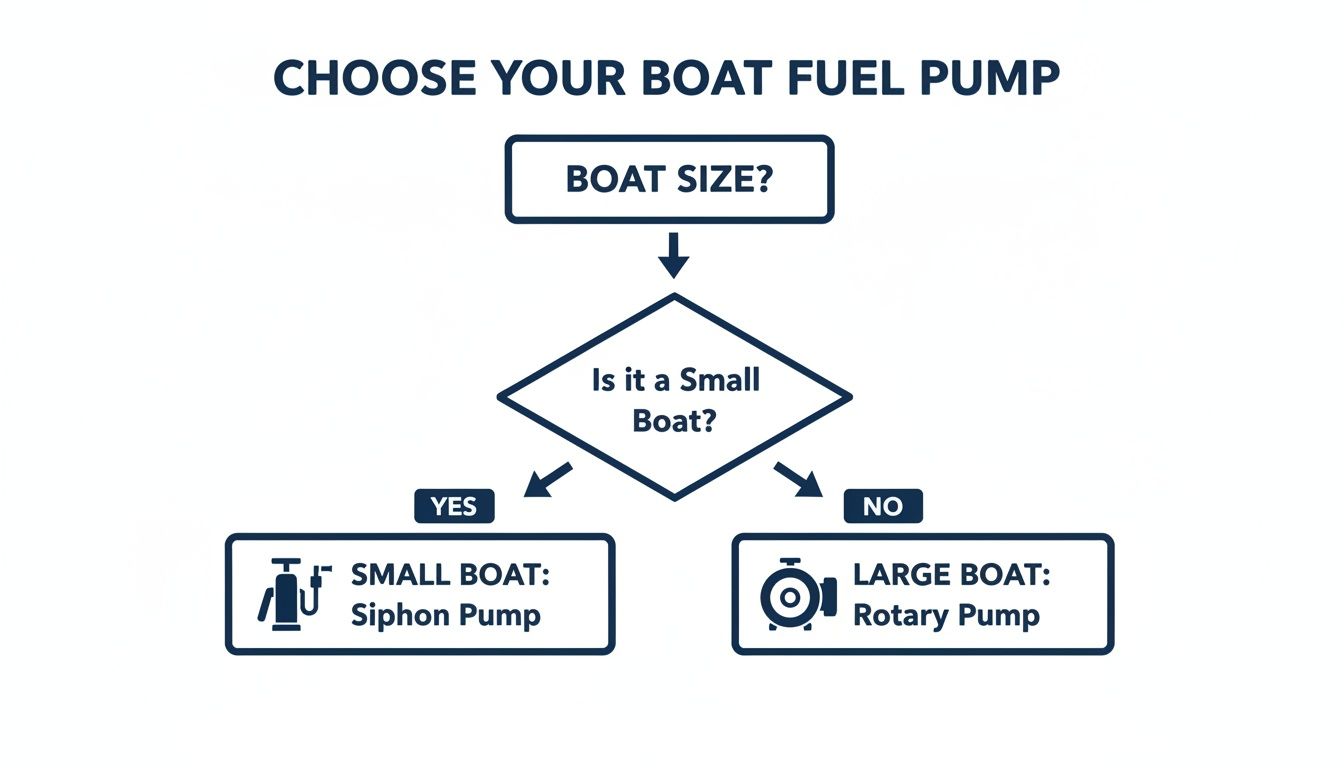

This quick guide can help you narrow it down based on your boat size.

As you can see, it often comes down to how much fuel you're moving and how often you're doing it. Simpler pumps work great for smaller boats, while larger vessels need something more robust.

The Precision Tool: Piston Pumps

A piston pump works just like a big syringe. You pull the handle up, and a piston inside a cylinder creates a vacuum that sucks fuel in. Push the handle down, and it forces that fuel out under pressure. This simple action gives you incredible control over the flow rate.

This makes piston pumps perfect for smaller, more delicate tasks. Need to get that last bit of fuel from the bottom of a can, prime a fussy engine, or just transfer a gallon or two without making a mess? The piston pump gives you the accuracy you need. They're definitely slower for large volumes, but that controlled action is a huge plus when you can't afford a spill.

The real beauty of a piston pump is the control. It stops that sudden "glug-glug" surge of fuel that causes spills, making it a much safer bet for transfers where you need to be precise.

It’s this level of control that makes a small piston pump a must-have in any boater's toolkit, especially for maintenance jobs.

The Simple Solution: Siphon Pumps

The siphon pump is about as basic as it gets, using gravity and a simple squeeze bulb to get the fuel flowing. You just have to put your fuel can higher than your tank, stick the hoses in, and give the bulb a few good squeezes to get things started. Once it's primed, gravity takes over and does the rest.

Siphon pumps are incredibly simple, lightweight, and cheap. They're the perfect tool for small-scale jobs, like filling up the tank on your dinghy, jet ski, or a portable generator. Their biggest drawback is that they absolutely require a height difference to work, and you have almost no control over the flow once it’s going.

Still, for a quick and easy gravity-fed transfer, you really can't beat their simplicity. You can see more great options in our guide to the top manual transfer pumps for fuel in 2025.

Key Features to Look For Before You Buy

So, you’ve figured out whether a rotary, piston, or siphon pump is the right style for your boat. Now it’s time to get into the nitty-gritty. Not all hand pumps are built the same, and a few small details can be the difference between a tool you can count on and one that’s just a frustrating liability.

Paying attention to these specifics will help you pick a pump that’s safe, durable, and gets the job done without any fuss. Let’s break down the three most important things to look at before you pull the trigger.

Fuel Compatibility and Material Quality

This is the big one. If you ignore everything else, pay attention to fuel compatibility. This isn't just a friendly suggestion—it's a critical safety rule. Using a pump made for diesel with gasoline will destroy its internal seals and gaskets, leading to dangerous leaks.

Always, always check that the pump is explicitly rated for the type of fuel you'll be using. You’re looking for materials that can stand up to the tough marine environment and the fuel itself:

- Nitrile (Buna-N) Seals: This is the go-to standard for seals and O-rings that come into contact with gasoline and diesel. It’s tough and offers great resistance.

- Viton Seals: If you’re dealing with more aggressive fuels or certain biofuels, Viton is a step up in chemical resistance, though it usually costs a bit more.

- Cast Iron or Aluminum Housing: You want a pump body that can handle being knocked around. These materials provide the rugged durability you need on a boat.

A pump is only as strong as its weakest link. Using the wrong fuel can cause the seals to swell, crack, or completely dissolve. On a boat, that's a serious fire hazard you just can't risk.

Understanding Flow Rate and Pumping Effort

Flow rate tells you how fast a pump can move fuel, usually measured in gallons per minute (GPM) or by how much it moves with each stroke. It’s tempting to think that faster is always better, but it’s really a trade-off. A higher flow rate almost always means more elbow grease.

For instance, a rotary pump might boast a quick 10 GPM, which sounds great when you need to move 20 gallons from a drum. But that continuous cranking can wear you out. A small piston pump, on the other hand, might move just a trickle with each stroke but requires very little effort, giving you pinpoint control for smaller jobs.

Ask yourself what matters more for your typical task: speed or control? For topping off a small dinghy tank, a slow, easy-to-manage pump is perfect for preventing spills. But for refueling your main tank from a few jerry cans, a faster rotary model will save you a lot of time and sore muscles.

Hose Quality and Safety Features

The pump itself is only one part of the system. The hoses are just as important, and in a marine setting, flimsy hardware-store hoses are a definite no-go. They crack from sun exposure, get brittle in the cold, and quickly become a leaking mess.

Here’s what to look for in a quality hose setup:

- Reinforced Construction: Good hoses are built to prevent kinking. A kink not only stops the fuel flow but can also put a strain on the pump.

- Anti-Static Properties: As fuel rushes through a hose, it can build up a static charge. An anti-static hose is absolutely essential to safely discharge that electricity and prevent a spark from igniting fuel vapors.

- Secure Fittings: Check that the hose fittings are made of a durable metal, like brass, and are designed to create a tight, leak-proof seal with the pump.

Spending a little extra on a pump with high-quality, purpose-built hoses isn't just about better performance—it's a fundamental safety precaution when you're handling flammable liquids on the water.

Fueling Safely and Protecting the Environment

Moving fuel around with a hand pump is a routine job for many boaters, but it’s one that deserves your full attention every single time. Let's be honest, handling fuel on the water brings some real risks, from fire hazards to environmental messes. The good news is that a simple, repeatable safety routine makes the whole process safe and manageable.

The biggest danger? Those invisible gasoline fumes. They're heavier than air and love to settle in low spots like your bilge, creating a recipe for disaster. All it takes is one stray spark from a battery connection or static electricity to turn your boat into a very bad memory.

Your Essential Safety Checklist

Before a single drop of fuel moves, make these steps a non-negotiable habit. This isn't just about following rules; it's about protecting yourself, your crew, and your boat.

- Air it Out: Pop open every hatch, porthole, and door you can. Get that air moving. You need to run your bilge blower for a solid four to five minutes both before and after you're done fueling to kick out any trapped vapors.

- Kill All Sparks: This is an absolute. No open flames—that means the galley stove, pilot lights, everything. Shut down all engines, electronics, and even the main battery switches. You're creating an ignition-free zone.

- Stay Grounded: Static electricity is the silent enemy here. Keep the fuel nozzle in constant contact with the boat's fill pipe. This simple action grounds the connection and prevents a static spark from building up as fuel flows.

Once you’ve run through the checklist, you’re ready to pump. But always—always—have fuel-absorbent pads right there with you. You want to be able to instantly mop up any drips or small spills before they hit the water. It’s also why understanding things like safe fueling practices for bareboat charters is so important for anyone taking the helm.

Environmental Responsibility on the Water

Every boater knows that even one drop of fuel in the water creates that ugly, rainbow sheen. Preventing spills is about more than just dodging fines; it’s about being a good steward of the lakes and oceans we love to be on. A hand pump, used with care, is a great tool for this, but we're all human, and mistakes can happen.

The push for safer, cleaner fueling gear isn't just coming from boaters. Tighter environmental rules are driving real innovation in pump design, with a huge emphasis on features that make spills less likely.

This focus on safety and environmental care is a big reason the hand fuel transfer pump market, valued at USD 1.2 billion, is expected to more than double to USD 2.5 billion by 2034. A major factor here is the effort to design out human error, which has historically caused 15-20% of industrial spills.

At the end of the day, a manual pump is only as safe as the person using it. For a more comprehensive look at staying safe on the fuel dock, check out our complete boat fueling safety playbook. This need for constant diligence is exactly why modern, automated solutions are becoming so popular—they offer an extra layer of protection against the simple mistakes we can all make.

How to Maintain Your Fuel Hand Pump

Your fuel transfer hand pump is a simple, tough tool, but a little routine care will make sure it works perfectly when you need it most. Just like any other piece of gear on your boat, a quick inspection now and then prevents frustrating surprises like lost suction or a stiff handle when you’re trying to refuel.

Think of it like this: you wouldn't ignore a sputtering engine, so don't neglect the simple pump that gets fuel to it. A few minutes of preventative maintenance can save you a world of trouble and mess later on. Keeping up with maintenance schedules is crucial for longevity, much like following the recommended servicing intervals for equipment in other fields.

Simple Maintenance Checklist

To keep your pump in prime condition, run through these quick steps after you're done using it. This simple habit will stop most common issues before they ever start.

- Pump It Dry: Once the fuel is transferred, give the pump a few extra cranks in the open air. This purges any leftover liquid from the mechanism and hoses.

- Wipe It Down: Grab a clean, dry rag and wipe down the pump's body and hoses. This removes fuel residue that can attract dirt and grime, which can break down the materials over time.

- Inspect Hoses and Seals: Before putting it away, give the hoses a quick visual check for any cracks, kinks, or brittle spots. Make sure the seals at the connection points look good and aren't dried out.

Proper storage is just as critical. Find a clean, dry spot for your pump, away from direct sunlight and any potential sources of ignition. Tucking it into a sealed bag can help contain any lingering fuel vapors and keeps it free from dust. For more in-depth care advice, check out our complete boat fuel pump guide with expert maintenance tips.

Quick Troubleshooting Guide

If your pump starts acting up, one of these easy fixes will usually get it working again.

Problem: The pump won't draw fuel or has weak suction.

Solution: The most likely culprit is an air leak. Double-check that all your hose connections are completely airtight. Take a close look at the hose itself for any tiny cracks or pinholes that might be letting air in.

Problem: The handle is stiff or hard to operate.

Solution: The mechanism probably needs a little lubrication. For rotary or piston pumps, a small amount of light oil on the moving parts can make a huge difference and restore that smooth action.

Problem: The pump is leaking at the connections.

Solution: It's time to inspect and likely replace the seals. The O-rings or gaskets can wear out over time or get damaged by certain types of fuel.

Is It Time to Upgrade from a Manual Pump?

Don't get me wrong, a simple hand pump is a fantastic tool to have in your locker for emergencies or small jobs. But for routine fueling? They have some pretty serious drawbacks. That same simplicity that makes them reliable can also be their biggest weakness, especially when you need precision and want to keep your deck clean.

Let's be honest: manual pumping is a guessing game. You're listening for the gurgle, peering into the filler neck, and trying to stop just at the right moment. It’s incredibly easy to get it wrong, and the result is a messy, wasteful overfill.

That little bit of spilled fuel isn't just a hassle to clean up. It can stain your gelcoat or teak, and more importantly, it's a real environmental problem. When you combine the physical effort with the constant risk of a spill, it's clear why hand pumps aren't the best choice for filling up at the dock week after week. This is exactly where modern fueling tech comes into the picture.

The Modern Answer: Spill-Free Fueling

For boaters who want more convenience and a lot less risk, automatic, spill-free systems are the way to go. These systems take the guesswork completely out of the equation. No more listening, no more peeking—just a perfect, full tank every single time, with zero chance of an overflow. It's a massive upgrade for protecting your boat and the water we all enjoy.

The global demand for better fuel transfer pumps is growing, with the market expected to hit USD 2.51 billion by 2030. This push is largely driven by a need for safer, more reliable technology. In fact, in areas with stricter regulations, better pump systems have already cut down on spills from bad transfers by as much as 20%. That means less water pollution and less corrosion on boats. You can dig deeper into the growth of the fuel transfer market for more details.

In the end, moving from a basic hand pump to an automated system like CLiX isn't just about convenience. It's an investment in your peace of mind, your safety, and your commitment to being a responsible boater.

Got Questions About Fuel Hand Pumps? We’ve Got Answers.

Even the most seasoned boaters run into questions when dealing with new gear. Let's tackle some of the most common ones that come up when using fuel transfer hand pumps.

Can I Use the Same Hand Pump for Gasoline and Diesel?

It's a common question, but the answer is a firm "no" — unless the pump is explicitly designed and rated for both. Gasoline is much more aggressive on seals and internal components than diesel.

Using a diesel-only pump for gasoline will quickly chew through the seals, leading to dangerous leaks and pump failure. Always play it safe and check the manufacturer's specs before you even think about switching fuels.

My Pump Won't Start Pumping. What's Wrong?

If your pump is just sucking air, you've almost certainly got an air leak somewhere. The pump needs a perfect vacuum to get started, and even a tiny gap can ruin the prime.

Start by checking every single hose connection. Make sure they are screwed on tight and completely sealed. Next, give the hoses a once-over, looking for any small cracks or pinholes that could be letting air sneak in.

Pro Tip: If you have a rotary or piston pump that's being stubborn, try adding a little light oil into the pump housing. This can help create that initial seal it needs to build suction and get the fuel moving.

What’s the Best Way to Store My Fuel Hand Pump?

A little care after each use goes a long way. Once you’re done transferring fuel, give the pump a few more cranks in the open air to push out any leftover liquid.

Wipe down the outside and find a clean, dry place to store it, well away from direct sunlight or anything that could create a spark. For an extra layer of safety, pop it in a sealed bag to keep any lingering fuel vapors contained and protect it from dust.

Ready to eliminate spills and fueling guesswork for good? CLiX Fueling Solutions offers a modern, automatic system that prevents overfills and protects your boat and the environment. Discover a safer, cleaner way to fuel at https://clixfueling.com.