When it comes to your boat, the fuel pump is far more than just another part—it's the heart of your engine's fuel system. It’s got one critical job: delivering a steady, reliable stream of fuel.

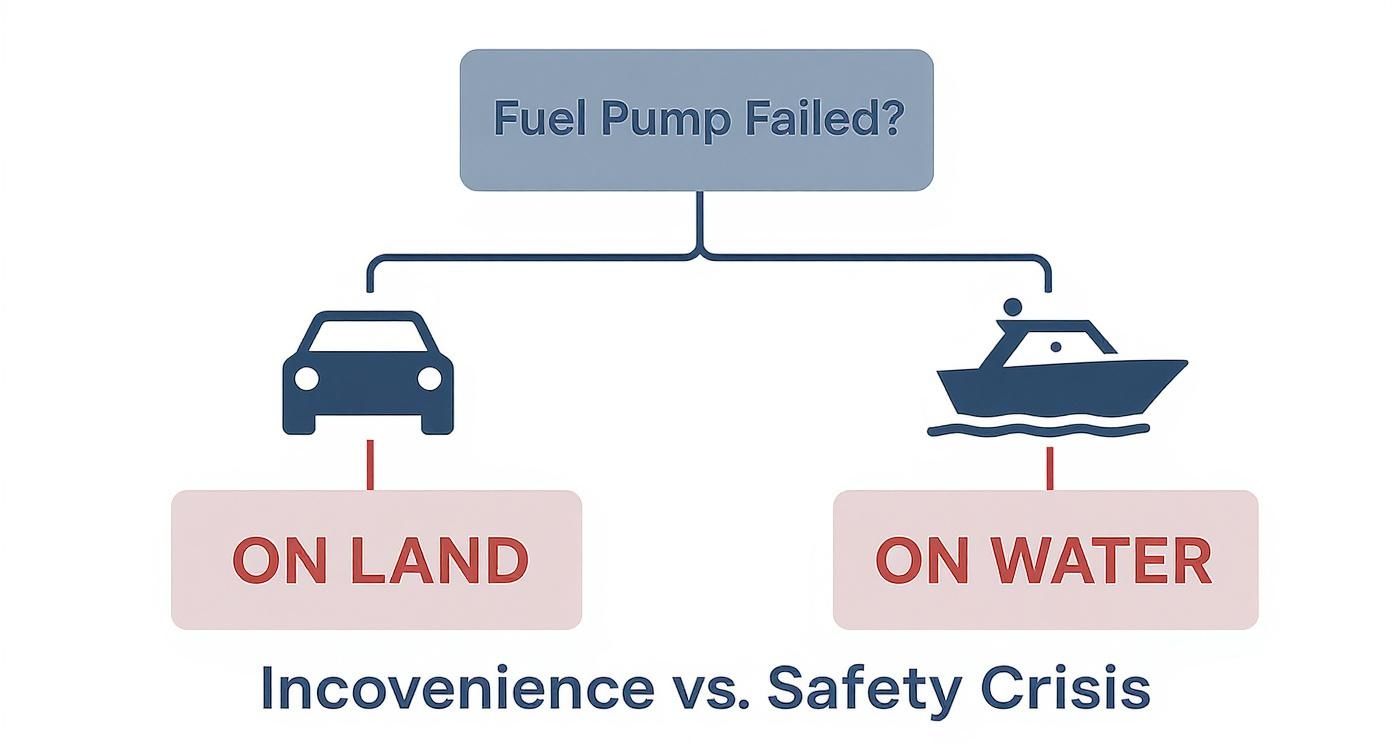

A pump failure in your car is an annoyance. On the water, however, it can quickly turn into a serious safety situation, leaving you stranded miles from the nearest shore.

Understanding Your Boat’s Marine Fuel Pump

Think of your marine fuel pump as the tireless workhorse hidden away in the engine compartment. Its whole purpose is to move fuel from the tank to the engine at just the right pressure and volume. This small but essential component is what lets your engine fire up and run smoothly, whether you're just cruising the coastline or making a long run offshore.

Unlike the pump in your car, a marine fuel pump is engineered for a much tougher life. It has to stand up to constant vibration, salt-laced air, and high humidity. This is exactly why a quality, marine-grade pump isn't just a suggestion—it's a must-have for safe and reliable boating.

The Core of Your Propulsion System

The fuel pump is a critical link in a chain that includes your fuel tank, lines, filters, and engine. When you understand how they all work together, the pump's importance really clicks into place. For a complete look at how everything connects, check out our guide on fuel systems for boats. A healthy pump is the key to making sure the whole system does its job, preventing everything from sputtering performance to total engine failure.

This focus on reliability is a big deal across the marine industry. The global market for marine engines, where these pumps play a vital role, was valued at a staggering $8.9 billion in 2024 and is expected to keep growing. That growth comes from boaters demanding more efficient, durable, and cleaner marine technology. You can see more details about this growing market and its trends.

Critical Takeaway: A failing fuel pump isn't just a performance headache; it's a safety risk. Treating it as a vital component is the first step toward responsible boat ownership, helping ensure every trip you take is a safe one.

This guide will give you the know-how to choose the right pump, keep it in top shape, and spot trouble before it starts. It’s all about empowering you to make smart decisions that protect your investment and, most importantly, keep you safe on the water.

Mechanical vs Electric: Which Fuel Pump Is Right for You?

When it comes to boat fuel pumps, picking between mechanical and electric isn't really about personal preference. It's about matching the right pump to your engine's specific demands. Think of it like a classic car with a manual stick shift versus a modern car with an automatic transmission—each one is engineered to work in a very particular way, and you can't just swap them out.

The Old-School Workhorse: Mechanical Fuel Pumps

A mechanical fuel pump is the tried-and-true classic. It runs directly off the engine's power, using a lever on the camshaft to create a suction that pulls fuel from the tank and pushes it toward the carburetor. It’s a beautifully simple and durable design that’s been the heart of marine engines for decades.

The real magic is that its pumping speed is directly tied to your engine's RPMs. This means it naturally delivers more fuel as the engine works harder. Its simplicity is its biggest advantage—fewer moving parts and no dependence on your boat's electrical system make it incredibly reliable. That’s why you’ll almost always find one on older boats with carbureted engines.

The Modern Standard: Electric Fuel Pumps

On the flip side, an electric fuel pump is the more precise, modern solution. Instead of relying on the engine's motion, it uses a dedicated electric motor to push fuel from the tank at a constant, steady pressure. This consistent flow is absolutely critical for today's fuel-injected engines, which need stable pressure to run efficiently.

Electric pumps have some serious perks. They are much less prone to vapor lock, that frustrating problem where fuel turns to vapor in the line from engine heat and starves your motor. Because they push fuel from the tank, they keep the entire line pressurized, which helps keep the fuel in a liquid state. This means easier starts, smoother performance, and better overall fuel economy.

Key Insight: Your engine type is the deciding factor. If you have a carbureted engine, you're likely using a mechanical pump. But if you have a fuel-injected engine, you must have an electric pump to provide the constant, high-pressure flow it needs to run.

A pump failure on the water is a whole different ballgame than a breakdown on the side of the road. This infographic drives home just how critical a reliable pump is when you're miles from shore.

As you can see, what’s a minor inconvenience on land can quickly become a major safety issue at sea.

Making the Right Choice for Your Vessel

Choosing the right pump isn't a tough decision once you know what to look for. Have an older boat with a carbureted engine? A mechanical pump is almost certainly what it was built with and what it needs. Running a modern engine with electronic fuel injection (EFI)? An electric fuel pump isn't just an upgrade—it's a requirement.

To help you see the differences at a glance, here’s a quick comparison of the two pump types. This side-by-side look should make it clear which one is the right fit for your boat's specific setup.

Comparing Mechanical and Electric Marine Fuel Pumps

| Feature | Mechanical Fuel Pump | Electric Fuel Pump |

|---|---|---|

| Power Source | Engine's camshaft | Boat's electrical system |

| Fuel Delivery | Pulsating, varies with RPM | Constant, steady pressure |

| Best For | Older, carbureted engines | Modern, fuel-injected engines |

| Reliability | Very high due to simplicity | High, but depends on electricals |

| Vapor Lock | More susceptible | Highly resistant |

| Cost | Generally lower upfront | Typically more expensive |

| Installation | Simpler, direct engine mount | More complex, requires wiring |

Ultimately, both pumps get the job done, but only when they're matched with the right engine.

The push for better marine technology is a big deal. The fuel pump market alone was valued at $1.13 billion in 2025 and is expected to hit $1.38 billion by 2034. This trend is all about the demand for reliable, efficient systems in boats, cars, and industrial gear. You can dig into more on fuel delivery system market trends here.

Sometimes you need a pump for a totally different job, like moving fuel between tanks. For those situations, we have a guide on marine fuel transfer pumps that breaks down the best options for auxiliary fueling tasks.

In the end, your engine chooses the type of pump you need. Your job is to make sure it's a high-quality, marine-grade component that you can count on when you're far from the dock.

Why Gasoline and Diesel Fuel Pumps Are Not Interchangeable

It’s one of the first and most important rules you learn in marine maintenance: you absolutely cannot swap a gasoline fuel pump for a diesel one, or vice versa. They might both move fuel, but that's where the similarities end.

Thinking they’re interchangeable is like trying to use a garden hose to do the job of a high-pressure washer. They are completely different tools built for entirely different jobs, and mixing them up is a serious recipe for disaster.

The core differences boil down to two things: pressure and volatility. A diesel engine uses compression to ignite fuel, which means it needs that fuel injected into the cylinders under enormous pressure—often hitting over 20,000 PSI. A diesel fuel pump has to be a heavy-duty piece of engineering, built like a powerlifter, just to handle those forces.

Gasoline engines are a different story. They run at much lower pressures, typically somewhere between 40 and 60 PSI. But their fuel is extremely volatile and flammable, creating a whole different set of engineering problems to solve.

The Powerhouse Diesel Pump

Diesel fuel pumps are all about brute strength. They’re made from tough, robust materials that can stand up to the corrosive nature of diesel and the crazy-high pressures needed for proper atomization and combustion. That high-pressure delivery is the secret sauce to the engine's power and efficiency.

Because diesel fuel is far less flammable than gasoline, the engineering focus is squarely on durability and pressure management. Every component inside is precisely machined to take a beating without failing. Trying to put a gasoline pump in a diesel system would be like asking a bicycle pump to inflate a truck tire—it just doesn't have the muscle for the job.

The Safety-Focused Gasoline Pump

A gasoline fuel pump doesn't need to be a bodybuilder, but it has an even more critical job: preventing an explosion. Gasoline fumes are incredibly flammable. Worse, they're heavier than air, so they can pool in low-lying areas like the bilge. All it takes is one stray spark from an unsealed motor or a bad wire to ignite those fumes with catastrophic results.

To prevent this nightmare scenario, every marine gasoline fuel pump must be ignition-protected.

What is Ignition-Protection?

An ignition-protected component is built and sealed to ensure no internal sparks can ever escape and ignite flammable gases or vapors in the surrounding air. This is a non-negotiable safety standard required by the U.S. Coast Guard for every boat with a gasoline engine.

This means the pump's motor, wiring, and switches are completely sealed inside a housing that traps any potential sparks. It’s a life-saving feature that also makes them more complex to build than diesel pumps. While both fuels need to be handled with care, the properties of diesel present a different kind of challenge. For some practical advice on that, our guide on fuel funnels for diesel has some great tips.

Using a pump that isn't ignition-protected—like one from a car or a diesel boat—in a gasoline engine compartment is one of the most dangerous mistakes you can make. The risk of fire or an explosion is incredibly high. Always, always double-check that you're installing the correct, marine-certified pump for your fuel type.

Keeping Your Fuel Pump Happy: Maintenance and Troubleshooting

Your boat’s fuel pump is one of those out-of-sight, out-of-mind parts that works tirelessly in a pretty harsh environment. But just like any critical piece of your engine, it needs a little attention to stay reliable. A bit of proactive maintenance is your absolute best defense against getting stranded. It can turn a potential trip-ruining disaster into a minor fix you handle back at the dock.

Honestly, a little prevention goes a very long way. Putting together a simple checklist and running through it periodically will help you catch most issues before they spiral out of control. Think of it as a quick health check-up for your boat's heart—the fuel system.

Your Go-To Maintenance Checklist

Getting ahead of problems is everything on the water. The whole marine pump industry—a market hitting around $5.86 billion in 2025—is built on one thing: reliability. Failure just isn't an option out there. The fact that the market is expected to grow to $8.43 billion by 2032 shows how much boaters depend on tough, durable parts. You can read more about the trends driving marine pump technology if you're curious.

Here’s a straightforward checklist to keep your fuel pump humming along nicely:

- Swap Out Fuel Filters Regularly: Your filter is the first line of defense against gunk. A clogged one forces the pump to work overtime, leading to a much shorter lifespan. Follow the manufacturer's schedule, or just make it a habit to change it at the start of every season.

- Give Fuel Lines a Good Once-Over: At least once a season, take a close look at all the fuel lines and hoses. You're searching for any cracks, spots that feel too hard or mushy, or loose connections. Boat vibrations are notorious for shaking clamps loose, so double-check that everything is snug.

- Listen to What the Pump is Telling You: An electric fuel pump should make a steady, quiet hum when you turn the key. If you hear a loud whine, a grinding noise, or dead silence, that's the pump screaming for help.

- Keep That Fuel Tank Clean: Water and sediment collecting at the bottom of your tank are a fuel pump’s worst nightmare. Always use a good fuel stabilizer, especially for storage, and think about having the tank professionally cleaned if the boat has been sitting idle for a long time.

Spotting Common Fuel Pump Problems

Even with the best maintenance routine, things can happen. When your engine starts acting up, the fuel pump is often one of the first things to suspect. Knowing how to connect the symptoms to the source will save you a world of time, money, and frustration.

If your boat starts showing any of these signs, it's time to take a look at the fuel pump:

-

Symptom 1: Engine Sputters or Bogs Down Under Load

- What it means: This is a classic sign of fuel starvation. The pump just can't keep up with the engine's demand for more fuel when you accelerate. It often points to a dying pump motor or a serious clog somewhere in the system.

-

Symptom 2: It's Tough to Start the Engine

- What it means: An electric pump is meant to prime the fuel system before the engine even cranks. If the pump is weak or failing, it can't build that initial pressure, making the engine difficult or even impossible to get started.

-

Symptom 3: The Engine Stalls Completely or Won't Start at All

- What it means: You're looking at a total failure here. The pump isn't moving any fuel, period. The cause could be electrical—like a blown fuse or a bad relay—or the pump's internal motor might have just given up for good.

A Pro Tip for Troubleshooting: Always check the easy stuff first. Before you convince yourself the pump is shot, check its fuse and relay. A $5 fuse is a much, much better fix than a $300 fuel pump.

A Quick Guide to Finding the Problem

When you think you have a fuel pump issue, follow these steps to methodically track down the culprit. This will help you figure out if it's a simple fix or something you need to call in a certified marine mechanic for.

- Check the Electrics First: With electric pumps, your first stop is the fuse box. A blown fuse is a very common problem. If the fuse looks good, have someone turn the key to the "on" position (without starting the engine) while you listen for that distinct humming sound from the pump.

- Hunt for Clogs: Disconnect the fuel line right after the filter (on the engine side) and aim it into a safe container. Have your helper briefly turn the key again. If you only get a weak trickle of fuel or nothing at all, your problem is either the pump itself or a blockage somewhere before it.

- Test the Fuel Pressure: The most surefire way to know is to check the pressure with a proper gauge. This tool hooks up to a test port on the engine's fuel rail. If the pressure reading is lower than what the manufacturer calls for, you've got your answer: the pump isn't pulling its weight.

Marine Safety Standards for Fuel Pumps

On the water, safety rules aren't just suggestions—they are your first line of defense against things going seriously wrong. When we're talking about fuel pumps for boats, following the established standards isn't optional. It’s absolutely essential for protecting your boat, your passengers, and the water you enjoy.

These regulations were written for the tough realities of a marine environment, where fuel, volatile fumes, and ignition sources are all crammed into a small, constantly vibrating space. Think of it this way: knowing the rules is a fundamental part of boat ownership, right up there with knowing how to tie a knot or read a chart. It’s all about preventing fires, explosions, and messy fuel spills.

Why "Ignition-Protected" Is a Life-Saving Term

If there's one term you need to burn into your memory, it's ignition-protected. This isn't just marketing jargon; it's a critical engineering standard for any electrical device—especially a fuel pump—that lives in the engine space of a gasoline-powered boat.

Here's why it matters so much. Gasoline fumes are heavier than air, so they sink and collect in the lowest part of your boat: the bilge. This creates a hidden, highly explosive pocket of gas just waiting for a spark. A single stray spark from a standard electrical motor could ignite those fumes with terrifying force.

What Does Ignition-Protected Really Mean? It means the component is built and sealed to ensure it cannot create a spark in the air around it. An ignition-protected fuel pump has its motor, wiring, and switches completely enclosed, trapping any tiny internal sparks safely inside the housing.

This is precisely why you can never, ever substitute an automotive fuel pump in a boat. A car's pump is designed for an open, well-ventilated engine bay, not a sealed boat bilge. Using one is an invitation for disaster.

Following USCG Fuel System Rules

The U.S. Coast Guard (USCG) lays out clear, comprehensive regulations for marine fuel systems. While the full rulebook is dense, a few core principles apply directly to your fuel pump and how it's installed.

- Rock-Solid Mounting: The fuel pump must be fastened down tight. It can't be allowed to shake, rattle, and roll with the boat's movement.

- Safe Electrical Connections: All wiring needs to be properly routed, secured to prevent rubbing or chafing, and connected with marine-grade terminals that won't corrode in a saltwater environment.

- Tough Fuel Lines: Any hoses attached to the pump must be USCG-approved (look for ratings like A1-15 or B1-15) and held in place with corrosion-resistant clamps.

These standards all work together to build a robust, closed-loop system that can handle the motion and moisture of life on the water. When you buy certified fuel pumps for boats, you're getting a component that's already built to meet these non-negotiable safety requirements.

Keeping Fuel in the Tank, Not in the Water

Beyond preventing fires, responsible boating means protecting the environment. A leaky fuel pump or a clumsy refueling job can send gasoline or diesel straight into the ecosystem, where it can do a lot of damage.

Federal law is crystal clear: discharging oil or fuel into U.S. waters is illegal. Even a small spill that leaves a sheen on the water can lead to hefty fines. The best way to avoid this is to ensure your entire fuel system is leak-free.

Make it a habit to regularly inspect your fuel lines, check the connections, and look over the pump housing for any signs of trouble. Catching a small weep or a cracked hose early is the key. This simple bit of maintenance doesn't just protect the environment—it keeps your boat safer by making sure every last drop of flammable fuel stays where it belongs.

Modern Upgrades for Your Boat’s Fuel System

It’s one thing to just replace a broken part, but it’s another thing entirely to upgrade your whole fueling experience. Today's technology goes way beyond a simple new pump; it offers smart, connected solutions that finally solve some of the most annoying and persistent problems in boating.

Think about pulling up to the fuel dock without that nagging feeling of "am I about to overfill it?" No more cringing as diesel or gas spills over the side, staining your gelcoat and polluting the water. That’s what a modern fueling system can do—make the entire chore faster, cleaner, and a whole lot less stressful.

Moving Beyond the Pump

A real upgrade isn't just about the pump; it's about looking at the entire fuel system from the dock to the engine. We often focus on how the pump gets fuel to the engine, but what about how the fuel gets into the tank? For decades, we've relied on listening for that gurgling sound from the fuel fill—a notoriously unreliable method that almost guarantees a spill.

This is exactly the problem innovative systems are built to fix. They provide a complete set of components designed to work together perfectly.

- Spill-Proof Refueling: These systems create a sealed connection from the fuel nozzle to your tank. The moment the tank is full, the flow stops. Automatically.

- A Huge Safety Boost: By preventing spills, you get rid of flammable fuel pooling on your deck or, worse, leaking into the bilge. That’s a massive fire hazard you no longer have to worry about.

- Protecting the Water: Let's face it, even tiny spills are bad news for the environment. A modern setup helps you stay compliant with clean water laws and protect the very ecosystems we love to be out on.

At the end of the day, it's an investment in smarter, safer, and more enjoyable boating.

For most boaters, the messy and wasteful process of refueling is a constant headache. Modern systems like CLiX Fueling Solutions are designed to stop spills completely, making refueling quicker, cleaner, and safer for you and the environment. Find out how a simple upgrade can transform your fueling experience.

The CLiX Fueling Solutions Advantage

The CLiX system is a perfect example of this new way of thinking. It’s not a different kind of fuel pump; it’s a smart addition that works with your current setup to nail the refueling process. It solves that ancient problem of not knowing your tank is full until fuel is already splashing onto your deck.

The system gives you a dependable, mechanical shut-off that cuts the fuel flow at the perfect moment—every single time. It’s a straightforward but incredibly effective way to prevent overfills, protect your boat from fuel damage, and make one of the most tedious parts of boating completely hassle-free. By focusing on that critical moment at the fuel dock, CLiX makes your entire system safer and more reliable.

Got Questions About Your Boat's Fuel Pump?

Even after you get the basics down, a few questions always seem to surface when boaters start talking about fuel pumps. Getting a straight answer to these common queries can fill in the gaps and give you the confidence you need to handle your boat's fuel system. Let's dig into a few of the most frequent ones.

How Long Do Marine Fuel Pumps Last?

There’s no hard-and-fast expiration date on fuel pumps for boats, but a good rule of thumb is to expect 500 to 1,000 hours of service from a quality pump. Of course, several things can either cut that time down or stretch it out.

A simple mechanical pump often lasts a bit longer, provided it's taken care of. The lifespan of an electric pump, on the other hand, is closely tied to the health of your boat's electrical system and, crucially, the quality of the fuel it's pumping.

Here’s what really makes a difference:

- Fuel Quality: Clean, ethanol-free fuel treated with a stabilizer is your pump's best friend. Water, dirt, and other gunk are its worst enemies.

- Regular Maintenance: Changing your fuel filters on schedule is the single most important thing you can do. A clogged filter forces the pump to work overtime, and that's a quick path to burnout.

- Hours of Use: Like any other part of your engine, a pump simply wears out over time. The more you're on the water, the more wear and tear it accumulates.

Can I Replace My Boat Fuel Pump Myself?

For a boater who's comfortable with a wrench, swapping out a fuel pump can definitely be a weekend project. But let's be crystal clear: working with a gasoline fuel system is extremely dangerous. If you feel even the slightest bit unsure, call in a certified marine mechanic. It's always the smart and safe call.

Tackling this yourself is probably okay if you:

- Have solid, hands-on experience with marine engines.

- Genuinely understand the risks of gasoline vapors and can work in a space with plenty of fresh air.

- Have the correct tools for the job, including a safe way to relieve pressure in the fuel lines.

Safety First: Always disconnect the battery before you touch a single fuel line. Make absolutely sure there are no sparks or flames nearby, and keep a marine-rated fire extinguisher right next to you. The risk of a fire is no joke.

What Are the Warning Signs of a Failing Fuel Pump?

A fuel pump rarely just quits on the spot without giving you a heads-up. If you learn to spot the early warning signs, you can fix the problem at the dock instead of finding yourself stranded and calling for a tow.

Keep an eye (and an ear) out for these classic symptoms:

- Engine Sputtering or Losing Power: If your engine stumbles or feels weak when you hit the throttle, it's a textbook sign of fuel starvation. The pump just can't keep up with what the engine is asking for.

- Difficulty Starting: You should hear a faint hum from your electric fuel pump when you first turn the key. If the engine is hard to start, the pump might not be building enough pressure to get things going.

- A Loud Whining Noise: A happy electric pump is a quiet one. A loud, high-pitched whine coming from the tank is often the sound of a motor straining itself to death.

- Sudden Engine Stall: If the engine just cuts out and won't restart, there's a good chance the pump has finally given up completely.

A dependable fuel system is at the heart of every good day on the water. For a truly worry-free experience, especially when it's time to refuel, upgrading your gear is a smart move. The system from CLiX Fueling Solutions is designed to prevent those dangerous and messy fuel spills at the dock, making the whole process faster, cleaner, and completely stress-free. You can learn more about their system.