Ever wonder what keeps your boat running so smoothly on the water? It’s not just the engine or the hull. The real workhorses are the hidden networks of pumps, hoses, and tanks that move critical liquids like fuel, oil, and water exactly where they need to go.

These are the unsung heroes of your vessel, and we call them fluid transfer systems.

Your Boat’s Circulatory System

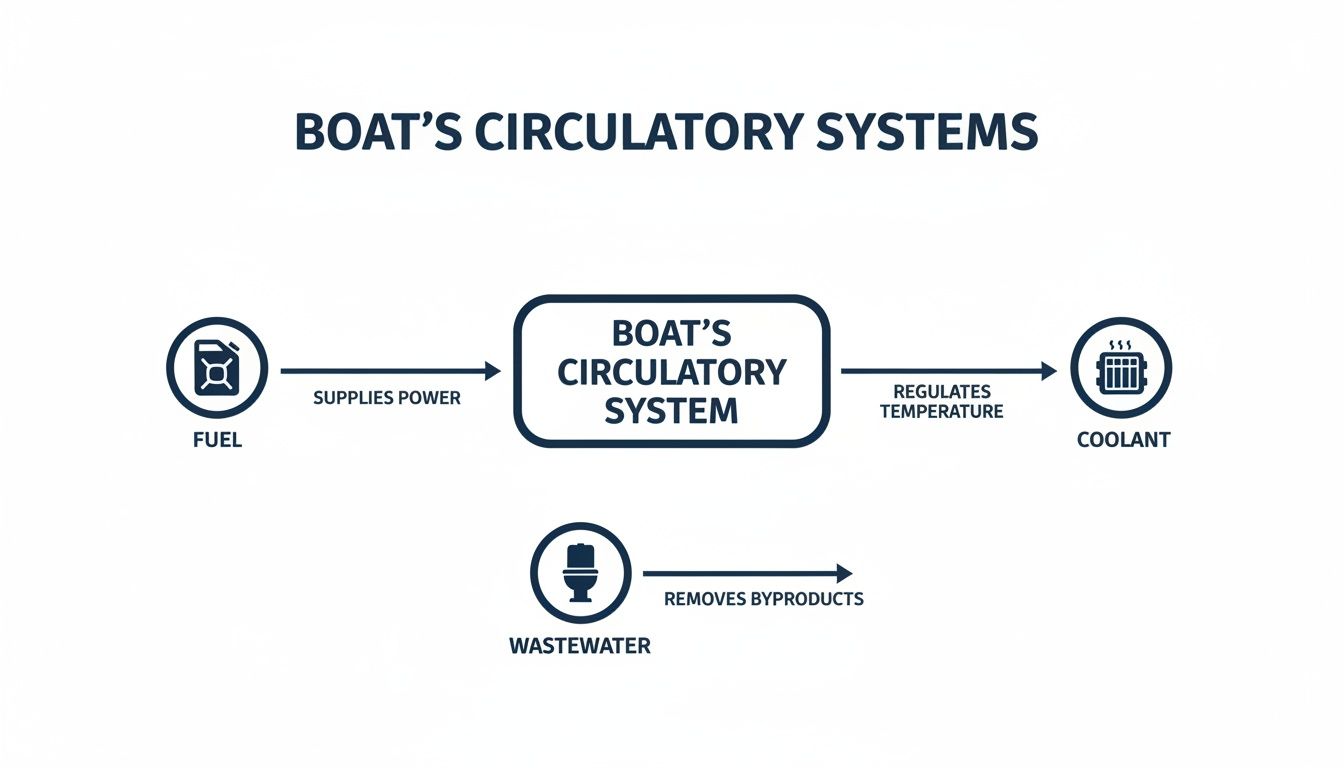

The easiest way to think about this is to picture your boat’s circulatory system. Just like your body uses veins and arteries to move blood, your boat relies on this complex web of plumbing to transport essential fluids. This network handles everything from getting fuel to the engine to pumping out wastewater.

Simply put, without these systems, your boat is just a floating shell. They are the operational heart that makes everything else work. Whether it's the fuel powering your day trip or the coolant stopping your engine from overheating, every key function depends on the reliable movement of fluids.

It’s More Than Just Fuel Lines

When people think of fluid systems, the fuel lines are usually the first thing that comes to mind. But that’s just one piece of a much bigger, interconnected puzzle. To really understand your boat, you need to know about all the systems working together.

On most recreational boats, you’ll find a few key systems:

- Fuel Systems: This is the big one. It stores your gasoline or diesel and delivers it clean and ready to the engine. For a deeper dive, you can learn about the complete anatomy of boat fuel systems in our other guide.

- Cooling Systems: These circulate raw water or antifreeze to keep your engine at the right temperature, preventing a catastrophic failure and keeping things reliable.

- Freshwater Systems: This is what provides clean water to your galley, sinks, and showers, making your time on board comfortable.

- Wastewater Systems: Manages blackwater (from toilets) and greywater (from sinks) safely, ensuring you stay compliant with environmental laws.

- Bilge Systems: A critical safety feature. This system removes any water that collects in the bilge, the lowest part of your boat, to prevent flooding.

Understanding how these systems work together is the first step toward becoming a more confident and capable boat owner. It transforms complex mechanics into manageable concepts, empowering you to spot potential issues before they become serious problems.

When you demystify this essential network, you go from just operating your boat to truly understanding it. That knowledge is your best defense against expensive breakdowns, and it’s what keeps everyone on board safe while protecting the marine environment we all love. It's all about gaining peace of mind on the water.

The Core Components of Marine Fluid Systems

Just like your car has an engine, transmission, and wheels, every fluid system on your boat is built from a core set of components. Getting to know these parts and what they do is the first step toward spotting potential problems before they become big ones. Think of it as learning the basic anatomy of your vessel’s most vital systems.

Each piece has a very specific job, and they all have to work together to move liquids around safely and efficiently. From the pump that gets things started to the tank that holds the fluid, a failure in any single component can bring the entire system to a grinding halt.

This infographic gives you a great visual of how a boat's main systems manage fuel for power, coolant for engine temperature, and wastewater for removal.

Whether we're talking about fuel, coolant, or waste, the fundamental process is the same: storage, transfer, and management.

Pumps: The Heart of the System

If a fluid transfer system is your boat’s circulatory system, the pump is its heart. Its only job is to create the pressure needed to move liquids through the maze of hoses and pipes. Without a working pump, fluids aren't going anywhere.

The marine environment is tough, so boats need specialized pumps built to handle specific tasks and resist the corrosive bite of saltwater. You'll usually find a few different types on board:

- Impeller Pumps: These use a flexible rubber impeller to move a lot of water quickly, making them perfect for engine cooling systems.

- Diaphragm Pumps: By using a pulsating membrane to create suction, these pumps can run dry without getting damaged. This makes them a great choice for bilge pumps and freshwater systems.

- Centrifugal Pumps: A spinning rotor moves the fluid in these pumps, which you’ll often find in air conditioning units and circulation applications.

Choosing the right marine fuel transfer pump is a big deal for both performance and safety. It's worth taking the time to understand the differences.

Hoses and Pipes: The Veins and Arteries

Think of hoses and pipes as the veins and arteries of your boat. They are the pathways that carry fluids from one point to another, connecting everything from the fuel tank to the engine and the water tank to the faucet. But in the marine world, not just any old hose will do.

All hoses must be USCG-approved for their specific purpose. Fuel hoses, for instance, are made from special materials to stop gasoline or diesel from seeping through the hose wall and creating explosive fumes in an enclosed space like a bilge. Using a standard automotive hose for fuel is a major fire hazard on a boat.

A cracked, brittle, or bulging hose is a huge red flag. It’s screaming that a failure is coming. Regularly checking all the hoses in your fluid systems is one of the most important maintenance tasks you can do as a boater.

Valves and Fittings: The Gatekeepers and Connectors

Valves and fittings are the control points of the whole system. Valves act as gatekeepers, letting you start, stop, or redirect the flow of fluids whenever you need to. Fittings are the connectors that join hoses to pumps, tanks, and other components, creating a leak-proof seal.

Some of the most common components you’ll see are:

- Ball Valves: These give you simple on/off control with just a quarter-turn of a handle.

- Seacocks: These are heavy-duty valves attached right to the hull, controlling the intake or discharge of raw water from outside the boat.

- Hose Clamps: Absolutely critical for securing hoses to fittings. Marine-grade 316 stainless steel clamps are a must to prevent them from rusting away and failing.

- Thru-Hull Fittings: These are the ports that go through the boat’s hull below the waterline, connecting to the seacocks.

Bronze and stainless steel are the go-to materials for marine fittings and valves because they stand up to saltwater corrosion so well. If you use cheaper, non-marine-grade metals, you're just asking for rapid deterioration and dangerous leaks. By getting familiar with these core parts, you'll be much more confident in managing your boat's health.

To put it all together, let’s look at the key players in one of the most critical systems on any powerboat: the fuel system.

Key Components in a Marine Fuel System

| Component | Primary Function | Why It's Critical for Boaters |

|---|---|---|

| Fuel Tank | Stores the boat's fuel supply. | Must be properly vented and secured to prevent leaks and fumes. Material (aluminum, plastic) matters for longevity. |

| Fuel Lines/Hoses | Transport fuel from the tank to the engine. | Must be USCG-approved (Type A1-15 or B1-15) to prevent permeation and fire hazards from fuel vapors. |

| Fuel Pump | Draws fuel from the tank and pushes it to the engine. | A failing pump means a dead engine. Electrical pumps must be ignition-protected to prevent sparks. |

| Fuel Filter | Removes water and debris from the fuel before the engine. | Prevents engine damage and performance issues. Water in fuel is a common cause of engine trouble on the water. |

| Valves/Seacocks | Control the flow of fuel, allowing shut-off. | Essential for maintenance, emergencies (like a fire), and switching between multiple tanks. |

| Fittings/Clamps | Securely connect all components, ensuring no leaks. | A single loose clamp can lead to a dangerous fuel leak in the bilge, creating a major fire or explosion risk. |

Understanding how these parts function as a team is crucial. A problem with a simple hose clamp can be just as dangerous as a faulty fuel pump, making regular inspection of the entire system a non-negotiable part of boat ownership.

Mastering Safe Fueling and Environmental Rules

Fueling your boat is probably the most common—and riskiest—fluid transfer you'll ever do. It’s one of those moments where being careful isn't just a good idea; it's an absolute necessity. A simple mistake can have disastrous consequences for you, your boat, and the water we all love.

Following the right steps is about more than just dodging fines. It's about preventing fires, protecting your investment, and keeping our waterways clean for everyone. Every boater has a responsibility to get this right.

The Dangers Hiding in Plain Sight

Gasoline fumes are tricky. They're heavier than air, which means they sink and collect in the lowest parts of your boat, like the bilge. All it takes is a single spark—from a stray bit of static or a faulty wire—to ignite those vapors and cause a devastating explosion. This is why following a strict procedure is non-negotiable.

Before you even think about unscrewing the fuel cap, run through this checklist:

- Moor securely: Make sure the boat is tied up tight and isn't going anywhere.

- Extinguish all flames: That means pilot lights on stoves, heaters, everything.

- Shut down everything: Turn off the engine, all electronics, and anything else that could create a spark.

- Get everyone off: Have all passengers step onto the dock before you start.

These aren't just suggestions. They are the fundamental rules for creating a safe environment and drastically reducing the risk of something going terribly wrong.

Fueling is a high-stakes moment, and your focused attention is the single most important safety tool you have. Nearly every fueling accident, from spills to overfills, starts with a simple distraction.

Proper Fueling Procedures Step by Step

Once you've made the area safe, the fueling process itself demands your full concentration. Always keep the fuel nozzle in direct contact with the fill pipe. This simple action grounds it and prevents a static spark. And whatever you do, never use that little hands-free clip to lock the nozzle open—you need to be in control the entire time.

Knowing when to stop is probably the hardest part. The best cue is the sound—listen for a gurgling or burbling noise from the fill pipe, which tells you the tank is almost full. Fill slowly, and never try to cram every last drop in. Fuel expands as it warms up, and it needs that extra space. For a more detailed look, check out our guide on the best way to fill a marine fuel tank.

After you're done, wipe up any small drips and screw the fuel cap on tightly. Then, open up all your hatches and ports to air things out. You absolutely must run your bilge blower for at least four minutes to clear out any leftover fumes before starting the engine. As a final check, do a quick "sniff test" down in the bilge and engine compartment to be sure the air is clear.

Environmental Responsibility and Legal Requirements

Even a tiny fuel spill can do a surprising amount of damage. Just one pint of gasoline can create a slick the size of a football field on the water, harming marine life and their habitats. Federal law actually requires you to have something on board to clean up spills, like absorbent pads.

If you do have a spill that leaves a visible sheen on the water, you are required to report it to the U.S. Coast Guard National Response Center.

This is why spill prevention technology is so critical. The market for advanced fluid transfer systems is already valued at USD 21.05 billion in 2024 and it's growing fast. Why? Because marine fuel spills cost the industry an estimated $1-2 billion a year in cleanup and fines, and overfills alone are responsible for 30% of those incidents. Modern fueling solutions are designed to stop this expensive and destructive problem right at the source.

Adhering to these rules is also a core part of being a good steward of the environment. If you're interested in structured approaches to minimizing environmental impact, you can learn more about environmental management systems (EMS). Following the regulations doesn't just protect you—it protects our waterways for generations to come.

How to Prevent Fuel Spills and Overfills

We’ve all been there. That split second of distraction at the fuel dock, the unreliable gauge, or the dreaded fuel "burp" from the vent line. Suddenly, there’s a rainbow-colored slick spreading across the water, and your heart sinks.

That spill isn’t just an eyesore. Fuel is incredibly corrosive and will immediately start to damage your boat's gelcoat and striping, often leaving a permanent stain. More importantly, it contaminates the very water you're out there to enjoy, harming marine life.

This isn't just a problem for individual boaters. Inaccurate fueling leads to an estimated 10-15% overfill waste across the marine industry, damaging boats and polluting our waterways. While other industries are adopting smarter fueling tech—check out these insights on advanced fuel transfer pumps to see the trend—boating has lagged behind.

The Guesswork of Traditional Fueling

The root of the problem is pure guesswork. You're left listening for the gurgle of a nearly full tank, watching the vent for that first little spit of fuel, and just hoping you shut the nozzle off in time. It’s a messy, imprecise art form.

All it takes is a moment of inattention, and your peaceful day at the dock turns into a frantic, expensive, and environmentally damaging cleanup. Traditional fueling setups just don't have a reliable way to account for human error.

That’s exactly where modern solutions come in, replacing that stressful guessing game with automated precision.

A Modern Solution to an Old Problem

Imagine fueling up with zero anxiety. You connect the nozzle, squeeze the handle, and when your tank is full, the pump clicks off. Automatically. Every single time. This isn’t some far-off idea; it’s what purpose-built systems now offer.

The CLiX fueling system delivers this exact certainty. It creates a smart, closed-loop connection between the fuel nozzle and your boat's tank, creating a fluid transfer system that knows precisely when the tank is at capacity.

How does it work? The system detects the back-pressure that builds up as the tank fills, which instantly trips the fuel nozzle’s auto-shutoff. It physically prevents an overfill, protecting your boat, your wallet, and the environment.

The Benefits of Spill-Free Fueling

Adding a spill-prevention system like CLiX to your boat is about more than just convenience. It’s a smarter way to handle fueling that protects your investment and demonstrates responsible boat ownership.

The advantages are clear:

- Complete Peace of Mind: Fuel up without constantly worrying about a spill. The system handles the timing, so you don't have to.

- Environmental Stewardship: You can take a hands-on role in keeping our waters clean by making sure fuel stays where it belongs—in your tank.

- Investment Protection: You’ll safeguard your boat’s expensive gelcoat, decals, and finish from the permanent damage caused by fuel spills.

- Financial Savings: By eliminating overfills, you stop paying for fuel that ends up in the water and avoid the risk of hefty fines for pollution.

This technology turns one of the most tedious parts of boating into a clean, simple, and foolproof process. For any boater who values safety and a clean environment, it’s not just another gadget—it's an essential upgrade. It's the final answer to the age-old problem of spills and overfills at the dock.

Choosing and Maintaining Your System Components

Picking the right parts for your boat’s fluid transfer systems isn’t just about performance—it’s about safety. Think of it like putting the right tires on your car; the wrong choice can lead to a total disaster. In the same way, a single hose clamp or fuel filter that isn't built for the marine world can become the weak link that puts your entire boat at risk.

You don't need to be a professional mechanic. It's all about understanding a few key ideas to make smart choices that protect your boat and everyone on it. By focusing on compliant, high-quality parts and setting up a simple maintenance routine, you'll keep your systems running smoothly season after season.

Selecting the Right USCG-Approved Parts

When it comes to your boat's plumbing, "good enough" is a recipe for failure. The United States Coast Guard (USCG) has strict standards for any component used in a marine environment, especially for fuel systems where the risk of fire is very real. Always look for parts that are clearly marked "USCG Approved" or meet specific marine ratings.

Here's what to look for when you're shopping for key components:

- Hoses: Fuel hoses absolutely must be rated for marine use (like USCG Type A1-15 for gasoline). This ensures fuel vapors can't escape through the hose wall and build up in your bilge. Never use an automotive hose as a substitute.

- Clamps: Don't skimp here. Always choose 316 stainless steel hose clamps. They have far better corrosion resistance than cheaper options and won't rust away, causing a dangerous leak.

- Filters: A top-notch fuel filter/water separator isn't optional—it's essential. This is your engine's only defense against bad fuel, which is one of the biggest reasons for engine trouble on the water.

A Simple Maintenance Checklist

You don't need a massive toolbox to keep your fluid systems healthy. Regular visual checks are your best weapon for catching problems before they get serious. A couple of minutes spent looking things over at the dock can save you from a massive headache (and a huge bill) down the line.

Proactive maintenance is about prevention, not reaction. A five-minute check that reveals a cracked hose in the slip is infinitely better than discovering it miles from shore with a bilge full of water or fuel.

Creating a routine is the best way to make sure nothing gets missed. The table below offers a straightforward checklist to get you started.

Basic Marine Fluid System Maintenance Checklist

| Inspection Item | What to Look For | Recommended Frequency |

|---|---|---|

| Fuel Hoses & Lines | Cracks, stiffness, soft spots, visible abrasion | Monthly & before long trips |

| Hose Clamps | Rust, corrosion, looseness | Monthly |

| Fuel Filter/Separator | Water in the bowl, sediment, signs of clogging | Check weekly, service as needed |

| Fittings & Connectors | Leaks, drips, corrosion (white/green powder on metal) | Monthly |

| Seacocks/Thru-hulls | Stiff operation, leaks, corrosion, marine growth | Before each outing |

| Bilge Area | Any signs of fuel, oil, or water where it shouldn't be | Before and after each trip |

This consistent attention to detail is what separates a well-maintained boat from one that's just a breakdown waiting to happen. For more specific advice, you might find these helpful pontoon inspection tips useful, as they cover many points that apply to all kinds of boats.

Spotting Trouble Before It Starts

Think of yourself as a detective during your routine checks. You’re hunting for clues that a part is getting old or starting to fail. Knowing what to look for is half the battle.

Here are the most common signs of trouble you should never, ever ignore:

- Leaks and Drips: Any sign of fuel, oil, or water where it shouldn’t be is an immediate red flag. Look carefully around fittings, clamps, and filter housings, as these are the usual suspects.

- Cracked or Brittle Hoses: Give your hoses a gentle squeeze. If they feel mushy, rock-hard, or have any visible cracks, their time is up. Replace them immediately.

- Corroded Fittings: Look for rust or that tell-tale green or white powdery gunk on metal fittings, clamps, and seacocks. Corrosion is metal's worst enemy and a clear sign that a failure is on the horizon.

- Clogged Filters: If your engine starts to sputter or lose power, a clogged fuel filter is often the culprit. Be sure to change them on schedule—or sooner if you think you got a bad batch of fuel.

Arming yourself with this knowledge means you'll spend more time enjoying the water and a lot less time dealing with a frustrating and expensive repair.

Your Top Questions About Marine Fluid Systems Answered

Even when you know your way around a boat's plumbing, some questions always seem to pop up. Let's tackle some of the most common ones I hear from boat owners. Getting these right will give you a lot more confidence when it comes to maintenance, choosing parts, and keeping things safe on the water.

How Can I Tell If a Fuel Hose Needs Replacing?

You’ll want to give your fuel hoses a good look-over regularly. A simple visual inspection can tell you a lot—look for obvious cracks, any spots that look brittle and dry, or sections that seem to be swelling up.

A good hands-on trick is to give the hose a gentle squeeze. If it feels oddly soft and mushy or, conversely, hard as a rock, it’s probably time for a new one.

Any persistent smell of fuel around the lines or seeing the outer cover peeling away are huge red flags. Don't wait on those. For safety, stick with USCG-approved marine-grade hoses, like a Type A1-15 for gas engines, and make a plan to replace them every 5-10 years, even if they look fine on the outside.

What’s the Difference Between a Diaphragm Pump and an Impeller Pump?

Both of these are absolute workhorses on a boat, but they work very differently, which is why you find them doing different jobs. Knowing the "why" helps you understand your boat's systems a lot better.

- Diaphragm Pump: Think of this one like a beating heart. It uses a flexible membrane (the diaphragm) that flexes back and forth to pull and push fluid. Its biggest advantage is that it can run dry for a bit without self-destructing. This makes it perfect for your freshwater system or a bilge pump, where it might not always have a steady stream of water.

- Impeller Pump: This pump has a spinning, flexible rubber rotor inside with little fins (vanes) that grab water and sling it through the system. They move a ton of water very efficiently, which is why they’re the go-to for engine cooling. The catch? They need that water to lubricate and cool the spinning impeller. If they run dry, even for a short time, the impeller can get fried.

The key takeaway is simple: diaphragm pumps are tough and forgiving for jobs with inconsistent flow. Impeller pumps are powerful movers but need a constant supply of fluid to stay healthy.

Why Can’t I Just Use Automotive Parts on My Boat?

Putting car parts on your boat isn't just cutting a corner—it's incredibly dangerous and, in many cases, illegal. Marine parts are engineered from the ground up to handle a world that automotive parts just aren't built for.

The number one reason is ignition protection. An enclosed space like your boat's bilge can easily fill with explosive gas fumes. Marine starters, alternators, and fuel pumps are sealed and designed to prevent any internal sparks from escaping. An automotive part isn't. A single spark from a non-marine part could ignite those fumes, leading to a fire or a catastrophic explosion.

On top of that, marine components are built to fight off constant humidity and the corrosive power of saltwater. Car parts will rust and fail in a hurry in that environment, which could lead to critical leaks in your fluid systems. Always, always look for parts specifically marked as "marine-grade" or "USCG-approved."

Besides Overfilling, What Else Causes Fuel Spills?

Overfilling is definitely the most common reason for a spill at the fuel dock, but it's not the only one. A few other culprits can create a dangerous, messy situation.

A worn-out or cracked gasket on your deck fill is a frequent problem. If that seal isn't tight, fuel can easily splash out while you’re fueling, especially if there's any wave action.

Another big one is "fuel blow-back" from the tank's vent line. This happens when the vent gets clogged with dirt, salt, or even a wasp's nest. It can also happen if you're trying to fill the tank too fast, causing pressure to build up and shoot fuel back out the vent.

It's so important to listen for that gurgling sound that tells you the tank is almost full and to never, ever walk away from the fuel nozzle. Of course, the best defense is to take the guesswork out of it. A spill collar can help, but a system that shuts off the flow automatically is the ultimate solution.

Ready to eliminate the risk and stress of fueling for good? CLiX Fueling Solutions offers a patented system that guarantees a perfect, spill-free fill-up every single time by automatically shutting off the nozzle when your tank is full. Protect your boat, the water, and your peace of mind by upgrading to a smarter fueling experience. Find out more about how CLiX works.