So, you're dealing with a big 55-gallon drum of fuel and need to get it into a boat, vehicle, or piece of machinery. Tipping it is out of the question. That's where a drum fuel pump comes in.

Think of it less like a tool and more like a lifeline. It's essentially a purpose-built, high-powered straw that lets you transfer fuel safely and cleanly, without the back-breaking effort or the dangerous mess of trying to pour it manually. For anyone who stores fuel in bulk, it's not a luxury—it's a necessity.

What Is a Drum Fuel Pump and Why You Need One

Picture this: you have a 55-gallon drum that weighs well over 400 pounds. Trying to lift and tip that is, frankly, a recipe for disaster. Spills, injuries, and contaminated fuel are the all-too-common consequences of wrestling with a heavy drum. This is exactly the problem drum pumps were invented to solve. They give you a controlled, clean, and safe way to move liquids from point A to point B.

The setup is brilliantly simple. A long tube goes down into the drum, a motor or handle provides the power, and a hose with a nozzle delivers the fuel right where you need it. The power source creates suction, pulling the fuel up and out. This elegant design turns a hazardous, two-person struggle into a straightforward, one-person task.

The Three Core Benefits of Using a Drum Pump

Switching from manual methods to a dedicated drum pump isn't just about convenience; it’s about being smarter, safer, and more efficient. The advantages are crystal clear.

- Serious Safety: It dramatically cuts down the risk of spills, which are not only bad for the environment but also create a major fire hazard.

- No More Physical Strain: Forget trying to lift or tip those heavy drums. This pump saves your back and prevents the kind of injuries that can put you out of commission.

- Keeps Your Fuel Clean: A sealed transfer process means no dirt, water, or random debris gets into your fuel. Clean fuel is critical for protecting your engines from damage.

A single 55-gallon drum of gasoline can weigh over 400 lbs, making manual handling not just impractical but also a significant workplace safety risk. A drum pump makes this a one-person job.

Different Power Sources for Different Jobs

The heart of the pump is its power source, and that's what really determines where and how you can use it. Each type is designed for a specific environment and workload, so there’s a pump for just about any situation you can think of.

Here are the three main players:

- Manual Pumps: These are your hand-crank or lever-operated models. They’re perfect for smaller jobs, occasional use, or when you're working somewhere with no access to power. Simple, reliable, and always ready to go.

- Electric Pumps: For frequent, high-volume transfers, electric is the way to go. They deliver a steady, powerful flow rate, making them the workhorses of busy marinas, workshops, and industrial sites.

- Pneumatic Pumps: Powered by compressed air, these are the top choice for handling highly flammable liquids like gasoline. Because there are no electrical components, there’s no risk of a stray spark causing an ignition. Safety first.

Diving Into the Main Types of Drum Fuel Pumps

When you're looking to buy a drum fuel pump, the first question to ask is simple: what job do I need this pump to do? There's no one-size-fits-all answer. Drum pumps generally fall into three buckets based on how they're powered: manual, electric, and pneumatic. Each one is a specialized tool built for different situations, environments, and workloads.

Getting a handle on these differences is key to picking the right one. It’s not about which is "best," but which is best for you. A manual pump might be your best friend for a quick job out in the field, while a powerful electric model is what a busy marina needs to keep things moving.

Manual Drum Pumps

These are the old-school, reliable workhorses of the group. Manual pumps are powered by good old-fashioned elbow grease, typically using either a lever handle or a rotary crank to draw fuel out of the drum. A lever pump works a lot like a classic water well pump—each stroke moves a specific amount of liquid. A rotary pump, on the other hand, uses a steady cranking motion for a smoother, more continuous flow.

Since they don’t need any external power, manual pumps are incredibly versatile. They're perfect for small-scale jobs, remote locations without electricity, or just as a foolproof backup. Their simple mechanical design also means they're tough as nails and easy to fix. If you need a straightforward, dependable tool for occasional fuel transfers, you can learn more about the practical uses of a fuel hand transfer pump in our detailed guide.

Electric Drum Pumps

When you need to move a lot of fuel and you need to do it fast, an electric pump is the clear winner. These pumps plug into an AC or DC power source, using a motor to provide a high, steady flow rate that a manual pump just can't match. This makes them the go-to choice for frequent, high-volume fueling in workshops, industrial sites, and bustling commercial docks.

An electric drum fuel pump can empty a 55-gallon drum in a matter of minutes. That's a job that would take a lot more time—and effort—with a manual pump. In any business where time is money, that kind of efficiency is a huge advantage.

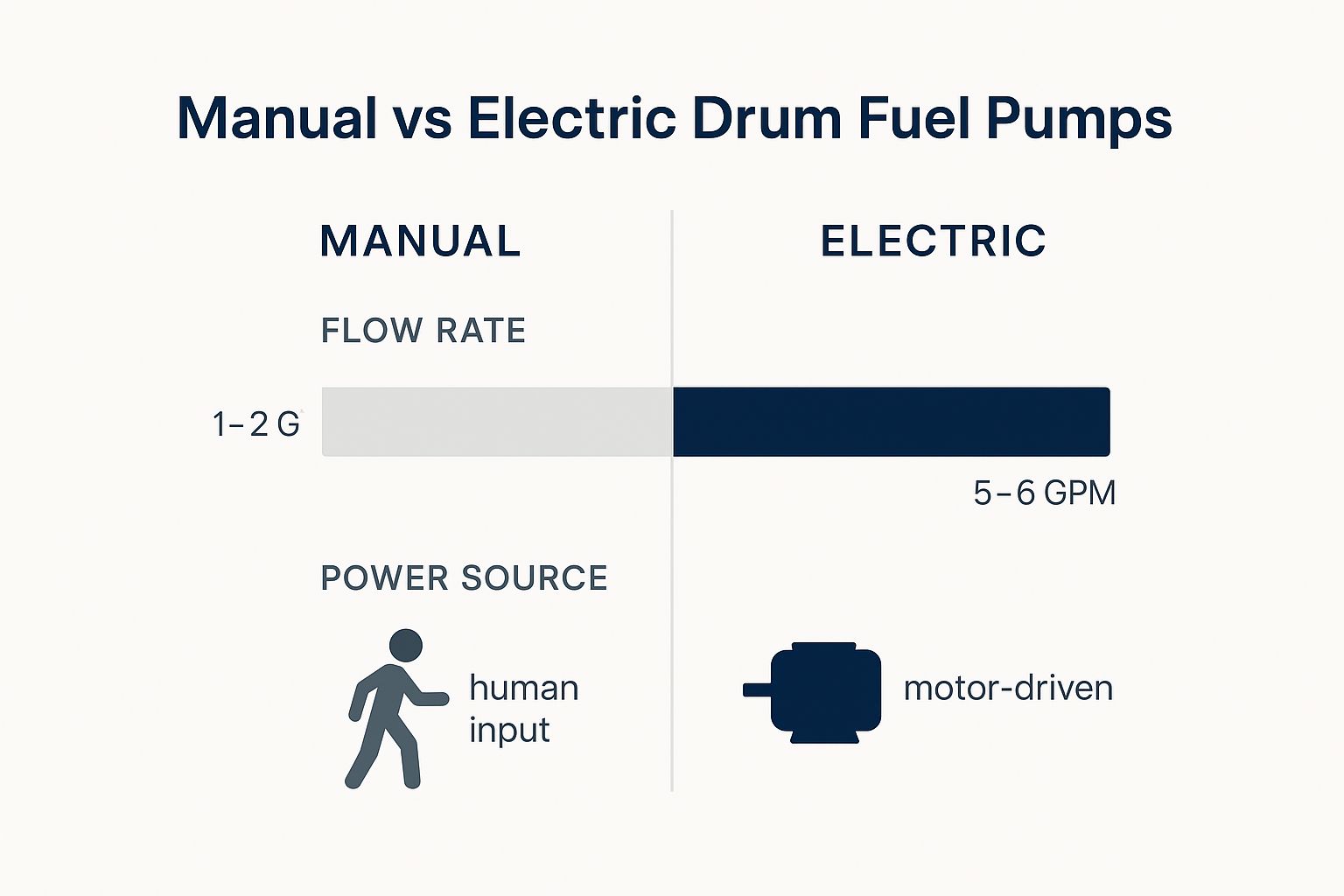

This image really drives the point home, showing just how much faster an electric pump gets the job done compared to its manual counterpart.

Pneumatic (Air-Powered) Pumps

For situations where safety is the absolute top priority, you need a pneumatic pump. Also known as air-operated pumps, these use compressed air to run the motor instead of electricity. This design is brilliant because it completely removes the risk of an electrical spark—a critical feature when you're dealing with flammable liquids and their vapors.

Because they have no electrical parts that can spark, pneumatic pumps are the safest choice you can make for transferring highly volatile fluids like gasoline or specific industrial solvents.

This focus on safety and performance is why the drum pump market is growing so quickly. It was valued at around USD 692.7 million and is expected to hit USD 1.17 billion by 2033, reflecting just how essential these tools have become across various industries.

Drum Fuel Pump Comparison Guide

Choosing the right pump can feel tricky, so let's break it down side-by-side. This table gives you a quick snapshot of how the three main types stack up against each other.

| Pump Type | Power Source | Best For | Pros | Cons |

|---|---|---|---|---|

| Manual | Hand-operated (lever or crank) | Low-volume, remote use, or as a backup. | Portable, affordable, no power needed, easy to maintain. | Slow, requires physical effort, not for high-volume jobs. |

| Electric | AC/DC electricity | High-volume, frequent transfers in workshops or marinas. | Fast and efficient, consistent flow rate, less labor. | Requires a power source, not for flammable liquids (unless explosion-proof). |

| Pneumatic | Compressed air | Hazardous environments with flammable liquids. | Extremely safe (no sparks), powerful, reliable. | Requires an air compressor, can be noisier than other types. |

Ultimately, the right pump is the one that best fits your specific needs for volume, location, and safety. By weighing the pros and cons, you can find the perfect tool to make your fuel transfer tasks easier and safer.

Understanding Key Components and Materials

At first glance, a drum fuel pump can look a bit intimidating, but it’s really just a handful of key parts working in harmony. Getting to know this anatomy is the first step in picking a pump that’s not just going to get the job done, but will do it safely and last for years. The core idea is simple: move liquid out of a big drum and into something else, quickly and cleanly.

Think of it as a high-tech straw. You’ve got a long tube that reaches down into the drum, a motor or a handle that creates the power, and a hose with a nozzle to control where the liquid goes. Each piece has a specific job, and the materials they’re made of are every bit as important as the design.

The Anatomy of a Drum Fuel Pump

To really get a feel for how these pumps operate, let’s break them down into their essential parts. Every component is designed to handle the pressures of moving fluid from one place to another.

- The Immersion Tube: This is the long pipe that goes right into the drum. It has to be long enough to get to the very bottom, ensuring you can pull out as much fuel as possible.

- The Motor or Handle: This is the powerhouse. On electric or pneumatic pumps, a motor drives the whole operation. For manual versions, it’s the classic hand-crank or lever that you power yourself.

- The Hose and Nozzle: After the fuel is pulled up through the tube, it flows through a flexible hose. The nozzle at the end gives you total control to start, stop, and direct the fuel right where you want it.

These three parts make up the basic skeleton of any drum fuel pump. But what they're made of is what truly defines what they can—and can't—do.

Why Material Compatibility Is Non-Negotiable

This is a big one. Choosing a pump just because it’s cheap is a recipe for disaster. The single most important factor for both safety and the pump's lifespan is the material it's built from. Certain fuels and chemicals will eat right through the wrong materials, leading to corrosion, dangerous leaks, and eventually, total failure.

The wrong material choice isn't just an inefficiency—it's a safety hazard. A pump that degrades can leak flammable liquids, creating a serious risk of fire or environmental contamination.

For instance, a pump made with polypropylene is a fantastic and affordable option for moving diesel fuel or water. But if you try to use that same pump for gasoline or a strong solvent, the plastic will start to break down, and the seals will fail.

On the other hand, a pump built from stainless steel is a workhorse, designed to handle a much broader spectrum of aggressive liquids and fuels. Its natural resistance to corrosion makes it a must-have in industrial settings where you can't afford to take chances. The same goes for the internal seals and gaskets—materials like Viton or Teflon are chosen specifically to hold up against whatever you're pumping. The bottom line? Always, always check the manufacturer’s chemical compatibility chart before you buy anything.

Drum Pumps in Marine Fueling Applications

When you're refueling on the water, there's zero room for error. Precision is everything, which is exactly where a good drum fuel pump shines. A small spill in a marine environment isn't just a mess—it's an immediate threat to the local ecosystem. Using a drum pump turns a risky chore into a safe, controlled process.

You'll see these pumps everywhere, from docks and marinas to the decks of larger vessels. They are the go-to tool for getting fuel from a 55-gallon drum into a boat's tank safely. Trying to pour it manually is just asking for trouble. A drum pump gives you the control needed to prevent overfills that can stain decks, ruin equipment, and lead to hefty environmental fines.

Integrating Technology for Smarter Fuel Management

A drum pump doesn't have to be a standalone tool. In fact, they really come into their own when they're hooked into a modern fuel management system. This simple connection transforms a basic piece of hardware into a smart device that tracks every single gallon.

Imagine a system that logs who is using the fuel, how much they take, and when they take it. That’s what you get. This is incredibly useful for commercial fleets or marinas that need to keep meticulous records for billing, inventory, or compliance. It’s the perfect bridge between old-school hardware and modern-day accountability.

When you connect a drum fuel pump to a fuel management system, you get a bird's-eye view of your entire fueling operation. This makes sure every drop is accounted for, which is a huge step in preventing theft or unauthorized use—a common headache in busy marine environments.

This push for greater control is a big reason why the market for fuel transfer pumps, including drum pumps, is growing. It was valued at USD 1.71 billion and is expected to keep climbing. This isn't surprising when you consider how much industries like transportation and marine operations depend on efficiency and safety. You can dive deeper into the numbers with Grand View Research's industry analysis.

The CLiX Connection for Spill-Free Operations

For the highest level of safety and to make spills a thing of the past, you can pair your drum fuel pump with smart nozzle technology. For boaters, this means connecting the pump’s nozzle to a system like CLiX, which automatically shuts off the fuel the instant the tank is full.

This combination creates a fueling process that’s pretty much foolproof.

- The drum fuel pump gives you a steady, manageable flow from the drum.

- The CLiX system acts as the final line of defense, stopping the overfill that causes most spills.

Put them together, and you have a complete solution for clean, responsible refueling on the water. To see how all the pieces fit together, you can learn more about picking the right marine fuel transfer pump in our complete guide. It’s an integrated approach that protects the environment and gives you total peace of mind.

How to Choose the Right Drum Fuel Pump

Picking the right drum pump isn't about grabbing the most expensive one off the shelf. It’s all about matching the tool to the job. Get it wrong, and you're looking at slow work, a busted pump, or worse, a serious safety hazard.

To nail the decision, you just need to think through a few key questions. What are you pumping? How fast do you need to move it? And what kind of power do you have on site? Answering these upfront will point you directly to the perfect pump for your needs.

Assess Your Fuel and Fluid Type

First thing's first: what are you actually moving? The chemical you're pumping is the single most important factor, as it dictates what the pump needs to be made of. This isn't just a suggestion—it's critical for safety and the pump's lifespan.

- Diesel and Oils: For less volatile fluids like these, pumps made from materials like polypropylene or aluminum usually do the trick just fine.

- Gasoline: This is a different beast altogether. Gasoline is highly flammable, so you absolutely need a pump with an explosion-proof motor and corrosion-resistant materials like stainless steel.

- Chemicals: When you're dealing with industrial solvents or other corrosive liquids, you'll need to consult a chemical compatibility chart. This will help you find a pump built with tough materials like stainless steel and specialized seals (think Viton or Teflon).

Using a pump made from the wrong materials is a recipe for disaster. The pump can degrade and fail, leading to dangerous leaks.

Determine Your Required Flow Rate

Next up, how quickly do you need the job done? The flow rate, measured in gallons per minute (GPM), tells you how fast you can empty a drum. If you’re in a commercial setting where every minute counts, a higher GPM is a must. For occasional use, a slower pump will be perfectly adequate.

When it comes to speed, electric pumps are the undisputed champions. They can often deliver 10-15 GPM or more, making them perfect for high-volume jobs. Manual pumps are much slower, of course, but they give you pinpoint control for smaller tasks. This need for efficiency is a big reason the global electric drum pump market was valued at around USD 500 million and is expected to keep growing. You can dig into more insights on this trend from Verified Market Reports.

Consider Your Power Source and Environment

Finally, take a look around your workspace. Where you'll be using the pump is just as important as what you're pumping.

A workshop with plenty of outlets has totally different needs than a remote job site or a hazardous area where flammable vapors are a concern.

If you're near an electrical outlet, an electric drum fuel pump is hard to beat for power and convenience. For field operations or off-grid sites, a trusty manual pump is your most reliable bet. But if you’re moving flammable liquids like gasoline, your only safe options are a pneumatic (air-powered) pump or a certified explosion-proof electric model to eliminate any risk of sparks.

Essential Maintenance and Safety Practices

Think of your drum fuel pump as a long-term investment. Like any crucial piece of gear, its reliability hinges on how well you take care of it. If you let maintenance slide, you're not just cutting its life short—you're introducing serious risks into your workspace.

A few minutes spent on a routine check can head off most common failures. Getting a handle on what is preventive maintenance and sticking to a schedule is the best way to keep your pump in top shape and ready to go when you need it. This proactive mindset makes all the difference.

Your Simple Maintenance Checklist

Regular inspections are the bedrock of a long-lasting pump. Before you even think about starting it up, take a moment to give the key components a quick once-over. This simple habit can spot a small issue before it escalates into a major headache.

- Inspect Hoses: Look for any cracks, weird bulges, or signs of wear and tear, paying close attention to where they connect. A bad hose is one of the top causes of dangerous fuel leaks.

- Check Seals and Gaskets: Keep an eye out for any breakdown or weeping around the fittings. Solid seals are absolutely vital for holding pressure and stopping drips.

- Clean or Replace Filters: A clogged filter makes the motor work way too hard and kills your flow rate. Make sure it’s free of gunk to keep the pump running like it should.

Non-Negotiable Safety Protocols

When you're dealing with fuel, there's absolutely no room to cut corners on safety. Flammable liquids demand your full respect and a strict commitment to the rules. Your number one job is creating a safe environment.

Properly grounding your drum and pump isn’t just a good idea—it’s a critical step to stop static electricity from building up. A single spark is all it takes to ignite fuel vapors and cause a fire or explosion.

Always work in a well-ventilated space to let fumes scatter. It also goes without saying that you need the right personal protective equipment (PPE), like safety glasses and chemical-resistant gloves.

Even when you do everything right, you have to be prepared for the unexpected. Keeping a spill kit within arm's reach is non-negotiable. For a solid game plan on handling an emergency, make sure you know these essential fuel spill cleanup procedures. It’ll help you respond fast and get things under control.

Common Questions About Drum Fuel Pumps

Even after you get the hang of using a drum fuel pump, practical questions pop up all the time. Think of this as a quick-reference guide to handle those day-to-day situations safely and keep things running smoothly.

Can I Use the Same Drum Pump for Different Fuels?

That's a definite no-go unless the pump is explicitly designed for it. Pumps made for multiple fuel types will have robust materials like stainless steel and special seals that can handle different chemicals.

Trying to pump gasoline with a diesel-only pump is a recipe for disaster. The aggressive solvents in gasoline can eat away at the internal seals and plastic parts, leading to leaks and creating a serious safety risk.

Always, and I mean always, check the manufacturer's chemical compatibility chart. If you do have a multi-fuel pump, make sure you completely flush and clean it before switching liquids. You don't want cross-contamination or a nasty chemical reaction on your hands.

What Does "Explosion-Proof" Actually Mean for an Electric Pump?

When you see a pump labeled as "explosion-proof" or ATEX-rated, it means the motor and all its wiring are housed in a specially sealed, heavy-duty casing. This design is all about containment.

The idea is that if an electrical spark happens inside the motor, the enclosure is strong enough to contain the small ignition and prevent it from ever reaching the flammable vapors in the air outside the motor.

This isn't a premium feature; it's an absolute must-have for transferring anything highly volatile like gasoline or certain industrial chemicals. Never, ever use a standard electric pump where flammable fumes could be present.

How Do I Prime a New Manual Drum Pump?

Good news: most modern manual pumps are self-priming, so there's not much to it.

Just make sure the suction tube is screwed in tight and sitting deep in the fuel. Then, start pumping the handle or turning the crank. The first few strokes will pull the liquid up, purge the air out, and get the flow going.

If it's struggling to prime, you almost certainly have an air leak. Check that every connection is sealed tight and that the end of the tube is well below the surface of the liquid.

For a truly spill-free and stress-free experience on the water, pair your drum fuel pump with a smart fueling system. CLiX Fueling Solutions offers an automatic shut-off nozzle that prevents dangerous overfills, protecting your boat and the environment. Explore our innovative products at clixfueling.com.