A hand gas transfer pump is one of those simple, manual tools you don't think you need until you really need it. It's designed to move fuel from one container to another without needing any power source, making it an absolute must-have for safety and convenience out on the water.

Think of it as your get-out-of-jail-free card for refueling, preventing messy spills and saving you from a long paddle back to shore.

The Essential Tool for Every Smart Boater

Picture this: you're having a perfect day on the water, miles from the nearest marina. Then you glance at the fuel gauge and see it's creeping toward empty. You brought a full jerry can for this very reason, but now comes the tricky part. How do you get that fuel into your tank cleanly, especially with the boat gently rocking on the waves?

This is precisely where a hand gas transfer pump shines. Trying to pour directly from a heavy, sloshing fuel can is a recipe for disaster. It almost always leads to dangerous spills that can damage your boat's finish and, worse, pollute the water. A manual pump takes that risk right out of the equation.

Understanding the Basic Principle

At its core, the pump works on a beautifully simple principle: the siphon. By creating a pressure difference with a few squeezes, you get the fuel flowing, and gravity does the rest of the work. It’s a lot like using a straw to get liquid started from one glass to another—once it’s going, it keeps going.

This incredibly straightforward mechanism is what makes these pumps so reliable. There are no batteries to die or complicated electronics to fail. It’s a dependable tool you can count on for several key jobs:

- Emergency Refueling: Safely transfer fuel from a reserve can when you're far from the dock.

- Routine Transfers: Easily top off your tank without wrestling with awkward funnels and spouts.

- Winterizing Engines: A great way to remove old fuel from your tanks and lines before putting the boat away for the season.

To give you a clearer picture, here’s a quick breakdown of what makes these pumps so practical for boaters.

Hand Gas Transfer Pump at a Glance

| Feature | Description | Benefit for Boaters |

|---|---|---|

| Manual Operation | Requires no electricity or batteries; typically uses a siphon bulb or hand crank. | Works anytime, anywhere. You're never stranded by a dead battery. |

| Portability | Lightweight and compact design. | Easy to stow away in a boat locker or emergency kit without taking up space. |

| Spill Prevention | Creates a closed system for moving fuel from can to tank. | Protects your boat's finish and prevents harmful water pollution. |

| Versatility | Can be used for gasoline, diesel, and even removing water from a bilge. | A multi-purpose tool that handles more than just refueling. |

As you can see, its simplicity is its biggest advantage, offering a foolproof solution right when you need it most.

A manual fuel pump isn't just a backup plan; it's a core piece of gear for any well-prepared boater. While you’re ensuring your fueling system is ready, it’s also a good time to review a comprehensive boat safety equipment checklist to make sure you're prepared for anything.

For more detailed advice on finding the perfect pump for your specific boat, check out our guide on choosing a marine fuel transfer pump.

How a Manual Fuel Pump Really Works

A hand gas transfer pump looks pretty simple, and thankfully, it is. The whole operation runs on a basic law of physics: creating a pressure difference. It's a bit like an old-fashioned well pump—you have to prime it a few times to get the water flowing. Your manual pump works the same way, needing just a little help to get the fuel moving before gravity can do the heavy lifting.

The goal is to kickstart a siphon. A siphon is just a continuous flow of liquid from a higher container to a lower one, all on its own. A few squeezes of the bulb or pulls on the handle are all you need to get things going. This action pushes air out of the hose, creating a low-pressure zone. The higher atmospheric pressure on the fuel's surface in your jerry can then pushes the liquid up and into the hose.

Once the fuel gets past the highest point in the hose and starts heading down into your boat's tank, the siphon is officially started. You can stop pumping and let physics take over.

Breaking Down the Components

Every piece of the pump has a specific role to play in making the transfer smooth and spill-free. Think of it as a simple, closed system designed to move fuel cleanly from point A to point B.

- Intake Hose: This is the end that goes into your fuel container. It's usually a bit rigid or might have a weight on the end to make sure it sinks and stays at the bottom of the can.

- Pump Mechanism: This is the heart of the whole thing. It could be a flexible squeeze bulb or a piston-style handle you pull and push. Its only job is to create that initial vacuum to get the fuel flowing.

- Discharge Hose: This hose carries the fuel into your boat’s tank. For the siphon to work, it's critical that this end stays lower than the fuel level in the jerry can.

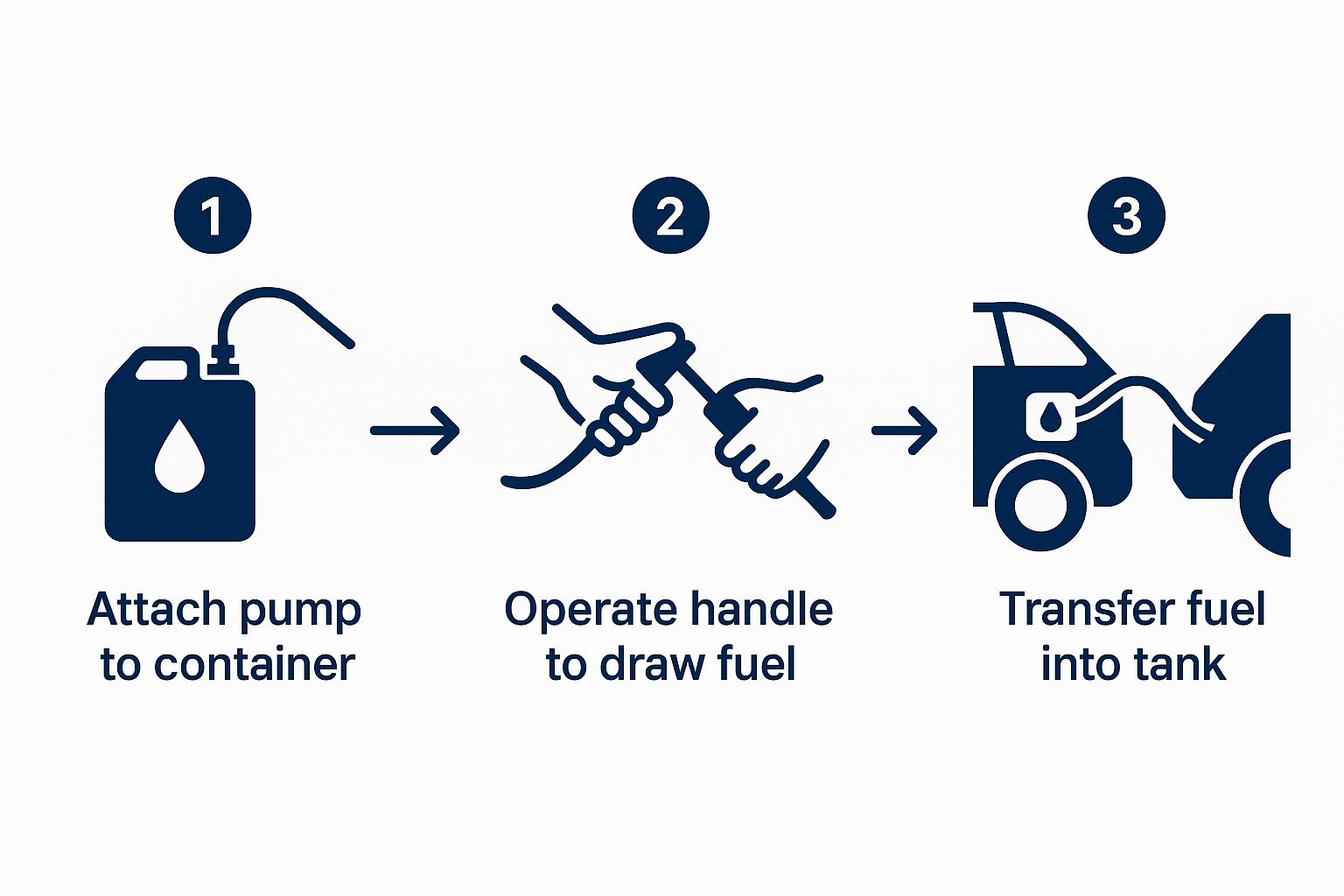

This infographic lays out how these simple parts work together.

As you can see, it’s a straightforward process that uses basic physics to get fuel where it needs to go, safely and without a mess.

The Physics in Action

The science behind how these pumps work is actually pretty clever. When you squeeze that bulb or pull the handle, you're just pushing air out of the hose. This simple action lowers the pressure inside the hose compared to the normal atmospheric pressure all around you.

The key takeaway is that you aren't pulling the fuel up; you're creating a pressure void that allows the atmosphere to push the fuel for you.

This difference in pressure is what forces the fuel from the can up into the hose. As long as the end going into your boat is lower than the fuel level in your can, the weight of the fuel in the downward-sloping hose creates a continuous pull, keeping the siphon going. It’s a fantastic little bit of engineering that makes a boater's life a whole lot easier.

Comparing the Different Types of Hand Fuel Pumps

When you start shopping for a hand gas transfer pump, you'll see right away they aren't all created equal. The best one for you really boils down to what you’ll be using it for—whether it's for a quick emergency top-off or more routine refueling. Getting a handle on the key differences between the common types is the first step to picking the perfect tool for your boat.

You'll mostly run into two main players: the classic bulb-style siphon pump and the beefier piston or plunger-style pump. Each has its own job to do and shines in different situations, so let's break them down.

Bulb-Style Siphon Pumps

The bulb-style pump is probably the one you picture first. It’s about as simple as it gets: a flexible rubber bulb sits between two hoses. You give it a few good squeezes to get the siphon going, and gravity takes care of the rest.

These pumps are fantastic because they're so straightforward and portable. They’re small, light, and can be coiled up to stash in just about any locker or emergency kit.

- Best For: Quick, small-volume transfers and those "just in case" moments.

- Pros: Super portable, cheap, and ridiculously easy to use.

- Cons: Flow rate is on the slow side, and they struggle to move fuel uphill or very far.

Think of the bulb pump as the perfect backup. It’s the tool you’ll be thrilled to have when you just need to move a few gallons from a jerry can into your tank without a big production.

Piston and Plunger Pumps

Now, for the bigger jobs, the piston-style pump is the undisputed champ. This design features a hand-operated plunger or crank that you pull and push to actively pump the fuel. Unlike a simple siphon that relies on gravity, this pump creates its own pressure. This lets you move fuel much faster and even push it uphill.

That power makes it a much better option for transferring larger amounts of fuel or when you need to lift fuel from a can on the dock up into your boat's tank. They’re also typically built from tougher materials to handle more frequent use.

The real game-changer with a piston pump is its ability to generate its own pressure, which makes it incredibly versatile. You're not just relying on gravity, which gives you far more control over the whole process.

This added muscle and reliability are why these pumps are so valued. The global market for fuel transfer pumps, including these manual types, was pegged at USD 1.71 billion back in 2021 and is expected to climb to USD 2.47 billion by 2029. That kind of growth shows just how essential they are for everyone from boaters to farmers.

For a closer look at some of the best models out there, check out our 2025 review of the top manual transfer pumps for fuel.

How to Choose the Right Pump for Your Boat

Picking the right hand gas transfer pump isn't as simple as grabbing the first one you see at the marine store. It's a lot like choosing the right anchor for your boat—what works for a small skiff won't cut it for a larger cruiser. The best choice really depends on your vessel, how you use it, and the conditions you face. Getting this right means every fuel transfer will be safe, quick, and spill-free.

To make a smart decision, you just need to run through a quick mental checklist. Thinking about a few key things before you buy will ensure you end up with a pump that’s tough, effective, and a perfect match for your boat.

Check for Material Compatibility

First thing's first: make sure the pump can actually handle fuel. Gasoline and diesel are aggressive solvents and will eat through standard plastics and rubber in no time. Using a pump made from the wrong stuff isn't just a waste of money—it's a massive safety risk.

Always double-check that the pump and its hoses are specifically rated for whatever fuel you're using. You want to see materials like nitrile or other fuel-resistant composites listed. A pump designed for water or oil is guaranteed to fail, and the last thing you want is a flammable leak all over your deck.

A pump is only as good as the materials it's made from. Spending a bit more on a model built with fuel-grade, anti-static materials means it won't crack or leak after a season, giving you peace of mind for years.

Hose Length and Diameter Matter

Next up, take a look at the hoses. Their length and diameter have a surprisingly big impact on how well the pump works for you.

-

Hose Length: The hose needs to be long enough to comfortably reach from your fuel can down to your boat's tank without being stretched tight. A kinked hose is a useless hose. But don't go overboard—a hose that’s way too long can create drag and slow things down, especially with a simple siphon. Just measure the distance you typically need to cover and find a pump that fits.

-

Hose Diameter: As a general rule, a wider hose moves fuel faster. This is great if you’re transferring a lot of gas. For smaller top-offs, a standard, narrower hose is fine and is usually more flexible and easier to coil up for storage.

Match the Flow Rate to Your Needs

Pumps are rated by their flow rate, which is just a measure of how fast they can move liquid, usually in gallons per minute (GPM). A basic bulb siphon might trickle along at 1-2 GPM, whereas a good piston pump can easily push double or triple that amount.

Think about your typical refueling scenario. If you just carry a small five-gallon can for emergencies, a slower pump is no big deal. But if you’re regularly moving 10-20 gallons from jerry cans, a higher GPM pump will save you a ton of time and arm-ache. Matching the flow rate to your needs makes the whole process feel effortless instead of like a chore.

A Step-by-Step Guide to Safe Fuel Transfer

Using a hand gas transfer pump is a pretty simple job, but let's be clear: you're handling fuel, and that always deserves your full attention. One little mistake can turn a simple task into a dangerous mess. That’s why having a consistent, safety-first routine is key to making sure every transfer is clean and accident-free.

These pumps are getting more popular for a reason. The global market was already valued at USD 1.2 billion in 2023 and is expected to climb to USD 2.0 billion by 2032. You can dig into those numbers over at dataintelo.com.

Before you even think about starting the pump, there are a few checks you absolutely have to run through.

Pre-Transfer Safety Checks

Think of this as your pre-flight checklist. It only takes a minute, but it can save you from a world of trouble.

- Get Some Airflow: Always work in a well-ventilated area. If you're docked or in a tight spot, make sure fresh air is moving through to carry away any fumes.

- Kill All Ignition Sources: This one is a deal-breaker. Shut down all engines, put out any cigarettes, and make sure there's nothing that can create a spark. Gas vapors are incredibly flammable.

- Keep a Spill Kit Handy: Have some absorbent pads or a proper spill kit right there with you. If a little spill happens, you can deal with it on the spot.

- Inspect Your Gear: Give the pump and hoses a quick look. Are there any cracks? Are the connections tight? A small leak can quickly become a big problem.

Once you’ve ticked off these boxes, you're ready to get started.

The Fuel Transfer Process, Step-by-Step

Follow these steps in order for a smooth, controlled transfer from your gas can to your tank.

- Position Your Containers: Set your fuel can (the source) on a stable spot that’s higher than your boat’s fuel tank opening (the destination). Getting that bit of elevation is a huge help, as gravity will do most of the work to keep the siphon going.

- Secure the Hoses: Push the intake hose deep into the fuel can so it hits the bottom. Then, place the discharge hose well inside the boat's fuel tank opening. Some pumps even have a clip to hold the hose in place—a great little feature to prevent it from popping out mid-transfer.

- Start the Flow: Now it's time to get things moving. Squeeze the bulb or pump the handle with a few smooth, steady motions. You'll see the fuel start to travel through the hose. Once that siphon effect kicks in, the fuel should flow on its own.

- Monitor the Transfer: This is not a "set it and forget it" job. Never walk away while fuel is transferring. Keep your eyes on the fuel level in your boat’s tank to avoid an overfill. Spilling fuel isn't just messy; it's a serious environmental hazard.

Critical Safety Warning: Never, ever try to start a siphon with your mouth. Getting gasoline in your mouth or lungs is extremely dangerous and can cause severe health problems. Always use the pump to start the flow.

By sticking to this process, you can use your hand pump safely and confidently. And for those times when a pump isn't the right tool, it's good to know how to choose the right fuel funnel for your boat to round out your fueling kit.

Keeping Your Pump in Shipshape Condition

A hand gas transfer pump is a beautifully simple piece of gear, and thankfully, keeping it that way is just as easy. But like anything else on a boat, a little bit of care goes a long way. Taking a few moments for maintenance ensures it'll work without a hitch when you really need it, saving you from a major headache on the water.

The single most important thing you can do is clean the pump after you use it. Any fuel residue left inside will slowly eat away at the plastic and rubber parts, making them brittle and prone to cracking. Just pump fresh air through the hose for a minute or so to clear out the lines and help evaporate any lingering fuel. It’s that simple.

Quick Pre-Storage Check-Up

Before you pack the pump away, give it a quick once-over. This two-minute habit can spot a problem before it leaves you stranded.

- Hoses: Give the hoses a gentle squeeze and look for any tiny cracks or stiff spots. Fuel vapors and sunlight are tough on these materials.

- Seals & Connections: Make sure every connection is snug and the seals look good. A leaky seal is the number one reason a siphon won't start.

- The Squeeze Test: Squeeze the bulb or pull the plunger a few times. It should feel solid and spring back into shape, not feel sticky or mushy.

When it comes to storage, think cool, dry, and dark. Coil the hoses loosely and keep the pump out of direct sunlight, as those UV rays are the biggest enemy of plastic and rubber.

A well-maintained pump is a dependable pump. Spending five minutes on a clean-and-check can easily add years to its life and ensure it's ready for an emergency.

It's a small effort for a critical tool. And it's not just boaters who rely on this kind of equipment; fuel transfer is a massive global industry. In 2021, for example, the Asia Pacific region alone accounted for 35.9% of the entire fuel transfer pump market, driven by its huge industrial and manufacturing sectors. You can read more about these market trends over at Grand View Research.

Got Questions? We've Got Answers.

Even with a simple tool like a hand gas transfer pump, you're bound to run into a few questions out on the water. Getting a straight answer can be the difference between a quick top-off and a real headache. Let's tackle some of the most common things boaters ask.

Can I Use the Same Pump for Both Gas and Diesel?

The short answer? You really shouldn't. While the pump itself might be made of materials that can handle both, the real danger is cross-contamination.

Even a tiny amount of gasoline mixed into a diesel engine can cause serious, expensive damage—and the same goes for diesel in a gas engine. The best practice is to have a dedicated pump for each fuel type. Grab a marker, label them clearly, and never mix them up. It's a simple habit that could save you a fortune in engine repairs.

The golden rule of fuel handling is to keep everything separate. Designating a specific hand gas transfer pump for each fuel type eliminates any risk of contamination and protects your engine's integrity.

My Siphon Won't Start. What's Wrong?

You're pumping away, but nothing's happening. Frustrating, right? Nine times out of ten, the problem is an air leak somewhere in the system. A siphon needs a completely sealed path to work its magic.

Before you get too frustrated, run through this quick checklist:

- Check the Connections: Are both hoses pushed on tight? A loose connection is the most common culprit.

- Inspect the Hoses: Look for tiny cracks or pinholes, especially near the ends where they bend the most.

- Submerge the Hose: Make sure the intake end of the hose is all the way under the fuel. If it's sucking in even a little bit of air, the siphon will break and you'll lose your flow.

Can I Pump Fuel Uphill?

This one really comes down to the kind of pump you're using. If you have a basic bulb-style siphon, you’re relying almost entirely on gravity to do the work. Trying to pump uphill with one of those is a recipe for failure.

On the other hand, piston or plunger-style pumps are built for this. They create their own pressure, actively pushing the fuel where it needs to go. This makes them perfect for lifting fuel from a jerry can on the dock up into your boat's tank. If you know you'll be fighting gravity, a piston pump is a smart investment.

Ready to make every refueling effortless and spill-free? Discover how CLiX Fueling Solutions can bring modern safety and convenience to your boat. Explore our automatic shut-off systems at https://clixfueling.com.