At its core, a fuel hand transfer pump is a straightforward, non-electric tool that lets you move fuel from a jerry can to your boat, or between tanks. It’s one of those simple pieces of gear that can turn a potential crisis—like running a tank dry miles from shore—into a minor inconvenience.

Why a Hand Pump Is Your Most Reliable First Mate

Let’s paint a picture. You’re having a perfect day on the water, the dock is a distant memory, and you suddenly realize one fuel tank is bone dry while the other is full. That beautiful day can get stressful, fast. This is exactly the moment a simple hand pump proves it’s worth its weight in gold, acting as your most reliable first mate.

Unlike electric pumps that need power and can fail when you least expect it, a hand pump is beautifully simple. It’s all mechanical. You're in complete control, and you don’t have to rely on your boat's electrical system at all. That independence is what makes it an absolute must-have in any boater's safety kit.

The Power of Simplicity and Self-Reliance

The real value of a manual pump goes way beyond just balancing fuel in an emergency. It’s a handy problem-solver for a bunch of common situations on the water, giving you more control and flexibility.

- Refueling from Jerry Cans: You can safely and cleanly top off your tank from spare cans without trying to hoist a heavy can and make a mess with a funnel.

- Winterizing Your Boat: Need to drain old fuel from your tanks and lines before layup? A hand pump makes this job easy, helping you avoid engine trouble next season.

- Fuel Management: It's perfect for consolidating fuel into one main tank, which makes tracking your consumption and managing your supply much simpler when you're underway.

This humble tool is all about self-sufficiency. It’s the difference between being stranded and being able to fix the problem with your own two hands, giving you real peace of mind on every single trip.

It's not just boaters who are catching on to these practical benefits. The global market for hand fuel transfer pumps was valued at approximately USD 1.2 billion in 2023 and is expected to grow, all because people in many industries need dependable, cost-effective solutions. You can discover more about this market's growth and see why this kind of reliability is in high demand.

Here is the rewritten section, designed to sound completely human-written and natural.

How These Simple Pumps Get the Job Done

Ever wondered how a simple hand pump can move fuel so effectively? At its heart, it’s a beautifully simple machine. Think of it less like complex machinery and more like a very tough, controlled drinking straw. You provide the power, and the pump does the rest, moving fuel safely from one container to another without any need for batteries or electricity.

It all comes down to a bit of basic physics: creating a pressure difference. When you squeeze the bulb or work the handle, you push air out of the pump and the hose. As the bulb re-inflates or the handle returns, it creates a small vacuum inside. Nature hates a vacuum, so the normal air pressure pushing down on the surface of the fuel in your jerry can forces the liquid up into the hose to fill that empty space.

Once the fuel is in the line, every squeeze or crank you make pushes that slug of fuel further down the pipe until it comes out the other end. That’s it. This brilliant simplicity is precisely why a manual pump is one of the most reliable tools a boater can have on board.

A Look at the Core Components

To really get a feel for why these pumps are so dependable, it helps to know the main parts and what they do. Each component plays a specific role, working together to create a sealed system for a clean, spill-free transfer. If you ever have a problem, knowing how it's built makes troubleshooting a breeze.

- The Pump Itself: This is the engine of the whole operation. It could be a rubber squeeze bulb, a lever you pump up and down, or a rotary crank you turn. Its only job is to get things started by creating that initial vacuum.

- Intake Hose: This is the tube that goes into the tank or can you're drawing fuel from. You'll want to make sure it's long enough to reach the very bottom so you don't leave any fuel behind.

- Discharge Hose: This is the delivery end, where the fuel comes out into your boat's tank. For the siphon to work best, this end should always be lower than the fuel level in the container you're emptying. Gravity becomes your best friend here.

- One-Way Valves: These are the secret heroes of the system. Tucked inside the pump, these little check valves act like one-way doors, letting fuel flow out but never back in. This is what keeps the fuel moving in the right direction and maintains the siphon between pumps.

The real magic of a hand pump is how these simple parts work in harmony. Your manual effort creates a vacuum, air pressure provides the push, and the valves make sure the fuel only goes one way.

This mechanical teamwork makes the pump incredibly effective. For instance, a good rotary hand pump can easily move 7-8 liters per minute, which is plenty fast for topping off a tank without needing any power source. When you understand how these pieces fit together, it’s easy to see why this humble tool is essential for managing fuel safely out on the water.

Choosing the Right Type of Hand Pump for Your Boat

Picking the right fuel hand transfer pump for your boat is a lot like choosing any other tool for a job. The tiny, simple pump that's perfect for a dinghy just won't cut it for a big cruiser. Not all manual pumps are created equal, so getting to know the main types is the first step to making a smart choice for your time on the water.

Your options really come down to three main designs: Siphon, Piston, and Rotary Vane pumps. Each works a little differently, and each has its moment to shine. The trick is to match the pump’s design to how you’ll actually be using it, whether that’s for quick top-offs from a jerry can or moving a serious amount of fuel.

Siphon Pumps The Simple Solution

Siphon pumps are about as basic as it gets, making them perfect for simple, low-volume fuel transfers. They work with gravity—you just need a little effort to get the flow started. Think of these as your go-to for topping off a small outboard from a 5-gallon can.

- Bulb Siphon: This is the classic you’ve probably seen everywhere, with a flexible rubber bulb in the middle of the hose. A few good squeezes create the initial suction, and gravity does the rest. They're dead simple, cheap, and easy to toss in a locker.

- Shaker Siphon: This is a clever twist on the classic siphon. It has a one-way valve—often just a small marble—inside the hose's intake end. You just shake the hose up and down in the fuel can. This motion forces fuel up past the valve and starts the siphon, all without any squeezing.

Piston and Rotary Pumps For More Power

When you need to move a bit more fuel, or if you have to pump uphill, you're going to need a more powerful pump. This is where piston and rotary pumps come in. They give you some mechanical advantage, which makes them much better suited for bigger jobs.

A more robust pump isn't just about speed; it's about control and reducing physical effort when transferring significant amounts of fuel, like emptying an old tank for winterization.

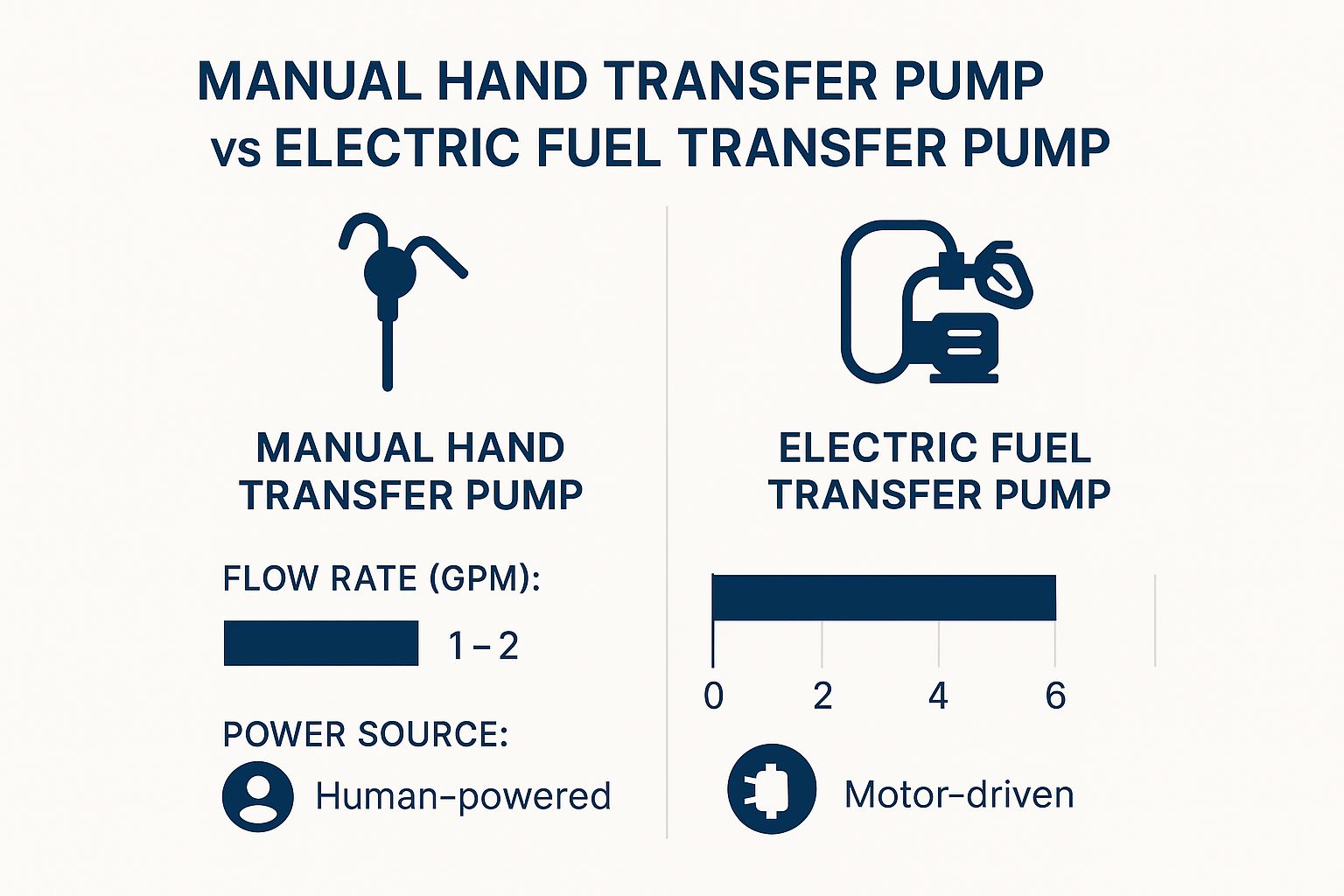

As you can see, electric pumps definitely move fuel faster. But a good manual pump gives you reliable, human-powered operation that doesn't depend on a battery or power source—a huge plus when you're out on the water.

- Piston Pumps: These usually have a lever handle that you pump up and down, kind of like an old well pump. Each stroke pulls fuel into a cylinder and then pushes it out the hose. They create much more suction than siphons, making them great for pulling fuel from large drums or up to a higher deck.

- Rotary Vane Pumps: Operated with a hand crank, these pumps deliver a smooth, continuous flow of fuel. As you turn the handle, little vanes inside spin and move the fuel efficiently. These are the real workhorses of manual pumps, often moving 7-8 liters per minute and making them a top choice for regular, high-volume transfers.

The need for good fueling systems isn't just a boater thing; it's a huge global market. The entire fuel transfer pump industry was valued at USD 1.71 billion in 2021 and is expected to grow to USD 2.47 billion by 2029. You can read the full research about this growing market if you're curious about how industrial trends influence the tools we use. This growth just underscores how important it is to have dependable equipment, even something as simple as a hand pump.

Comparing Common Fuel Hand Transfer Pumps

To help you find the best manual fuel pump for your boating needs, here’s a quick side-by-side comparison of the types we've just covered.

| Pump Type | How It Works | Best For | Pros | Cons |

|---|---|---|---|---|

| Bulb Siphon | Squeeze a flexible bulb to create initial suction; gravity maintains the flow. | Small, quick transfers from a jerry can to an outboard or personal watercraft. | Inexpensive, very simple to use, compact and easy to store. | Low flow rate; requires the source tank to be higher than the destination. |

| Shaker Siphon | A one-way valve (often a marble) at the intake end starts the siphon with a simple shaking motion. | Transferring fuel when you want to avoid spills from squeezing a bulb; good for tight spaces. | Easy to start, no pumping required once started, low cost. | Also has a low flow rate and relies on gravity. |

| Piston Pump | A lever handle moves a piston up and down, drawing fuel in and pushing it out. | Emptying larger tanks, transferring fuel uphill, or moving fuel from 55-gallon drums. | Generates good suction and pressure, can pump against gravity. | Slower than rotary pumps, can be tiring for large volumes. |

| Rotary Vane Pump | A hand crank spins internal vanes that trap and move fuel continuously. | Regular, high-volume transfers, such as refueling from large containers or for maintenance. | Smooth, continuous flow; highest flow rate of manual pumps. | More expensive, bulkier, more moving parts to maintain. |

Ultimately, the best pump is the one that fits your boat, your budget, and the jobs you do most often. For most boaters, having a simple siphon on hand for emergencies and a more robust piston or rotary pump for bigger tasks is a great combination.

What to Look for When Buying a Fuel Hand Pump

So, you’ve figured out which type of pump makes sense for your boat. Now it’s time to get into the details and pick the right one. Choosing a good fuel hand transfer pump isn't just about finding the cheapest option. It’s about getting a reliable, safe, and efficient tool that won’t let you down when you're out on the water.

A few key details make all the difference, and they'll help you buy a pump that stands up to the job and the tough marine environment.

The number one thing you need to check is material compatibility. This is non-negotiable. Not all plastics and rubbers can handle fuel. Gasoline, in particular, is incredibly harsh and will eat through the wrong materials in no time, causing dangerous leaks, pump failure, or even contaminating your fuel. Make sure the pump is clearly marked as safe for the specific fuel you use, whether that's gasoline, diesel, or both.

Build Quality and Durability

If a pump feels cheap and flimsy in your hands at the store, it's going to fail you on your boat. You need something built to last. For boaters, that means finding a pump that can take a beating from salt, sun, and constant moisture.

- UV-Resistant Hoses: Hoses left in the sun will get brittle and crack surprisingly fast. Look for ones specifically made to resist UV damage.

- Corrosion-Resistant Metals: Any metal bits, like hose clamps or the pump body itself, should be stainless steel or a coated aluminum to keep rust at bay.

- Reinforced Construction: A quality pump feels solid. Pay close attention to where the hoses connect to the pump—this is a classic weak spot.

Think of your hand pump like any other piece of safety gear on your boat. Spending a bit more on a tough, marine-grade model gives you peace of mind that it will work perfectly when you need it, season after season.

Hose Length and Diameter

The size of the hoses will make or break your experience. If a hose is too short, you won't be able to get to the bottom of a deep fuel can. If it's too narrow, you'll be there all day pumping. It's a real pain.

Before you buy, think about the distance from where you typically place your jerry can to your boat's fuel tank opening. You need an intake hose long enough to hit the bottom of your deepest container. The hose diameter is just as important; a wider hose means a higher flow rate, which gets the job done much faster.

The demand for reliable fueling gear is bigger than you might think. The fuel transfer equipment market, including simple hand pumps, was worth USD 1.76 billion in 2022 and is still growing. Buying a quality tool now is a smart move. For more hands-on advice, be sure to read our guide with expert tips for the safe use of your fuel transfer hand pump.

Here’s a more natural, human-written version of the section:

A Step-by-Step Guide to Safe Fuel Transfer

Using a fuel hand transfer pump is a pretty simple job, but doing it safely is what really matters. We’re dealing with fuel, after all, and a moment of carelessness can lead to a very bad day on the water. Following a solid process every time isn't just about being cautious; it’s about making safety a habit so you can handle transfers confidently and without any drama.

Before a single drop of fuel moves, your most important task is getting the boat ready. Think of it as setting the stage for a safe operation. First, get some fresh air moving. Pop open all the hatches and portholes to create good cross-ventilation. This ensures any fumes don't have a chance to build up. The last place you want to be transferring fuel is in a sealed-up, stuffy cabin.

Next, take a look around. Let everyone else on board know what you're about to do so they can steer clear. And this is the big one: kill any and all potential sources of a spark. That means no smoking, no open flames from the galley stove, and definitely shutting down engines or generators.

Preparing for the Transfer

Once the area is safe, it's time to get your gear in position. A few deliberate steps here can prevent spills and make the whole process go much smoother.

- Have Safety Gear Ready: Keep a B-I rated fire extinguisher right next to you, within easy reach. It's also smart to have a few absorbent pads handy to tackle any drips the second they happen.

- Position Your Containers: Set your fuel can on a stable surface where it won't tip over. If you can, place it a bit higher than the tank you're filling. Gravity will become your best friend, doing some of the work for you and making pumping that much easier.

- Ground the Pump: Static electricity is the invisible enemy here. It can build up without you even knowing it. Before starting, simply touch the metal nozzle of the pump directly to the metal fill opening on your boat's tank. This little touch safely neutralizes any static charge.

A critical pro-tip: Always keep that pump nozzle touching the metal fill opening for the entire time you are transferring fuel. This constant contact is your best defense against a static spark.

Executing the Pumping Process

Alright, you're all prepped and ready to go. The actual pumping part is the easy bit.

Start by feeding the intake hose deep into your fuel can, making sure it hits the bottom. Then, place the discharge nozzle securely into the boat's fuel tank, remembering to maintain that metal-to-metal contact.

Begin pumping with a slow and steady rhythm. Don't go at it like you're in a race; pumping too hard can cause splashing and create unnecessary fumes. Just listen. You'll notice the sound changes as the tank starts to fill up—that's your signal to slow down and get ready to stop.

When you're done, lift the hose out carefully, letting the last few drops drain back into the tank. Immediately screw the caps back on both the boat's tank and the fuel can, and make sure they're tight. If you had any small spills, clean them up with your absorbent pads and dispose of them correctly. A quick wipe of the pump itself will keep it clean and ready for the next time you need it.

Keeping Your Pump in Top Condition

Think of your fuel hand transfer pump as a key piece of safety equipment. Just like any other essential tool on your boat, it’s only as good as the care you give it. A little preventative maintenance goes a long way, ensuring it’s ready to perform when you really need it.

The single best thing you can do is clean the pump after every single use. Fuel residue, especially gasoline, is nasty stuff that will eat away at plastic and rubber parts over time. This makes them brittle and likely to crack. Once you're done transferring, just pump the last bits of fuel out of the hoses and give the whole unit a quick wipe.

Smart Storage and Regular Inspections

Where you keep your pump matters just as much as cleaning it. Direct sunlight is the number one enemy of rubber and plastic hoses, as those UV rays will weaken them until they fail. Your best bet is to store the pump in a cool, dry, and well-ventilated locker, far away from engine heat and the sun's glare.

Taking 30 seconds to inspect your pump before stowing it away can save you from a massive headache out on the water. A quick check now prevents a serious failure later.

Before the season kicks off, or at least every few times you use it, give your pump a quick once-over. This simple routine is your best defense against surprises.

- Check Hoses for Cracks: Gently flex the hoses and look closely for any tiny cracks or signs of stiffness.

- Inspect Seals and Connections: Make sure every fitting is snug and that the seals where the hoses connect to the pump are in good shape, with no signs of leaking.

- Test the Pump Action: Give the bulb a few squeezes or work the handle a couple of times. It should feel smooth and build pressure like it's supposed to.

Troubleshooting Common Pump Problems

Even the most well-cared-for pump can act up now and then. The good news is that when a pump stops working correctly, it’s usually a simple fix. Loss of suction is the most common complaint, and it's almost always caused by an air leak. Start by checking that all your hose connections are screwed on tight.

A blockage is another frequent issue. It's easy for a bit of debris from a jerry can to get sucked into the hose and jam one of the internal one-way valves. Disconnecting the hoses and flushing them out with a little clean fuel or air can usually clear it right up. For a deeper dive into your boat's fuel system, our guide to boat fuel tank maintenance has some great information that pairs perfectly with keeping your pump in good order.

Got Questions? We’ve Got Answers

Even with a solid guide, you're bound to have questions. It’s all part of the learning process. Let's tackle some of the most common things boaters ask about fuel hand transfer pumps so you can feel completely confident every time you refuel.

Can I Use the Same Pump for Both Gas and Diesel?

This is a big one. It seems practical to use one pump for everything, but you really need to check what the manufacturer says. Some top-notch pumps are built to handle both, but most aren't.

Gasoline is much harsher on materials than diesel. It can eat away at seals and hoses that aren't specifically designed for it. To be safe and avoid a pump failure at the worst possible time, your best bet is to stick with a pump rated for the exact fuel you're moving.

Using the wrong pump is more than just a bad idea for your gear—it's a serious safety risk. A seal damaged by gasoline can leak fuel and create dangerous fumes.

How Do I Keep from Spilling Fuel into the Water?

Preventing spills is all about stability and control. Before you even start pumping, make sure your boat and the fuel can are both secure and not rocking around.

Here's a pro tip: keep the pump’s nozzle firmly pressed against the inside wall of the tank's fill opening. This simple trick stops splashing and helps ground against any static buildup.

Pump slowly and steadily—don't rush it. And always have some absorbent pads within arm's reach, just in case a few drips escape. If you want to really master this, check out our guide on boat fueling safety in our complete playbook.

What’s the Right Way to Store My Pump?

Proper storage is simple, but it's absolutely crucial for keeping your pump in good working order. Once you're done, make sure to drain every last drop of fuel from the pump and its hoses.

Find a dedicated, well-ventilated locker for it. Keep it out of direct sunlight, which can make hoses brittle over time. For an extra layer of safety and to keep any residual fumes contained, you might want to pop the drained pump into a sealed, fuel-resistant bag.

Ready to make every refueling a spill-free, stress-free experience? The innovative system from CLiX Fueling Solutions automatically stops fuel flow when your tank is full, protecting your boat and the environment. Find your perfect fueling solution at clixfueling.com today!