The DEF fluid tank and pump are the heart and soul of your engine's emissions control system, officially known as a Selective Catalytic Reduction (SCR) system. If you've got a newer marine diesel, you know the one—it's the tank with the little blue cap. This system isn't just an add-on; it's essential for meeting today's strict emissions laws.

The tank holds a special liquid called Diesel Exhaust Fluid (DEF), which is just a simple, non-toxic mix of urea and super-pure water. The pump's job is to precisely spray this fluid into the hot exhaust stream. When it does, a chemical reaction happens that zaps harmful Nitrogen Oxides (NOx) and turns them into plain old nitrogen and water.

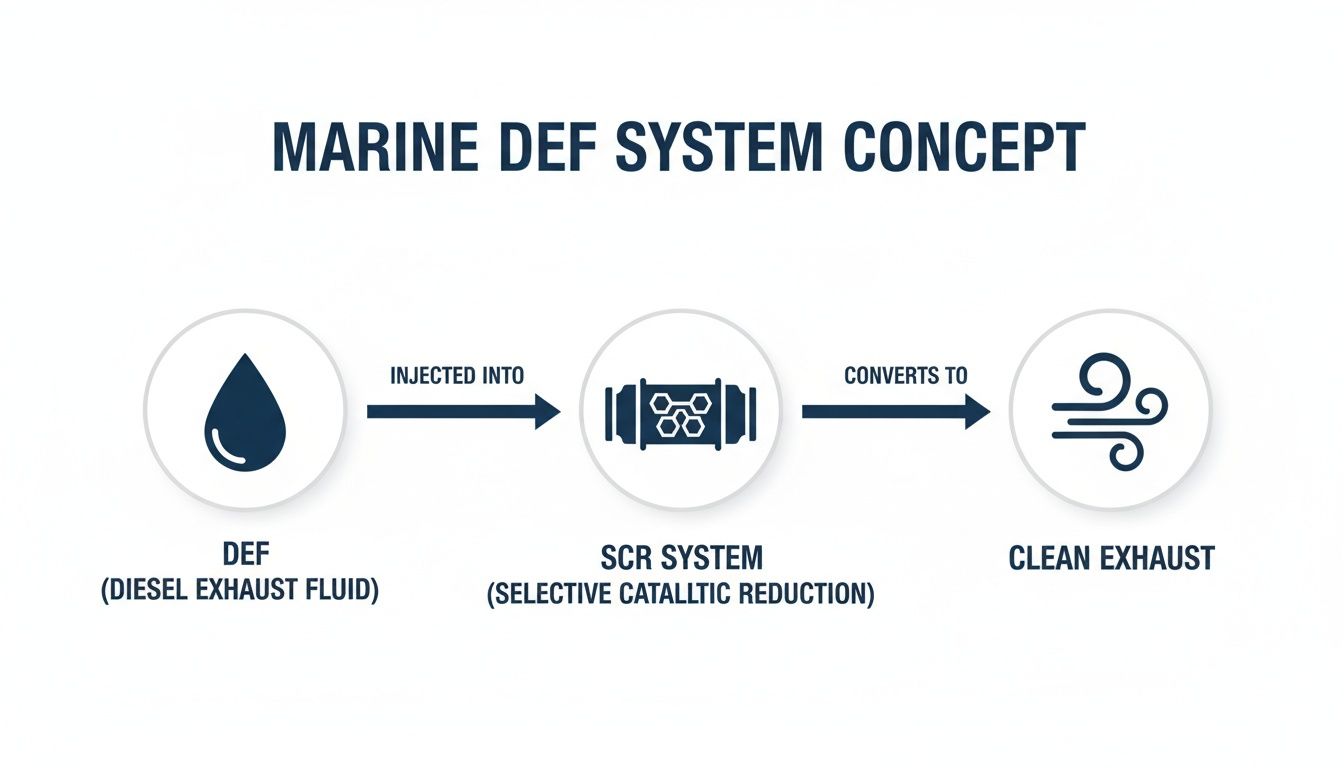

What a Marine DEF System Does and Why It Matters

That blue cap next to your fuel fill isn't for an optional accessory. It's for a system that's absolutely critical for keeping your modern diesel engine compliant and running smoothly. When you understand what it’s doing, topping off the DEF tank becomes less of a chore and more a part of responsible engine care.

Think of it as a water purifier, but for your engine's exhaust. Its main job is to scrub the exhaust clean before it hits the open air. The specific pollutants it targets are Nitrogen Oxides (NOx), which are nasty compounds that contribute to smog, acid rain, and breathing problems.

To get rid of NOx, marine engine builders have turned to Selective Catalytic Reduction (SCR) technology. The system injects a fine mist of DEF into the hot exhaust gases right before they flow through a special catalyst. Inside that catalyst, the DEF works its magic, neutralizing the NOx and turning it into harmless nitrogen and water vapor. It’s a pretty clever bit of chemistry, really.

The Driving Force Behind DEF Adoption

Engine manufacturers didn't just decide to add these systems for fun. Their hands were forced by tough environmental regulations designed to protect our air and water. Two big ones are constantly in play:

- EPA Tier 4: In the United States, the Environmental Protection Agency’s Tier 4 rules place strict limits on what can come out of a new marine diesel engine’s exhaust pipe.

- IMO Tier III: For vessels operating in designated Emission Control Areas (ECAs) around the world, the International Maritime Organization’s Tier III standards require a significant reduction in NOx.

For most modern diesels, hitting these targets is flat-out impossible without an after-treatment system like SCR. That’s why the DEF fluid tank and pump have become standard issue on virtually every new commercial and recreational boat hitting the water.

This isn't just a marine thing; it’s a shift happening across every industry that relies on diesel power. From semi-trucks to construction equipment, AdBlue/DEF systems are now mandatory. Proper management is key to avoiding costly engine "derates," a safety mode that can bring hundreds of millions in daily freight operations to a grinding halt. You can read more about the trends in the fuel management market for a bigger picture.

The Key Parts of Your Marine SCR System

Don't let the technical name fool you; the system is actually pretty straightforward once you know the key players. It's just a handful of components working together to get the job done. Each part has a very specific role, from simply holding the fluid to making sure it’s injected at the perfect time.

Here’s a quick overview of the main components in the SCR system and what each one does, giving you an at-a-glance understanding.

The Key Parts of Your Marine SCR System

| Component | Function |

|---|---|

| DEF Fluid Tank | This is a dedicated tank that securely stores the Diesel Exhaust Fluid, keeping it safe from contaminants and extreme temperatures. It's also equipped with sensors to tell you how much fluid you have left. |

| DEF Pump | Think of this as the heart of the system. It pulls DEF from the tank, pressurizes it, and sends it on its way. Most marine units include a heater to keep the fluid from freezing in cold weather. |

| DEF Injector | This is a high-precision nozzle. Its only job is to spray a perfectly atomized mist of DEF directly into the hot exhaust gases right before they enter the catalyst. |

| SCR Catalyst | This is where the magic happens. It looks a bit like a honeycomb and is made of a special ceramic coated with precious metals. This is the chamber that hosts the chemical reaction that converts NOx. |

| Engine Control Unit (ECU) | The "brain" of the whole operation. The ECU constantly monitors things like engine load, exhaust temperature, and NOx sensor readings to calculate the exact amount of DEF needed at any given moment. |

Once you see how these parts work together, the whole system makes a lot more sense. It’s a well-coordinated process that keeps your engine running clean and compliant.

How Your DEF Fluid Tank and Pump Work Together

Think of your vessel's SCR system like a well-drilled team, where the DEF fluid tank and pump are the star players. They aren't just standalone parts; they’re a highly coordinated duo, working in sync to deliver a precise dose of DEF at just the right moment. Knowing how these two interact is the key to understanding the whole emissions control process.

The DEF tank is far more than a simple plastic jug. It's the secure storage locker for your Diesel Exhaust Fluid, carefully engineered to protect its purity. DEF is extremely sensitive to contamination from materials like copper, zinc, and brass, which can poison the SCR catalyst and land you with a very expensive repair bill.

This is why you'll find that nearly all DEF tanks are made from high-density polyethylene (HDPE). This tough, durable plastic is completely non-reactive with the urea in DEF. It guarantees the fluid stays pure and effective from the moment you pour it in to the second it's injected into the exhaust.

Inside the DEF Fluid Tank

Beyond the plastic itself, the tank is a smart piece of kit with its own integrated electronics. These sensors constantly feed information back to the engine's main computer, ensuring the entire system operates within tight tolerances.

Here are the key features you'll find inside almost every marine DEF tank:

- Level Sensor: This one's pretty straightforward—it's just like your fuel gauge. It sends a continuous signal to your helm display, showing you exactly how much DEF you have left and giving you a heads-up when it's time to refill.

- Temperature Sensor: DEF has a freezing point of about 12°F (-11°C). To combat this, a temperature sensor monitors the fluid and kicks on a built-in heater when things get too cold. This keeps the DEF liquid and prevents blockages or damage.

- Quality Sensor: Many modern systems include this advanced feature. The sensor can tell if your DEF has been contaminated with something else (like water or diesel) or if its urea concentration has dropped below the required 32.5%.

These components work together to protect both your engine and the SCR system. If any sensor flags a problem—low level, wrong temperature, or poor quality—you'll get a warning light on your dash. This gives you time to fix the issue before the engine reduces power in a "derate" mode.

The Role of the DEF Pump

If the tank is the reservoir, the DEF pump is the heart of the operation. It's in charge of moving the fluid under very specific pressure. This isn't just a simple transfer pump; it's a sophisticated delivery module that often bundles the pump, pressure regulators, filters, and even heating elements into a single unit.

The pump’s main job is to pull DEF from the tank, pressurize it (usually to around 50-80 PSI), and send it on to the injector nozzle in the exhaust stream. Maintaining that exact pressure is crucial for creating the super-fine mist needed for an efficient chemical reaction in the SCR catalyst. A weak or sputtering spray means incomplete NOx conversion, which will quickly trigger fault codes.

For a deeper dive into the different models and what to look for, check out our detailed guide on choosing and maintaining your DEF fuel pump.

A common mistake is thinking the DEF pump runs all the time, like a fuel pump. In reality, it cycles on and off as needed to keep the line pressurized. The engine's computer tells it exactly when to work based on real-time data from engine and exhaust sensors.

This diagram shows you exactly how DEF travels from the tank, through the SCR system, and out as clean exhaust.

This visual helps simplify a complex process, tracing the fluid's journey until it becomes harmless nitrogen and water vapor. Together, the DEF tank and pump create a smart, self-monitoring delivery system that is absolutely essential to your engine’s performance and compliance.

Installing the System on Your Vessel

Putting a DEF fluid tank and pump on a boat isn't anything like bolting one onto a truck. The marine world throws a whole different set of curveballs at you—think constant moisture, corrosive saltwater, and the kind of vibrations that can shake fillings loose. A good installation isn't just about finding a spot where it fits; it's about making sure the whole system can stand up to these tough conditions day in and day out.

Getting this right from the get-go will save you a world of trouble later. A poorly placed tank can make refilling a real chore, and hoses routed the wrong way are just asking for leaks and system failure. Let's walk through what it takes to do a professional-grade installation that you won't have to worry about.

Choosing the Right Location

Deciding where to put the DEF tank and pump is probably the single most important part of the job. You're looking for that sweet spot that balances easy access, safety, and protection from the elements. A smart location makes top-offs a breeze and keeps the gear safe from harm, which means it will last longer and work when you need it.

Before you even think about picking up a drill, size up potential spots with these key things in mind:

- Easy Access for Refills: You'll be filling the DEF tank on a regular basis, so it has to be somewhere you can get to without turning into a contortionist. If you have to fight to get to the cap, you've picked the wrong spot.

- Keep it Cool: DEF doesn't like heat. High temperatures can cause it to break down and become less effective. Keep the tank well away from the engine block, exhaust manifolds, or anything else that gets hot.

- Shield it from the Elements: Even though marine-grade systems are built tough, you still want to minimize their exposure to direct sun and constant salt spray. A spot that’s covered but has good airflow is perfect.

- Dampen the Vibrations: That constant rumble from a diesel engine puts stress on everything. Mount the system in a structurally solid area and use rubber mounts or bushings to isolate the tank and pump from the worst of the shaking.

Mounting and Securing Components

Once you’ve found the perfect home for your system, it’s time to lock it down. On a boat, "secure" means it absolutely cannot move, no matter how rough the seas get. Anything left loose is just waiting to become a problem, leading to chafed wires, cracked fittings, or a major leak.

Never underestimate the forces at play on the water. A bracket that feels rock-solid at the dock can easily fail when you're pounding through heavy chop. Always overbuild, using marine-grade stainless steel fasteners for every single mounting point.

When you’re securing the DEF fluid tank and pump, stick to the manufacturer’s instructions. Use the mounting points they provide and make sure the unit is sitting level. If the tank is tilted, the level sensor can give you a false reading, and you might find yourself running out of DEF when you least expect it.

Routing Hoses and Electrical Lines

With the main hardware bolted down, it's time to connect the dots. The goal here is a clean, protected path for every hose and wire. A rat's nest of lines isn't just ugly—it's a serious safety hazard.

Follow these best practices for a pro-level setup:

- No Kinks or Sharp Bends: DEF hoses need smooth, gradual curves to work properly. A hard kink will choke off the flow, which can set off low-pressure alarms or even burn out the pump.

- Use Chafe Protection: Any place a hose or wire passes through a bulkhead or rubs against an edge needs protection. Use rubber grommets or chafe guards, because vibration will eventually wear right through an unprotected line.

- Secure Lines Every 18 Inches: Lock down all lines with cushioned clamps or good-quality zip ties. This stops them from drooping, sagging, and rubbing against other parts.

- Create Drip Loops: For any electrical connection in a damp area like an engine room, form a small downward loop in the wire right before the connector. This simple trick ensures any moisture drips off the bottom of the loop instead of running straight into your connection.

- Waterproof Every Connection: Don't skimp here. Use marine-grade, heat-shrink connectors on all your wiring to seal out moisture and prevent the corrosion that kills so many marine electrical systems.

For more in-depth guidance on storage and handling, check out our guide on diesel exhaust fluid storage tanks, which details best practices for both fixed and mobile setups.

Keeping Your DEF System in Peak Condition

The secret to a long-lasting, trouble-free SCR system isn't really a secret at all—it's proper maintenance. Just like changing your engine's oil, giving your DEF fluid tank and pump a little preventative care goes a long way in avoiding expensive headaches down the road. A simple, proactive plan is your best defense, ensuring reliability and protecting your investment season after season.

Think of it as a quick health checkup for a vital piece of equipment. When you catch the small issues early, you can steer clear of those dreaded dashboard warnings and potential engine derates that can completely ruin a day on the water.

This is especially true when you look at the wider world of fuel systems. The global market for automotive fuel transfer pumps is on track to nearly double from $2.6 billion to $4.7 billion, with replacement parts making up a huge chunk of sales. Pump failures are a major cause of breakdowns, which just goes to show how critical reliability is for any fluid delivery system, including the one on your boat. If you want to dive deeper into this trend, you can review detailed insights on automotive fuel transfer pumps.

Routine Checks for System Health

Making a few quick inspections a standard part of your boating routine is one of the smartest things you can do. These checks are easy and can be done while you're already in the engine room for other tasks. Try adding these three steps to your pre-departure checklist.

- Look for Leaks: Get your eyes on all the DEF lines, fittings, and connections, along with the tank and pump housing. You’re looking for any tell-tale signs of white, crystalline residue. That stuff is a dead giveaway of a DEF leak.

- Keep the DEF Pure: When it's time to refill, always use a clean, dedicated funnel or container. Even a tiny bit of dirt, diesel, or water can contaminate the fluid and permanently damage the expensive SCR catalyst.

- Check the Filter: Your DEF pump module has a small filter inside that needs to be changed based on your manufacturer's service schedule. If that filter gets clogged, it puts a major strain on the pump, leading to low pressure and, eventually, failure.

The Critical Task of Winterization

For any boater in a colder climate, winterizing the DEF system isn’t just a good idea—it’s absolutely essential. DEF is made of 67.5% water, which means it freezes solid at 12°F (-11°C). When that water turns to ice, it expands with enough force to crack the DEF pump housing, split hoses, or ruin the injector.

Don’t just assume the system’s built-in heaters will protect it during long-term winter storage. While those heaters are great for preventing freeze-ups during operation, they aren’t meant to run for months on end while the boat is laid up without power.

So, what’s the right way to protect your system from ice damage? You've got two main options, and the best choice depends on your specific setup and what the manufacturer recommends.

Preparing for the Freeze

- Option 1: Drain the System. This is the most foolproof method. It usually involves disconnecting a hose at a low point in the system—often on the pump module—and letting the tank, pump, and lines drain out completely. Always check your service manual for the exact procedure.

- Option 2: Rely on Heaters (With Caution). If you store your boat where you have consistent shore power and your system is designed for it, you might be able to rely on the heaters. This is the riskier approach, though. One power outage is all it would take to leave your system vulnerable to a hard freeze.

Proper winterization is the single best thing you can do to make sure your DEF fluid tank and pump are ready to go when spring rolls around. A few minutes of work in the fall can save you from a major repair bill and a delayed start to your next boating season.

Troubleshooting Common DEF System Problems

Even the most meticulously maintained DEF fluid tank and pump will act up now and then. When that little amber warning light starts glowing on your dash, it’s easy to jump to the worst conclusion, but more often than not, the fix is surprisingly simple.

Knowing how to spot the usual suspects can empower you to solve minor problems on your own, saving you a trip to the yard and keeping you out on the water. Think of this as your first line of defense—a way to rule out the easy stuff before you have to call in a pro.

Low DEF Pressure Warnings

A "Low DEF Pressure" warning is probably one of the most common alerts you'll encounter. All this means is that the pump is having a hard time getting the DEF to the injector at the right pressure, which is usually somewhere around 50-80 PSI. That pressure is crucial for turning the fluid into a fine mist inside the hot exhaust.

Before you start pricing out a new pump, take a deep breath and work through this checklist. It’s almost always one of these four things:

- Clogged DEF Filter: Just like a fuel filter, the DEF filter gets gummed up with tiny bits of debris over time, choking off the flow. It’s a simple maintenance item that many people forget about.

- Frozen DEF Lines: If you’re boating in the cold and the system’s built-in heaters aren’t doing their job, you could easily have an ice block somewhere in the lines.

- Kinked or Pinched Hoses: Take a good look at the entire DEF line, from the tank all the way to the injector. A sharp bend or a spot where a hose got squashed can stop the system in its tracks.

- A Leaky Connection: Hunt for any tell-tale white, crusty residue around the hose fittings. Even a tiny leak that isn't dripping can be enough to keep the system from building and holding pressure.

Always start with the filter. It's the easiest thing to check and the most frequent culprit. If that doesn't solve it, a careful visual inspection of the lines usually uncovers the problem.

Inaccurate DEF Level or Quality Readings

Here’s another one that can drive you crazy: the gauge insists the tank is empty right after you filled it, or a "Poor DEF Quality" light pops on. When this happens, the problem almost always lies with the sensor unit inside the DEF tank.

These sensors are pretty sensitive. They can get thrown off by contamination or just plain fail after a few seasons of hard work.

A false quality warning is a real headache because the engine's computer will likely cut back the power, thinking the DEF is bad. It’s a built-in safety measure to protect the expensive SCR catalyst, but a faulty sensor can trigger it just the same.

If you are 100% certain you filled the tank with fresh, high-quality DEF from a brand-new, sealed jug, then the sensor module is your prime suspect. Replacing it isn't always a simple DIY job, as the whole sensor and pump assembly often has to be swapped out. But knowing that's the likely issue will save you a ton of time and money when you explain the situation to your mechanic.

Decoding Common DEF System Faults

Your boat’s dashboard uses specific lights and codes to tell you what's going on with the SCR system. While the exact symbols can differ between engine manufacturers, they generally follow a predictable pattern. Think of this table as your quick-reference decoder ring for those pesky warnings.

| Fault Code or Warning Light | What It Likely Means | What You Should Do First |

|---|---|---|

| "DEF Level Low" Light | The fluid level in the tank is critically low. The engine will soon enter a derate (power reduction) mode. | Refill the DEF tank immediately. This is the most urgent and common warning. |

| "Poor DEF Quality" Alert | The quality sensor has detected fluid that is contaminated, diluted, or has the wrong urea concentration. | If you recently refilled, drain the tank and add fresh DEF from a trusted source. If the problem persists, the sensor may be faulty. |

| "DEF System Fault" Message | This is a general error indicating a problem with a component like the pump, injector, or a sensor. | Check for obvious issues like leaks or loose connections. If none are found, professional diagnostic tools are needed. |

Running through these basics first can often resolve the issue without needing specialized tools. It puts you back in control and helps you understand what your engine is trying to tell you.

Safely Handling and Storing Your DEF

Even though Diesel Exhaust Fluid is considered non-hazardous, you still need to handle it with care. Think of it less like a dangerous chemical and more like a high-purity fluid that demands cleanliness to work properly. Treating it right is key to protecting your sensitive SCR system and the marine environment.

Contamination is the number one enemy of your DEF system. Just a tiny speck of dirt, a drop of diesel, or some saltwater can cause crystals to form inside the delicate pump or injector, leading to a very expensive repair bill. That’s why using dedicated, sealed containers for refilling your DEF fluid tank and pump is an absolute must. Never, ever use an old fuel jug or a dirty funnel.

Best Practices for DEF Storage

How you store your DEF is just as important as how you handle it. The goal is to maintain its purity and get the most out of its shelf life. Its biggest weaknesses are extreme temperatures and direct sunlight, which can cause the urea to break down and become less effective.

Just stick to these simple storage rules:

- Keep it Cool and Shaded: Find a spot for your DEF containers that stays between 12°F (-11°C) and 86°F (30°C). Keeping it out of direct sunlight is critical.

- Use Original Containers: Leave DEF in its original sealed container until you’re ready to pour it. This is the best way to prevent contamination and evaporation.

- Check the Date: DEF typically lasts about one to two years, but this can change based on how it's stored. Always glance at the expiration date before you use it.

The golden rule is simple: keep it clean, sealed, and cool. If you don't, the fluid's precise 32.5% urea concentration can be thrown off. That's a surefire way to trigger a "Poor DEF Quality" warning from your engine's sensors and cause performance problems.

Managing Spills Responsibly

Accidents are a part of life on the water, but thankfully, a DEF spill is pretty easy to handle. Since it’s non-toxic and dissolves in water, you won’t need a hazmat suit.

If you spill a small amount on deck, just soak it up with a rag or an absorbent pad. Then, give the area a good rinse with fresh water to stop the white urea crystals from forming as it dries.

For a larger spill, use absorbent materials to contain it, then dispose of them according to your local regulations. While it’s a different fluid, many of the same principles in our guide on the proper diesel fuel spill cleanup procedure can be applied here too.

The equipment for handling fluids like DEF is part of a huge global industry. For perspective, the DC fuel transfer pump market was valued at $78.3 million and is expected to grow to $128.8 million as more industries adopt safer, smarter systems. In fact, real-time monitoring features on this equipment have been shown to boost productivity by up to 20%. You can dive deeper into how safety and technology are driving the fuel pump market on Market.us.

Your Top Questions About Marine DEF, Answered

Even when you know the basics, real-world questions always come up. Here are some quick answers to the most common things we hear from boat owners about their marine DEF fluid tank and pump.

How Long Does DEF Last on the Shelf?

Diesel Exhaust Fluid has a pretty good shelf life, but it won't last forever. If you store it correctly—somewhere between 12°F (-11°C) and 86°F (30°C) and out of the sun—an unopened jug of DEF is good for about one to two years.

The biggest killer of DEF is heat. Leaving it in a hot engine room or letting the sun beat down on the container will cause the urea to break down, making it useless. Just be sure to glance at the expiration date before you pour it in.

Can I Use Automotive DEF in My Boat?

Absolutely. The recipe for DEF is the same no matter where you get it. It has to meet a specific standard, ISO 22241, which calls for a mixture of 32.5% urea and 67.5% deionized water.

What really matters isn't the label on the jug but the quality inside. As long as it's a fresh, sealed container meeting that ISO spec, the DEF from the truck stop is just as good for your boat as the stuff from the marina.

The key difference isn't the fluid, but the hardware. Marine DEF systems are built tougher to survive life on the water. Think corrosion-resistant parts and heavy-duty heaters designed to handle the constant moisture and vibration.

What Happens If I Run Out of DEF?

You definitely don't want to run out of DEF on the water. Your engine's computer is designed to stay emissions-compliant, and it won't let you get very far without it.

First, you’ll see a series of warnings light up on your dash. If you ignore them, the engine will go into what’s called a "derate" mode, drastically cutting your power and speed. It usually leaves you with just enough juice to limp back to the dock, but that's about it. Once you refill the DEF fluid tank and pump, the system resets itself and you'll have full power again.

A stress-free day on the water means not having to worry about common problems like fuel spills. That’s where CLiX Fueling Solutions comes in. Our smart system automatically shuts off the fuel nozzle the second your tank is full, preventing messy and hazardous overflows. To make every fill-up clean and safe, learn more about our spill-free solutions.