Understanding DEF Fuel Pumps: The Heart of Modern Emissions Control

Diesel engines are known for their power and efficiency. However, they also produce harmful emissions. Diesel Exhaust Fluid (DEF), often called AdBlue, is a major advancement in controlling these emissions. Used with Selective Catalytic Reduction (SCR) systems, DEF transforms harmful NOx emissions into harmless nitrogen and water. The DEF fuel pump is at the core of this system, precisely delivering the DEF.

A DEF fuel pump is essential for modern diesel engines. It ensures the vehicle meets emission standards while maintaining optimal performance.

How DEF Fuel Pumps Work

Unlike pumps delivering diesel to the engine, DEF fuel pumps meter DEF into the exhaust stream. This isn't continuous. The pump activates based on sensor readings and engine conditions. This ensures the correct DEF-to-exhaust ratio, maximizing NOx reduction and preventing fluid waste. This precise metering is crucial. Both over and under-injection can negatively affect the engine and emissions.

Accurate DEF delivery is essential for SCR system effectiveness. The pump's precision minimizes emissions and ensures efficient DEF usage.

The Importance of a Healthy DEF Fuel Pump

A malfunctioning DEF pump can have serious consequences. Insufficient DEF flow can increase NOx emissions. This could cause your vehicle to fail emissions tests. A faulty pump can also trigger warning lights, put the engine into “limp mode,” or even shut it down. Over-injection wastes DEF and can damage the SCR catalyst.

Maintaining a healthy DEF pump is vital for complying with emission regulations and avoiding costly repairs. Regular checks and timely maintenance can prevent issues and ensure proper engine function.

To further understand the differences between DEF pumps and standard diesel fuel pumps, let's look at a comparison table:

This table compares the fundamental differences between DEF pumps and standard diesel fuel pumps to help readers understand their distinct functions and requirements.

| Feature | DEF Pump | Diesel Fuel Pump |

|---|---|---|

| Fluid | Diesel Exhaust Fluid (DEF) | Diesel Fuel |

| Purpose | Emissions reduction | Engine power |

| Delivery Location | Exhaust stream | Engine cylinders |

| Flow Rate | Lower, precisely controlled | Higher, based on engine demand |

| Pressure | Lower | Higher |

| Material Compatibility | Specific to DEF, corrosion-resistant | Compatible with diesel fuel |

The table highlights the specialized nature of DEF pumps compared to diesel fuel pumps. Their distinct roles require specific designs and materials for optimal performance and longevity.

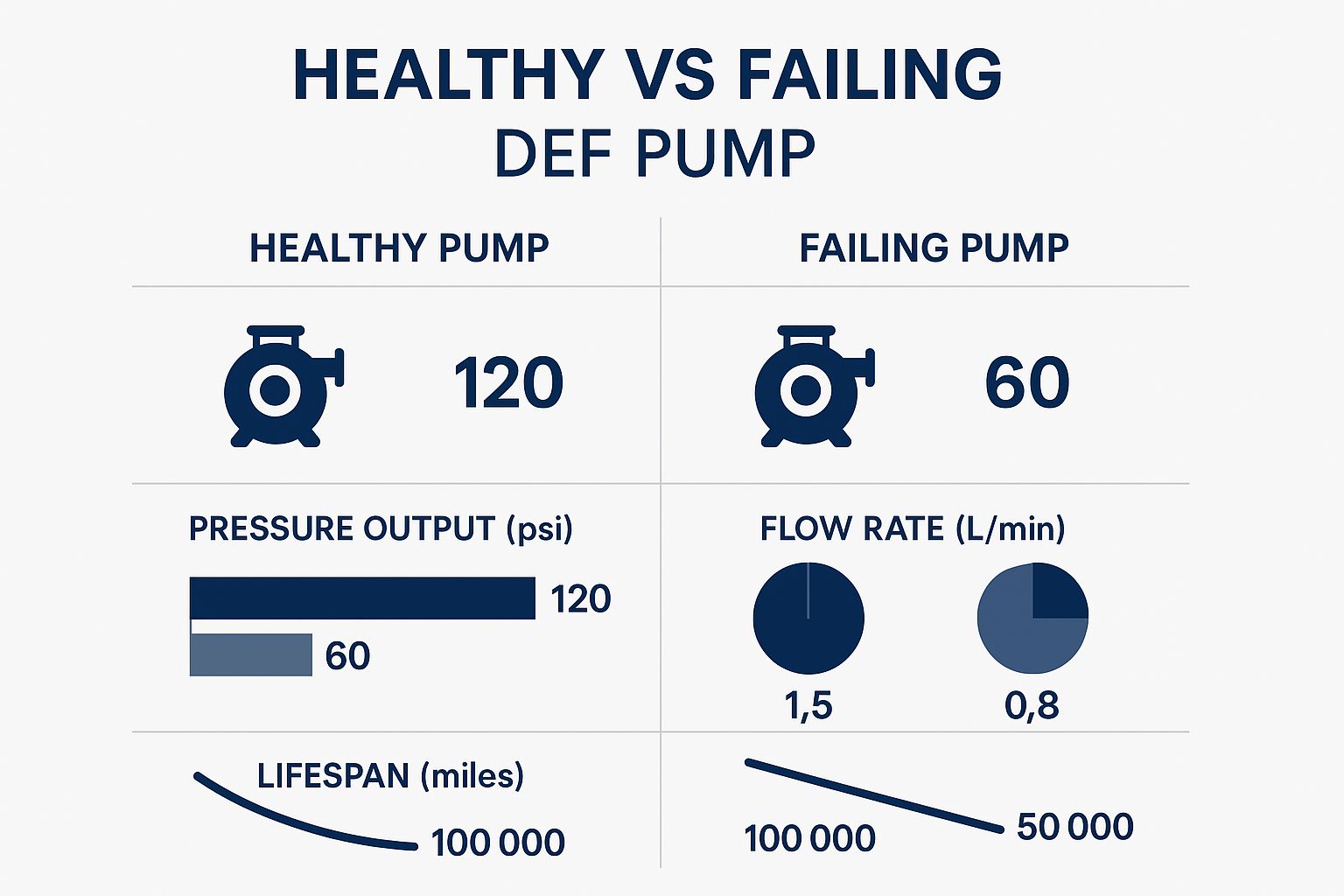

This infographic compares key performance indicators of healthy and failing DEF pumps. A failing pump delivers significantly lower pressure and flow rate, drastically reducing its lifespan. This emphasizes the importance of regular maintenance and prompt replacement of faulty pumps.

Market Growth and Technological Advancements

The importance of DEF systems is reflected in the fuel pump market's growth. The overall fuel pumps market, including diesel and gasoline, was valued at USD 8 billion in 2024. It's projected to reach USD 11.51 billion by 2034, with a CAGR of 3.71%. This highlights the ongoing demand for reliable fuel delivery systems, including specialized DEF pumps. Learn more about fuel pump market research here: https://www.precedenceresearch.com/fuel-pumps-market

The growing market shows the increasing need for efficient and reliable fuel systems. The demand for DEF pumps is directly linked to stricter emission standards worldwide.

Technological advancements are shaping DEF pumps. Electric pumps are replacing traditional mechanical ones. These offer superior pressure control and integrate with the vehicle's electronic control unit. This optimizes DEF delivery and reduces emissions. Durable materials ensure longer pump lifespans and reduce contamination risks, improving DEF system reliability.

Electric DEF pumps offer increased precision and control compared to their mechanical counterparts. This leads to more efficient DEF usage and better emission control.

Choosing the Right DEF Fuel Pump for Your Operation

Picking the right DEF fuel pump is essential for smooth operations and avoiding expensive repairs. This involves understanding your specific needs and matching them to the correct pump specifications. Whether you operate a single truck or an entire fleet, several factors will influence your decision. These range from engine requirements and how often you use your vehicle, to the environmental conditions it operates in.

Matching Pump Specifications to Your Needs

The first step in choosing a DEF pump is understanding your engine’s requirements. Check your vehicle's manual or contact the manufacturer to determine the recommended flow rate and pressure. These specifications ensure compatibility and optimal performance of your Selective Catalytic Reduction (SCR) system.

Also, think about how often you use your vehicle. Does it run constantly, or just occasionally? Does it operate in extreme temperatures or harsh environments? These factors impact the durability and lifespan you’ll need from your DEF pump. For more information on our products, visit our product catalog.

Exploring DEF Pump System Types

Several DEF pump systems are available, each with advantages and disadvantages. Manual pumps are the simplest and most budget-friendly option, but they require manual operation. This might not be suitable for high-volume use.

Electric pumps provide automatic operation and precise DEF delivery. However, they need a power source and are typically more expensive. Integrated DEF systems, common in newer vehicles, combine the pump and other components into a single unit. This simplifies installation and maintenance.

Material Considerations and Pump Design

The materials used in DEF pump construction are vital for preventing contamination and ensuring a long lifespan. DEF is corrosive, so pumps must be made from compatible materials like stainless steel or specialized plastics.

The pump design itself also impacts performance. Certain designs handle challenging environments better, offering greater durability and resistance to vibration or extreme temperatures. This is especially important for off-road or heavy-duty applications.

The Broader Context of Fuel Handling

Looking at the bigger picture, the fuel transfer pumps market is seeing significant growth. Valued at $1.87 billion in 2024, this market is projected to reach $2.54 billion by 2029, growing at a CAGR of 6.5%. Fuel transfer pumps are used across various sectors, including construction, mining, agriculture, and military applications. This increasing demand is driven by product innovation, remote monitoring solutions, and emerging markets. The different types of fuel transfer pumps, including AC, DC, and hand pumps, further showcase the diverse applications and the need for flexible solutions.

Choosing the Right DEF Pump for Your Application

To help you choose the right DEF pump, we’ve put together this handy table:

DEF Pump Selection Guide By Application This table provides recommendations for DEF pump types based on different vehicle classes and usage scenarios

| Application Type | Recommended Pump Type | Flow Rate | Key Features to Consider |

|---|---|---|---|

| Light-Duty Vehicles (e.g., passenger cars, pickup trucks) | Electric Pump | Low to Medium | Compact size, ease of installation, power consumption |

| Medium-Duty Vehicles (e.g., delivery trucks, buses) | Electric Pump | Medium | Durability, reliability, flow rate accuracy |

| Heavy-Duty Vehicles (e.g., semi-trucks, construction equipment) | Integrated DEF System | High | Robust design, high flow rate, integration with vehicle systems |

| Off-Road/Agricultural Equipment | Manual or Electric Pump | Low to High (depending on application) | Resistance to vibration and extreme temperatures, material compatibility |

This table offers a quick guide for selecting a DEF pump based on your vehicle type and usage. Remember to consider flow rate and features that match your specific needs.

Consider these factors when deciding:

- Vehicle type and engine specifications: Ensure the pump's flow rate and pressure meet your engine’s requirements.

- Operational demands: Factor in how often you use the vehicle, the environment it operates in, and its duty cycle.

- Budget: Find a balance between cost, features, and durability.

- Maintenance requirements: Opt for a pump that is easy to maintain and service.

By carefully evaluating these factors, you can select the right DEF fuel pump to ensure optimal performance, minimize downtime, and maximize the life of your SCR system.

DEF Fuel Pump Installation: Getting It Right the First Time

Installing a DEF fuel pump correctly is essential for the lifespan and performance of your diesel emissions system. A proper installation helps you avoid expensive repairs down the road and ensures your vehicle stays compliant with emission regulations. This guide, based on insights from seasoned diesel mechanics, will walk you through a proven installation process.

Positioning and Connecting the DEF Fuel Pump

The first step involves positioning the DEF pump correctly in the engine compartment. This can sometimes mean working in confined spaces. Securely mount the pump to minimize vibration, which can lead to premature wear and tear. Next, connect the DEF lines, making sure you create a tight seal to prevent leaks and contamination. It's crucial to use only DEF-compatible materials, such as stainless steel fittings, to avoid corrosion. This meticulous approach protects the DEF system and prevents future problems.

Integrating the DEF Pump with the SCR System

Integrating the DEF pump with the Selective Catalytic Reduction (SCR) system requires close attention to the electronic connections. Carefully follow the manufacturer’s instructions to avoid damaging sensitive electronic components. This includes proper wiring and grounding for reliable operation. This careful approach minimizes the risk of electrical issues and ensures the system works as designed.

Another important consideration is the DEF injector’s placement in relation to the exhaust stream. Correct positioning maximizes the effectiveness of the NOx reduction process, which is key for optimal emissions control.

Real-World Challenges and Workarounds

Limited space in the engine compartment can be a major challenge when installing a DEF pump. Experienced installers often use creative solutions, such as flexible DEF lines or custom mounting brackets, to make the most of the available space.

The complexity of electronic integrations can also pose a challenge. Troubleshooting these systems requires a solid understanding of the vehicle's electrical system. Using diagnostic tools can greatly assist in identifying and resolving any issues.

Testing and Interpreting Performance Indicators

After installing the DEF pump, thoroughly test the entire system. Check for leaks, monitor the DEF flow rate, and verify the pump's pressure output. Pay attention to any warning lights or error codes, as these can indicate potential problems that need immediate attention.

It’s also important to understand the normal operating parameters of your DEF system. This allows you to quickly spot any deviations from the norm, enabling early diagnosis and preventing major malfunctions. Interestingly, the automotive fuel transfer pumps market, which includes diesel fuel pumps, is experiencing significant growth. Valued at USD 2.5 billion in 2024, it's projected to grow at a CAGR of 5.9% from 2025 to 2034, driven by the increasing demand for efficient fuel management systems. Learn more: https://www.gminsights.com/industry-analysis/automotive-fuel-transfer-pumps-market

By following these steps and proactively addressing potential challenges, you can ensure a successful DEF fuel pump installation that maximizes system performance, prevents costly repairs, and keeps your vehicle running smoothly.

DEF Fuel Pump Maintenance: Extending Life and Preventing Failures

Preventative maintenance is essential for keeping your DEF fuel pump running smoothly and reliably. It's the difference between trouble-free operation and expensive repairs. This section offers a practical maintenance schedule for real-world driving conditions, drawing on insights from fleet maintenance managers and diesel specialists. Before starting any DEF fuel pump installation, remember to use a drone pre flight checklist, a critical step for drone operations as well.

Recognizing Warning Signs and Diagnostic Procedures

Experienced mechanics can often spot subtle warning signs of DEF pump problems. These might include things like reduced flow, strange noises, or recurring system errors. Understanding these signs yourself can potentially save you a lot of money on repairs. Simple checks, like looking for leaks or monitoring the DEF flow rate, can help catch problems early. Early diagnosis is key to preventing bigger problems down the road.

The Importance of DEF Quality and Fluid Handling

The quality of your DEF has a direct impact on the life of your DEF fuel pump. Low-quality or contaminated DEF can cause corrosion and lead to early pump failure. Proper fluid handling is also critical. This includes using the right containers and following strict storage procedures. Contamination can happen during transfer or storage, so careful handling is a must.

Troubleshooting Common DEF Fuel Pump Issues

Reduced flow is a frequent problem with DEF pumps. This could be due to a clogged filter, a failing pump, or problems with the DEF injector. Unusual noises, like whining or grinding, could indicate problems with the pump's internal parts. System errors, often shown as warning lights or diagnostic codes, can point to a variety of issues. Learning to troubleshoot these common problems can help you address issues proactively. For more information, explore these additional resources about DEF fuel systems.

DIY Repairs vs. Professional Assistance

Knowing when to handle a repair yourself and when to call a professional is important. Some tasks, like changing a filter, are manageable with basic mechanical skills. But more complex problems, such as internal pump damage, require specialized knowledge and tools. Trying complex repairs without the right experience can worsen the damage. A qualified diesel mechanic should always handle these more involved repairs.

Practical Maintenance Schedule for DEF Fuel Pumps

Regular maintenance is key to getting the most life out of your DEF pump. Here’s a recommended schedule based on experience from fleet managers:

-

Every 10,000 miles: Inspect DEF lines and fittings for leaks, check the DEF filter, and look over the pump for any visible damage.

-

Every 25,000 miles: Replace the DEF filter, even if it looks clean. This prevents potential flow problems and pump damage.

-

Every 50,000 miles: Have a qualified diesel mechanic inspect the entire DEF system, including the pump, injector, and SCR catalyst. Professional inspections can uncover hidden issues.

-

Annually: Test the DEF quality to ensure it meets ISO standards. This protects against contamination and potential pump damage.

This schedule is a general guide. You might need to adjust it based on your specific driving conditions and the manufacturer's recommendations. Following a regular maintenance routine will maximize your DEF pump’s lifespan, reduce downtime, and contribute to the overall efficiency and reliability of your diesel vehicle.

Optimizing DEF Fuel Pump Performance in All Conditions

A DEF fuel pump does more than just function; it can be optimized for peak performance, boosting overall vehicle efficiency. This involves understanding how driving habits, environmental conditions, and monitoring techniques impact DEF consumption and system lifespan. Preventive maintenance is essential for DEF fuel pump upkeep.

Operational Habits and DEF Efficiency

How you drive significantly affects DEF usage. Aggressive driving, excessive idling, and frequent short trips can increase consumption. On the other hand, smooth driving and well-planned routes lead to more efficient DEF usage. This translates to lower costs and a smaller environmental impact.

Proper trip planning and load management can further enhance efficiency. Minimizing unnecessary weight and choosing optimal routes reduces fuel consumption, and consequently, DEF usage. This proactive approach maximizes the benefits of the Selective Catalytic Reduction (SCR) system.

Extreme Temperatures and DEF Pump Performance

Extreme temperatures present unique challenges for DEF fuel pumps. In freezing conditions, DEF can freeze, hindering pump operation and potentially causing damage. Conversely, extreme heat can accelerate DEF degradation, reducing its effectiveness and potentially shortening the pump's lifespan.

Proper DEF storage and handling are crucial in all climates. Insulated storage tanks and heated DEF lines prevent freezing in winter. During summer, store DEF in a cool, dry location away from direct sunlight to maintain its quality and prolong its shelf life.

Monitoring DEF Usage and Identifying Inefficiencies

Many successful fleet operators use monitoring systems to track DEF consumption. These systems provide valuable data on usage patterns, allowing for early identification of inefficiencies before they become major expenses. This data-driven approach enables informed decision-making and proactive maintenance.

For example, a sudden spike in DEF consumption could signal a leak, a faulty injector, or other problems requiring immediate attention. Addressing these issues promptly can prevent more extensive and costly repairs later. For more information, you can explore additional resources related to DEF fuel pump management.

DEF Delivery Precision and Fuel Economy

There's a direct correlation between precise DEF delivery and overall fuel economy. A properly functioning DEF fuel pump, delivering the exact amount of DEF needed by the SCR system, contributes to optimal combustion and lower fuel consumption.

A malfunctioning pump, however, disrupts this balance, resulting in increased fuel consumption and higher emissions. This highlights the importance of regular maintenance and prompt attention to any DEF fuel pump issues. Ensuring the DEF system operates at peak efficiency maximizes fuel economy and minimizes your environmental impact.

Avoiding Costly DEF Fuel Pump Mistakes and Misconceptions

Maintaining a healthy DEF fuel pump is crucial for modern diesel engines. But even experienced operators can fall victim to common misconceptions, leading to expensive repairs. This section, drawing on insights from diesel repair experts, addresses these misconceptions and offers practical advice for keeping your DEF system in top shape.

Common DEF Pump Misconceptions

One frequent misunderstanding is that all DEF is the same. This simply isn't true. Using low-quality or contaminated DEF can damage the entire system, including the pump. It's similar to using the wrong oil in your engine – a seemingly small mistake can have significant consequences. Another myth is that DEF doesn't expire. In reality, DEF degrades over time, especially with improper storage. Using expired DEF can reduce its effectiveness and potentially harm the pump.

Some operators mistakenly believe they can stretch their DEF by diluting it with water. This is a serious error. Water contamination is a leading cause of DEF pump failure. Even a small amount of water can corrode the pump's internal components, reducing flow, increasing emissions, and ultimately causing complete pump failure.

The Hidden Dangers of Installation Shortcuts

While professional installation is always recommended, understanding the potential problems of DIY installations can save you from costly errors. One common shortcut is using incompatible materials. For example, using standard steel fittings instead of stainless steel can introduce corrosion into the DEF system, damaging the pump.

Another risky shortcut is skipping proper testing after installation. This can lead to undetected leaks or flow rate problems, causing long-term damage to the pump and other SCR components. Incorrect pump placement, such as mounting it in a high-vibration area, can also drastically shorten its lifespan.

Contamination Risks and Regulatory Non-Compliance

Maintaining DEF purity is essential. Using improper storage containers, especially those previously used for other fluids, introduces contamination risks. Even seemingly clean containers can harbor residues that can damage the DEF fuel pump.

Trying to tamper with or bypass the DEF system to avoid using DEF is not only illegal but also harmful to the engine and the environment. Regulatory violations can result in significant fines, and the damage to the SCR system can lead to major repair bills.

Best Practices for Handling DEF and Maintaining Your DEF Fuel Pump

To avoid expensive mistakes, follow these best practices:

- Use high-quality DEF that meets ISO 22241 standards.

- Store DEF in dedicated, sealed containers designed for DEF storage.

- Regularly replace DEF filters as recommended by the manufacturer.

- Never dilute DEF with water or other substances.

- Regularly inspect the DEF system for leaks or damage.

- Have the DEF system professionally inspected and serviced at the recommended intervals.

Following these guidelines will ensure the long life and optimal performance of your DEF fuel pump, prevent costly repairs, and maintain regulatory compliance. Investing in proper DEF handling and maintenance pays off in the long run, ensuring the efficiency and reliability of your diesel engine.

Ready for hassle-free fueling and equipment protection? Visit CLiX Fueling Solutions for an innovative solution that eliminates spills and simplifies fueling. CLiX automatically stops the fuel nozzle when your tank is full, protecting your boat and the environment.