Let's be honest, nobody enjoys the "tip and pray" method of refueling. Wrestling with a heavy, sloshing gas can, trying to aim it just right into a small fuel tank opening, is a recipe for a messy, frustrating, and sometimes dangerous situation.

It’s an awkward dance we’ve all done—hoisting a 35-pound container, trying to keep it steady as the fuel glugs out unpredictably. More often than not, this clumsy process leads to spilled fuel. That's not just wasted money; it’s a hazard to the environment, a risk to your boat's finish, and a serious fire risk. Plus, all that lifting and awkward holding is just asking for a sore back.

A Smarter Way to Refuel

This is where portable gas cans with built-in pumps come in. They completely change the game by turning a dreaded chore into a simple, controlled task. Instead of relying on gravity and a bit of luck, you let a small but powerful pump do all the heavy lifting for you.

Think of it like this: would you rather try to pour a five-gallon bucket of water into a small bottle, or would you use a faucet? The pump acts like that faucet, giving you a steady, manageable flow that ensures the fuel goes exactly where you want it—in the tank.

The real magic is simple: you never have to lift a heavy, full gas can above the tank you're filling. Just set it on the dock or deck, place the nozzle in the tank, and push a button.

This move toward smarter fueling isn't just about convenience. It reflects a bigger shift in how we handle fuel for our boats, ATVs, and equipment. The demand for safer, more efficient methods is growing fast. The global market for mobile fuel pumps was valued at USD 3.4 billion in 2023 and is expected to hit USD 6.1 billion by 2033. You can discover more insights about the growing mobile fuel pumps market and what's driving this change.

This simple upgrade makes a world of difference:

- No More Spills: With a controlled flow and auto-stop features, the fuel stays in the tank, not on your deck or in the water.

- Zero Strain: Forget hoisting those heavy cans. This is a lifesaver, especially when fueling boats, generators, or tall equipment.

- Seriously Safer: Fewer spills mean a much lower risk of fire and less exposure to harmful fumes. The whole process just becomes safer for everyone.

Traditional Vs Pump-Equipped Gas Cans

To put it in perspective, let's break down the key differences between the old way and the new way. The advantages of a pump-equipped can become crystal clear when you see them side-by-side.

| Feature | Traditional Gas Can | Gas Can With Pump |

|---|---|---|

| Fuel Transfer | Requires lifting and tipping the entire can (gravity-fed) | Pump transfers fuel through a hose; no lifting required |

| Spill Risk | High, due to glugging, poor aim, and overfilling | Very low, thanks to controlled flow and auto-shutoff |

| Physical Effort | High, can cause back and muscle strain | Minimal, involves holding a lightweight nozzle |

| Flow Control | Poor and unpredictable | Precise and steady, with on/off controls |

| Safety | Increased risk of fire, slips, and fume exposure | Significantly safer with reduced spills and fumes |

| Speed & Efficiency | Slow and often wasteful due to spillage | Faster, cleaner, and more efficient transfer |

As you can see, making the switch is less of an upgrade and more of a common-sense evolution in how we handle fuel. It's about working smarter, not harder, and keeping yourself and the environment safer in the process.

How Different Pump Mechanisms Actually Work

Ever wondered what's going on inside those pumps? It's not rocket science, but understanding the simple mechanics at play can really help you appreciate why a portable gas can with a pump is such a game-changer. Each design takes a slightly different approach to turn a frustrating chore into a quick, clean task.

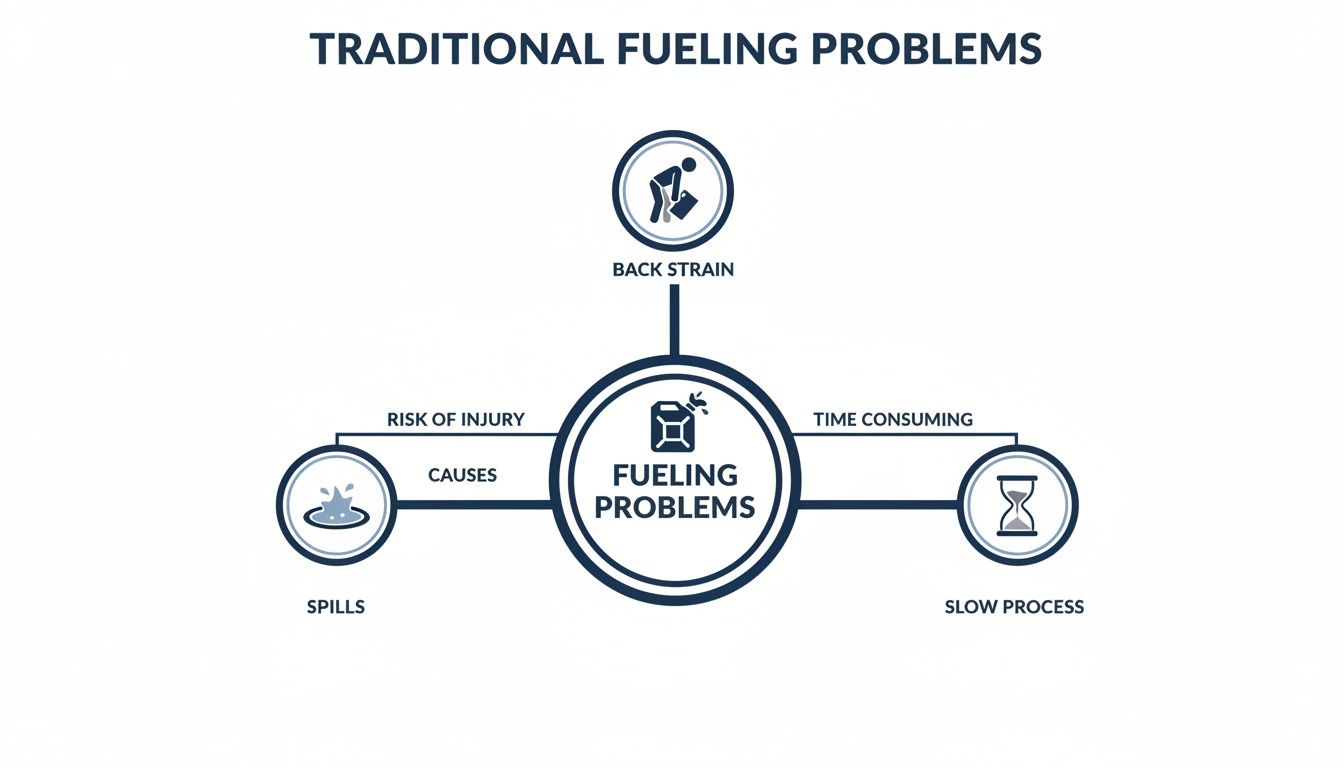

At the end of the day, all these pumps are designed to solve the same old problems: spilling fuel, straining your back, and that painfully slow "glug-glug-glug" of a traditional can. This diagram really brings those common headaches to life.

As you can see, a simple pump is the perfect answer. It gives you control, saves you from hoisting a heavy can, and delivers a smooth, steady stream of fuel. Let's break down how each type pulls it off.

The Manual Siphon Pump: A Lesson In Gravity

The manual siphon pump is the simplest of the bunch. If you've ever used a straw, you already understand the basic principle. You give it a little help to get started, and physics does the rest.

To kick things off, you usually squeeze a primer bulb or work a small hand pump a few times. That initial action pulls fuel up into the hose, and once it crests the highest point and starts heading down into your tank, gravity takes over and keeps the fuel flowing all on its own.

- Best For: Occasional use with smaller engines (think lawnmowers or dinghies) or as a foolproof backup that doesn't need batteries.

- Typical Flow Rate: It's the slowest option, typically moving about 1-2 gallons per minute (GPM).

- How it Works: Uses gravity and an initial bit of suction to move liquid from a higher container to a lower one.

Because there's no motor, these pumps are incredibly lightweight and dependable. The big catch, though, is that the fuel can has to be sitting higher than the tank you're filling, which can sometimes defeat the whole purpose of avoiding heavy lifting.

The Battery-Powered Pump: Automated Convenience

This is where things get really easy. A battery-powered pump basically puts a tiny, automated fuel pump right in your hands. Instead of fighting with gravity or pumping by hand, a small electric motor does all the heavy lifting for you.

Inside the pump is a small, fan-like part called an impeller. When you flip the switch, a set of common batteries (usually D-cells) powers the motor, spinning the impeller at high speed. This creates powerful suction that actively pulls fuel out of the can and pushes it through the hose into your tank.

The active pumping is what makes all the difference. Unlike a siphon, a battery-powered pump couldn’t care less about gravity. You can leave that heavy 5-gallon can flat on the dock and effortlessly send fuel up into your boat.

This technology is also finding its way into tougher environments. In construction and farming, for example, similar pumps run on higher voltages or connect directly to vehicle batteries to dispense fuel on remote job sites. It’s no surprise that portable models are seeing the most growth in the market, valued for their get-it-done-anywhere flexibility.

The Manual Crank Pump: Simple Mechanical Advantage

Splitting the difference between a simple siphon and a battery-powered model is the manual crank pump. This style uses a hand crank connected to gears, turning your effort into pumping power. As you turn the handle, it spins a rotor inside the pump, drawing fuel in and forcing it out the nozzle.

Picture a hand-cranked winch or an old-fashioned meat grinder—your simple cranking motion is converted into surprisingly strong suction. It definitely takes more work than just flipping a switch, but it gives you more control and a much faster flow rate than a basic siphon. For a closer look at why a motor can be a huge upgrade, you might want to read our guide on the advantages of a gas can with an electric pump.

This design is a rock-solid choice if you want more oomph than a siphon can offer but prefer not to rely on batteries.

Critical Fueling Safety For Boaters

Fueling a boat on the water isn’t anything like filling up your car at the gas station. On land, you're on solid, stable ground. Out on the water, you're dealing with constant motion, open air, and the very real risk of spilling fuel directly into the environment.

The biggest danger, though, is invisible. Gasoline vapors are heavier than air. They don't just blow away; they sink and can collect in the lowest parts of your boat, like the bilge. This creates a hidden, highly explosive pocket of fumes just waiting for a spark.

That's why getting your fueling routine right isn't just a good idea—it's one of the most important responsibilities you have as a boat owner. A good portable gas can with a pump makes the job much safer, but the basic rules of handling fuel never change.

The Right Way To Fuel Your Boat

Let's walk through the textbook example. You’ve just tied up at the dock after a great morning out. First things first: everyone gets off the boat. Next, you shut all the hatches and ports to stop any fumes from getting inside, and you kill any potential ignition sources—no cigarettes, no galley stoves, nothing.

Your portable gas can is sitting securely on the dock, not rocking around on the boat. Before you even open the fuel cap, you touch the nozzle to the metal fuel deck fill to get rid of any static electricity. With a spill pad in place, you start fueling. The pump gives you a nice, steady flow, and its auto-shutoff feature means there’s zero chance of an overfill.

Once you’re done, you wipe up any small drips, open everything back up, and run the bilge blower for at least five minutes to air things out. Only then, after you're sure it's safe, do you start the engine. This careful, unhurried process is the gold standard.

The Wrong Way: A Recipe For Disaster

Now, let's look at the flip side. A boater is in a hurry and starts refueling with people still on board. The gas can is balanced on a seat, and they jam the nozzle in without grounding it. An invisible spark of static electricity—something you’d never even notice—jumps from the nozzle to the fill opening.

Poof. The gasoline vapors ignite. Because the hatches were left open, fumes had already crept into the cabin, turning a small flare-up into a full-blown fire. This entire nightmare is completely avoidable just by following a simple safety routine.

Every year, boat fires and explosions cause millions of dollars in damage and lead to serious injuries. A huge number of these disasters are tied directly to someone cutting corners while fueling. Respecting the fuel is the first rule of boating safety.

Your Marine Fueling Safety Checklist

To make sure you get it right every time, commit this checklist to memory. Run through these steps every single time you refuel from a portable can.

- Moor Securely: Tie your boat firmly to the dock so it doesn't drift.

- Unload Passengers: Get everyone off the boat and onto the dock.

- Extinguish Everything: Turn off engines, electronics, and any open flames.

- Seal The Boat: Close all hatches, ports, and cabin doors.

- Ground Yourself: Touch a metal part of the boat or dock before you touch the fuel can.

- Use Spill Pads: Place an absorbent pad around the fuel inlet to catch drips.

- Keep Nozzle Contact: Make sure the fuel nozzle stays in contact with the fill pipe to prevent static buildup.

- Ventilate Thoroughly: When done, open all hatches and run the bilge blower for four to five minutes.

- Perform a Sniff Test: Before starting the engine, do a quick check in the bilge and cabin for any fuel smell.

Following these steps protects you, your passengers, your boat, and the marine environment. While this covers fueling, it's always good to brush up on general boating safety guidelines to stay sharp on the water. To learn more about different fueling containers, check out our deep dive on choosing a pump gas can for your boat.

Alright, we know how these pumps work in theory. Now let’s get practical and talk about what separates a great gas can pump from a frustrating piece of plastic.

Choosing the right one isn't just about grabbing the first thing you see on the shelf. It’s about matching the right tool to your specific needs so that every refueling is quick, clean, and—most importantly—safe.

Think of it like buying any other important piece of gear. The little details make all the difference, turning a chore into a seamless task. If you focus on build quality, performance, and safety, you’ll end up with a reliable workhorse that will serve you well for years.

Build Quality And Durability

A good pump starts with solid bones. It needs to handle the occasional bump or drop and live in a world of gasoline without falling apart. The can itself should be made from high-density polyethylene (HDPE), a tough-as-nails plastic that won’t degrade or get brittle from fuel exposure.

Pay close attention to the seals around the pump housing and caps. A weak seal is a ticking time bomb for leaks, letting dangerous fumes escape and fuel seep out. Hoses should be thick and resilient, not flimsy, to prevent them from kinking up or cracking over time.

Performance And Flow Rate

When it comes to performance, the magic number is the flow rate, measured in gallons per minute (GPM). This tells you exactly how fast the pump moves fuel from the can to your tank. Faster isn't always better; the right GPM really depends on what you're filling.

- High Flow Rate (3+ GPM): This is for the big jobs, like filling a large boat tank or an RV. When you need to move a lot of fuel quickly, a high GPM is your best friend, filling a 20-gallon tank in under seven minutes.

- Moderate Flow Rate (2-3 GPM): This is the sweet spot for most people. It's quick enough for most tasks but still offers enough control for filling smaller tanks on things like generators or ATVs.

- Low Flow Rate (1-2 GPM): Ideal for small equipment where you need precision over speed. Think lawnmowers, dinghy outboards, or anything where a powerful gush of fuel would just make a mess.

Another huge factor is hose length. A longer, more flexible hose is a lifesaver. It lets you set the heavy gas can down on the dock or the ground and still comfortably reach that awkwardly placed fuel port on your boat. You’ll want at least a few feet of hose to work with.

Crucial Safety Innovations

Modern safety features are completely non-negotiable. They turn what could be a hazardous job into a simple, controlled process. The single most important innovation here is the auto-shutoff nozzle. It works just like the handle at a gas station, automatically sensing when the tank is full and cutting the flow.

This feature didn't just appear out of nowhere; it’s a direct result of a push for greater safety and environmental protection. Regulations brought in since 2015 have helped cut down on fuel spills by an estimated 40%. The whole industry is moving this way, and you can discover more insights about the fuel transfer pump market to see where things are headed.

An auto-shutoff feature is your best defense against overfills. It takes the guesswork out of the equation and prevents those costly, dangerous spills that can ruin your boat's finish and pollute the water.

Besides the nozzle, fuel compatibility is another critical safety check. Always, always double-check that the pump is rated for the type of fuel you’re using. Trying to pump gasoline with a diesel-only unit is a recipe for disaster, as its materials and motor aren't built to handle the higher volatility of gasoline.

Here's a quick checklist to keep in mind:

| Feature Category | What To Look For | Why It Matters |

|---|---|---|

| Construction | Durable HDPE plastic, strong seals, and thick hoses. | Ensures the unit lasts and prevents dangerous leaks or cracks. |

| Performance | The right GPM for your needs and a long, flexible hose. | Matches the pump's speed to your task and makes reaching fuel ports easy. |

| Safety | Auto-shutoff nozzle and a clear fuel compatibility rating. | Prevents messy overfills and ensures the pump can safely handle your fuel. |

By prioritizing these key features, you aren't just buying a gadget. You're investing in a safer, cleaner, and way more efficient method for handling one of the most common tasks any boat owner faces.

Navigating Marina Rules And Fuel Regulations

Handling fuel safely is more than just a good idea—it's the law. The moment you bring gasoline or diesel near the water, you enter a world of strict regulations designed to protect people, property, and the marine environment. Skirting these rules can lead to some serious fines, but more importantly, it puts everyone at risk.

These rules aren't just red tape. They've been carefully developed by agencies like the U.S. Environmental Protection Agency (EPA) and the U.S. Coast Guard to prevent fires and devastating fuel spills. This means any portable gas can you use for your boat has to meet their demanding standards for construction and safety features.

Understanding Federal Fuel Container Laws

Remember those old, simple vented gas cans? Their time has passed. Today, federal regulations require that any portable fuel container sold in the U.S. must have specific features to cut down on spills and the release of harmful vapors. This is why checking for compliance labels is so crucial.

When you're shopping for a portable gas can with a pump, keep an eye out for these key certifications:

- EPA Compliant: This is your assurance that the can meets federal standards for preventing hydrocarbon vapors from escaping and polluting the air.

- CARB Compliant: The California Air Resources Board (CARB) has even tougher regulations. A CARB-compliant can is often considered the best you can get, usually featuring advanced spill-proof nozzles and vapor-locking seals.

- U.S. Coast Guard Approved: This one is non-negotiable for boaters. The USCG sets specific requirements for materials and design to make sure the can can handle the rough-and-tumble marine environment without failing.

A compliant can is far more than just a plastic jug; it's a vital piece of safety equipment. These certifications guarantee it's made from the right stuff, won't leak dangerous fumes, and is designed to prevent spills when you're moving it around or fueling up.

When Marinas Have Their Own Rules

On top of federal laws, the marina where you keep your boat operates like its own little community with its own set of rules. Marina managers are on the hook for the safety of every person and boat at their docks, and they don't mess around when it comes to fuel. Ignoring their policies can easily get you a fine or, in some cases, kicked out for good.

While policies can vary from one place to the next, a few rules are pretty much universal. They're all designed to manage the inherent risks of handling flammable liquids in a busy, water-based environment.

Here are a few common marina-specific fueling policies to expect:

- Designated Fueling Zones: Most marinas will only allow you to refuel at their dedicated fuel dock. This strategy helps contain any spills and ensures their trained staff is right there to handle an emergency.

- No Dockside Refueling from Cans: Some facilities flat-out prohibit filling up your boat from a portable can while it's in a slip. They'll insist you use their on-site fuel pumps instead.

- Spill Prevention Requirements: Even if they do allow you to use your own can, they will almost certainly make you use absorbent pads or a boom around your boat's fuel inlet to catch every last drop.

The bottom line? Always check the rules before you start pumping. A quick chat with the marina office or a look at the dockside signage can save you a world of headaches. Showing up with a high-quality portable gas can with a pump and an auto-shutoff feature demonstrates you’re serious about safety—something marina staff will always notice and appreciate.

Simple Maintenance and Troubleshooting Tips

Even the best gear needs a little TLC to keep working right, and your portable gas pump is no exception. A few minutes of simple, preventative care can save you from a major headache out on the water. Think of it as part of your regular boating routine—a quick check to make sure your pump is ready for a fast, clean, and safe refueling every time.

Taking care of your pump is easy. By looking over a few key parts now and then, you'll catch small problems before they become big ones, extending the life of your equipment and ensuring it's always ready when you need it.

Routine Maintenance Checklist

A simple, consistent routine is the best way to prevent surprises. Take a couple of minutes to run through these checks after every few uses, or at the very least, at the start of each boating season.

-

Inspect Hoses and Seals: Run your fingers along the hoses, feeling for any cracks, kinks, or stiff, brittle spots. A tiny crack can introduce air and kill your suction. Don't forget to check the seals on the caps and pump housing to make sure they're soft and creating a tight fit.

-

Clean the Intake Filter: Look at the end of the intake hose—most pumps have a small screen or filter there. It’s designed to catch gunk from the bottom of your fuel can, but it can get clogged and slow down the flow. Just pop it off and give it a quick rinse.

-

Check Battery Contacts: If you have a battery-powered pump, open up the compartment and take a look at the metal contacts. Any green or white corrosion? A pencil eraser or a dry cloth will scrub it right off and give you a solid connection again.

Proper off-season storage is a game-changer. If you're packing the pump away for a few months, either add a good fuel stabilizer to the gas or, even better, run the can and pump completely dry. This stops old fuel from turning to varnish and gumming up the works.

Quick Troubleshooting Guide

So your pump isn't working right. Don't sweat it. The fix is usually incredibly simple and takes less than a minute to figure out.

Problem: Pump Won't Start

You flip the switch and... nothing. Before you assume the motor is shot, check the batteries. Seriously. Make sure they're in correctly, and if you have any doubt, just swap in a fresh set. This one easy step fixes the issue 90% of the time.

Problem: Weak or Slow Fuel Flow

The motor is humming along, but the fuel is barely trickling out. This almost always points to either a blockage or an air leak. First, check that little intake filter for clogs. If it looks clean, run your eyes and hands over the hoses again, looking for tiny cracks or a loose fitting. Even a pinhole leak is enough to ruin the pump's suction.

For a deeper dive into how these pumps work, our complete boat fuel pump guide has tons of great info on selection and maintenance.

Problem: Pump Runs But Won't Prime

You can hear the motor whirring away, but zero fuel is moving. The pump just can't get that initial "grab" of the fuel. The most common culprit? The intake hose isn't deep enough in the gas. Just turn the pump off, push the hose all the way to the bottom of the can, make sure there are no kinks, and fire it up again. That usually does the trick.

Frequently Asked Questions

Even after getting the hang of these pump cans, a few common questions always seem to come up. Let's tackle them head-on with some straight-to-the-point answers to help you stay safe and get the most out of your gear.

Can I Use The Same Pump For Gasoline And Diesel?

This is a big one, and the answer is almost always no. You have to check what the manufacturer says, but mixing and matching is a recipe for disaster.

Most pumps are built for one fuel type and one fuel type only. Gasoline is incredibly volatile—its vapors are just waiting for a spark. Trying to use a pump designed for diesel with gasoline is asking for trouble. Pumps made for gasoline have special spark-resistant materials and electronics for a reason. Bottom line: always use a pump that's explicitly approved for the fuel you're handling.

How Fast Do These Pumps Actually Transfer Fuel?

The speed really depends on the pump you've got. It can be the difference between a quick top-off and a long, tedious job.

- Manual Siphon Pumps: These are the slowest of the bunch, usually moving about 1-2 gallons per minute (GPM).

- Battery-Operated Pumps: These are a game-changer. You'll see speeds anywhere from 2.5 to 5 GPM, making them much more practical.

A higher GPM is a lifesaver when you're filling a big boat tank. For smaller jobs like a generator, a slower GPM can give you a bit more control to prevent splashing.

Are The Auto-Shutoff Features Reliable?

For the most part, yes. On pumps from good, reputable brands, the auto-shutoff works just like the one at the gas station. It senses the back-pressure when the tank is full and cuts the flow.

But don't trust it blindly. Things like the angle of the nozzle or a really fast flow rate can sometimes trip it up. It’s always smart to visually monitor the fueling process and be ready to stop it yourself. Think of the auto-shutoff as a great backup, not a replacement for paying attention.

What Is The Best Way To Store My Gas Can And Pump?

Storing your gear correctly is key for safety and making sure it lasts. Keep the can in a well-ventilated spot—like a shed or garage that isn't attached to the house—and keep it out of direct sunlight or away from heat sources.

If you're storing it for a while, either add a good fuel stabilizer to the gas or run the can completely dry. Old fuel breaks down and leaves behind a gunky varnish that can clog up the pump's insides. And of course, always triple-check that the caps and vents are screwed on tight to keep vapors from escaping.

Tired of the stress and mess of traditional fueling? CLiX Fueling Solutions offers a smarter, spill-free way to refuel your boat. Our system automatically stops the fuel flow when your tank is full, protecting your boat, your wallet, and the environment. Experience the peace of mind that comes with a perfect fill-up every time. Learn more about our innovative fueling solutions.