Choosing the right diesel exhaust fluid storage tanks is about more than just checking a compliance box—it's a direct investment in your vessel's performance and the long-term health of its engine. In a marine setting, proper storage is absolutely non-negotiable. Why? Because Diesel Exhaust Fluid (DEF) is incredibly sensitive to contamination and temperature changes, which can wreck your Selective Catalytic Reduction (SCR) system.

Why Your Marine DEF Storage Solution Matters

At its core, DEF seems simple, but its chemical balance is fragile. This solution is easily ruined by two major culprits at sea: temperature swings and contamination. If you don't store it right, its effectiveness tanks, putting your engine and your entire emissions system in jeopardy.

The challenges are unique out on the water. Constant exposure to salty air can corrode the wrong kind of tank material, leaching harmful gunk straight into your DEF. Likewise, a long voyage through warm tropical waters can cook the fluid past its optimal temperature, causing it to break down into ammonia and lose its power.

The Composition of Diesel Exhaust Fluid

The power of DEF comes from its precise chemical recipe. The right diesel exhaust fluid storage tanks are designed to protect this sensitive mix of 32.5% urea and 67.5% deionized water. The shelf life and performance of DEF depend entirely on keeping it clean and at the right temperature, which is why tanks made from materials like stainless steel or high-density polyethylene are essential.

Contamination isn't just about obvious things like dirt or rust. Even tiny, unseen impurities can crystallize and clog the delicate parts of an SCR system. This can lead to eye-watering repair bills and serious downtime. A small oversight in storage can have massive consequences down the line.

A purpose-built marine DEF tank isn't a luxury; it's a necessity. It protects your engine, ensures you remain compliant with emissions laws, and prevents the kind of system failures that can leave you stranded.

Real-World Consequences of Poor Storage

The visual below really drives home why maintaining that specific 32.5% urea concentration is so important, especially when it comes to temperature.

This chart shows that the standard DEF mixture has the lowest possible freezing point at 12 °F (-11 °C). Deviate from that concentration, and it will freeze much sooner, making it far less resilient in cold climates.

Ultimately, poor storage doesn't just degrade the fluid. It hits your vessel's reliability and your bottom line. And while you're focused on proper storage, it's also smart to be prepared for the worst. Knowing the correct diesel fuel spill cleanup procedure is a fundamental part of responsible vessel operation.

Selecting The Best Tank Material And Type

Picking the right material for your DEF tank is one of the most critical calls you'll make. Out on the water, with constant salt spray and moisture, the tank material is your first line of defense in protecting DEF purity and the health of your expensive SCR system. For marine use, it really boils down to two main players: high-density polyethylene (HDPE) and stainless steel.

Each has its pros and cons, and the right answer for your vessel will depend on how you use it and what your budget looks like.

High-Density Polyethylene (HDPE) Tanks

HDPE is a tough, specialized plastic that’s become incredibly popular, and for good reason. For most recreational boats and smaller commercial craft, HDPE tanks hit a sweet spot between performance and price. They are completely immune to rust and corrosion from saltwater—a massive advantage at sea.

Another big plus is their weight. HDPE tanks are much lighter than steel ones, which can make a noticeable difference in fuel economy and handling on smaller vessels where every pound counts. They also tend to be the more wallet-friendly option upfront.

Stainless Steel Tanks

When you get into heavy-duty commercial operations or long-haul voyages, stainless steel tanks are often the go-to. Their main selling point is raw strength. On a busy commercial fishing boat or a freighter where gear gets banged around, the sheer durability of steel is invaluable.

Sure, they're heavier and carry a higher price tag, but stainless steel provides the ultimate protection against contamination and is built to last a lifetime. Its non-porous surface is also a breeze to clean, helping you keep your DEF in perfect condition. This focus on durable, corrosion-resistant materials is a core principle for all onboard fluid systems, a topic we dive into deeper in our guide to choosing the right boat fuel tanks.

Expert Tip: If you go with stainless steel, don't just get any kind. Make sure it's grade 304 or, even better, 316. These specific grades have the right mix of chromium and nickel to stand up to the relentless abuse of a saltwater environment.

To make the choice a bit clearer, let's break down how these two materials stack up against each other.

Marine DEF Tank Material Comparison

Here's a side-by-side look at HDPE and stainless steel, focusing on the factors that matter most for a marine environment.

| Feature | High-Density Polyethylene (HDPE) | Stainless Steel | Best For |

|---|---|---|---|

| Corrosion Resistance | Excellent; completely immune to rust. | Excellent; especially grades 304/316. | Both are great, but HDPE is inherently inert. |

| Weight | Lightweight, ideal for smaller vessels. | Heavy, adding significant weight. | Vessels where weight management is a priority. |

| Durability | Good, but can be punctured by impact. | Exceptional; highly resistant to damage. | Demanding commercial or industrial settings. |

| Cost | Lower initial investment. | Higher upfront cost. | Budget-conscious builds or recreational use. |

| Typical Application | Recreational boats, weekend cruisers. | Commercial vessels, superyachts. | Matching the tank to the vessel's mission. |

This table should give you a solid framework for deciding which material aligns best with your vessel's needs and operational demands.

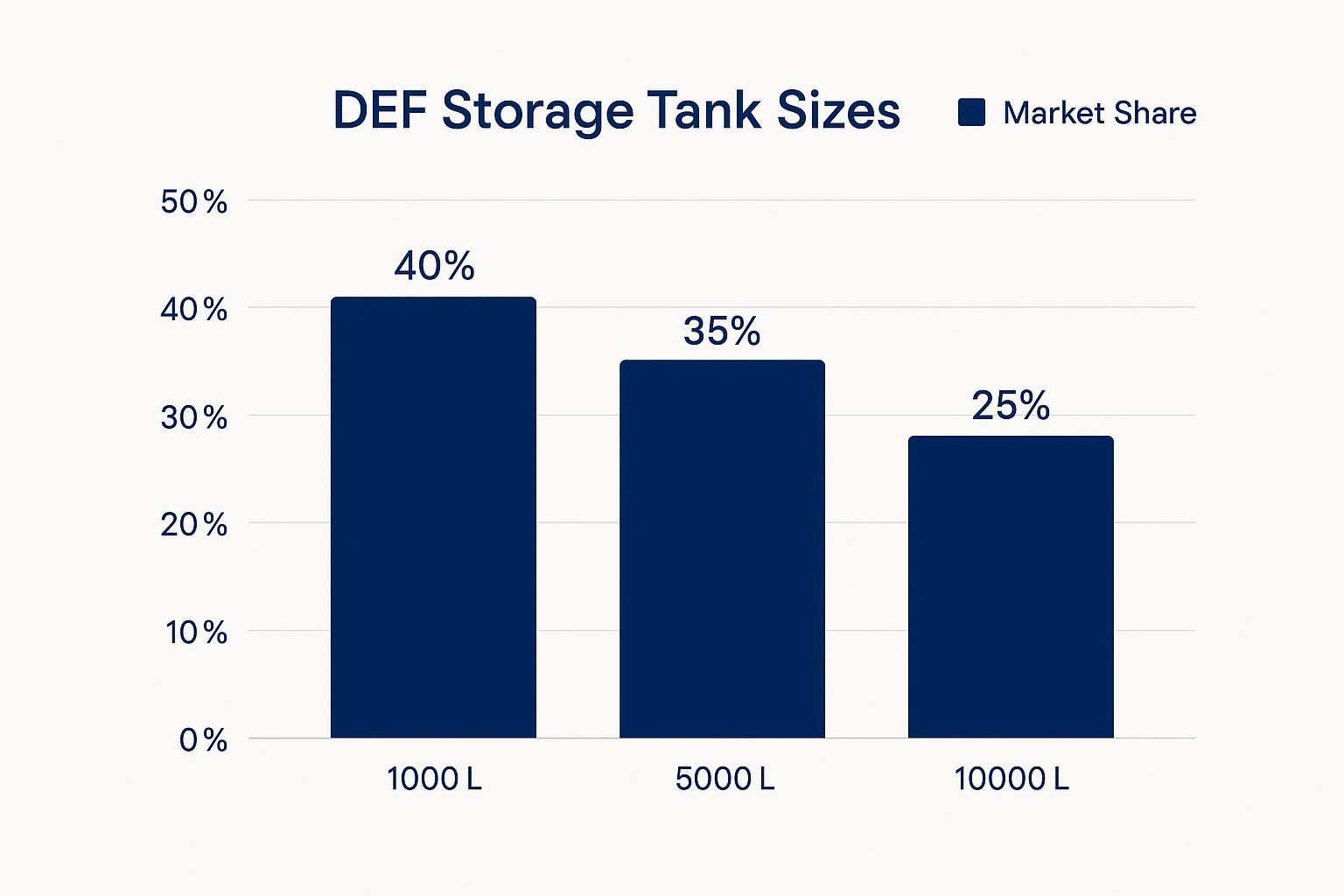

Looking at the commercial market, it's interesting to see how sizing preferences play out. There’s a clear trend toward mid-range capacities that offer a good balance of volume and physical footprint.

As you can see, the 1,000 L tank is the most popular, capturing 40% of the market. It’s a versatile size that works for a wide range of commercial applications without taking up excessive deck space.

How to Size Your DEF Tank Correctly

Picking the right size for your diesel exhaust fluid storage tanks is a classic Goldilocks problem. Go too small, and you're constantly worried about refilling, or worse, running out when you're miles from shore. Go too big, and you're stuck with hundreds of gallons of DEF that could expire before you even use it.

The goal is simple: match your tank capacity to what your vessel actually uses. This way, you always have a fresh supply without the hassle of constant top-offs.

Calculating Your DEF Consumption

Let's skip the complicated math. Out on the water, we rely on a solid rule of thumb: your DEF consumption will be about 2% to 5% of your diesel fuel consumption.

Where you fall in that range depends on your engine and how you run it. Newer, high-performance engines tend to be thirstier, landing closer to the 5% mark. Older or more efficient models will likely hover around 2%.

Let's walk through a real-world example. Say you run a charter yacht that burns through 1,000 gallons of diesel on a typical week-long trip.

- Low-end DEF use (2%): 1,000 gallons x 0.02 = 20 gallons of DEF

- High-end DEF use (5%): 1,000 gallons x 0.05 = 50 gallons of DEF

Just like that, you have a realistic range. For this vessel, you're looking for a tank somewhere between 20 and 50 gallons to cover a standard excursion.

Factoring in a Safety Buffer

Once you know your baseline, it’s time to plan for the unexpected. The sea doesn't always cooperate. Rough weather can make your engines work harder, or a last-minute change of plans could extend your voyage. You need a cushion.

A smart move is to add a 20% safety buffer to your highest consumption estimate. This gives you peace of mind without weighing you down with DEF you'll never use.

Let's apply this to our charter yacht example, which had a maximum consumption of 50 gallons:

50 gallons x 0.20 = 10 extra gallons

Total needed capacity: 60 gallons

This straightforward approach gets you a tank size that’s just right for your vessel's real-world needs. For smaller boats used for day trips, a portable tank is often more than enough. The same sizing principles apply, which you can see in our discussion on the 10-gallon diesel fuel container.

The need for DEF isn't going away—it’s growing. With stricter environmental laws and more modern diesel engines hitting the water, the market for DEF was valued at USD 34.4 billion in 2022. This huge number, which you can read more about in this report on the expanding DEF market on verifiedmarketresearch.com, just highlights how essential it is to have a reliable, correctly sized storage solution on board.

A Practical Guide to Tank Installation and Placement

A top-of-the-line DEF tank is worthless if it's installed poorly. Where you decide to put your diesel exhaust fluid storage tanks is just as critical as the material it’s made from. Putting it in the wrong spot can expose the fluid to engine heat, direct sunlight, or constant vibration—all things that will degrade its quality and put your SCR system’s health at risk.

Getting the installation right from the start saves you from some massive headaches down the road. It’s all about creating a stable, cool, and secure environment where the DEF can stay pure and effective.

Finding the Right Home for Your DEF Tank

The best spot for your tank is a cool, dry, and well-ventilated area, shielded from the elements. I'm talking about places like a dedicated storage locker, a protected lazarette, or a section within the hull that doesn't experience wild temperature swings. The main goal here is to keep the DEF within its happy place, temperature-wise, which is between 12°F (-11°C) and 86°F (30°C).

On the flip side, some locations are completely off-limits.

- Never install a tank in the engine room. The high ambient heat will cook the DEF, causing it to break down into ammonia way too quickly.

- Avoid areas with direct sunlight exposure. UV rays can compromise both the tank material (especially if it's HDPE) and the fluid inside.

- Steer clear of spots with excessive vibration. While some vibration on a boat is unavoidable, mounting the tank right next to heavy machinery can stress the fittings and eventually cause leaks.

As you plan the installation, it's a smart move to develop a comprehensive emergency response plan just in case you have a DEF spill or system failure. Thinking ahead means you're prepared for anything.

Marine Tech Insight: So many system failures I've seen trace back to poor placement. It's common to see tanks squeezed in right next to an engine room bulkhead. It might save a little space, but the constant heat transfer effectively cooks the DEF, leading to premature SCR failure. Don't make that mistake.

Securing the Tank for Rough Seas

The marine environment is anything but static, and your tank installation has to be tough enough to handle rough seas. A loose tank is a serious hazard. It can cause major damage to your vessel and create a dangerous spill you don't want to deal with.

Secure mounting is simply non-negotiable. Use heavy-duty, corrosion-resistant straps or brackets to anchor the tank firmly to a solid structural part of the vessel, like a stringer or bulkhead. Make sure all the mounting hardware is stainless steel to fend off corrosion. The tank should be completely immobile—no room to shift, slide, or bounce, even when the vessel is pitching and rolling in heavy seas.

Your Pre-Launch Installation Checklist

To sidestep the common pitfalls, run through a clear checklist. This is the best way to make sure you've covered all the bases for a safe and effective setup.

- Confirm Hose Compatibility: Only use hoses and fittings specifically rated for DEF. If you try to use standard fuel or water lines, you're guaranteed to contaminate the fluid.

- Use a Dedicated Pump: Never, ever use a pump that has handled other fluids like diesel, oil, or coolant. Cross-contamination is one of the fastest ways to kill an expensive SCR system.

- Check the Ventilation: Make sure the tank’s vent line is clear and positioned where it can’t take on seawater or rain. A clogged or poorly placed vent is a recipe for trouble.

- Seal Every Connection: Go back and double-check that all fittings, caps, and seals are totally airtight. This keeps moisture and airborne contaminants from getting in and compromising your DEF.

Following these steps will help ensure your diesel exhaust fluid storage tanks are installed for maximum reliability and a long service life, ultimately protecting your investment and keeping your vessel running smoothly.

Essential Maintenance for DEF Quality and System Health

Alright, your DEF tank is installed and ready to go. Now, the real work begins: keeping it that way. Proper upkeep isn't just a suggestion; it’s the only way to protect your engine's highly sensitive SCR system from some very expensive problems.

Think of it this way: a few minutes of prevention are worth far more than a week in the repair yard. Building a simple, repeatable maintenance routine is your best defense against contamination and system failure.

Your Regular Inspection Checklist

Before you head out, get in the habit of doing a quick walk-around of your tank setup. Your own eyes are the best tool you have for spotting issues before they escalate. This shouldn't take more than a few minutes, but it can save you a world of trouble down the line.

Here’s what to look for every time:

- Scan for Leaks: Give all the fittings, hoses, and the tank body itself a close look. Are there any drips, wet spots, or white, crusty residue? Even a tiny leak can let contaminants in and drain your tank surprisingly fast.

- Check the Seals: Is the filler cap on tight? A loose cap is basically a welcome mat for humidity, salt spray, and dust to contaminate your DEF.

- Glance at the Fluid: If your tank allows, check the DEF itself. It should look as clear as water. If you spot any cloudiness, discoloration, or tiny crystals floating around, that's a major red flag that something is wrong.

If you notice your DEF level dropping but can't find the source, you might have a slow, sneaky leak. For that, it’s often best to call in professionals. Specialized leak detection and repair services can pinpoint the problem and give you confidence that your system is sealed tight.

Best Practices for Refilling and Handling

Most contamination issues happen during a refill. It only takes one dirty funnel or a hose that was used for something else to ruin a whole tank of good DEF. This is one area where you can't cut corners.

Always—and I mean always—use dedicated, sealed equipment just for DEF. Never, ever use a container, funnel, or pump that has touched diesel, oil, coolant, or anything else.

Pro Tip: Before you even twist off the fill cap, wipe down the area around it. This dead-simple step prevents any dust or grime sitting on the surface from falling straight into your tank.

Temperature is another huge factor. In hot climates, make sure your tank is insulated or shielded from direct sun to keep the DEF below its 86°F (30°C) sweet spot. For those in colder regions, if temperatures are going to drop below 12°F (-11°C), an integrated tank heater isn't a luxury—it's essential to stop the fluid from freezing and potentially damaging the system.

Finally, remember that DEF has a shelf life. It doesn't last forever. I always recommend grabbing a marker and writing the fill date on the tank. Use a first-in, first-out system to make sure you're always using fresh, potent fluid to keep that engine happy.

Common Questions About Marine DEF Storage Tanks

Even with a solid plan, new systems on a vessel always bring up a few questions. When it comes to diesel exhaust fluid storage tanks, I find the same concerns tend to surface time and again. Let's tackle them head-on so you can feel confident managing your DEF system.

How Long Can I Store DEF in My Tank?

This is easily the most common question I get, and the answer comes down to one thing: temperature. Under ideal conditions—kept below a steady 86°F (30°C)—DEF can last up to two years. But let's be honest, that's not the reality for most marine environments.

The heat really chews through its shelf life. A good rule of thumb is that for every 10°F rise above that 86°F mark, the lifespan of your DEF gets cut in half. If you're running a vessel in the Caribbean where it's always hot, you might only get a few months out of a batch.

Here’s a quick breakdown of what to expect:

- Below 86°F (30°C): Up to 2 years

- At 95°F (35°C): Roughly 6 months

- Above 100°F (38°C): 2-3 months, max

My best advice? Treat DEF like you would any other perishable. I always recommend clients aim to use their supply within six months to a year, just to be safe. That way, you know your SCR system is getting fresh, effective fluid every time.

What Happens If My DEF Freezes?

This is a frequent worry for those operating in colder waters, but the solution is thankfully simple. DEF starts to freeze around 12°F (-11°C). As it solidifies, it expands by about 7%, but here's the good news: freezing doesn't damage the fluid's quality at all.

Once it thaws out, your DEF is good to go, with its concentration and effectiveness fully intact. Modern marine SCR systems are built for this. They almost always come equipped with tank heaters to keep the fluid in a liquid state and ready for action, no matter how cold it gets. The most important thing is to let it thaw naturally—never add any anti-gelling agents or chemicals to try and speed up the process.

Can I Top Off a Partially Full DEF Tank?

Yes, absolutely. You can and should top off your DEF tank whenever you have the chance. Unlike some other fluids, there’s no need to wait until it's nearly empty.

In fact, keeping the tank closer to full is a great habit to get into. A full tank leaves less air at the top, which means less space for condensation to form and contaminate your fluid with water. Just make sure you're sticking to the clean filling procedures we talked about earlier. Using dedicated, sealed equipment isn't just a suggestion; it's a must.

This kind of careful handling is becoming more important every day. With emissions regulations getting stricter worldwide, the demand for DEF is booming. The market was valued at USD 43.02 billion in 2025 and is on track to hit USD 85.72 billion by 2034. You can dig deeper into what's driving this growth in this detailed report on the diesel exhaust fluid market on towardschemandmaterials.com. This massive expansion just highlights why proper storage and handling are so crucial for every single vessel operator out there.

At CLiX Fueling Solutions, we know that safe and clean fluid handling is non-negotiable. Our spill-free fueling system was designed to prevent costly messes and protect the marine environment we all depend on. To make every refueling stop simple and secure, check us out at https://clixfueling.com.