As the boating season winds down, the most critical maintenance period begins. Improperly preparing your boat for the off-season is not just a minor oversight; it's a gamble against freezing temperatures, moisture, and corrosion that can lead to catastrophic failures and costly repairs come springtime. A comprehensive winterizing boat checklist is your single most important tool to protect your vessel's engine, fuel system, hull, and interiors.

This guide moves beyond the basics, offering a detailed, 8-step roundup of essential tasks. We provide actionable specifics, from preventing engine block cracks to stabilizing your fuel system, a step where preventing spills with tools like CLiX Fueling Solutions becomes crucial for both your boat and the environment. This level of detailed preparation is vital for protecting valuable assets, much like how a thorough winter camping checklist is essential for safely enjoying cold-weather adventures. Follow these steps meticulously to ensure your boat survives the winter unscathed and is ready for a seamless launch next season.

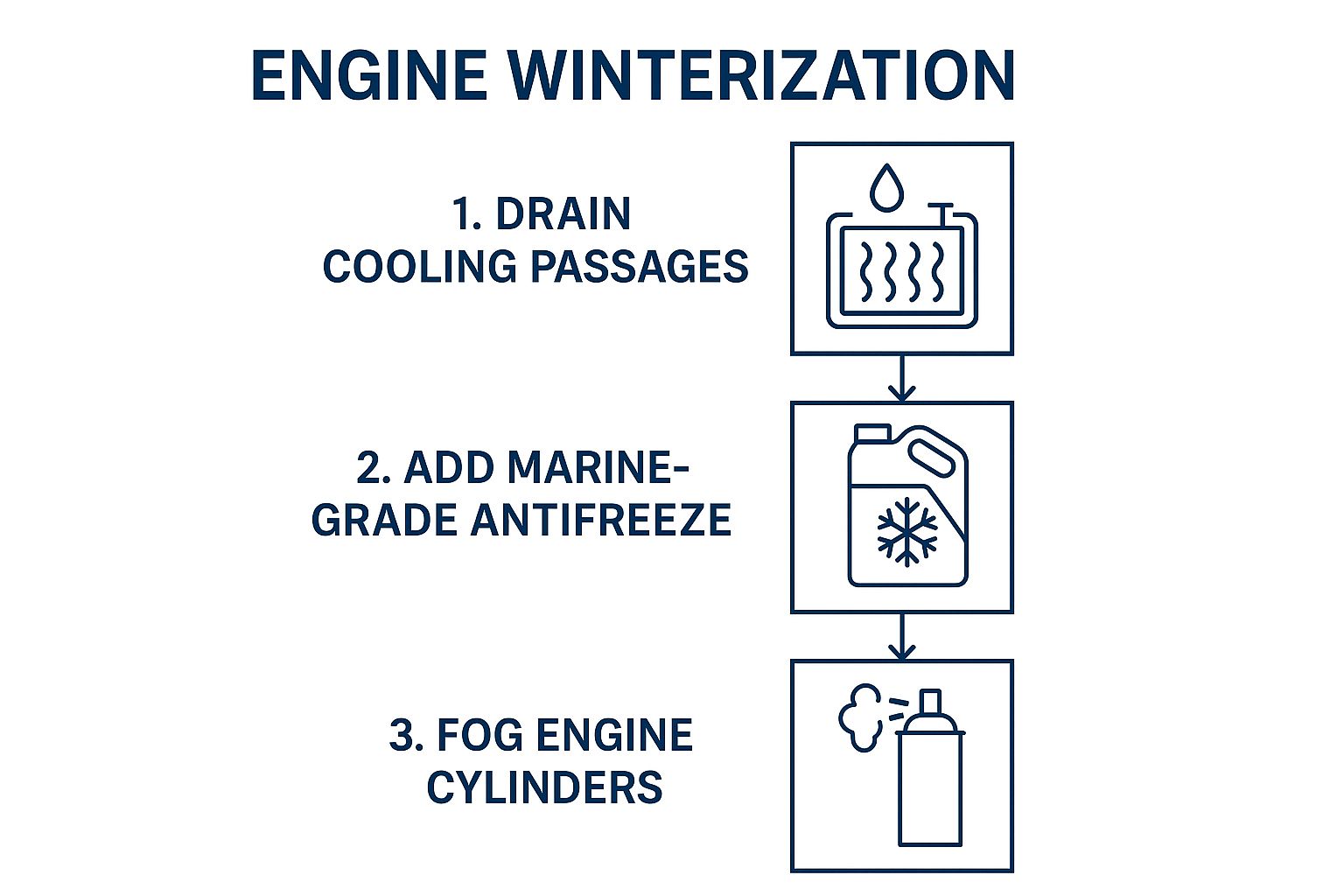

1. Engine and Cooling System Winterization

Your boat's engine is its heart, and protecting it from harsh winter conditions is the most critical step in any winterizing boat checklist. Freeze damage is the primary enemy. When water left in the engine block, manifolds, or cooling passages freezes, it expands with enough force to crack metal components, leading to catastrophic and expensive repairs. This process ensures all water is removed and internal parts are shielded from corrosion during long-term storage.

Why It's Essential

Properly winterizing your engine and cooling system prevents the most common and costly off-season damage. It involves two main goals: removing every drop of plain water and coating internal components to prevent rust and corrosion. Skipping this step is a gamble that can result in a cracked engine block or damaged exhaust manifolds, turning your spring launch into a nightmare of repairs. For complex inboard systems, consulting a professional is a wise investment, but many outboard and sterndrive engines can be winterized by a diligent boat owner.

Key Steps for Engine Protection

The process varies slightly between engine types (inboard, outboard, sterndrive), but the core principles remain the same.

- Drain Completely: Start by thoroughly draining all water from the engine block and cooling system. Locate all petcocks or drain plugs on the block, manifolds, and cooler. It is crucial to ensure every drop is out.

- Circulate Antifreeze: Refill the system with a non-toxic, marine-grade propylene glycol antifreeze. Never use automotive (ethylene glycol) antifreeze, as it is highly toxic to aquatic life and can damage marine engine components. Briefly run the engine to circulate the antifreeze until you see it exit the exhaust.

- Fog the Engine: Fogging oil coats internal engine parts like cylinder walls and pistons, preventing corrosion from forming due to moisture in the air. This is a vital step to ensure your engine is ready to perform reliably next season.

This simple infographic outlines the core workflow for protecting your engine from freeze damage.

Following this sequence ensures that you first remove the threat (water) before adding protection (antifreeze and fogging oil).

2. Fuel System Stabilization

Your boat’s fuel system is vulnerable to damage over the winter, not from freezing, but from the fuel itself degrading. Modern gasoline, especially ethanol-blended fuel, can break down, absorb water, and form gums and varnishes that clog fuel lines, filters, and injectors. Properly stabilizing the fuel prevents this degradation, ensuring your engine starts smoothly and runs reliably come springtime.

Why It's Essential

Untreated fuel is one of the leading causes of post-winter engine problems. Ethanol in gasoline is hygroscopic, meaning it attracts and absorbs water from the air. Over a long storage period, this can lead to "phase separation," where the water and ethanol mixture settles at the bottom of your tank. This separated, corrosive mixture can then get drawn into your engine, causing significant damage. A quality fuel stabilizer prevents this by keeping the fuel fresh and inhibiting corrosion. This simple step is a crucial part of any winterizing boat checklist. To explore this topic further, you can learn more about maintaining your boat's fuel system.

Key Steps for Fuel Protection

The goal is to treat the fuel and ensure that treated fuel runs through the entire system before storage.

- Fill the Tank: Fill your fuel tank to about 90-95% full. A full tank leaves less room for air, reducing the potential for water condensation to form inside the tank walls as temperatures fluctuate.

- Add Stabilizer: Add a high-quality marine fuel stabilizer, such as one from STA-BIL or Star Tron, to the tank. Follow the manufacturer's instructions for the correct ratio of stabilizer to fuel. Marine-specific formulas are designed to combat the harsh effects of ethanol.

- Circulate the Mixture: After adding the stabilizer, run your engine for 5-10 minutes. This is a critical step that circulates the treated fuel through the fuel lines, filters, and engine, ensuring the entire system is protected. Simply adding stabilizer to the tank isn't enough.

- Replace Filters: Before storage, it's a best practice to replace your fuel-water separator filter. This ensures you start the next season with a fresh filter, free from any water or contaminants captured during the previous season.

3. Battery Maintenance and Storage

Your boat's batteries are the lifeblood of its electrical systems, from starting the engine to powering navigation and cabin lights. Leaving them connected and unmaintained over the winter is a recipe for disaster. Cold temperatures can cause batteries to lose their charge, and a discharged battery can freeze, leading to permanent damage, a cracked case, and a costly replacement come springtime. Proper battery maintenance is a core part of any winterizing boat checklist.

Why It's Essential

Properly storing your marine batteries prevents irreversible capacity loss and extends their functional lifespan significantly. A battery left to slowly discharge over several months can suffer from sulfation, where lead sulfate crystals harden on the battery plates, reducing its ability to hold a charge. Removing, cleaning, and properly maintaining your batteries ensures they will have the power you need for a reliable start to the next boating season. To ensure your boat's power source is ready for next season, dive into a comprehensive deep cycle marine battery guide that complements these winterization steps.

Key Steps for Battery Protection

The goal is to keep the battery fully charged and safe from freezing temperatures throughout the off-season.

- Remove and Clean: Disconnect the battery cables (negative first) and remove the battery from the boat. Clean the terminals and case with a solution of baking soda and water to neutralize any acid corrosion.

- Store Properly: Store the fully charged battery in a cool, dry, and well-ventilated location off the concrete floor, such as on a wooden block or shelf in a garage or basement. The ideal temperature is above freezing (32°F / 0°C).

- Maintain the Charge: Connect the battery to a "smart" battery charger or maintainer, like those from Battery Tender or NOCO. These devices monitor the battery's charge and deliver power only when needed, preventing overcharging which can damage the battery. Avoid using a simple trickle charger, as it can overcharge and boil out the electrolyte.

4. Plumbing and Water System Protection

Your boat’s plumbing is an often-overlooked network susceptible to severe winter damage. From freshwater tanks and pipes to toilets and drain lines, any water left behind can freeze, expand, and crack fittings, lines, or pumps. This step in the winterizing boat checklist ensures every component of your onboard water systems is either completely dry or protected with non-toxic antifreeze, preventing costly and messy leaks come springtime.

Why It's Essential

Properly winterizing your plumbing systems prevents cracked pipes, damaged water pumps, and ruined fixtures. The goal is to eliminate any possibility of freeze damage in potable water, raw water, and waste systems. Unlike engine work, this is a very manageable DIY task for most boaters, but it requires thoroughness. Forgetting a single faucet, shower head, or ice maker can lead to a significant repair bill and potential water damage to your boat’s interior.

Key Steps for Plumbing Protection

The process involves draining and then circulating antifreeze through all lines, faucets, and appliances connected to the water system.

- Drain Completely: Start by opening the petcock on your fresh water tank to drain it entirely. Then, open all faucets, both hot and cold, and turn on the water pump to push out any remaining water from the lines. Don’t forget shower heads, deck washdowns, and livewell pumps.

- Add Non-Toxic Antifreeze: Disconnect the inlet side of your water pump and connect a bypass hose leading into a jug of non-toxic, marine-grade propylene glycol antifreeze. Never use automotive antifreeze in potable water systems.

- Circulate Through System: Turn on the pump and go to each faucet one by one. Let the antifreeze run until the colored liquid flows out consistently. Do this for both hot and cold sides. Remember to flush toilets, run the shower, and activate any other water-using appliances until the antifreeze appears.

5. Canvas and Upholstery Protection

Your boat's canvas and upholstery are constantly exposed to sun, salt, and moisture, making them susceptible to damage during the off-season. Protecting these fabric elements is a key part of any winterizing boat checklist. Mold, mildew, and UV degradation are the primary threats. When moisture gets trapped under a cover or inside cushions, it creates a breeding ground for mildew, which can stain fabrics permanently and lead to unpleasant odors. This process ensures all fabrics are clean, dry, and properly stored to preserve their appearance and function.

Why It's Essential

Properly caring for your canvas and upholstery prevents costly replacements and maintains your boat's value. The main goals are to remove dirt and organic matter that feed mildew, treat fabrics with protective coatings, and store them in a way that avoids moisture buildup. Ignoring this step can lead to ruined cushions, stiff and brittle canvas, and a boat that looks and smells neglected come springtime. Brands like 303 Products and Star Brite offer specialized cleaners and protectants designed for the marine environment.

Key Steps for Fabric Protection

The specific steps depend on the material (vinyl, Sunbrella, etc.), but the fundamental approach is universal for ensuring your boat's fabrics survive the winter.

- Clean Thoroughly: Remove all canvas, bimini tops, seat cushions, and other fabric items. Clean them according to the manufacturer's recommendations, using a gentle brush and a dedicated marine fabric cleaner to remove salt, dirt, and any fledgling mildew spots.

- Dry Completely: This is the most critical step. Ensure every item is 100% dry before storing. Even a small amount of dampness can lead to widespread mildew growth over the winter. Air dry everything in the sun if possible.

- Store Properly: Ideally, store cushions and removable canvas indoors in a dry, climate-controlled, and well-ventilated area like a garage or basement. If you must leave canvas on the boat, ensure it is properly supported to prevent water from pooling and consider using vents to promote air circulation.

6. Hull and Drive Unit Protection

While the engine is the heart, the hull and drive unit are the boat's foundation and legs. Protecting these external components from the harsh winter environment is just as vital as internal system care. Damage from ice, corrosion, moisture, and improper storage can lead to costly structural repairs, compromised performance, and a shortened lifespan for your vessel. This process focuses on cleaning, inspecting, and securing the entire exterior below the waterline.

Why It's Essential

Properly protecting your hull and drive unit prevents a range of off-season issues. A thorough cleaning removes marine growth and salt, which can cause blistering and corrosion. Inspecting and sealing through-hulls prevents water intrusion and freeze damage. Finally, correctly supporting the hull on land distributes its weight evenly, avoiding stress cracks and deformation. Skipping these steps can lead to severe structural damage that compromises the boat's integrity.

Key Steps for Hull and Drive Protection

The goal is to create a stable, dry, and protected environment for your boat's exterior during storage.

- Clean and Inspect: Pressure wash the hull immediately after haul-out to remove marine growth, barnacles, and slime. This is the best time to inspect for blisters, dings, or cracks. Beyond the hull itself, consider how to safeguard all your equipment from winter's effects. You can apply some expert winter vehicle protection tips, including salt removal, to prevent corrosion on trailers, metal fittings, and other exposed parts.

- Support Properly: The boat must be supported with proper jack stands and blocks. Position stands on structurally sound areas like bulkheads to distribute the load and prevent hull deformation. Never support the boat by the keel alone unless it was specifically designed for it.

- Manage Water and Corrosion: Close and secure all through-hull fittings to prevent water from entering and freezing. For sterndrives and outboards, ensure they are stored in the full down position to allow all water to drain out completely. Apply a coat of corrosion inhibitor to propellers, shafts, and other exposed metal components.

7. Ventilation and Moisture Control

A tightly sealed boat cover is great for keeping out snow and debris, but it can also trap moisture, creating a breeding ground for mold, mildew, and corrosion. Effective ventilation and moisture control are crucial for protecting your boat’s interior, upholstery, and electronics from the damaging effects of condensation that builds up during temperature swings. This part of the winterizing boat checklist ensures the air inside your vessel stays dry and fresh throughout the off-season.

Why It's Essential

Without proper air exchange, the humid air trapped inside your boat will condense on cool surfaces, leading to musty odors, stained fabrics, and even electrical shorts. Mold and mildew are not just unsightly; they can cause permanent damage to vinyl, canvas, and wood, and can be difficult and costly to remove. Proactive moisture management prevents these issues from taking root, preserving the value and comfort of your boat for the next season.

Key Steps for a Dry Interior

The goal is to allow moist air to escape while preventing rain and snow from getting in. This can be achieved through both passive and active methods.

- Create Cross-Ventilation: Use specialized boat cover vents or props to create a high point in your cover, allowing air to circulate. Position vents to create a natural airflow, with an intake point and an exhaust point, to prevent stagnant air pockets.

- Use Moisture Absorbers: Place moisture-absorbing products, like those from DampRid, in key areas such as the cabin, head, and storage lockers. These products use calcium chloride crystals to pull humidity out of the air, collecting it as water in a container.

- Consider a Dehumidifier: For larger boats or in particularly damp climates, a small, low-wattage marine dehumidifier or a gentle air circulator like a Caframo fan can provide active moisture control, running periodically to keep humidity levels in check. Avoid completely sealing the boat; some air exchange is necessary. While ensuring your boat's interior is ventilated, it's also a good time to check that your fuel system's ventilation is clear. Understanding your boat's fuel tank vent system on clixfueling.com is essential for overall safety and performance.

8. Comprehensive Cover and Security Setup

Once the internal systems are protected, the next crucial step in your winterizing boat checklist is shielding its exterior. A high-quality cover is your boat’s first line of defense against snow, ice, rain, UV radiation, and falling debris. Left exposed, your boat's gelcoat can fade, vinyl can crack, and unwanted moisture can lead to mold, mildew, and pest infestations. A secure setup also deters theft and vandalism during the long, quiet off-season.

Why It's Essential

A comprehensive cover and security plan is about more than just keeping your boat dry. It preserves its value, appearance, and structural integrity. A sagging, ill-fitting tarp can trap moisture and cause more harm than good by promoting mold growth. Similarly, a boat stored without any security measures is an open invitation for thieves. Investing in a proper cover and basic security provides peace of mind and ensures your vessel emerges from storage in the same condition it went in.

Key Steps for Exterior Protection

Choosing and installing the right cover is critical for effective protection. The goal is to create a breathable yet impenetrable shield.

- Select the Right Material: Invest in a cover made from breathable, UV-resistant, and water-repellent fabric like those from Carver Industries or Taylor Made. For ultimate protection, consider professional shrink-wrapping, a method perfected by companies like Dr. Shrink, which creates a drum-tight barrier against the elements.

- Ensure Proper Support and Fit: The cover must be supported to prevent water and snow from pooling, which can damage the cover and the boat itself. Use a frame or support poles to create a tent-like shape. Ensure it is secured tightly with straps to prevent wind from getting underneath and causing damage.

- Ventilate Properly: A breathable cover is a good start, but adding vents is even better. Ventilation prevents condensation from building up under the cover, which is a primary cause of mold and mildew. Proper airflow is key to keeping the interior dry and fresh.

Securing your boat and its cover properly protects your investment from both environmental and human threats. For a deeper look at different materials and styles, you can learn more about boat dock cover options at clixfueling.com.

Winterizing Checklist: 8 Key Areas Compared

| Item | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Engine and Cooling System Winterization | High: requires mechanical skills and careful procedure | Moderate to High: antifreeze, tools, possible pro service | Prevents freeze damage and corrosion; ensures reliable startup | Boats stored in freezing climates needing engine protection | Protects expensive engine parts; extends engine life |

| Fuel System Stabilization | Moderate: additive mixing and fuel circulation | Low to Moderate: stabilizers, ethanol treatments | Prevents fuel degradation and gum formation; easy startup | Boats using ethanol-blended fuels or stored long-term | Protects fuel system components; reduces contamination |

| Battery Maintenance and Storage | Moderate: removal, cleaning, periodic charging | Moderate: charger/maintainer, storage space | Extends battery life; prevents sulfation; reliable performance | Any marine battery stored over winter | Prevents capacity loss; avoids leakage damage |

| Plumbing and Water System Protection | Moderate to High: multi-system draining and antifreeze | Moderate: marine antifreeze, supplies | Prevents freeze damage and bacterial growth in water systems | Boats with complex water systems prone to freeze damage | Protects pumps, valves; maintains system integrity |

| Canvas and Upholstery Protection | Moderate: labor-intensive cleaning and treatment | Moderate: cleaning and UV protection products | Prevents mold, mildew, UV damage; preserves appearance | Boats with fabric tops, cushions, and covers | Maintains aesthetics; reduces spring prep time |

| Hull and Drive Unit Protection | High: requires proper equipment and expertise | High: haul-out, stands, paints, professional help | Prevents hull and running gear damage; corrosion prevention | Larger boats or those needing professional winter storage | Preserves hull integrity; protects propulsion gear |

| Ventilation and Moisture Control | Moderate: setup and ongoing monitoring | Moderate: dehumidifiers, fans, absorbers | Prevents mold, mildew, and humidity damage | Boats prone to interior moisture buildup during storage | Protects interior fabrics and electronics |

| Comprehensive Cover and Security Setup | Moderate to High: fitting, installation, security systems | High: quality covers, security installations | Shields boat from weather, UV, theft; maintains appearance | Long-term outdoor storage needing weather and security protection | Maximizes protection; deters theft and vandalism |

From Checklist to Launch Day: Your Payoff for a Job Well Done

As you step back and look at your fully prepared vessel, you've done more than just check boxes on a list. You've completed a crucial ritual in the lifecycle of responsible boat ownership. This comprehensive winterizing boat checklist is your blueprint for protecting your significant investment, ensuring that the harsh winter months do not compromise its integrity, performance, or value. Think of it not as an end-of-season chore, but as the very first step in preparing for a spectacular season next year.

The payoff for this diligence is immense. When spring arrives, bringing with it the promise of open water and sunny skies, you will be rewarded with a smooth, predictable, and stress-free launch. Instead of discovering cracked engine blocks, mold-infested upholstery, or a dead fuel system, you will find a boat that is ready and waiting for your next adventure. This foresight saves you from expensive, time-consuming, and entirely preventable repairs that sideline so many boaters at the start of the season.

Key Takeaways for a Successful Winter Layup

Let’s quickly recap the cornerstones of a successful winterization process:

- Engine & Fuel are Paramount: The heart of your boat, the engine, and its lifeblood, the fuel system, demand the most attention. Properly flushing the engine, changing the oil, and stabilizing the fuel are non-negotiable tasks that prevent internal corrosion and system failure.

- Dryness is Your Best Friend: Moisture is the enemy during storage. From draining every drop of water from the plumbing systems to ensuring adequate ventilation under the cover, your primary goal is to create a dry environment that wards off mold, mildew, and freeze damage.

- Protection is a 360-Degree Job: A thorough winterization covers every angle. It includes protecting the hull from blisters, caring for the canvas and vinyl to prevent cracking, removing batteries for safe storage, and securing the entire vessel against pests and theft.

By mastering this detailed winterizing boat checklist, you are not just performing maintenance; you are practicing stewardship. A well-maintained boat is a safer boat, a more reliable boat, and one that holds its value for years to come. The peace of mind you gain, knowing your vessel is secure all winter, is invaluable. When you hear that engine turn over flawlessly on the first try next season, you’ll know every moment you invested in this process was well worth it.

Ready to make your fuel system winterization foolproof and spill-free? Upgrade your process with the innovative, click-on spill-proof system from CLiX Fueling Solutions. Ensure every drop of fuel and stabilizer goes exactly where it should by visiting CLiX Fueling Solutions to see how our technology can protect your boat and the environment.