Let's be real for a moment. A detailed boat maintenance schedule isn't just another checklist to tack on your to-do list. It's the single most important document you can have for your vessel. Think of it as your strategic plan for safety, reliability, and ultimately, protecting the big investment you've made. It’s what turns reactive, frantic repairs into calm, proactive care, making sure your boat is ready to go whenever you are.

Why a Maintenance Schedule Is Your Most Important Tool

You bought a boat for the freedom of being on the water, not for the "adventure" of having your engine die miles from shore. That's where a good maintenance schedule comes in. It's your first line of defense against those trip-ruining breakdowns and serious safety risks. It brings peace of mind by breaking down what feels like a mountain of upkeep into small, manageable tasks.

Here's a story that perfectly illustrates this. I know a skipper who, every single week, does a quick fluid check. It’s part of his routine. One Saturday morning, he spotted a tiny, almost unnoticeable coolant leak. Because of that simple five-minute check, he was able to swap out a bad hose right there at the dock. The cost? Under fifty bucks.

Now, imagine if he'd skipped that check. That tiny drip could have easily turned into a catastrophic engine overheat far from any help. We're talking thousands in damages and a genuinely dangerous situation. That's the power of a simple, consistent schedule.

Protecting Your Investment and Ensuring Safety

Consistent maintenance is just part of responsible boat ownership. A boat that's well cared for doesn't just run better—it holds its value far longer. This proactive mindset stops small, cheap-to-fix issues from snowballing into major repairs that drain your bank account.

The real win with a disciplined maintenance schedule isn't just about the money you save. It's about maximizing your time on the water. A reliable boat means fewer canceled trips and more confidence every time you cast off the lines.

This shift from "fix it when it breaks" to proactive care is a trend we're seeing across the entire boating industry. The boat repairing market, which is all about maintenance, is growing fast. It was valued at $6.59 billion and is expected to hit $10.14 billion by 2029.

Several things are pushing this growth:

- Smarter Owners: Boaters today simply expect more reliability from their vessels.

- Insurance Demands: A lot of insurance policies now require proof of regular maintenance.

- Environmental Rules: Stricter regulations mean engines and systems have to be in top shape to prevent pollution.

This all points to one thing: a personalized maintenance schedule isn't just a nice-to-have anymore. For anyone who owns a boat today, it’s absolutely essential. If you're interested, you can learn more about these market trends and see why a disciplined schedule is your best bet for staying safe and protecting your boat's value for years to come.

Building Your Custom Maintenance Checklist

Let’s be honest: a generic, one-size-fits-all checklist isn't going to cut it. Every boat is different. The age of your vessel, how you use it, and whether you're in freshwater or salt all play a huge role in what it needs. Crafting a custom boat maintenance schedule isn't about just ticking boxes—it's about creating a smart plan tailored to your boat.

Think about it this way. That quick pre-departure glance at the engine fluids isn't just a chore. It's your first line of defense against being stranded miles from shore. Likewise, inspecting your sacrificial anodes every month is more than just a quick look-see; it’s a simple act that can prevent thousands of dollars in corrosion damage.

The goal here is to build a schedule that feels second nature, not overwhelming. A small fishing boat with an outboard used on a lake has completely different maintenance needs than a 40-foot cruiser that lives in the ocean.

Categorizing Your Maintenance Tasks

The best way to get a handle on maintenance is to break it down by frequency. When you group tasks into smaller, regular intervals, the whole process feels much more manageable. Nothing important gets overlooked.

I like to organize my own schedule into four main buckets:

- Before Every Trip: These are the essential, non-negotiable safety and operational checks you do at the dock.

- Weekly Checks: Quick inspections to spot small problems before they grow into big, expensive ones.

- Monthly Tasks: More involved checks that require a bit more time and attention.

- Annual or Seasonal Jobs: This is the major-league preventive work, usually handled during winterization or spring commissioning.

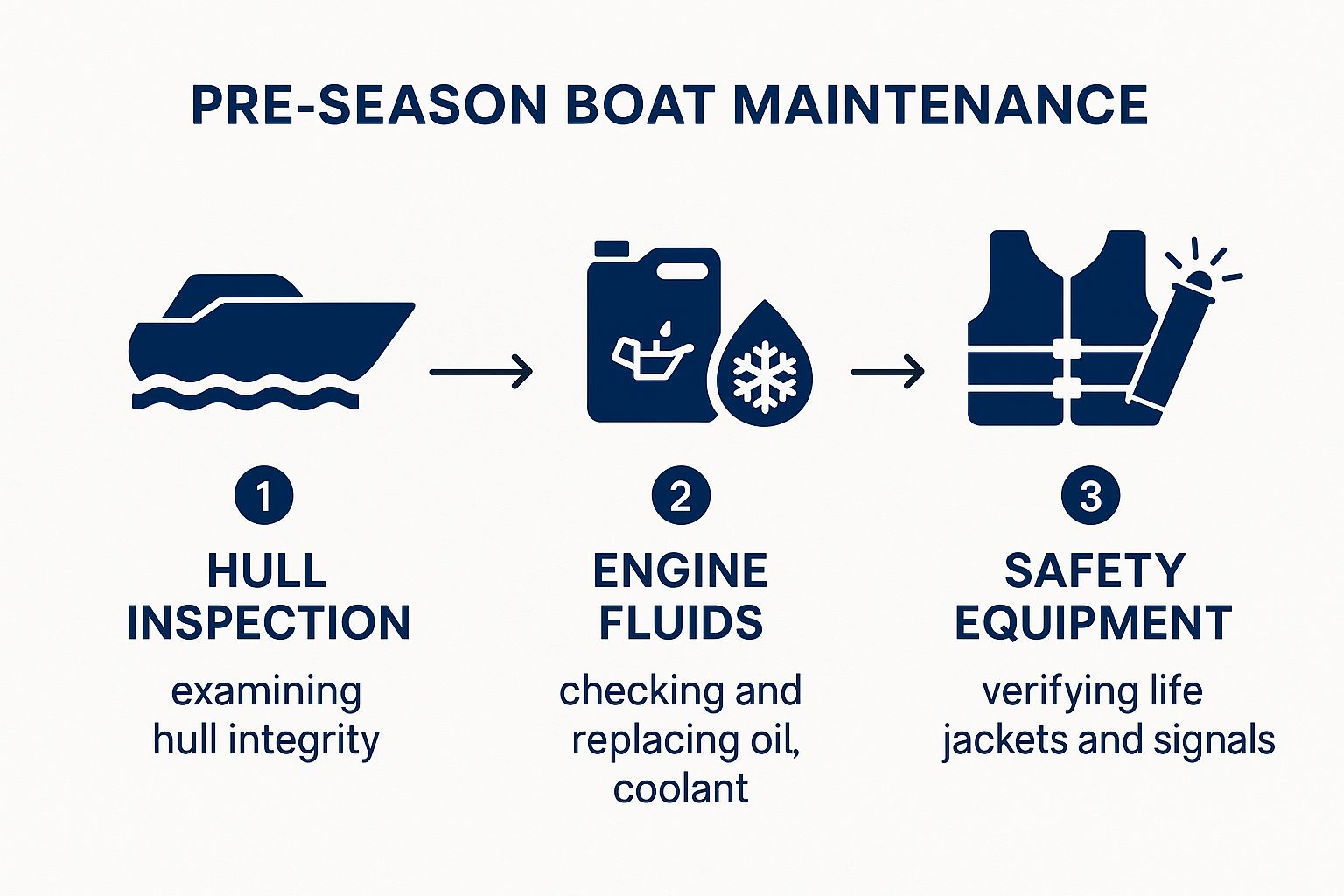

To get a better sense of how this flows, especially when getting ready for a new season, this simple visual breaks down the key areas to focus on.

As you can see, getting back on the water involves a top-to-bottom review of your boat's most critical systems—from its hull integrity to its essential safety gear.

To give you a clearer picture of how to structure this, I've put together a simple table. Think of it as a starting template you can build on.

| Sample Boat Maintenance Schedule by Frequency | | :--- | :--- | :--- | :--- | | Frequency | Engine & Propulsion | Hull & Deck | Electrical & Safety | | Before Each Trip | Check engine oil & coolant levels. Visually inspect fuel lines. | Check for new dings or scratches. Ensure drain plug is in. | Test horn and navigation lights. Check battery charge. | | Weekly | Inspect belts for wear. Check prop for damage. | Wash down hull and deck (especially in salt water). | Check bilge pump operation. Inspect battery terminals. | | Monthly | Change engine oil (or per manual). Inspect sacrificial anodes. | Inspect and clean thru-hulls. Check all hardware for tightness. | Test all safety equipment (flares, fire extinguishers). | | Annually/Seasonally | Replace water pump impeller. Full tune-up. | Wax and polish hull. Inspect and reseal windows/hatches. | Inspect all wiring for corrosion or chafe. |

This table is just a framework. The real magic happens when you adapt it to your specific boat and boating style.

Putting It All Together

So, where do you begin? Start by making a list of every single component on your boat. I mean everything—the engine, bilge pumps, deck cleats, navigation electronics, everything. Then, assign each item a check-up frequency based on the categories above. A quick monthly rinse of your stainless steel might be enough to keep salt at bay, while a deeper quarterly polish is needed to really protect it.

A maintenance schedule is a living document. It should change and grow as you get to know your boat's quirks. If you keep finding a loose connection somewhere, you might want to add that check to your weekly list.

It can be helpful to see how other complex systems are maintained. To get a feel for a truly thorough approach, you can even download a free HVAC maintenance checklist and see how professionals structure preventive care in a different industry.

For a fantastic starting point designed specifically for boaters, our comprehensive https://clixfueling.com/blogs/news/boat-maintenance-checklist-keep-your-vessel-in-top-shape offers an excellent base to build from. Use it as your guide, adding or removing tasks to create a custom plan that keeps your vessel safe, reliable, and ready for the water.

Engine and Mechanical System Checks You Can Do Yourself

Popping open the engine hatch doesn't have to be intimidating. I know that maze of hoses and wires can look like spaghetti, but trust me, some of the most important mechanical checks are things you can absolutely handle yourself. Working these simple tasks into your regular boat maintenance schedule will make you a more confident skipper and help you spot trouble long before it ruins a day on the water.

Think of your boat’s engine like your car's. You wouldn't hit the highway for a long trip without a quick peek under the hood, right? Same principle applies on the water. These quick checks take just a few minutes but buy you a whole lot of peace of mind.

Fluids and Belts: Your First Line of Defense

Before you cast off the lines for any trip, make these checks a non-negotiable habit. It's the foundation of a reliable engine.

- Engine Oil: It’s exactly like checking the oil in your car. Pull the dipstick, wipe it clean, push it all the way back in, and pull it out again. The oil level should sit nicely between the "add" and "full" marks. Pay attention to the color, too. Healthy oil is a clear, golden-brown. If it looks milky or has a sludgy texture, that’s a red flag for a serious problem, like water getting into the engine. That’s a job for a professional mechanic, and you shouldn't start the engine.

- Coolant Level: Find the heat exchanger or overflow tank for your closed cooling system. The coolant needs to be at the correct level—low coolant is one of the top reasons an engine overheats.

- Drive Belts: Give the belts a firm press with your thumb. You want to feel a little bit of give, usually about half an inch, but they should never feel loose or sloppy. Also, give them a good look. Any cracks, frayed edges, or a shiny, glazed look means they're getting old and need to be replaced soon.

Doing this consistently is the best early warning system you have. You'll catch slow leaks or worn parts while they’re still small problems you can fix at the dock.

Raw Water and Bilge Pump Inspections

Okay, beyond the core engine components, two other systems are absolutely critical for safety and performance. They’re easy to check and vital for your boat's well-being.

First up is your raw water sea strainer. This little basket is what stops seaweed, jellyfish, and stray plastic bags from being sucked into your engine's cooling system. Most have a clear housing, making it easy to spot when it's getting full. Cleaning it is a breeze: close the seacock, unscrew the lid, lift out the basket, and dump the gunk. A clogged strainer is a fast track to an overheating engine.

Your bilge pumps are your last line of defense against taking on water. Never just assume they are working. Get in the habit of manually lifting the float switch to make sure the pump kicks on instantly. You should hear that reassuring hum right away.

A working bilge pump is a non-negotiable safety item. A stuck switch can turn a tiny leak into a massive headache. While you're at it, remember that keeping all your lines and filters clear is key. For a deeper dive into how these components connect, you can explore our complete guide to your boat's fuel system at https://clixfueling.com/blogs/news/boat-fuel-system. Knowing what you can handle and when it's time to call in a pro is the mark of a truly great boat owner.

Mastering Seasonal Care for Winter and Spring

Your boat's needs change with the seasons, and no two times are more critical than the end of the boating season and the very beginning of the next. Getting your head around winterization and spring commissioning is the absolute key to avoiding serious damage and ensuring you get a hassle-free start when the weather warms up.

Honestly, these seasonal routines are where a small oversight can turn into a massive repair bill. I like to think of them as the bookends to my boating year. Each one needs its own dedicated, detailed checklist to make sure my investment is protected.

Preparing for the Cold with Winterization

Putting your boat away for the winter is so much more than just throwing a tarp over it. It’s a methodical process designed to shield every system from the destructive force of freezing temperatures. I've seen it happen: a single water line that was overlooked leads to a cracked engine block. That's a heart-sinking, expensive mistake that's completely avoidable.

Your winter prep needs to be thorough. Here’s what you can't afford to miss:

- Fuel System Care: Get your tank filled to about 90% full. This little trick minimizes the air inside, which is what causes condensation. Then, add a good fuel stabilizer and run the engine for a bit to make sure that protected fuel gets everywhere it needs to be.

- Draining All Water: This is non-negotiable and the most critical step. Every single drop of water has to come out—from the engine block, manifolds, heat exchanger, and all the plumbing for your sinks, showers, and head. Once it's drained, run non-toxic antifreeze through the systems for total peace of mind.

- Proper Covering: Invest in a quality, breathable boat cover. You need air to circulate underneath to prevent a winter-long science experiment of mold and mildew from growing. Make sure it’s tied down securely enough to handle whatever winter storms roll through.

For a complete walkthrough, our https://clixfueling.com/blogs/news/winterizing-boat-checklist gives you a step-by-step guide so nothing gets missed.

Waking Your Boat Up for Spring

After a long winter tucked away, bringing your boat back to life is an exciting time. But spring commissioning isn't just about pulling off the cover. It’s a careful, top-to-bottom inspection to guarantee your boat is safe and reliable for that first launch of the year.

Don't rush your spring prep. This is your chance to catch any issues that may have developed over the winter. A thorough inspection now saves you from a potential breakdown on your first trip out.

Start with a simple walk-around. Look for any new dings, cracks, or damage to the hull or deck that might have happened in storage. After that, it's time to dig into the systems.

Here’s a practical list to guide your spring commissioning:

- Engine De-Winterization: Reconnect any hoses you removed, pop in some fresh spark plugs, and change the engine oil and filter. This is also the perfect time to replace the water pump impeller—it’s a small, cheap part that can cause huge problems if it fails on the water.

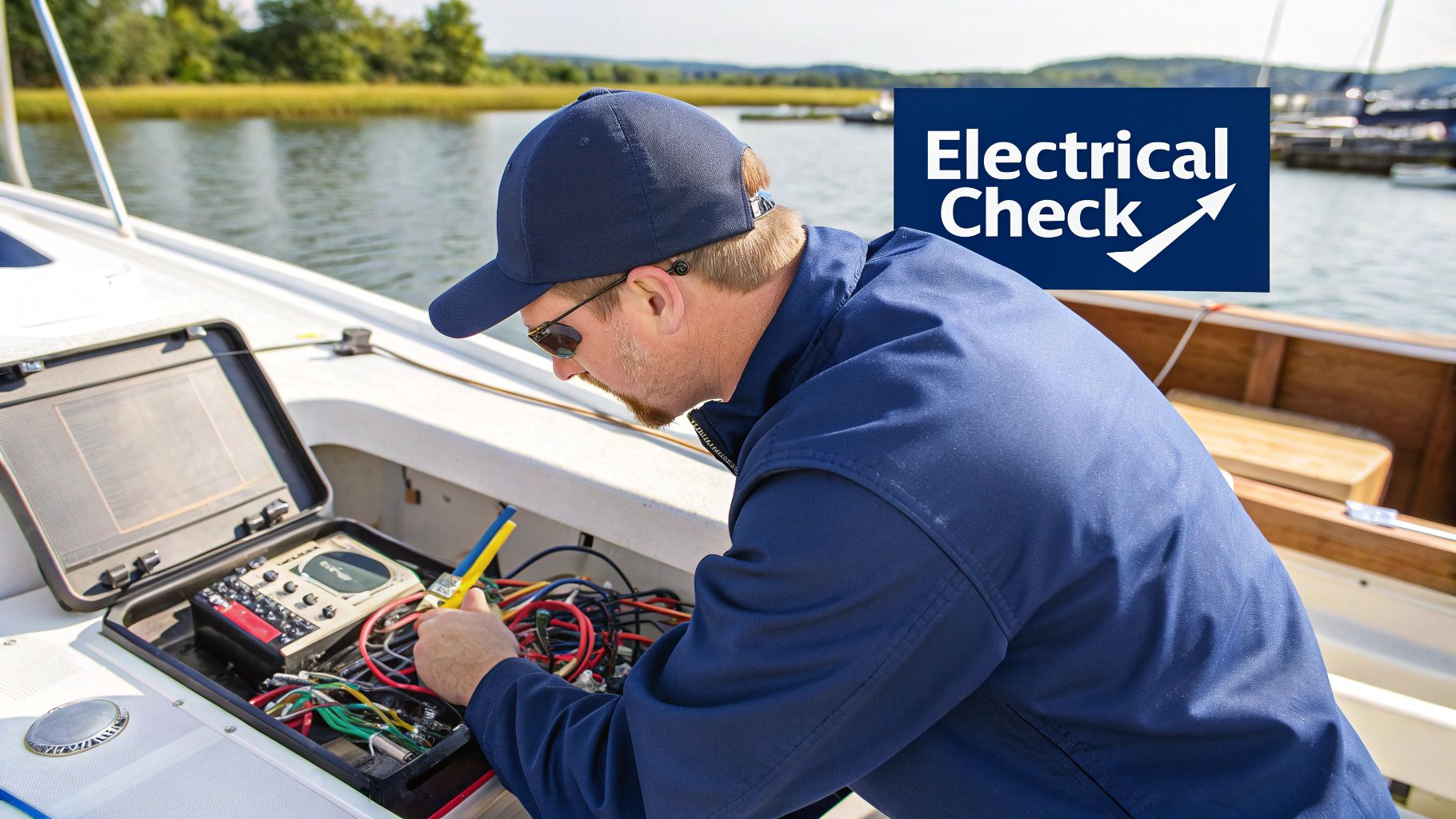

- Systems Inspection: Reinstall and charge your batteries. Check every electrical connection for corrosion, and then flip every switch. Test the lights, pumps, and electronics to make sure they all wake up properly.

- Safety Gear Check: Pull out your life jackets, fire extinguishers, flares, and first-aid kit. Check expiration dates and make sure everything is in good working order.

- Final Polish: A good coat of wax on the hull does more than make it shine; it protects the gelcoat from UV damage. And if you boat in saltwater, a fresh coat of bottom paint is essential for keeping marine growth at bay.

This focus on proper seasonal care is becoming even more important. The boat building and repair market, currently valued at $44.66 billion, is expected to grow to $48.15 billion. As boats become more complex, having a precise maintenance plan is no longer just a good idea—it's a necessity.

Let's Bring Your Boat Maintenance Into the 21st Century

A good old paper checklist certainly gets the job done, but why not make life easier? Technology has come a long way, and the tools available to us as boat owners are incredible. We're talking about moving from a simple "to-do" list to a smart, data-driven approach that was once reserved for massive commercial ships.

This is about more than just swapping paper for a screen. It’s about having a real-time pulse on your boat's health. Modern engine monitoring systems, for instance, can pipe data directly to your smartphone. You can see your engine’s exact temperature, oil pressure, and fuel consumption from anywhere. Catching a small fluctuation here can alert you to a problem long before an alarm ever goes off.

Say Goodbye to the Greasy Notebook

We’ve all been there—trying to decipher oil-stained notes in a logbook. Digital apps and software completely change this experience. Every time you change the oil, replace a part, or do an inspection, you can log it with a few quick taps.

With a digital log, you can:

- Get automatic reminders for crucial tasks, like when it's time to swap out the impeller or check your zincs.

- Snap photos of receipts and part numbers so you're not digging through drawers a year from now.

- Spot trends in engine performance or fuel burn over time, helping you identify subtle issues.

For those who want to get serious about organization, consider implementing a document management system. This keeps all your manuals, receipts, and logs in one tidy, searchable place.

This move to digital isn't just a small-time trend. The entire marine industry is leaning into this tech. The global market for boat and ship Maintenance, Repair, and Overhaul (MRO) was recently valued around $129.32 billion and is expected to hit $172.69 billion by 2029. What's driving that growth? Things like predictive maintenance and remote diagnostics—tech that's finally trickling down to us.

Smarter Alerts, Fewer Surprises

Remote diagnostics might be the most exciting development for the average boat owner. Imagine your boat is sitting at the dock and a battery starts to fail. Instead of finding out when you're ready to cast off, a monitoring system sends an alert straight to your phone.

Here's a real-world example: Your boat flags an unusual voltage drop while it's tied up. You get a text. Now you can get down to the marina and fix a loose connection or replace a dying battery before it ruins your weekend.

This is where boat care is heading. It’s no longer just about reacting to what breaks. By embracing these tools, you turn your maintenance schedule into a smart, proactive system. You're not just making your life easier—you're making your boat safer, more reliable, and ready for whatever adventure comes next.

Common Questions About Boat Maintenance

Even with the best checklist in hand, there are always those nagging questions that pop up when you're down in the bilge or getting ready for the season. We’ve all been there. So, I’ve put together some of the most common—and practical—questions I hear from fellow boat owners.

Think of this as the "what if" and "how often" section, designed to give you that extra bit of confidence and know-how.

Engine and Mechanical Questions

How often should I really change my boat's engine oil? The standard advice from most manufacturers is to change your oil every 100 hours of run time, or at least once a year, whichever comes first. But don't just take that as gospel. Pull out your engine's manual, because a high-performance engine or a seasoned older diesel might have its own set of rules.

What's the single most important check before leaving the dock? If you do nothing else, do a quick pre-departure check. It’s your first line of defense against a ruined day on the water. At the very least, pop open the engine compartment and look for any new drips or puddles—fuel, oil, or water. Check your fluid levels and give the bilge pump a quick test flick. And, of course, make sure your safety gear like life jackets and fire extinguishers are right where they should be.

Can I use automotive parts on my boat's engine? Let me be blunt: absolutely not. I see people tempted by this, but it's a dangerous shortcut. Marine parts are specifically designed to be ignition-protected and resist corrosion in a damp, fuel-vapor-filled space. An automotive starter or alternator isn't. Using one could create a spark, and in an engine bay, that's a recipe for a fire or a catastrophic explosion. Don't risk it.

Hull and Component Care

How do I know when to replace my sacrificial anodes? If you’re boating in saltwater, you should be glancing at your zinc or aluminum anodes every month. The rule of thumb I've always followed is to replace them when they look about 50% gone. Don't wait until they’ve completely vanished.

Once an anode is gone, the galvanic corrosion doesn't just stop—it starts eating away at the next most expensive piece of metal it can find, like your prop shaft, outdrive, or rudder.

Neglecting a $20 anode can easily lead to thousands of dollars in repairs to your underwater gear. It's one of the most cost-effective preventive maintenance tasks you can perform.

What's the best way to maintain stainless steel to prevent rust? The marine environment is relentless, especially on shiny metal. Keeping your stainless steel fittings looking good isn't hard, but it does require a consistent routine. Here's what works:

- Rinse After Every Use: Especially in salt water, give all your metal hardware a good spray-down with fresh water. This gets the corrosive salt off before it can do any damage.

- Polish Monthly: Keep an eye out for any small rust spots, often called "tea staining." Catch them early with a quality marine metal polish before they have a chance to get worse.

- Dry Everything: After a wash-down, take a few extra minutes to wipe the metal dry with a microfiber cloth. This prevents water spots and stops moisture from just sitting there.

A little bit of effort here goes a long way in preserving both the function and the beauty of your boat's hardware.

Speaking of care, fueling your boat safely is just as critical as any maintenance task. To take the stress and mess out of refueling, check out CLiX Fueling Solutions. Our automatic shut-off device is designed to prevent those dangerous and costly overfills, protecting both your boat and the water we all enjoy. Find out more about spill-free fueling.