Understanding Your Boat's Fuel Tank Vent System

Your boat's fuel tank vent system is essential for safe and efficient operation. It's more than just a minor component; it plays a vital role in preventing dangerous pressure buildup and minimizing explosion risks. Understanding how this system works is crucial for every boat owner.

This includes knowing the different parts of the system and what they do.

Components of a Typical Boat Fuel Tank Vent

A standard boat fuel tank vent system has several key parts:

- Vent Line: This line lets air in and out of the fuel tank, keeping the pressure balanced as you use or add fuel.

- Vent Fitting: This fitting, located on the tank, connects the vent line to the tank itself.

- Anti-Siphon Valve: This valve stops fuel from siphoning out if your boat capsizes or in other similar situations.

- Flame Arrestor: This important safety device prevents flames from getting into the fuel tank.

These components work together to keep your fuel system safe and working correctly. But like any mechanical system, problems can occur, creating potential hazards. For help with troubleshooting, check out this helpful resource: How to master boat fuel tank vent problem troubleshooting.

How the System Works and Why It Matters

When fuel is used, a vacuum would form without a vent, stopping the fuel flow. The vent lets air into the tank, replacing the fuel and maintaining normal pressure. When filling the tank, the vent releases air, preventing dangerous pressure buildup.

This process is essential for avoiding serious issues. Too much pressure can damage the tank, leading to costly repairs and potential fuel spills. A blocked vent can also starve your engine of fuel, causing performance problems or leaving you stranded.

The vent system is also crucial for safety. It prevents fuel vapor buildup, which is a major safety concern. Proper ventilation lets these flammable vapors dissipate safely, reducing the risk of explosions, especially in enclosed engine compartments.

The Fuel Tank Vent Valve Market

The market for fuel tank vent valves, including those used in boats, is a significant global sector. In 2022, the market was valued at about $4.5 billion. It's expected to grow at an annual rate of 3.5% over the next ten years. This growth is fueled by increasing environmental regulations, especially those focused on vehicle and industrial emissions. You can find more detailed statistics here: https://www.verifiedmarketreports.com/product/fuel-tank-vent-valve-market/

A well-maintained boat fuel tank vent system is essential for the life of your boat and the safety of everyone on board. Regular inspections and maintenance will ensure it works effectively and prevent potentially dangerous situations.

Choosing The Right Vent System For Your Vessel

Selecting the correct boat fuel tank vent system is crucial for both safety and optimal performance. An unsuitable vent can lead to various issues, ranging from engine problems to dangerous pressure buildup. This section explores different vent system options, helping you make an informed decision for your vessel.

Types of Boat Fuel Tank Vent Systems

Several types of boat fuel tank vents cater to different needs and vessel sizes. Each system has its own set of advantages and disadvantages.

-

Atmospheric Vents: These are the simplest type, allowing air to move freely in and out of the tank. They are cost-effective but offer minimal protection against spills or vapor leaks.

-

Anti-Siphon Vents: These vents include a valve that prevents fuel from siphoning out if the boat capsizes or lists significantly. This added safety makes them a popular choice.

-

Vapor Recovery Systems: Designed for larger vessels and areas with stricter environmental regulations, these systems capture fuel vapors, returning them to the tank to minimize emissions and explosion risks.

-

Combination Vents: Combining anti-siphon and vapor recovery features, these offer a comprehensive solution for safety and environmental protection.

Choosing the right system depends on factors like your boat's size, the type of fuel you use, and your typical operating conditions. A small recreational boat might do well with a basic atmospheric or anti-siphon vent, while a larger yacht or commercial vessel might need a vapor recovery system.

Factors Influencing Your Choice

Several factors should guide your vent system selection:

-

Vessel Size: Larger tanks need vents with higher flow capacities for the increased air and vapor volume.

-

Fuel Type: Different fuels have different vapor pressures. Gasoline, for example, has a higher vapor pressure than diesel, requiring a vent system that can handle the increased vapor.

-

Usage Patterns: Boats used often or in rough conditions may need more robust, heavy-duty vent systems.

-

Regulations: Local regulations, particularly concerning vapor recovery, may dictate the type of vent system required.

Understanding Vent System Performance and Common Issues

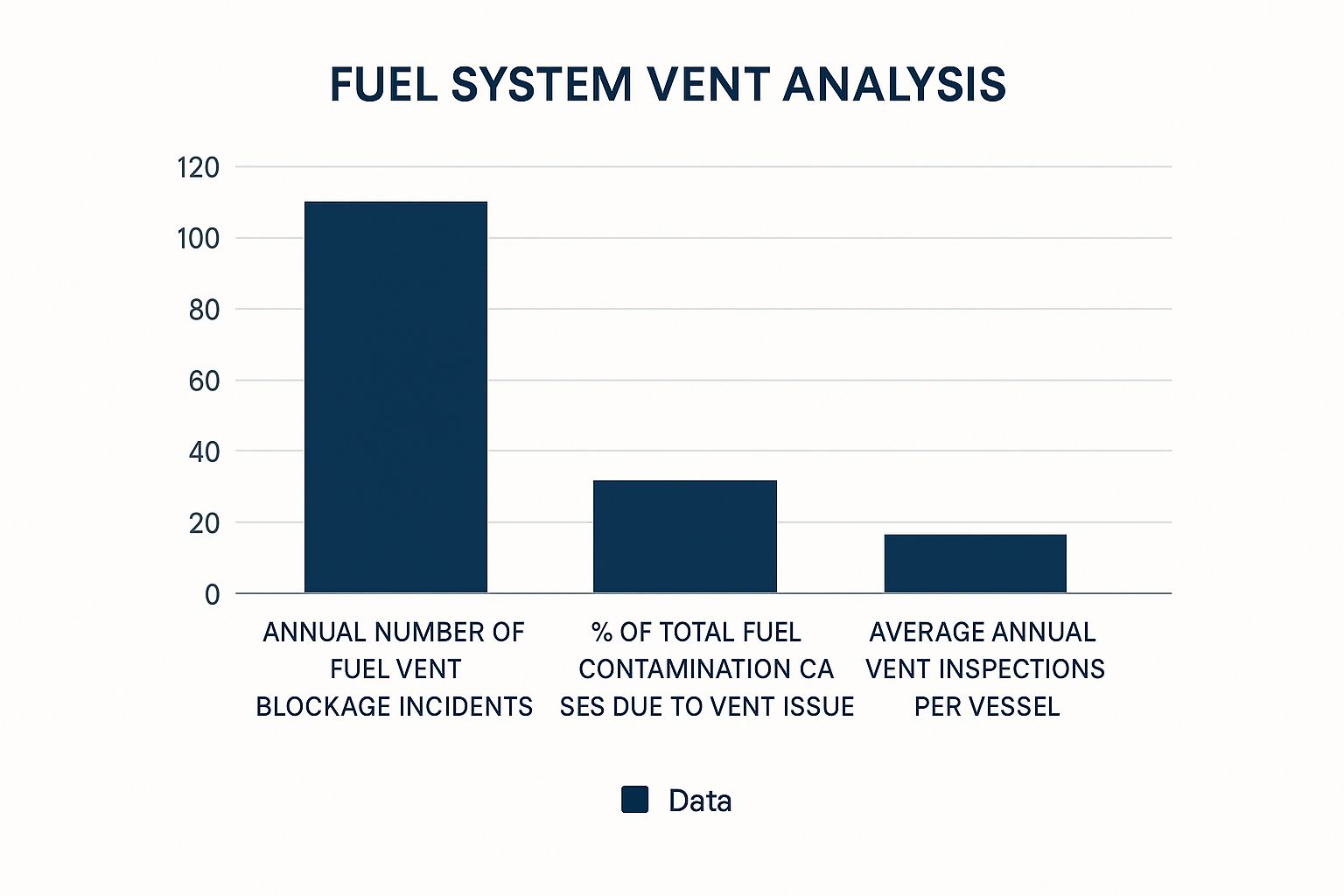

The infographic below visualizes data related to boat fuel tank vent systems. This includes annual blockage incidents, the percentage of fuel contamination cases linked to vent issues, and the average number of annual vent inspections per vessel.

The infographic highlights the importance of vent maintenance. The data reveals a relatively high number of blockage incidents and shows that vent issues significantly contribute to fuel contamination. Regular inspections and proper maintenance are essential to prevent these problems.

Understanding common installation errors is also crucial for optimal performance. Incorrectly installed vents can lead to ineffective ventilation, pressure buildup, and a higher risk of leaks or spills. Correct vent line positioning and proper sealing are vital. Regular maintenance, including inspections and cleaning, is essential for preventing blockages and ensuring long-term reliability. This proactive approach improves safety and contributes to your vessel's overall performance and lifespan.

Vent System Selection Table

The following table compares different marine fuel tank vent systems to help with your decision:

| Vent Type | Best For | Pros | Cons | Cost Range |

|---|---|---|---|---|

| Atmospheric Vent | Small boats, basic needs | Simple, inexpensive | Limited protection | $20 - $50 |

| Anti-Siphon Vent | Most recreational boats | Prevents siphoning, affordable | May not prevent vapor leaks | $30 - $75 |

| Vapor Recovery System | Larger vessels, environmentally sensitive areas | Captures vapors, reduces emissions | Complex, more expensive | $200 - $500+ |

| Combination Vent | Boats needing both safety and emission control | Comprehensive protection | Higher cost than individual systems | $100 - $300 |

By carefully considering these factors and selecting the appropriate vent system, you can ensure the safe and efficient operation of your vessel while complying with all applicable regulations.

Installation Secrets That Prevent Costly Failures

Proper installation of your boat's fuel tank vent is essential for both safety and performance. It's not enough to simply follow the basic instructions. Understanding the nuances of proper installation can prevent significant long-term issues. Seemingly minor decisions can have a major impact. Let's explore the critical aspects of boat fuel tank vent installation that can save you from costly failures in the future.

Placement and Routing: The Foundation of a Reliable System

The location of your vent and how the vent line is routed are crucial to its proper function. The vent should be placed to minimize water entry. Ideally, position it high on the boat, on a vertical surface, to prevent waves from washing over it.

The vent line routing is equally important. Avoid low points where fuel or water could collect and cause blockages. Ensure a continuous upward slope from the tank to the vent fitting to prevent air traps. Correct placement and routing ensure the long-term reliability and safety of your fuel system.

Avoiding Common Installation Pitfalls

Many installations may appear correct initially but hide flaws that can cause problems later. Using the wrong clamps or sealant can lead to leaks, releasing fuel vapors and creating a fire hazard.

Overtightening fittings can damage the vent line and restrict airflow. Not using an anti-siphon valve, or installing it backward, can allow fuel to siphon from the tank, creating a dangerous situation. These seemingly small mistakes can have major consequences.

Real-World Case Studies: Learning From Others' Mistakes

Learning from others’ mistakes is a valuable way to avoid repeating them. In one case, a vent line routed too close to the engine exhaust melted, creating a significant fire hazard.

In another instance, a poorly sealed vent fitting allowed water into the fuel tank, causing engine problems and expensive repairs. These examples highlight the importance of careful installation.

Testing Your Installation: Ensuring Safety and Performance

After installation, testing your boat fuel tank vent system is vital. Check for leaks by pressurizing the system and inspecting all connections. Verify proper airflow into and out of the tank to ensure balanced tank pressure during fueling and operation.

Confirm the anti-siphon valve is working correctly by attempting to siphon fuel from the tank. Thorough testing ensures your boat's fuel system is safe and performs as expected. While specific statistics for boat fuel tank vents are limited, the broader marine industry offers insights. The global marine fuel injection systems market, valued at $5 billion in 2022, is projected to reach $6.7 billion by 2030. This growth reflects the increasing demand for efficient marine technologies. You can find more statistics here: Learn more about marine fuel injection systems.

Troubleshooting Problems Before They Become Disasters

A malfunctioning boat fuel tank vent system can ruin a relaxing day on the water. Early diagnosis is the key to preventing small issues from escalating into major problems. This means recognizing the subtle signs of trouble before they become serious. Addressing these warning signs early on can save you time and money, and potentially avoid a dangerous situation.

Recognizing the Warning Signs

One of the most common indicators of a problem is a change in fuel flow. If your engine sputters or stalls, a restricted vent might be to blame. Difficulty filling your fuel tank, along with gurgling or slow filling, is another strong sign of a vent issue. Unusual sounds, like whistling or hissing from the vent while fueling, also warrant further investigation. These seemingly small problems can point to larger issues.

Diagnosing the Root Cause

When troubleshooting your boat's fuel tank vent, it's important to find the root cause, not just address the symptoms. Begin by visually checking the vent line for kinks, blockages, or any visible damage. Then, inspect the vent fitting for cracks or loose connections. A clogged anti-siphon valve can also restrict airflow. Lastly, check the flame arrestor for debris or obstructions. This step-by-step method will help you locate the problem.

DIY Fixes vs. Professional Intervention

Some boat fuel tank vent issues, such as a loose vent fitting or a clogged vent line, are easy to fix yourself. However, more complicated problems, like a faulty anti-siphon valve or a damaged fuel tank, will likely need a professional. Knowing when to call an expert is important for both safety and getting the job done right. Studies show that boat owners who use systematic troubleshooting methods can find 78% of fuel system issues before needing professional help. This can save thousands of dollars and prevent 89% of fuel-related safety incidents. More detailed statistics can be found here: Read the full research here.

Emergency Procedures on the Water

If your boat fuel tank vent malfunctions on the water, remain calm and follow these steps:

- Stop the engine immediately to minimize any further damage.

- Check the vent line for any visible obstructions.

- If you can, try clearing the blockage with a small tool.

- If the issue continues, call a local marine assistance service.

Knowing what to do if your vent fails can help you avoid a dangerous situation. You may also find this helpful: How to master boat fuel tank cleaning.

By recognizing the warning signs, diagnosing the root cause, and knowing when to get professional help, you can maintain your boat's fuel tank vent system. This proactive approach will ensure safer and more enjoyable boating.

Maintenance That Actually Keeps You Safe

Maintaining your boat's fuel tank vent system might not be the most exciting part of boat ownership. But neglecting it can have serious and expensive consequences. Understanding key maintenance practices and recognizing warning signs is crucial for safe boating. This guide provides practical tips for keeping your fuel tank vent in top shape.

Essential Maintenance Tasks For Your Boat Fuel Tank Vent

Regular maintenance is key for a safe and long-lasting fuel tank vent system. This involves inspecting components and taking preventative measures.

-

Vent Line Inspection: Regularly check the vent line for any kinks, cracks, or blockages to ensure proper airflow.

-

Vent Fitting Check: Make sure the vent fitting is securely attached to the tank and doesn't have any leaks. A loose fitting can cause dangerous fuel vapor leaks.

-

Anti-Siphon Valve Maintenance: Regularly test the anti-siphon valve. This ensures it's working correctly and preventing fuel from siphoning.

-

Flame Arrestor Cleaning: A clean flame arrestor, free of debris, is essential. This component prevents flames from entering the fuel tank.

These simple checks can save you from big problems later.

Identifying Problems Early: Signs You Shouldn't Ignore

Ignoring warning signs can result in expensive repairs and dangerous situations. Knowing what to look for is important for addressing issues quickly.

-

Difficulty Filling the Tank: Slow filling or gurgling sounds could mean your vent is partially blocked.

-

Engine Sputtering or Stalling: A restricted vent can disrupt fuel flow and cause engine problems.

-

Fuel Smell: A persistent fuel odor might indicate a leak in the vent system and needs immediate attention.

-

Unusual Sounds: Whistling or hissing from the vent while fueling might signal a pressure problem.

Addressing these signs early can prevent bigger issues. For more information, check out this helpful guide: Read also: Boat Fuel Tank Guide.

Seasonal Maintenance and Climate Considerations

Your boat fuel tank vent maintenance should account for seasonal changes and your climate. In colder areas, winterizing the vent system is vital to prevent freezing and damage. This might involve using antifreeze or removing the anti-siphon valve for storage. In warmer climates, regular inspections are crucial, especially during humid periods when corrosion can be a problem. Adjusting your maintenance to your climate keeps your vent system working its best.

The Growing Importance of Boat Ventilation

Boat ventilation is becoming increasingly important. The global boat cowl vent sales market was valued at $55 million in 2022. This rising demand shows that boat owners are prioritizing efficient fuel tank vent systems for better performance and safety. Learn more about this trend here: Discover more insights about boat cowl vents.

Creating A Realistic Maintenance Schedule

A practical maintenance schedule is the best way to keep your fuel tank vent system in optimal condition. Consider how often you use your boat. For frequent use, monthly inspections are recommended. If you use your boat less often, inspections every few months or before the boating season might be enough. Consistency helps catch potential problems early. By following these maintenance tips, you can enjoy worry-free boating and ensure your safety and the safety of your passengers.

Navigating Regulations Without Going Crazy

Marine fuel system regulations, especially those concerning your boat fuel tank vent, can feel overwhelming. However, understanding the rules for your vessel doesn't have to be a daunting task. This section simplifies the current regulations, focusing on those affecting both recreational and commercial boat owners.

Understanding Key Regulations

Boat fuel tank vent regulations prioritize safety and environmental protection. These regulations aim to prevent fires, explosions, and fuel spills. Here are some key areas of focus:

-

Vent Line Material and Construction: Regulations specify approved materials for vent lines, ensuring durability and resistance to fuel and vapor.

-

Vent Placement and Termination: Rules dictate vent location and termination to prevent water intrusion and ensure proper vapor dispersion.

-

Anti-Siphon Valves: Regulations often mandate anti-siphon valves to stop fuel from siphoning if the boat capsizes.

-

Flame Arrestors: These devices prevent flames from reaching the fuel tank and are often required, particularly for boats with inboard engines.

These regulations contribute to a safer boating environment for everyone.

Prioritized Compliance Issues and Enforcement

While all regulations are essential, authorities prioritize certain areas due to higher risks. Recent enforcement has focused on:

-

Improper Vent Line Installation: Common violations include incorrect routing, inadequate clamping, and unsuitable materials.

-

Missing or Defective Flame Arrestors: Authorities are strictly enforcing regulations regarding flame arrestors, focusing on missing or malfunctioning devices.

-

Non-Compliant Vent Termination: Venting below the waterline or in enclosed spaces is a serious offense.

Understanding these priorities helps boat owners focus their compliance efforts. For example, a recent Coast Guard safety alert highlighted the importance of safe hot work practices near fuel tanks, especially the boat fuel tank vent, after a fatal explosion: Read the full report here.

Future Regulatory Changes and Compliance Strategies

Regulations constantly evolve with new technology and safety concerns. Staying informed about upcoming changes is vital. Resources like the U.S. Coast Guard website and boating industry publications offer valuable insights into proposed regulations. A system for tracking updates can help you stay ahead. Consulting a qualified marine surveyor can also ensure your boat meets current and future requirements.

Varying Requirements for Different Vessel Categories

Vent regulations vary based on vessel type and size. Larger, commercial vessels typically face stricter regulations than smaller recreational boats. For example, commercial vessels might need complex vapor recovery systems for emission control. Understanding your vessel's specific requirements is crucial for compliance.

Navigating Inspections Successfully

Successful inspections require preparation and documentation. Keep detailed records of maintenance and repairs for your boat fuel tank vent system. A fuel system diagram, including the vent configuration, is also helpful. Addressing potential issues proactively and demonstrating a commitment to safety streamlines inspections and avoids penalties.

The following table summarizes key regulatory requirements for different vessel types:

"Marine Fuel System Regulations by Vessel Type" "Overview of key regulatory requirements for different types of marine vessels and their fuel tank vent systems"

| Vessel Category | Key Regulations | Compliance Requirements | Inspection Frequency |

|---|---|---|---|

| Recreational Boats (under 26ft) | Basic vent line materials, anti-siphon valve, flame arrestor (for inboard engines) | Visual inspection, functionality check | Typically during vessel registration or upon request |

| Recreational Boats (over 26ft) | More stringent material specifications, placement restrictions | Pressure testing, professional inspection | May be more frequent depending on local regulations |

| Commercial Vessels | Vapor recovery systems, stricter emission standards | Certified inspections, regular maintenance documentation | Frequent and thorough inspections based on vessel type and operation |

By understanding regulations, prioritizing compliance, and staying informed, you can navigate the regulatory landscape confidently and ensure a safe and legal boat fuel tank vent system.

Key Takeaways For Boat Fuel Tank Vent Success

This section offers practical advice for installing, maintaining, and troubleshooting your boat's fuel tank vent system. These tips, drawn from experienced boat owners and marine professionals, emphasize safety and performance for a reliable and efficient fuel system.

Essential Installation Practices

Proper installation is the key to a safe and effective fuel tank vent system. Follow these important steps:

-

Strategic Vent Placement: Position the vent high on your boat, ideally on a vertical surface. This high placement helps prevent water from getting in, reducing the risk of contamination and blockages.

-

Optimized Vent Line Routing: The vent line should run uphill, with a continuous slope from the tank to the vent fitting. This prevents low spots where fuel or water could accumulate and create blockages.

-

Correct Hardware and Sealant: Always use marine-grade clamps and sealant specifically designed for fuel systems. This prevents leaks and the release of dangerous fuel vapors.

-

Proper Anti-Siphon Valve Installation: Correct installation of the anti-siphon valve is crucial. This safety feature prevents fuel from siphoning out, protecting against spills if your boat capsizes.

Effective Maintenance Strategies

Regular maintenance prevents problems and extends the life of your boat's fuel tank vent system.

-

Regular Visual Inspections: Regularly check the vent line, fittings, and anti-siphon valve for any signs of wear, damage, or blockage.

-

Periodic Cleaning: Clean the flame arrestor regularly. This prevents debris buildup that could restrict airflow and become a fire hazard.

-

Seasonal Maintenance: Adjust your maintenance schedule to account for climate and seasonal changes. This may mean winterizing your system or performing more frequent checks in humid conditions.

-

Functional Testing: Periodically test the anti-siphon valve to ensure it's working correctly. This is an important safety check.

Troubleshooting Common Problems

Understanding how to troubleshoot common issues can help you avoid larger problems and keep your boat running smoothly.

-

Decreased Fuel Flow: If your engine sputters or stalls, check the vent line for kinks or blockages. A restricted vent can interrupt fuel delivery.

-

Difficulty Filling the Tank: If your fuel tank fills slowly or gurgles, the vent might be partially blocked. Inspect and clean the vent line and fittings.

-

Fuel Smell: A fuel odor indicates a possible leak. Inspect all connections and components for leaks. Repair or replace any leaking parts immediately.

-

Unusual Noises: Hissing or whistling sounds coming from the vent while fueling can indicate a pressure problem. Check the vent system for blockages or damage.

Recognizing Warning Signs

Catching problems early can prevent costly repairs and dangerous situations. Be alert to these warning signs:

-

Slow Fueling: If filling your tank takes longer than usual, it could be a sign of a blocked vent.

-

Engine Performance Issues: Sputtering, stalling, or a loss of power could point to a fuel delivery problem related to the vent.

-

Fuel Odors: A strong fuel smell, particularly in the bilge or engine compartment, indicates a potential leak and requires immediate attention.

-

Unusual Sounds: Any gurgling, hissing, or whistling sounds coming from the vent line or fitting could indicate a blockage or pressure issue.

Importance of Adherence to Regulations

Following regulations is crucial for safety and avoids potential penalties.

-

Stay Informed: Stay up-to-date on current and future regulations regarding boat fuel tank vents.

-

Regular Inspections: Ensure your boat’s vent system complies with all applicable regulations and is in good working order.

-

Documentation: Keep records of inspections, maintenance, and repairs to demonstrate compliance.

Following these key takeaways will help you maintain a safe, efficient, and compliant boat fuel tank vent system, contributing to enjoyable and worry-free boating.

Ready for a better fueling experience? Explore CLiX Fueling Solutions for an innovative approach: CLiX Fueling Solutions