When you're dealing with fuel or oil, you're not just moving a liquid from point A to point B—you're also fighting a hidden battle against contamination. That's where a transfer pump with a filter becomes your most valuable player. It's a simple but brilliant tool that does two jobs in one: moving fluids while cleaning them on the fly.

Think of it as both a delivery service and a bouncer for your boat’s engine. It ensures only the good stuff gets in, keeping the troublemakers out.

What a Transfer Pump with Filter Actually Does

You wouldn't want coffee grounds in your morning cup, right? You use a filter to make sure you only get smooth, clean coffee. A transfer pump with a filter works on the exact same principle, just for much more critical fluids like diesel fuel or hydraulic oil.

First, the pump itself does the heavy lifting. It creates a vacuum to pull fluid from a source—maybe a jerry can, a storage drum, or your boat's main tank. Then, it pushes that fluid down the line to its final destination. That’s the "transfer" part.

The All-Important Filtration Stage

But here's where the magic happens. Before that fluid gets to your pristine engine, it has to pass through an integrated filter. This isn’t just a basic mesh screen; it's a specialized element designed to trap microscopic gunk that you'd never see with the naked eye.

What kind of gunk are we talking about?

- Debris: Tiny flecks of rust from an old tank, dirt, or sediment that’s settled at the bottom.

- Water: The engine's worst enemy. Condensation builds up in fuel tanks, and it can cause corrosion and serious performance issues.

- Sludge: A nasty, gummy residue that forms as fuel breaks down over time.

To really understand how these parts work together, let's break down their jobs.

Key Functions at a Glance

| Component | Primary Function | Key Benefit |

|---|---|---|

| Pump | Moves fluid from the source to the destination. | Enables efficient and fast transfer of liquids. |

| Filter | Captures and removes contaminants from the fluid. | Protects sensitive engine parts from wear and damage. |

This two-in-one system is a game-changer for anyone who relies on clean fluids for their machinery.

By snagging these contaminants before they can ever reach your engine, the filter essentially stands guard. It makes sure the fuel or oil arriving is pure, which is the best defense you have against clogged fuel injectors, damaged pumps, and other costly repairs. This simple process is the cornerstone of good preventative maintenance, especially for marine engines where reliability is everything.

How These Pumps Protect Your Engines

Think of a transfer pump with a built-in filter as a dedicated bodyguard for your engine. To really get why this is so important, let's trace the fuel's path from the tank to your engine. It all starts when the pump begins to draw fuel, pulling it out of the source and into the filtration chamber. This is where the real magic happens.

This isn't just a basic screen, either. Inside the filter is a specially designed media that's engineered to catch all sorts of nasty contaminants. The filter's power is measured by its micron rating, which is just a fancy way of saying how small the particles are that it can stop.

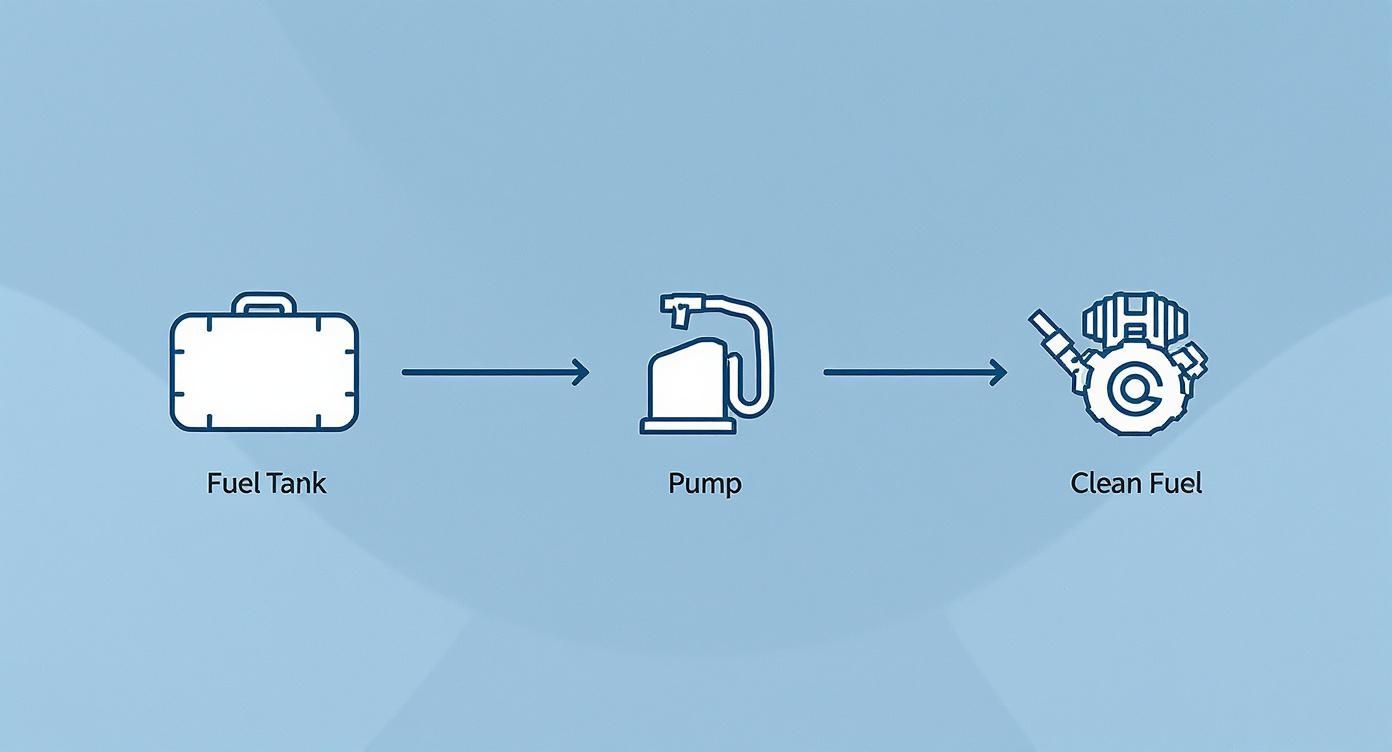

This infographic lays out the simple but essential journey the fuel takes, showing how the pump and filter work in tandem to deliver clean fuel.

As you can see, the pump and filter act as a critical checkpoint, stripping out harmful debris before it ever has a chance to reach your engine.

Understanding Micron Ratings

The micron rating is probably the single most important detail to look at when you're choosing a filter. A smaller number means finer filtration—and that’s a huge deal for modern engines built with incredibly tight tolerances.

- 10-Micron Filter: This is your super-fine net. It's the go-to for modern high-pressure diesel engines because it catches the tiny particles that can wreck sensitive fuel injectors, causing poor performance and some seriously expensive repair bills.

- 30-Micron Filter: This one has a slightly wider mesh. It’s a great fit for older engines or equipment that isn't quite as fussy about microscopic gunk.

Picking the right micron rating is more than just a technical choice—it's the best way to stop fuel system clogs and save your engine’s most critical parts from wearing out too soon. This level of filtration is especially crucial for protecting the sensitive components inside specific diesel portable generators and keeping them reliable for the long haul.

If you're a boater, getting the filtration right is even more critical because of the tough marine environment. You can dive deeper into choosing the right marine fuel filter to make sure your vessel runs like a dream. It’s a simple step that buys you a whole lot of peace of mind out on the water.

The Real-World Benefits of Clean Fuel Transfer

Using a transfer pump with a filter isn't just another box to check—it's one of the smartest investments you can make for the health and reliability of your engine. The link between clean fuel and real-world results becomes crystal clear when you look at the direct impact on your wallet and your time on the water.

Think about it this way: stopping contaminants before they ever reach your engine isn't just about being tidy. It’s about preventing catastrophic downtime. When dirt, water, or sludge finds its way into fuel injectors or other sensitive parts, you get an engine that won’t start, leaving you high and dry at the dock. Every single particle the filter catches is a potential repair bill you just avoided.

Maximizing Efficiency and Safety

Beyond just dodging breakdowns, clean fuel has a direct line to performance. A fuel system that’s free of gunk allows for a much more complete and efficient burn. What does that mean for you? More power out of every gallon. This isn't just about saving money at the pump; it ensures your engine runs smoother and responds the moment you need it to.

This whole "ounce of prevention" approach is a huge deal in modern maintenance. In fact, the global market for bulk filtration, which includes systems like a transfer pump with filter, was valued at $15.87 billion back in 2022 and is only getting bigger. You can dive deeper into these market trends on ResearchAndMarkets.com.

The takeaway is simple: a small investment in a quality pump pays for itself many times over by helping you sidestep thousands in potential repairs. It’s the easiest preventative maintenance you can do.

At the end of the day, a clean fuel supply is fundamental to your safety. An engine failing at the wrong time can be more than an inconvenience—it can be downright dangerous. For any boater, keeping your fuel pristine is a non-negotiable step, a point driven home in any expert guide on marine fuel tank cleaning.

Choosing the Right Transfer Pump for Your Needs

Picking the right transfer pump with a filter doesn't have to be complicated, but it does require thinking about exactly what you'll be doing. A boater's needs are worlds away from a farmer's, and getting this choice right from the start saves a lot of headaches later. It's all about ensuring efficiency, safety, and a long life for both your pump and the engine you're protecting.

Your decision really comes down to four key areas. Let's walk through them.

Evaluate Your Pumping Requirements

First up, what are you actually trying to accomplish? Think about the flow rate, which is just a fancy way of saying how fast the pump moves fuel, measured in gallons per minute (GPM). If you’re filling up a massive piece of machinery, a higher GPM is your best friend—it gets the job done quickly. But for smaller jobs, like topping off a dinghy, a slower pump is often easier to handle and all you really need.

Next, where are you getting your power? This is a big one. Your main choices are:

- AC (Alternating Current): These are your plug-in-the-wall models. They're perfect for a workshop, garage, or any spot with a standard outlet. They deliver steady, reliable power.

- DC (Direct Current): These are the road warriors. They hook right up to a vehicle or boat battery, usually 12V or 24V. This makes them the obvious choice for mobile refueling on a farm, at a construction site, or out on the water.

You can't mix and match these, so it's a critical decision.

Match the Pump to the Fluid

This is a non-negotiable safety point. You absolutely cannot use a pump meant for diesel to move gasoline. Gasoline is far more volatile, and doing so is just asking for trouble. The pump's materials—everything from the seals to the housing—must be built to handle the specific liquid you're transferring. Otherwise, they can break down, causing dangerous leaks.

Finally, look closely at the filter specifications. The micron rating tells you how small of a particle the filter can catch, and it needs to match your engine's requirements. A modern marine diesel engine, for example, has incredibly sensitive injectors and needs a very fine filter (around 10 microns) to keep them safe. We dive deeper into this in our guide on choosing the right marine fuel transfer pump.

The demand for clean fuel is massive. Consider that in 2023, global vehicle production hit a staggering 93.5 million units—a huge jump from the previous year. Every single one of those engines relies on pristine fuel to run properly, which is why pumps with built-in filters have become so common.

Pump Feature Comparison for Different Applications

To make it even clearer, let's look at how these needs change across different fields. The right pump for a boat isn't the best fit for a tractor.

| Feature | Boating / Marine | Agriculture | Construction Site |

|---|---|---|---|

| Typical Flow Rate | 5-15 GPM (controlled fueling for boats) | 15-25 GPM (faster refueling for machinery) | 20-30+ GPM (high-volume for heavy equipment) |

| Power Source | 12V / 24V DC (onboard battery power) | 12V DC or AC (from vehicle or shop) | 12V DC or AC (from trucks or generators) |

| Fluid Type | Diesel, Gasoline (marine-rated pumps) | Diesel, Kerosene | Diesel |

| Filter Needs | 10-micron filter for sensitive engines | 30-micron filter for general protection | 30-micron filter for durability |

As you can see, matching the pump's features to your specific job is the key to getting a reliable and effective setup.

Getting Set Up and Keeping It Running

Picking the right transfer pump is a great start, but getting the installation and maintenance right is what really counts. It's the difference between a tool that works flawlessly for years and one that causes constant headaches. Think of it this way: even the best engine won't last long without oil changes. A little bit of care goes a long way.

First things first, let's talk about installation. You want to mount your pump on a solid, level surface. Vibration is a killer for any kind of machinery, so bolting it down securely is non-negotiable. After that, make sure every hose connection is completely airtight. A tiny air leak in the suction line is one of the most common reasons a pump won't prime or perform well, so use a good thread sealant on all the fittings.

Finally, don't rush the electrical work. If you've got a DC-powered pump, use the right size wire for the job and always connect it through a properly rated fuse. Skimping here is just asking for trouble down the line.

A Simple Maintenance Checklist

Staying on top of maintenance is way easier than dealing with a breakdown when you least expect it. Keeping your transfer pump with filter in good shape is quick and simple—it just takes a bit of consistency.

A regular schedule makes sure your gear is always ready to go. Just like understanding servicing intervals for equipment like regulator brands is crucial for divers, knowing when to check on your pump is key for boaters. This focus on reliability is why the market for clean fuel handling has grown so much.

In fact, the global market for fuel transfer pumps hit a value of about USD 1.76 billion in 2022. That's a huge number, and it shows just how many people rely on these pumps to move fluids cleanly and safely.

Here’s a quick checklist to make it easy:

- Quick Look-Over: Before you fire it up, give the pump and hoses a quick visual inspection. Look for any cracks, leaks, or obvious signs of wear.

- Watch the Flow: Is the pump suddenly much slower than it used to be? That’s the classic sign of a clogged filter or a sneaky air leak.

- Swap the Filter: Don't wait for it to clog completely. Change the filter element based on the manufacturer's advice or as soon as you notice the flow slowing down.

- Wipe It Down: After you’re done, give the pump a quick wipe to get rid of any dirt or grime. This prevents buildup that can wear down the parts over time.

Common Questions About Transfer Pumps and Filters

https://www.youtube.com/embed/tKrkoxrY2wc

Even when you think you've got everything set up perfectly, questions pop up. It’s totally normal. Getting straight answers helps you run your gear with confidence and nip small issues in the bud before they turn into real headaches.

Here are some of the most common questions we hear from boaters about using a transfer pump with a filter.

How Often Should I Change the Filter?

This is easily the number one question we get. Unfortunately, there's no single magic number, since it all comes down to how clean your fuel is and how often you're actually using the pump.

A good rule of thumb is to swap out the filter element every six months. You can also follow the manufacturer's recommendation, which might be based on how many gallons you've pumped. But honestly, your pump will tell you when it's time.

The moment you notice a significant drop in your pump's flow rate, it's a dead giveaway that the filter is getting clogged. Don't wait—change it right away, even if it’s ahead of schedule.

Can One Pump Handle Both Diesel and Gasoline?

This is a huge safety question, and the answer is almost always a hard no. You should never use the same pump for both diesel and gasoline unless the manufacturer explicitly states it's rated for both.

Gasoline is way more flammable and needs a pump with an explosion-proof motor. It also requires special seals and gaskets that won't break down when exposed to gasoline's harsh additives. Using a diesel-only transfer pump with filter for gasoline is a recipe for disaster and could cause a fire or explosion. Always, always check the pump's specifications.

What Should I Do if My Pump Runs but Moves No Fluid?

It's a frustrating moment: you hear the pump humming away, but nothing is happening. Don't panic! This is usually just an air leak or a loss of prime, and the fix is often pretty straightforward.

Here’s what to check:

- Look at the Suction Hose: Make sure the end of the hose is completely submerged in the fuel. Give the hose a quick once-over for any cracks or loose fittings that might be letting air in.

- Give it a Minute to Prime: If you have a self-priming pump, sometimes it just needs a moment to work the air out of the line on its own. Be patient.

- Check for Blockages: A totally clogged filter or some gunk stuck in the hose can bring everything to a halt. Disconnect the lines and check for any debris.

Keeping these simple points in mind will help you get the most out of your equipment, making sure it's ready to go reliably whenever you need it.

At CLiX Fueling Solutions, we believe fueling your boat should be simple and safe. Our automatic shut-off system prevents dangerous and costly spills, protecting your vessel and the marine environment.

Discover a spill-free fueling experience on clixfueling.com