Manual transfer pumps are your get-out-of-jail-free card for moving fluids on a boat. Forget relying on electricity—these simple, dependable tools give you total control when transferring fuel, oil, or water.

Think of it this way: instead of wrestling with a heavy fuel can at an awkward angle, trying to pour into your tank while the boat is rocking, a manual pump creates a clean, direct bridge. It’s the difference between a messy, frustrating chore and a quick, simple task. Their genius is in their simplicity; they just work, every single time.

Why Manual Pumps Are a Boater's Best Friend

Anyone who's spent time on the water knows the unique headache of fueling. The boat is bobbing, the fuel intake is hard to reach, and the last thing you want is a costly, environmentally harmful spill. This is precisely where a good old-fashioned manual transfer pump becomes an absolute must-have piece of gear.

While automatic systems are great, they can't match the feel and precision of a manual transfer pump. You’re the one controlling the flow. You can feel the fluid moving, slow things down as the tank gets full, and stop on a dime. This hands-on control is the most straightforward way to prevent overfilling and make sure every expensive drop of fuel ends up in the tank, not in the water.

The Reliable Choice for Any Situation

The real beauty of a manual pump is that it's bomb-proof. There are no wires to corrode in the salty air, no batteries to die at the worst possible moment, and no fussy electronics to fail when you’re miles from shore. That makes it the perfect backup and an essential tool for all sorts of jobs on board.

- Spill-Free Fueling: Easily top off your tank from a jerry can without splashing fuel all over the deck.

- Engine Maintenance: Neatly pump out old oil during a change or transfer coolant without making a mess in the bilge.

- Winterization: Quickly and easily pump antifreeze through your engine and plumbing to get your boat ready for storage.

And it’s not just boaters who appreciate this kind of reliable utility. The global market for hand fuel transfer pumps was valued at around USD 1.2 billion in 2023 and is expected to climb to USD 2.0 billion by 2032. This isn't just a niche tool; it's a testament to how crucial portability and dependability are in the real world. You can see more market insights on dataintelo.com.

Finding the Right Pump for Your Needs

Not all manual transfer pumps are built the same, and picking the right one for your boat really comes down to matching the tool to the task. It’s a bit like choosing a wrench—you wouldn't use a tiny adjustable one to bust a big rusty bolt. The best pump for you depends entirely on what you're moving, how much of it, and where it’s going.

Getting a feel for the fundamental differences between pump types is what separates a frustrating experience from a job well done. It helps you move past the generic options at the hardware store and find a tool that’s truly a good fit for life on the water. Each design offers its own unique mix of control, speed, and simplicity.

The Main Types of Manual Transfer Pumps

Let's dive into the most common designs you'll run into. They all work on pretty simple principles but really shine in different situations on board.

Here's a quick look at the main players you’ll find in the marine world.

Manual Pump Types at a Glance

| Pump Type | How It Works | Best For | Pros | Cons |

|---|---|---|---|---|

| Siphon Pump | Creates a vacuum (often with a squeeze bulb) to start a flow, then lets gravity do the work. | Quick, downward transfers from a higher container to a lower one (e.g., jerry can to fuel tank). | Simple, cheap, no moving parts to break. | Requires a height difference; limited control over flow rate. |

| Piston Pump | Pulling a handle creates suction in a cylinder, drawing fluid in. Pushing the handle expels it. | Precise tasks like oil changes, adding coolant, or winterizing engines. | Excellent control, good for thick fluids. | Slower for large volumes; requires continuous effort. |

| Diaphragm Pump | A flexible diaphragm is moved back and forth, creating suction and pressure to move fluid. | Bilge pumping, wastewater, or moving water with small debris. | Can run dry without damage, self-priming. | Flow can be pulsating; not ideal for very high pressure. |

| Rotary Pump | A hand crank turns internal gears or vanes, creating a smooth, continuous flow. | High-volume transfers of fuel or oil from large drums or tanks. | Fast and efficient for large quantities. | More complex and expensive; can be bulky. |

Understanding these basic differences is the first step in making sure you have the right tool on hand when you need it most.

Matching the Pump to the Marine Task

Now, let's tie these pump types to some real-world jobs on a boat. This is where it all clicks.

The humble siphon pump is a must-have for just about every boater. It's the perfect tool for quick top-offs from a portable fuel can. They’re inexpensive, easy to tuck away, and ideal for smaller jobs where you can get the source container sitting higher than your tank.

Think of it this way: a siphon pump uses gravity as its engine. Once you get the flow started, it turns a potentially messy pour into a controlled, hands-off transfer.

But when you need a bit more muscle or accuracy, that's when piston or rotary pumps earn their keep. A piston pump is your best friend during maintenance. Its controlled suction is perfect for pulling old engine oil out through a narrow dipstick tube or carefully adding fluids without making a mess. For a detailed breakdown of the best models out there, check out our guide on the top manual transfer pump for fuel in 2025.

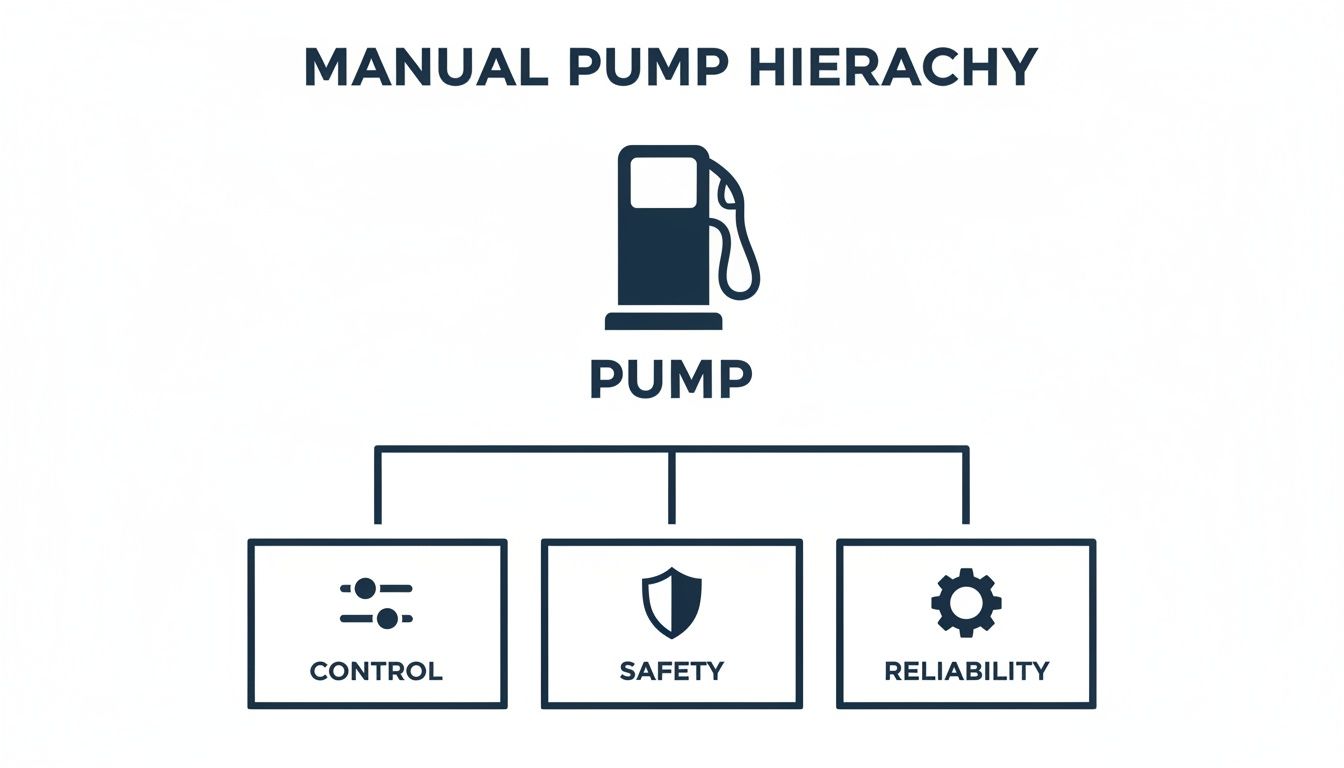

As you can see, a great pump isn't just about moving liquid from point A to point B. It’s about giving you complete command over the process while being safe and reliable every single time.

Finally, the rotary pump is the workhorse for bigger jobs. Think emptying a large auxiliary tank or refueling from a 55-gallon drum on the dock. Its ability to move fuel fast makes a long job much more manageable. By getting to know these core differences, you can equip your boat with the right manual pumps for any situation the water throws at you.

How to Choose a Safe and Reliable Pump

Picking the right manual transfer pump is about more than just getting fuel from one container to another. It's a critical decision that affects your safety, the life of your equipment, and the health of the water you're on. A cheap, flimsy pump isn't a bargain—it's a liability just waiting to cause a problem.

Taking a few minutes to think through the key criteria will help you find a pump you can count on. The big three are material compatibility, flow rate, and the pump's overall design, including its hoses. Nail these, and you'll have a reliable tool for years to come.

Material Compatibility Is Non-Negotiable

This is, without a doubt, the most important safety check. Gasoline and diesel are aggressive solvents that will eat away at standard plastics and rubber seals, creating the perfect conditions for a dangerous leak. A pump that isn't specifically rated for fuel can literally fall apart in your hands, leading to a spill and a serious fire hazard from the flammable vapors.

When you're looking at a manual transfer pump, keep an eye out for these must-have features:

- Fuel-Resistant Seals: Look for materials like Viton or Nitrile. They’re built to stand up to petroleum products without degrading.

- Durable Body Construction: The pump body should be made of high-grade, fuel-compatible plastics or a sturdy metal like aluminum that won't crack or dissolve.

- Anti-Static Hoses: This is a huge safety feature. Anti-static hoses prevent the buildup of static electricity, which could otherwise create a spark and ignite fuel vapors.

Choosing a pump made from the right materials isn't just a best practice—it's your first line of defense against catastrophic failure. A fuel-rated pump is a safe pump.

Balancing Flow Rate with Control

Flow rate, usually measured in gallons per minute (GPM), tells you how fast the pump can move liquid. But faster isn't always better. You're looking for the sweet spot between speed and control, and that really depends on the job.

A simple siphon pump, for instance, might move just 1-2 GPM. That's perfect for carefully topping off a small outboard without making a mess. On the other hand, a heavy-duty rotary pump designed for bigger jobs can churn out 5-10 GPM, which is great for quickly moving fuel from a large drum. Think about what you'll be doing most often and pick a flow rate that gives you controlled, spill-free transfers.

Hose Length and Portability

Finally, think about the practical side of actually using the pump on your boat. The hose has to be long enough to reach from your fuel can to your tank without being stretched tight. A hose that's too short or prone to kinking will just restrict the flow and make your life harder. A flexible, kink-resistant hose is a massive plus, especially in tight quarters.

Portability is another huge factor, especially for boaters. The hand fuel transfer pump has carved out its niche in the market precisely because it's so easy to carry and store. This is a big deal in North America, which accounts for about 60% of global demand. For the average boater, a good manual pump helps avoid spills caused by inaccurate tank gauges—a problem tied to over 25% of reported fuel-related damages. Discover more insights about the fuel transfer market on Grand View Research.

Mastering Your Manual Transfer Pump

A manual transfer pump is one of the most reliable tools you can have on board, but that dependability comes down to one thing: proper care. Just like any other essential piece of marine gear, taking a few moments to prep it before a job and clean it afterward makes all the difference. Mastering these simple routines ensures your pump is always ready to go when you need it, safely and without a fuss.

Think of it this way: these quick checks are your best defense against common frustrations. They turn what could be a messy, annoying task into a smooth, controlled process. It's all about building good habits that protect your gear and keep it in top shape for years to come.

Pre-Use Pump Checklist

Before you even think about moving fuel, run through this quick inspection. It seriously takes less than a minute and can save you from a world of headaches like leaks, spills, and poor performance.

- Inspect the Hoses: Give both the intake and outlet hoses a good look-over. You're searching for any visible cracks, signs of brittleness, or splits—pay special attention to the ends where they connect to the pump, as that’s where most of the stress happens.

- Check All Connections: Make sure the hoses are pushed on tight. A loose connection is the number one reason for air leaks, which will absolutely kill your suction and stop the pump from priming.

- Confirm Proper Setup: If you're using a siphon pump, remember that gravity is doing the heavy lifting. Your source container must be higher than the tank you're filling. Give the fuel a clear downhill path, and it will flow smoothly.

Simple Maintenance and Troubleshooting

With just a little care, your pump will be a reliable friend for years. The good news is that most issues you'll run into with manual transfer pumps are incredibly simple to fix. In fact, over 90% of "failures" aren't mechanical at all—they're just simple things like air leaks or a clog.

A well-maintained manual pump is a reliable one. A quick post-use cleaning prevents residue buildup from gasoline, which can jam internal valves and stiffen seals over time.

So, if you run into trouble, don't assume the pump is toast. Start with the basics. Here are the most common snags and how to fix them in seconds.

Common Problems and Quick Fixes

-

Problem The Pump Won't Prime or Loses Suction

- The Fix: This is almost always an air leak. Go back and double-check that both hoses are seated firmly on the pump. Even a tiny gap is enough to break the vacuum. If that looks good, check the hoses again for any tiny pinhole cracks you might have missed.

-

Problem The Flow Rate Is Very Slow

- The Fix: First, look for kinks. Just like a garden hose, a sharp bend will choke off the flow. Make sure the hose has a smooth, gradual path from start to finish. If the path is clear, check the intake end for a filter screen—it might be clogged with sediment from the bottom of a tank.

By following these simple steps, you can keep your pump working like new. For a deeper dive into best practices, check out these expert tips for safe fuel transfer hand pump use. A little bit of preventative maintenance goes a long, long way on the water.

Fueling Safely and Protecting the Water

Using a manual transfer pump isn't just about moving fuel from point A to point B; it’s a hands-on part of being a responsible boater. The direct control these pumps give you is fantastic, but that control comes with a serious duty to keep yourself, your crew, and the water safe. Every time you refuel, you have an opportunity to protect the very environment you enjoy.

The heart of safe manual fueling is managing two invisible but potent dangers: flammable vapors and static electricity. Fuel fumes, especially from gasoline, are heavier than air. This means they can sink and collect in low spots like your boat's bilge, creating a ticking time bomb. Good ventilation is your number one defense.

Essential Safety Protocols for Fuel Transfer

Before you even start pumping, pause and run through a quick mental checklist. These habits are simple, but they’re the key to preventing the vast majority of fueling accidents and turning a risky task into a routine one.

- Ventilate, Ventilate, Ventilate: Always fuel in an open space. If you're docked, try to position your boat so the wind helps carry fumes away from you. Open up every hatch and port to stop vapors from getting trapped inside.

- Kill All Ignition Sources: This is non-negotiable. Shut down engines, electronics, bilge pumps, galley stoves—anything that could create a spark. It only takes one tiny spark to ignite a cloud of fuel vapor.

- Gear Up with PPE: A simple pair of fuel-resistant nitrile gloves will protect your skin, and safety glasses are a must to shield your eyes from an unexpected splash.

Be Prepared for the Unexpected

Even the most careful boater can have a mishap. The difference between a minor cleanup and an environmental headache is being prepared. A well-stocked spill kit isn't just a "nice-to-have"; it's a critical piece of safety equipment.

Make sure your kit has absorbent pads or booms made for petroleum products—they’re designed to soak up fuel and repel water, which makes them incredibly effective. Just as important is knowing how to use them in a hurry. For a detailed walkthrough, check out our expert guide on fuel spill cleanup procedures.

Prevention is always the best strategy. When you pair the deliberate control of a manual transfer pump with modern safety features, you create the most secure fueling setup possible.

Sadly, spills from manual handling still account for up to 15% of marine pollution incidents in coastal areas. It’s a sobering reminder that our choices matter, especially when an estimated 1.5 million tons of fuel pollute marine ecosystems worldwide each year. This is why CLiX Fueling Solutions integrates modern auto-shutoff technology with the reliable foundation of manual control, giving boaters a powerful tool for both convenience and environmental stewardship.

Pairing Manual Control with Modern Safety

There’s a reason so many seasoned boaters stick with manual transfer pumps: you get an unmatched feel for the fueling process. You can sense the liquid moving, ease up as the tank gets close to full, and stop on a dime. This hands-on control is why they've been a staple for anyone who values precision and simple, reliable gear.

But let's be honest, that method relies 100% on you paying attention. One moment of distraction—a dropped tool, a question from a crew member—is all it takes to cause a messy and dangerous overfill.

This is where you can build a truly complete safety system, one that bridges the gap between old-school reliability and modern, failsafe technology. Just because you're in command with a manual pump doesn't mean it has to be your only line of defense.

The Ultimate Safety Combination

Picture this: you're using your trusty manual pump, feeling the controlled flow you know and love, but you've also got an intelligent, automatic shutoff system acting as your spotter. That's how you create the safest possible fueling experience. It’s the best of both worlds.

You get the precision of manual pumping with the absolute peace of mind that an overfill is physically impossible.

This is exactly what you get with a system like CLiX Fueling Solutions. It acts as the final backstop, instantly cutting off the fuel flow the very second your tank is full. No drips, no spills, no second-guessing.

By pairing a manual transfer pump with an automatic shutoff system, you create a two-layered safety net. You're still in the driver's seat, but technology provides a final, guaranteed safeguard against spills.

This combination tackles the single biggest weakness of manual fueling: human error. You can focus on pumping at a steady, manageable pace, knowing the CLiX system is standing guard, ready to act.

This integrated approach gives the modern boater a complete, end-to-end solution. It respects the simplicity and dependability of a manual pump while adding an essential layer of modern safety. For anyone serious about protecting their boat and the marine environment, this blend of manual control and automated prevention is the gold standard for responsible fueling.

Common Questions About Manual Transfer Pumps

Even the simplest tools can spark a few questions. When it comes to something as important as moving fuel or water around your boat, getting the right answers is crucial. Let's tackle some of the most frequent questions boaters ask about manual transfer pumps.

Can I Use the Same Pump for Fuel and Water?

It might seem practical to use one pump for multiple jobs, but this is one corner you should never cut. Using the same pump for both fuel and water is a major safety risk.

Think about it: even a trace amount of gasoline or diesel left in a pump can contaminate your fresh water, making it dangerous to drink or use. On top of that, pumps built for water are often made with materials that can be quickly destroyed by harsh fuels. This can cause the pump to fail, leading to dangerous leaks.

The golden rule on any vessel is simple: keep fuel and water systems completely separate. A dedicated pump for each is the only safe and reliable practice.

Always have separate, clearly labeled manual transfer pumps—one for fuel, one for water. It’s a small investment for a massive gain in safety.

How Can I Pump Fuel Faster?

Is your pump feeling slow and weak? More often than not, a few quick checks can get it working efficiently again. The biggest enemy of a good flow rate is an air leak, which completely kills suction. Start by making sure both hoses are pushed all the way onto the pump fittings to create an airtight seal.

Next, take a look at your hoses. Any kinks or sharp bends will choke off the flow, just like a pinched garden hose. Straighten them out. Finally, your pumping technique matters. A steady, consistent rhythm is far more effective than fast, jerky motions, which can actually introduce air into the line and slow you down.

What Are the Warning Signs of a Failing Pump?

A manual pump will usually give you a heads-up before it quits on you entirely. Keep an eye out for these tell-tale signs:

- Visible cracks or brittleness in the hoses or the pump body itself.

- Difficulty building or maintaining suction, even when you know all the connections are tight.

- Fluid leaking from anywhere other than the hose ends, especially from the pump body.

If you notice any of these issues, it’s a clear signal that it’s time to either repair or replace your pump before it fails when you need it most.

Eliminate fueling guesswork and prevent costly spills with the automatic shutoff technology from CLiX Fueling Solutions. Ensure every drop of fuel gets in your tank—not in the water. Learn more at clixfueling.com.