Even with all the high-tech gear available today, a simple hand pump gas tank setup is still one of the most essential tools a boater can own. It’s the one thing that guarantees you can transfer fuel when there's no electricity in sight, whether you're in a remote cove or dealing with a dead battery. Think of it as your get-out-of-jail-free card, giving you total control and peace of mind.

Why a Manual Pump Is a Boater's Best Friend

It’s easy to write off the old-school hand pump as a relic. But any boater with a few seasons under their belt knows that on the water, simple is almost always better.

Picture this: you’re anchored in a perfect, secluded spot, miles from the nearest dock. Your fuel gauge is reading lower than you’d like, and without power, that fancy electric pump is just dead weight. This is the exact moment a manual hand pump proves its worth and becomes the most valuable tool on your boat.

This isn't just about having a backup plan; it’s a strategy for being completely self-sufficient. I’ve heard countless stories from boaters stuck in line at a packed fuel dock on a holiday weekend, watching the best hours of the day just tick away. With a few jerry cans and a trusty hand pump, you can refuel on your own schedule, far from the chaos.

The Unbeatable Practical Advantages

The real appeal of a manual pump goes way beyond just emergencies. It's all about practical, real-world benefits that just make sense for life on the water.

- Go-Anywhere Portability: You can tuck a hand pump and a portable gas tank into a small locker. It’s ready to go whenever and wherever you need it, no dock or power outlet required.

- Ultimate Reliability: It's pure mechanics. There are no motors to burn out, wires to fray, or batteries to die. As long as you give it a little care, it’s going to work every single time.

- Cost-Effective Solution: Manual pumps are a fraction of the cost of electric models, both upfront and over the long haul. You won’t be shelling out cash for expensive replacement parts.

This isn't just old-timers clinging to the past, either. The global market for manual fuel transfer pumps was valued at around USD 1.2 billion in 2023. That shows just how crucial they still are for marine, farming, and other remote operations where you can't afford to have your equipment fail. You can dig into these market trends for fuel pumps to see just how widespread their use is.

Manual vs Electric Fuel Pumps: A Quick Comparison

While electric pumps are undeniably faster, a manual hand pump setup shines in other critical areas. Deciding between them really boils down to what you prioritize: speed and convenience at the dock, or bulletproof dependability when you’re far from it.

Here’s a quick breakdown to help you compare.

| Feature | Manual Hand Pump | Electric Fuel Pump |

|---|---|---|

| Power Source | Human-powered | Requires 12V/24V battery or AC power |

| Reliability | Extremely high; no electrical parts to fail | Good, but vulnerable to electrical issues |

| Portability | Excellent; lightweight and compact | Limited by power cord and battery access |

| Cost | Low initial cost, minimal maintenance | Higher initial cost, potential repair expenses |

| Flow Rate | Slower; dependent on user's pumping speed | Fast and consistent flow |

| Best For | Emergencies, remote fueling, backup use | Routine fueling at the dock, large tanks |

Ultimately, the choice depends on your specific boating style.

For any boater who values independence and preparedness, a manual pump isn't just an option—it's non-negotiable. It’s the tool that keeps a minor headache like a low fuel tank from turning into a full-blown, day-ruining emergency.

Think of it this way: an electric pump is a nice-to-have, but a manual pump is a need-to-have. It’s the difference between crossing your fingers and knowing for sure you can handle the situation. That kind of confidence is priceless when you’re out on the water.

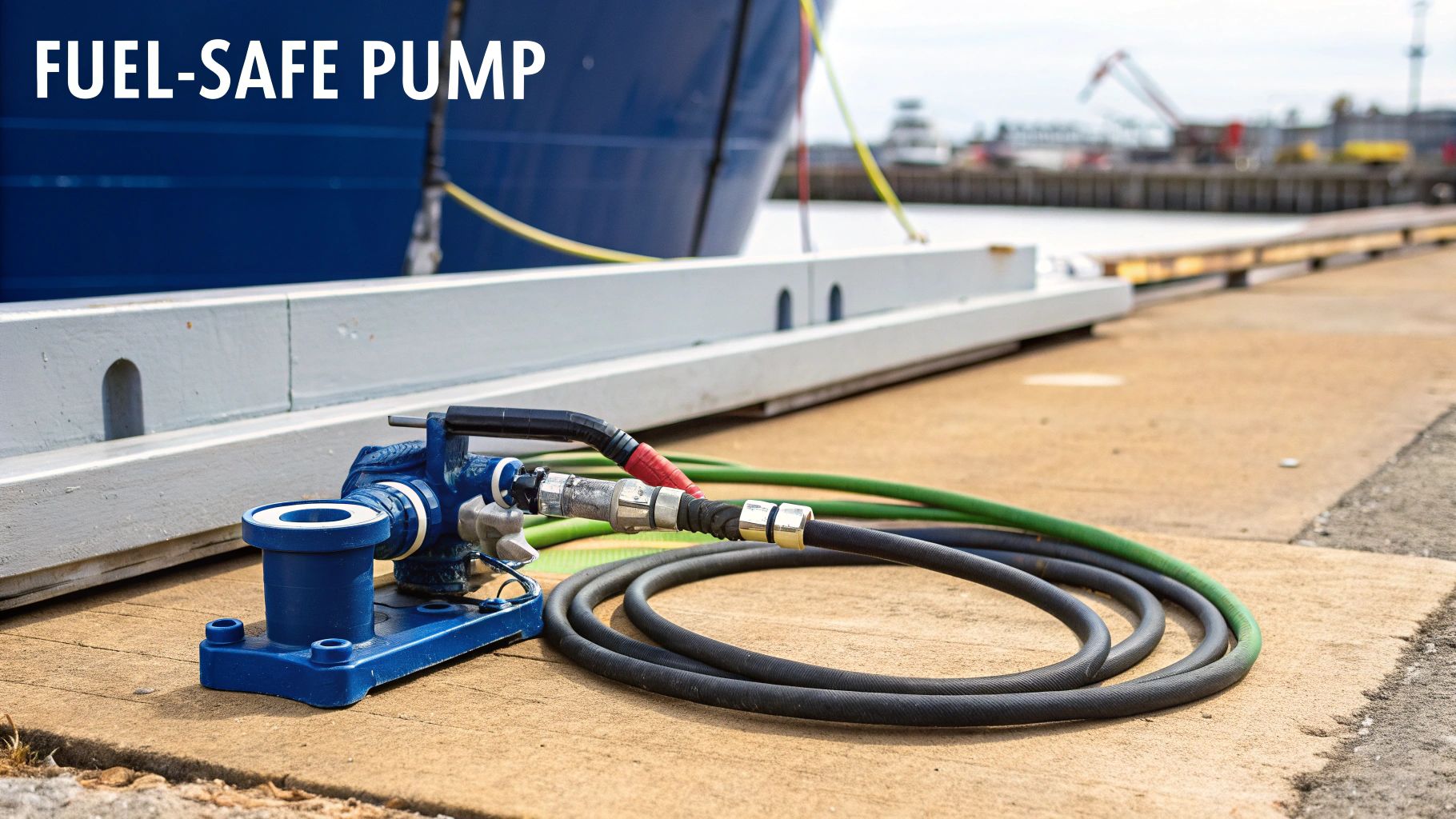

Choosing the Right Hand Pump for Gasoline Transfer

Picking the right hand pump for your boat isn’t just about convenience—it's a critical safety decision. A pump made for water or oil can fail in spectacular, dangerous ways when you introduce gasoline. The wrong materials will swell, degrade, or even dissolve, creating leaks that turn your refueling process into a serious fire hazard.

When you're looking for a hand pump gas tank solution, the number one thing to check is material compatibility. Gasoline is an aggressive solvent, so you need a pump specifically rated for flammable liquids.

This means looking for pumps made from fuel-resistant materials. Think sturdy plastics like nylon or metals like aluminum and coated steel. Pay close attention to the internal parts, too. The seals and gaskets must be made from materials like Viton or Nitrile, which won't break down when exposed to gasoline and ethanol blends.

Decoding Pump Types and Flow Rates

Once you've zeroed in on fuel-safe options, it’s time to think about how you'll actually use the pump. Most of what you’ll find falls into two categories: siphon and rotary pumps.

- Siphon Pumps: These are your basic, compact models. You give them a few squeezes to get the flow started, and the siphon effect takes over. They're perfect for smaller tanks or to keep stashed away as a backup. Just know their flow rate is on the slower side.

- Rotary Pumps: These are the workhorses. You turn a crank, and you get a steady, high-volume flow of fuel. If you’re regularly moving more than a few gallons at a time, a rotary pump is going to save you a ton of time and arm-ache.

A pump’s flow rate will tell you how quickly it moves fuel, usually measured in gallons per minute (GPM). A slow pump is fine for topping off a 5-gallon can, but you'll lose your patience fast trying to fill a 30-gallon tank with it. If you want to compare specific models, check out this review of the top manual transfer pumps for fuel.

Non-Negotiable Safety Features

Beyond basic construction, a few safety features are absolutely essential when you're handling gasoline. Static electricity is a real, and often forgotten, danger. The simple friction of fuel flowing through a hose can build up a static charge. It only takes one tiny spark to ignite gas vapors.

To prevent this, look for these two critical features:

- Anti-Static Hoses: These are built with conductive materials that safely dissipate static electricity before it can build to a dangerous level.

- Grounding Wires: Better pumps often come with a grounding wire and clamp. This lets you physically connect the pump, fuel can, and your boat to neutralize any static charge that builds up.

These aren't just nice-to-have extras; they are your primary defense against a potentially catastrophic accident. Don’t gamble by choosing a pump without them.

Remember, you're handling a highly volatile substance. A pump that's merely "fuel compatible" isn't enough. It must be designed from the ground up with features that actively manage the risks of gasoline.

Ultimately, the best hand pump is one that blends tough, fuel-safe materials with a practical flow rate and, most importantly, rock-solid safety features. Investing in a quality pump means you can refuel with confidence, whether you're at the marina or anchored out in a quiet cove. That kind of peace of mind on the water is priceless.

How to Safely Pump Gas into Your Boat

Alright, let's move from theory to what actually happens on the dock. Safely getting fuel from a can into your boat with a hand pump gas tank setup is a fundamental skill. It’s not just about avoiding a messy spill—it’s about building a solid, safe routine that becomes second nature, whether you're at a calm marina or topping off from a jerry can in a bit of a swell.

We're going to skip the generic checklists and walk through the process like a seasoned boater would. The small details are what make a huge difference, and getting them right is how you build habits that protect you, your boat, and the water.

Pre-Fueling Checks and Setup

Before a single drop of fuel moves, you absolutely have to do a quick inspection. This five-minute check can literally prevent a disaster.

First, give your pump and hoses a once-over. Are there any cracks? Does the rubber feel brittle or stiff? Pay close attention to where the hoses connect to the pump body. A worn-out hose is just a fuel spill waiting for an invitation.

Next, and this is critical, think about ventilation. Gasoline vapors are heavier than air, which means they can sink into low spots like your bilge and create a serious explosion hazard. Open up every hatch, port, and door you can to get the air moving. If your boat is equipped with a blower, you need to run it for at least four to five minutes before you start and keep it running the entire time you're fueling. No exceptions.

Now, let's get your gear set up for a clean transfer.

- Put the gas can on a stable, flat surface. The dock is usually best, or a sturdy part of your deck where it won’t get knocked over.

- If you can, place the can higher than your boat's fuel tank inlet. Gravity becomes your friend here, making the pumping a lot easier.

- Get the pump’s intake hose firmly seated in the gas can. Make sure it reaches all the way to the bottom so you can get as much fuel as possible.

- Place the outlet nozzle securely into your boat's fuel fill. Don’t just let it dangle in the opening—a sudden wake could pop it right out. It's really helpful to understand the design of your specific boat fuel fill area to ensure you have a solid, secure connection every time.

Finally, have some absorbent pads or a small spill kit right there, within arm's reach. You'd much rather have them ready and not need them than be fumbling for a rag while gas is splashing onto your deck.

The Pumping Process

With everything set, it's time to start moving fuel. The key here is to find a smooth, controlled rhythm. If you're using a rotary pump, turn the crank with steady, even motions. For a siphon-style pump, a few firm, quick squeezes will get the suction going and start the flow.

Resist the urge to pump like you're in a race. Going too fast can cause fuel to splash back out of the fill opening or build up too much pressure in the hose. Your goal is a consistent, manageable flow that you can keep an eye on.

Pro Tip: Use your ears. As the tank gets closer to full, you can actually hear the sound of the fuel entering change. That little audio cue, combined with watching the fill, is a great way to prevent an overfill.

Keep your eyes on both the nozzle and the gas can. As the can empties, it's going to get lighter and might want to shift around, so be ready to steady it. And most importantly, never, ever walk away or get distracted while fuel is flowing. This job requires your undivided attention from start to finish.

Preventing Spills and Storing Equipment

The last few moments of fueling are where a lot of preventable spills happen. As you feel the source container getting close to empty, slow down your pumping. Once you hear that tell-tale sound of the pump sucking air, give it a couple more slow pumps to push the last bit of fuel out of the hose.

Now for the tricky part. Carefully lift the intake hose out of the empty can first. Keep its end held high—above your boat’s fuel fill—so any gas left in the hose drains down into your tank, not onto the deck.

Once the hose is clear, you can remove the nozzle from the boat. Have an absorbent pad ready to immediately wrap around the nozzle's tip to catch those last few drips.

Proper cleanup and storage are just as important as the pumping itself.

- Wipe Down: Grab a clean rag and wipe up any small drips on the pump, hoses, and around your fuel fill.

- Secure Caps: Immediately screw the cap back on your boat’s fuel tank and on the now-empty jerry can. Make them tight.

- Store Safely: Put your hand pump and hoses away in a well-ventilated spot, far from direct sun and anything that could create a spark. A dedicated, sealed storage box is a great idea to contain any lingering fuel smells and protect your gear.

Follow these steps every single time, and you'll turn a risky task into a safe, boring routine. That kind of discipline is what separates a responsible boater from someone who just hopes for the best.

Keeping Your Hand Pump Working Like New

A hand pump for your gas tank is one of the most reliable tools on a boat, but "reliable" doesn't mean "invincible." A little routine care can be the difference between a pump that lasts two seasons and one that lasts ten. If you neglect it, you’re just inviting clogs, leaks, and failure right when you need it most.

The good news is that keeping your pump in top shape doesn’t require a full workshop or any special skills. It’s really just about building a few simple habits for after each use and doing a more thorough check at the start of the boating season. This small investment of time pays off big time in performance and longevity.

Routine Maintenance After Every Use

Believe it or not, the most damaging thing for your pump isn't just fuel—it's the gunk and moisture left behind. So, once you're done fueling, take just a minute for a quick post-op check.

First, try to clear as much leftover fuel from the pump and hoses as you can. A few extra pumps after the gas can is empty will push that last bit of gasoline into your tank. This simple move prevents fuel from just sitting on the seals and slowly eating away at them.

Next, give the whole exterior a quick wipe-down with a clean, dry rag. This isn't just for looks; it gets rid of any fuel residue that attracts dirt and grime. Putting a clean pump away is the first step to making sure it’s ready to go next time.

Seasonal Deep Clean and Inspection

When you're getting the boat ready for a new season, or if the pump's been sitting in storage, it's a great idea to give your hand pump gas tank setup a closer look. This is your chance to catch small problems before they turn into big headaches.

- Check All Seals and Gaskets: Take a close look at the O-rings and seals at every connection point. They should feel soft and pliable, not cracked. Gasoline, especially the ethanol blends, can make them brittle over time. If a seal looks even a little questionable, just replace it. It's a cheap part that prevents a major leak.

- Inspect the Hoses: Bend and flex the entire length of both the intake and outlet hoses. You're looking for any signs of cracking, stiffness, or swelling. A bad hose is a serious safety hazard and needs to be replaced immediately.

- Clean Out Sediment: Over time, tiny particles from fuel cans can build up inside the pump. If your pump can be taken apart, follow the manufacturer’s guide to carefully clean out the internal parts. Getting rid of any gunk will stop clogs and keep the fuel flowing smoothly.

A well-maintained hand pump is more than a convenience; it's a critical piece of safety equipment. The five minutes you spend on a quick inspection can prevent a dangerous fuel leak or a frustrating pump failure when you're miles from shore.

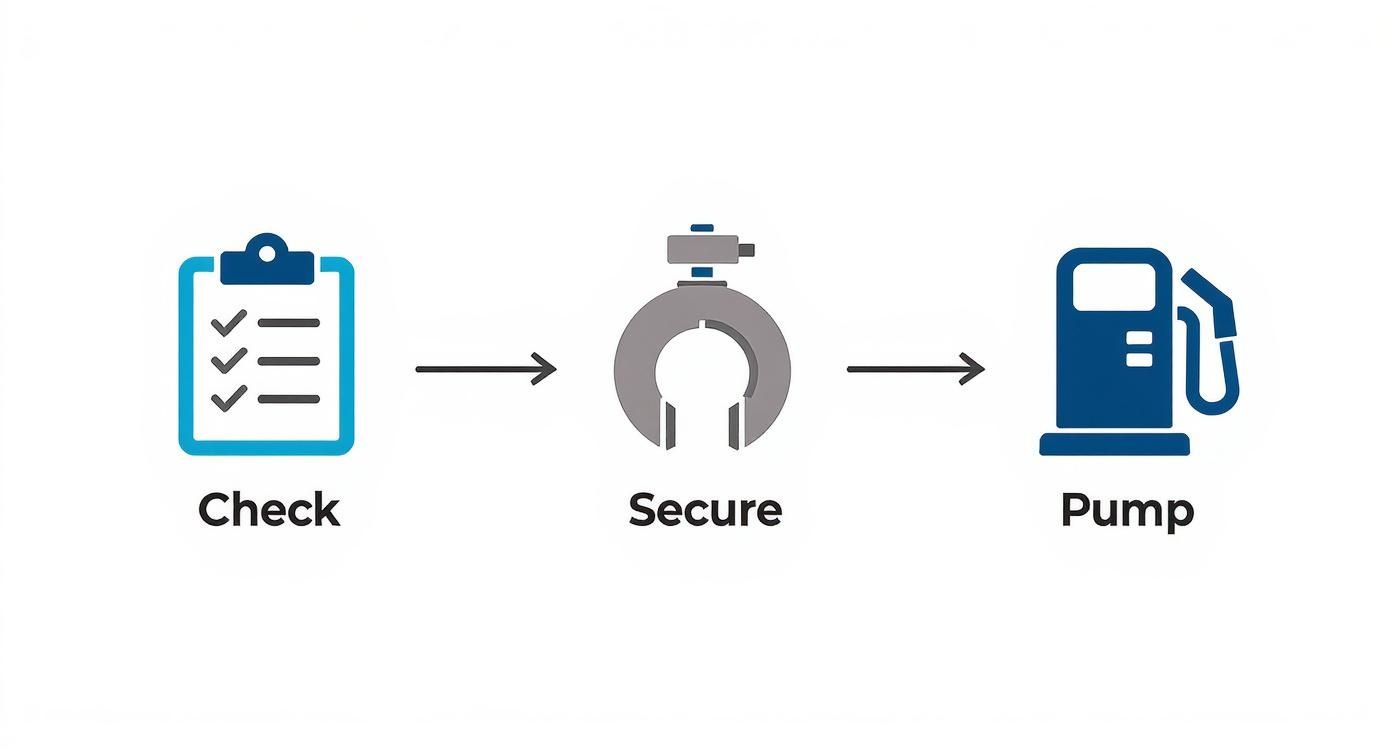

This simple infographic sums up the key steps for safe fueling, driving home the point of checking your gear first.

As you can see, a solid check of your equipment is the foundation. It's the very first thing you should do before you even think about clamping the pump down or starting the transfer.

Troubleshooting Common Pump Problems

Even with the best care, things can still go wrong. Knowing how to diagnose the issue can save you a frustrating trip back to the store.

Problem: My Pump Won't Prime or Has Lost Suction

This is the most common one. Nine times out of ten, the culprit is an air leak somewhere. First, make sure the intake hose is fully submerged in the fuel. Then, go back and check that every connection is hand-tight, from the hoses to the pump body itself. Even a tiny air leak will kill the vacuum the pump needs to draw fuel.

Problem: The Fuel Flow Is Weak or Slow

A sluggish flow usually means there’s a blockage. The first place to check is the intake end of the hose for any debris that might have gotten sucked up. If that looks clear, you probably have some sediment stuck inside the pump's mechanism. A good cleaning, like we covered in the seasonal maintenance section, should clear it right up.

Problem: Fuel Is Leaking from a Connection

Stop pumping immediately. A leak means you've got a failed seal or a loose connection. Try tightening the fitting where you see the leak. If that doesn't fix it, you’re likely dealing with a damaged O-ring or gasket that needs to be replaced. Never, ever use a pump that is actively leaking fuel.

Fueling Safety and Environmental Responsibility

Let's be honest—fueling up with a hand pump isn't just about getting gas into the tank. Every time you handle fuel, especially near the water, you're taking on a big responsibility. It's about being a good steward of the environment we all love to be out on.

Careless fueling is a major source of pollution in our waterways. Even a tiny spill might not seem like a big deal, but those little drops add up over time, harming aquatic life and water quality. Thinking "safety first" isn't just about avoiding a fine; it protects you, your passengers, and the very water you're there to enjoy.

Personal Protective Equipment: The Smart Essentials

Before you even think about unscrewing a fuel cap, you need to gear up. It’s not about wearing a full hazmat suit, but a couple of key items are non-negotiable.

Your hands are the first line of defense, so get the right gloves.

- Nitrile Gloves: These are your best friend when handling fuel. They provide a solid barrier against gasoline and other petroleum products, saving your skin from irritation and absorbing nasty chemicals. Unlike latex, they won't break down.

- Safety Glasses: A sudden splash or an unexpected gust of wind can send fuel right at your face. A simple pair of safety glasses can prevent a painful and potentially serious chemical burn to your eyes.

A great habit to get into: put your gloves on before you start and don't take them off until every cap is sealed and your gear is stowed. This little routine drastically cuts down your exposure to fuel and stops you from accidentally smearing residue all over your boat.

Mastering Spill Prevention and Response

The absolute best way to deal with a fuel spill is to stop it before it starts. Preparation is key. Always have an absorbent spill pad or a fuel bib wrapped around the fuel fill opening before you begin. These are cheap insurance against the inevitable drips and splashes.

But hey, accidents happen. If a small spill occurs, the trick is to act fast.

- Stop the Flow: The second you notice a spill, stop pumping.

- Contain It: Grab your absorbent pads and soak up the fuel immediately. Whatever you do, don't hose it into the water. That's not only illegal, but it's also an environmental disaster.

- Dispose of It Properly: Put the used pads into a sealed, dedicated bag or container. Never toss them in the regular trash or into the water. Your marina will have specific procedures for disposing of hazardous waste—just ask.

For a deeper dive into handling a fuel-related incident, our expert response guide offers detailed steps on fuel spill cleanup procedures.

Navigating Regulations and Best Practices

Marinas and local authorities have strict rules about fueling for good reason. Get to know the regulations in your area for portable fuel containers and transferring fuel. The fines can be hefty, but the real cost is the damage to the environment.

Of course, smart fueling is just one piece of the puzzle. Being ready for anything on the water is crucial, so always keep your gear in check by following an ultimate boat safety equipment checklist.

Being a responsible boater means every choice you make on the dock matters. By adopting safe fueling habits, you're doing your part to keep our marine environments healthy for generations to come.

Answering Your Questions About Hand Pumps for Gas

I’ve spent enough time on docks and in boating forums to know the same questions about hand-pumping gas come up over and over. When you're dealing with fuel, you need clear, no-nonsense answers. Let's tackle the common issues you're likely to run into so you can handle your pump correctly and avoid the usual headaches.

These are the real-world answers you’ve been looking for, from picking the right pump to troubleshooting on the fly.

Can I Just Use Any Old Hand Pump for Gasoline?

Absolutely not. I can't stress this enough—this is the single most critical safety point. Grabbing a pump designed for water or oil and using it for gasoline is a recipe for disaster. Gasoline is a powerful solvent that will chew through the seals and plastics in the wrong kind of pump, leading to dangerous leaks and a serious fire hazard.

You have to use a hand pump specifically built and rated for flammable liquids. These are made from fuel-resistant materials like nylon, aluminum, or specially coated steel. More importantly, their internal seals are made from tough stuff like Viton or Nitrile, which won't break down after being soaked in fuel and its additives.

Beyond the materials, a proper gasoline pump often has critical safety features to handle static electricity, like anti-static hoses or grounding wires. These aren't just bells and whistles; they're essential for preventing a stray spark from igniting fuel vapors while you're pumping.

My Hand Pump Won't Draw Fuel. How Do I Fix It?

Losing the prime is probably the most common frustration with hand pumps, but don't worry, it's usually a simple fix. The problem is almost always a small air leak somewhere in the system that's preventing the pump from creating enough vacuum to pull the fuel up.

Before you start taking things apart, check for an air-tight seal.

- Look at the Intake: First, make sure the intake hose is pushed all the way down into the gasoline. If the end is sucking air, you'll never get it primed.

- Tighten Everything Up: Next, run your hands over every connection point. Are the hoses screwed tightly onto the pump body? Even a slightly loose fitting is enough to break the seal.

- Re-Prime It: Once you're sure everything is secure, give the pump a few quick, full strokes. This can often force the air out of the line and re-establish the suction needed to get the fuel moving again.

If you've tried all that and it's still not working, it's time to check the pump's internal seals or gaskets. A tiny crack or a worn-out seal could be the culprit, and it might be time for a replacement.

How Do I Stop Spills When I'm Done Pumping?

That last moment, when you pull the nozzle out of the tank, is where most spills happen. A little technique goes a long way here to keep your boat and the water clean. The trick is to clear as much fuel out of the hose as you can before you remove it.

As your fuel can gets close to empty, slow down your pumping. When you hear that gurgling sound of the pump starting to suck air, give it a few more slow, deliberate pumps. This will push most of the fuel still sitting in the hose into your boat's tank.

Here’s the best technique I've found: pull the intake hose out of the fuel can first, but keep the nozzle in your boat's fuel fill. Hold the end of the intake hose up high. Gravity will do the work, draining the remaining gas down the hose and into your tank. Only then should you pull the nozzle out, wrapping an absorbent pad around it to catch those last few drips.

Is a Rotary or Siphon Pump Better?

This one really comes down to personal preference and how you'll be using it. There's no single "best" pump; each one is suited for different jobs. It all depends on how much fuel you're moving and whether you value speed or simplicity.

- Rotary Pumps: These crank-style pumps give you a much higher and more consistent flow. If you're regularly transferring larger amounts of fuel—say, emptying a few 5-gallon jerry cans into your main tank—a rotary pump is your best bet. It makes the job faster and is a lot less work for you.

- Siphon Pumps: Usually simpler and more compact, these are the ones you start with a few squeezes of a bulb or a few pumps of a handle. They're perfect for smaller jobs, like topping off the tank on your dinghy, or for stashing in a locker as a lightweight backup. Their flow is slower, so they aren't great for big refueling jobs.

For most boaters who want a reliable, primary way to refuel manually, a good-quality rotary pump usually hits that sweet spot between efficiency and control.

If you're tired of the guesswork and risks that come with manual fueling, CLiX Fueling Solutions offers a smarter way. Our automatic shut-off system prevents spills before they happen, giving you a perfect fill every time. Protect your boat, the environment, and your peace of mind by exploring our spill-free solutions.