Transferring fuel from a jerry can to your boat’s tank with a hand pump is a classic boater’s task. Whether you're using a simple siphon or a more robust piston pump, it’s a straightforward way to move fuel. But doing it right—and safely—is a skill every boater needs to master.

Why Safe Hand Pump Fuel Transfer Matters

We’ve all been there. You're anchored in a perfect spot, the sun's dipping low, and you realize the main tank needs a top-off from a reserve can. It seems routine, but this is exactly the kind of moment where a small slip-up can lead to a big mess. Getting the hang of a safe hand pump transfer isn't just about convenience; it's fundamental to good seamanship.

A sloppy fuel transfer creates immediate, tangible risks. Even a minor overfill sends gasoline or diesel down the side of your hull, which can eat away at the gelcoat and leave ugly stains. Worse, it turns your deck into a dangerously slick surface. A simple misstep becomes a serious fall hazard.

The Hidden Dangers Of Small Spills

It’s tempting to shrug off a few drips, but those little spills have real consequences. Beyond the obvious safety issues, fuel spills are terrible for the environment. A tiny amount of fuel can pollute a huge volume of water, harming the very ecosystem we're out there to enjoy. It's no wonder marinas and local authorities have such strict rules about fueling.

Anyone who has spent time on the water knows the common frustrations:

- Preventing Overfills: It’s notoriously tricky to guess how much room is left in the tank, often leading to messy, wasteful overflows.

- Managing Leaks: A worn-out seal on your pump or a hose that isn't quite secure can turn a controlled transfer into a chaotic cleanup.

- Ensuring Crew Safety: A spill puts everyone on board at risk from slippery decks and flammable fumes.

You'd be surprised how often these "minor" issues lead to bigger problems. Marine incident reports are full of stories about slips and falls, and many happen during routine but high-risk tasks like fueling. It's a leading cause of crew injuries.

A Mindset Of Prevention

Adopting a safety-first mindset for handling fuel isn't about being paranoid; it's about being prepared. It means you understand the fuel you're working with, whether it’s gasoline or diesel fuel, and you respect its potential to cause harm.

The numbers don't lie. Between 2014 and 2023, European waters saw 26,595 marine incidents. A huge portion of the resulting injuries happened during everyday onboard activities. In 2023, crew members made up 89.7% of the victims, frequently from slips and falls. These statistics show just how vulnerable we are during basic procedures like fuel transfer, where a small spill can create a genuinely hazardous situation. You can read more in the marine casualty findings.

Ultimately, knowing how to transfer fuel safely protects your boat, your crew, and the water itself. It’s a core skill that helps ensure your time on the boat stays relaxing and free of trouble.

Choosing The Right Hand Pump For Your Boat

When you're transferring fuel on a boat, the hand pump you choose can make all the difference. Get it right, and you have a clean, easy transfer. Get it wrong, and you're looking at a frustrating, messy—and potentially dangerous—ordeal.

Picking the right tool for the job is really the first step. It’s all about matching the pump’s design and materials to your specific boat, the type of fuel you use, and how you’ll be using it. A bad choice can lead to painfully slow transfers, a pump that wears out in a season, or even dangerous leaks if the materials can’t handle your fuel. Let's break down what you need to know.

What Kind Of Pump Do I Need?

You'll generally come across four types of manual pumps. Each one works a bit differently, and they all have their own pros and cons for life on the water.

When you're deciding on a pump, it’s helpful to see how they stack up against each other. Each type has a specific job it’s best suited for.

Comparison Of Hand Fuel Pump Types

| Pump Type | Best For | Pros | Cons |

|---|---|---|---|

| Siphon Pump | Small, simple transfers where speed isn't a factor. Great for dinghies or PWCs. | Simple, inexpensive, and very portable. No moving parts to break. | Slow, offers very little flow control, and can be messy to get started. |

| Piston Pump | Precise, controlled transfers, like topping off a tank from a jerry can in tight spaces. | Excellent control over flow rate, reliable, and generally well-built. | Can be slower than a rotary pump; requires a repetitive up-and-down motion. |

| Rotary Pump | Moving larger volumes of fuel quickly, like from a 55-gallon drum to your main tank. | Fast, continuous flow. Very efficient for large transfers and often very durable. | Can be too fast for small tanks, making overfills a risk. Can be bulky. |

| Diaphragm Pump | All-around use, especially when fuel might have some sediment or debris. | Very reliable, self-priming, and can handle small debris without clogging. | Can be more expensive and sometimes offers a lower flow rate than rotary models. |

Ultimately, the best pump is the one that fits your most common task. For most boaters, a good-quality piston or diaphragm pump offers the best blend of control and reliability.

Here's a tip from experience: faster isn't always better. That high-flow rotary pump might seem great for filling a big tank from a drum on the dock, but a controllable piston pump is a much safer bet when you’re topping off a tank from a jerry can on a rocking boat.

Critical Factors To Consider Before You Buy

Once you’ve settled on a type, there are a few other details you absolutely need to look at. These are the things that separate a good pump from one that’s going to fail you when you need it most.

Material Compatibility

This is the big one—it's completely non-negotiable. Modern fuel, especially gasoline with ethanol, is nasty stuff that can eat through the wrong kinds of plastics and rubber seals. Using a pump that isn’t rated for your fuel is just asking for a leak.

- For Gasoline: Make sure the pump is made from nylon, Teflon, or other certified fuel-resistant materials.

- For Diesel: While diesel is a bit kinder than gas, you still want a pump with high-quality seals made from Viton or Nitrile to ensure it lasts.

Flow Rate

This tells you how fast the pump moves fuel, usually measured in gallons per minute (GPM) or by how much fuel it moves per stroke. A higher flow rate gets the job done faster, but it also makes it much easier to overfill your tank if your attention wanders for even a second. Think about the size of your tank and fuel cans—a modest, controllable flow rate is often more practical.

Hose Length and Quality

Don't overlook the hoses. They need to be long enough to reach from your fuel can to your tank’s fill neck without being stretched tight or kinking. The intake hose has to reach the bottom of the can, and the outlet hose needs enough slack to sit securely in the tank opening. Always look for anti-static, fuel-grade hoses that won’t get brittle or crack over time.

For a deeper dive into specific models and our top recommendations, take a look at our guide on the top manual transfer pumps for fuel in 2025. Choosing the right tool from the start just makes every fuel transfer you do after that safer and a whole lot less of a headache.

Your Pre-Transfer Safety Checklist

Handling fuel on a boat demands your complete and undivided attention. Before a single drop of fuel moves, the most important thing you can do is run through a quick safety check. It's not about being paranoid; it’s about building a solid routine that makes a risky job predictable and safe.

This isn’t just theory. If you look at the history of commercial cargo transfers, spills were incredibly common during loading and unloading. While equipment and rules have gotten much better, the risk is always there. This history lesson, detailed in these industrial spill findings, really drives home why being careful matters, even for us recreational boaters.

Think of it like a pilot’s pre-flight checklist. Do it every single time, and it becomes second nature.

Prepare Your Environment

The first step has nothing to do with the pump itself. You have to create a safe zone for the hand pump fuel transfer. Fuel fumes are sneaky—they're heavier than air and will pool in low spots, creating a serious fire hazard just waiting for a spark.

- Ventilate, Ventilate, Ventilate: Open every hatch, porthole, and door. Got blowers? Fire them up for at least five minutes before you start, and keep them running the whole time. Good airflow is your best friend here.

- Kill the Power: Shut down everything. Engines, generators, galley equipment, battery chargers, even the stereo. You're on a mission to eliminate any possible source of an ignition.

- Clear the Area: Shoo away any passengers or crew from the fueling spot. This is a one-person job, perhaps with a buddy standing by at a safe distance, but not hovering over your shoulder.

Here's a pro tip: People often forget about automatic systems. Things like bilge pumps or refrigerators can kick on without warning. Before you begin, flip their breakers to the "off" position. No surprises.

Assemble Your Safety Gear

Having the right gear ready and within arm's reach is non-negotiable. Fumbling for an absorbent pad after a spill has already started is a game you'll never win. Get everything set up before you even think about unscrewing a fuel cap.

Your go-to safety kit should have:

- Fuel-Resistant Gloves: Don't even think about using standard latex gloves; fuel will eat right through them. You need proper nitrile gloves to protect your skin.

- Absorbent Pads: Keep a good stack of fuel-absorbent pads handy. A great habit is to place one right around the fuel fill opening to catch the inevitable drips and dribbles.

- Fire Extinguisher: Your boat already has them, but don't leave it buried in a locker. Grab a Class B (for flammable liquids) extinguisher and put it where you can grab it instantly.

Taking a few minutes to get prepared like this prevents 90% of potential headaches.

Inspect Your Fueling Equipment

Last but not least, give your gear a quick once-over. The pump that worked perfectly last fall could have developed a tiny crack or a bad seal over the winter. This simple check can save you a world of hurt.

- Check the Hoses: Run your hands along the entire length of the hoses. You're feeling for any spots that are brittle, cracked, or mushy. A bad hose is the most common failure point.

- Tighten Connections: Make sure the hoses are screwed on tight to the pump. A loose connection is the number one reason for leaks and a pump that won't prime during a hand pump fuel transfer.

- Look at Seals and Gaskets: Eyeball the pump’s seals and the gasket on your fuel can. If they look dried out, cracked, or flattened, it's time for a replacement.

Make this checklist a habit you never break. It completely shifts the odds in your favor, turning a moment of potential danger into just another simple task. That way, you can get back to what you're really out here for: enjoying your time on the water.

Executing a Spill-Free Fuel Transfer

Alright, with your safety checks done, it's time for the main event. A successful, spill-free hand pump fuel transfer isn’t about speed; it's about control, awareness, and having a steady hand. This is where your preparation pays off, turning what could be a messy chore into a smooth, routine part of boating.

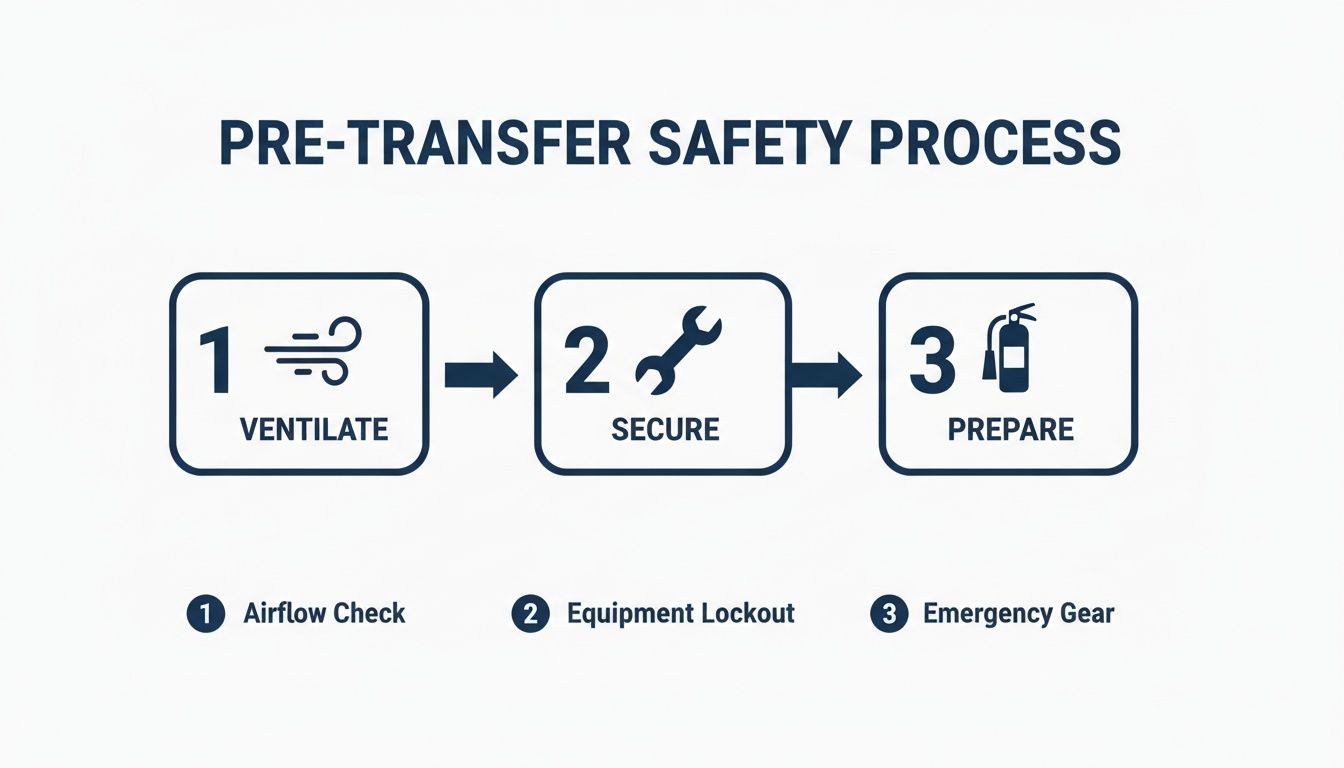

The process below lays out the core safety actions you should have already knocked out. Think of it as setting the stage for a clean transfer.

This simple sequence—Ventilate, Secure, and Prepare—is the bedrock of any safe fueling operation. It's all about making sure the environment is managed before fuel starts to flow.

Positioning for Success

Your first move is to get yourself, the fuel can, and the boat into a stable, secure position. A wobbly jerry can is just a spill waiting to happen. Place it on a flat, non-slip surface where it won’t slide or tip over, even if the boat rocks a bit.

If you can, try to place the fuel can slightly higher than the fuel tank's fill opening. This gives you a little help from gravity, making the pumping process less of a workout. But let's be clear: stability is more important than height. Never perch a can precariously just to gain a few inches.

The Art of the Initial Prime

Now, with your absorbent pad in place around the fill neck, you can get things started. The first step is priming the pump to get the fuel moving.

- Secure the Intake Hose: Push the intake hose deep into the fuel can, making sure the end hits the very bottom. This is key to preventing the pump from sucking air before the can is empty.

- Seat the Outlet Hose: Place the outlet hose securely into the boat's fuel fill. It should go in at least several inches so it doesn't pop out mid-transfer. For a deeper dive into the different fill systems out there, our guide on the modern marine fuel fill is a great resource.

- Create Suction: Start operating the pump with slow, deliberate strokes. Whether you're turning a crank or moving a piston handle, you're trying to create a consistent vacuum that draws fuel up the hose. You’ll feel the resistance change as soon as fuel enters the pump.

A classic rookie mistake is pumping way too hard right at the start. That initial surge of fuel can make the outlet hose jump right out of the fill neck. Start slow, make sure fuel is flowing smoothly, and then find a comfortable rhythm.

Finding and Maintaining a Steady Rhythm

Once the fuel is flowing, consistency is everything. A steady, even pumping motion keeps the flow constant and cuts down on the chance of splashing and air bubbles. This isn't a race. Trying to empty the can as fast as possible is how overfills happen.

As you pump, keep your attention on two things: the feel of the pump and the sound of fuel entering the tank. This mindful approach is what separates a careful boater from a careless one.

If you're interested in learning more about preventing and managing accidental fuel discharges, it's worth exploring resources on spill control and secondary containment. The same core principles apply whether you're on a small boat or in a large industrial setting.

Listening for the Finish Line

One of the most valuable skills you can develop for manual fuel transfer is using your ears. As the tank gets closer to full, the sound of the fuel hitting the fill pipe changes in a big way.

- At the start: You'll hear a hollow, echoing sound as fuel splashes into a mostly empty tank.

- As it fills: That sound will get deeper and less echoey, eventually turning into more of a gurgle.

- Nearing full: The gurgle will become a much higher-pitched sound as the fuel level rises up the fill pipe. This is your signal to stop immediately.

That auditory cue is the most reliable indicator you have. The moment you hear that pitch change, stop pumping. There’s still a bit of fuel left in the hose that will drain into the tank, so stopping at the first sign of fullness is the best way to prevent a messy overfill.

After you stop, leave both hoses in place for a few seconds to let them drain completely. Carefully lift the outlet hose from the fill neck—keeping its end pointed up to prevent drips—and then pull the intake hose from the can. Replace all the caps securely, and you've just completed a perfect, spill-free hand pump fuel transfer.

Keeping Your Hand Pump Ready For Action

Your hand pump is more than just a tool; it's a critical piece of your boat's safety gear. Letting its upkeep slide is like ignoring a frayed dock line—it’s guaranteed to fail you at the worst possible moment. Good maintenance makes every hand pump fuel transfer smoother and safer, stopping a simple task from turning into a real hazard.

Don't think it can't happen to you. Even major commercial operations slip up. A refueling mishap in San Francisco Bay back in 2009 spilled 400 gallons of fuel, a sobering reminder that risk is always present. The history of fuel transfer spills shows that taking a few small, preventative steps is the best way to avoid a minor drip becoming a major problem.

Post-Transfer Cleanup And Inspection

The most important part of maintenance happens the second you’re done fueling. Don't just coil the hose and toss the pump in a locker.

First, hold the pump and hoses upright over the can to let every last drop drain back out. Then, give the whole unit a thorough wipe-down with a clean, dry rag. This isn't just about being tidy; it's your chance to give it a quick once-over.

Pay close attention to the hoses, especially where they connect to the pump. You're looking for new cracks, scuffs, or any spots that feel unusually soft. While you're at it, double-check that all the fittings are still snug.

Proper Storage Is Your Best Defense

Where and how you store your pump can make or break it. The two biggest enemies of its plastic and rubber parts are sunlight and extreme heat.

- Dodge the Sun: Never leave your pump lying out on deck. UV rays will make the hoses brittle and degrade the plastic parts faster than you’d think.

- Keep it Cool and Dry: Find a home for it in a locker or storage box that’s well-ventilated and away from direct heat. The engine room is a definite no-go.

- No Kinks Allowed: When you coil the hoses, keep the loops loose. Sharp bends and kinks create weak points that will eventually fail.

Here’s a pro tip: Keep your pump in its own opaque bag or small container. This shields it from sunlight, contains any faint fuel odors, and stops it from getting banged up by other gear.

Troubleshooting Common Pump Problems

Even a well-maintained pump can act up. Before you write it off as broken, try these quick fixes for the most common headaches.

Problem: Slow or No Flow

If the pump suddenly loses its mojo, it's almost always an air leak or a blockage.

First, check every single connection. Make sure they are all hand-tight. A slightly loose fitting is the number one culprit for lost suction.

Next, take a look at the intake hose. Is it fully submerged in the fuel? Is the little filter screen on the end clogged with gunk from the bottom of the can?

Problem: The Pump Feels "Mushy"

When you lose that solid, firm resistance as you pump, that’s a dead giveaway that the internal seals are worn out. These seals are what create the vacuum needed for a hand pump fuel transfer.

Luckily, this is usually an easy fix. Many quality pumps have simple rebuild kits available with new seals. For a closer look at how these parts work, our article on the basics of a fuel tank hand pump is a great resource. Replacing them is a cheap and simple job that brings your pump right back to life.

Is It Time to Upgrade Your Fueling System?

Getting the hang of a manual hand pump fuel transfer is a rite of passage for boaters. It’s a great skill to have in your back pocket and builds real confidence on the water. But let's be honest—even with a steady hand and years of practice, manual transfers always come with a bit of risk. All it takes is a moment of distraction.

Maybe you're tired after a long day on the water, or the boat is rocking just enough to throw you off. That's when a simple refueling can go wrong. Knowing the limits of a hand pump is just as crucial as knowing how to use it. It's not about ditching this essential tool, but recognizing when a better system can give you a serious upgrade in safety and peace of mind.

The Guessing Game Is the Problem

The biggest challenge with any manual transfer is knowing exactly when to stop. You're listening for that gurgle, watching the fill neck for any sign of fuel backing up, and hoping your reflexes are quick enough. It’s a completely reactive process that leaves zero room for error.

This gets even trickier when conditions aren't perfect. Trying to fuel at dusk, with the engine rumbling or in choppy water? Good luck hearing those subtle cues that tell you the tank is nearly full. It's a recipe for a messy overfill.

Every time you transfer fuel by hand, you're making a small bet. You're betting on your perfect timing and undivided attention. Upgrading your system is about taking that bet completely off the table.

Automatic Spill Prevention Changes Everything

The next logical step is a system that takes the guesswork out of the equation for you. Modern solutions, like the CLiX system, build automatic shutoff technology right into the process. It works just like the nozzle at your local gas station—it senses when the tank is full and clicks off, stopping the flow before a spill can even start.

The benefits here are pretty clear:

- No More Overfills: The system physically stops the fuel, making spills a thing of the past.

- A Safer Boat: You're protecting your boat's finish, keeping the deck from becoming a slippery hazard, and cutting down on dangerous fumes.

- Fueling Without the Stress: You can finally stop hovering over the fuel fill, straining to listen. Just fuel up with confidence, knowing the system is doing the work.

This isn't about throwing out your reliable hand pump—it'll always be a fantastic backup. This is for the boater who wants to make their time on the water as safe and enjoyable as possible. It's about acknowledging that for your everyday fueling, a smarter, automated solution is simply the better way to go.

Answering Your Hand Pump Fuel Transfer Questions

Even the most seasoned boater has questions now and then, especially when it comes to safely moving fuel. Let's walk through some of the most common issues that come up when using a hand pump, so you can handle them like a pro.

What's The Best Kind Of Hand Pump For Gasoline?

When you're dealing with gasoline, the material of the pump is non-negotiable. You absolutely need a pump made from materials that can stand up to gas and its additives, like nylon, Teflon, or other certified plastics. Both rotary and piston-style pumps are fantastic options, giving you excellent control over the flow.

Before you buy, always read the fine print. The manufacturer's specs must explicitly state that the pump is rated for gasoline. Grabbing a pump designed for diesel and using it for gas is a recipe for disaster—the seals can dissolve, leading to dangerous leaks and a useless pump.

Think of it this way: using the wrong pump for gasoline is like using a regular plastic cup for a highly corrosive chemical. It might hold for a moment, but failure is inevitable and the consequences are serious.

My Siphon Pump Quit Sucking Mid-Transfer. Now What?

Losing suction halfway through a transfer is frustrating, but it's almost always caused by a simple air leak breaking the vacuum. The fix is usually quick.

First, take a look at the fuel can. Is the pump's intake hose still completely submerged? The second it starts pulling in air instead of fuel, the siphon breaks. If that's not the problem, check every connection point, especially where the hose attaches to the pump. A loose fitting is the most common culprit.

If everything is tight and the hose is deep in the fuel but you're still getting nothing, it might be time for a new pump. The internal seals or the bulb could have a tiny crack or are just plain worn out from use.

How Do I Transfer Fuel On A Rocking Boat Without Making A Mess?

Let's be clear: transferring fuel in rough water is a risky business and you should avoid it if you can. But if you're in a pinch and have no other option, you need to be extremely careful.

First, lock everything down. Wedge the fuel can securely so it can't slide around, and make sure you have a solid, stable stance. A pump with longer, more flexible hoses can be a real help here, as it can absorb some of the boat's motion. If you have a second person, ask them to steady the can or keep an eye on the fuel inlet.

Above all, go slow. This isn't a race. Your only goal is control. Keep a big stack of absorbent pads right at the fuel fill, ready to catch any drop the instant it escapes.

While mastering a manual transfer is a great skill to have, the best way to guarantee a clean fuel-up is to take human error out of the equation. CLiX Fueling Solutions provides an automatic shutoff system that eliminates the guesswork, stopping the fuel flow the moment your tank is full. To upgrade your boat’s safety and protect the environment, check out their solutions at https://clixfueling.com.