At its most basic, a fuel tank hand pump is a manual tool built to move fuel from one place to another, safely and without a mess. Think of it as a simple, non-electric solution for transferring liquids like gasoline, diesel, or oil. Because it doesn't need a power source, it's an incredibly useful piece of kit to have in a huge range of situations.

Why a Hand Pump Is a Must-Have Tool

So, what exactly is it? Imagine a powerful, specialized straw designed specifically for volatile fluids. A fuel tank hand pump lets you create suction to move fuel with total control, neatly bridging the gap between a heavy fuel can and an empty tank. No more spills, no more hassle. Its simple, mechanical design is what makes it so darn dependable.

This manual approach is a lifesaver in places where electricity is out of the question—either because it's not available, not practical, or just plain unsafe. You don't need to find an outlet or worry about a dead battery, giving you total freedom to get the job done.

Where Hand Pumps Become Essential

The real value of a good hand pump clicks when you see it in action. This isn't just some gadget you leave collecting dust in the garage; it’s a vital tool for pros, hobbyists, and anyone serious about being prepared.

You'll find them being used all over the place:

- Marine Fueling: Easily topping up a boat's tank from a jerry can out on the water, without spilling a drop into the ecosystem.

- Agricultural Operations: Refueling tractors, generators, and other equipment right in the field, miles away from a proper fuel station.

- Automotive and Powersports: Draining old, stale fuel from a car, lawnmower, or ATV before putting it into storage or doing maintenance.

- Emergency Situations: Powering up a generator during a blackout or siphoning gas from one vehicle to another during a roadside breakdown.

The true advantage of a manual pump is its unwavering reliability. With few moving parts and no dependence on electricity, it’s a tool that works every single time, giving you peace of mind when you need it most.

The Foundation of Safe Fuel Handling

Beyond just being handy, using a hand pump is a big deal for safety. We’ve all seen (or done) the classic "tip-and-pour," and it’s always a messy, risky gamble. Spills can ruin paint, contaminate the ground, and create a serious fire hazard. A hand pump gives you a controlled transfer that avoids all that drama.

By creating a sealed, direct line from the source to the destination, a pump drastically cuts down on escaping vapors and the chance of splashing. That controlled flow is absolutely critical when you're dealing with something as flammable as gasoline. It turns a potentially dangerous chore into a clean, simple, and secure task. At the end of the day, this simple tool is a core part of any complete toolkit, making sure you're ready for routine jobs and unexpected problems alike.

Decoding the Different Types of Hand Pumps

When you start shopping for a fuel tank hand pump, you’ll see right away that they’re not all created equal. Each type has a unique design and shines in different situations. It's a bit like picking tools from a toolbox—a screwdriver and a wrench both deal with fasteners, but you’d never use one for the other's job.

Picking the right pump is just as important. Using the wrong one can be slow, messy, or even unsafe. Let’s walk through the four main designs you're likely to come across so you can choose the perfect one for your needs.

Siphon Pumps: The Gravity-Powered Assistant

The siphon pump is the simplest of the bunch, working on a basic principle of physics: gravity. All it takes is a squeeze on the bulb or a few quick pumps of a handle to get the fuel moving.

Once the liquid starts flowing, gravity does the rest of the work, pulling fuel from a higher container down into a lower one. This makes them fantastic for quick, small jobs where you have that height difference, like emptying a lawnmower tank or getting gas from a can into your boat.

- How It Works: Creates a quick vacuum to start the flow, then lets gravity take over.

- Best For: Simple transfers, like moving fuel from a jerry can to a small engine.

- Key Advantage: Incredibly simple, lightweight, and usually the cheapest option you can find.

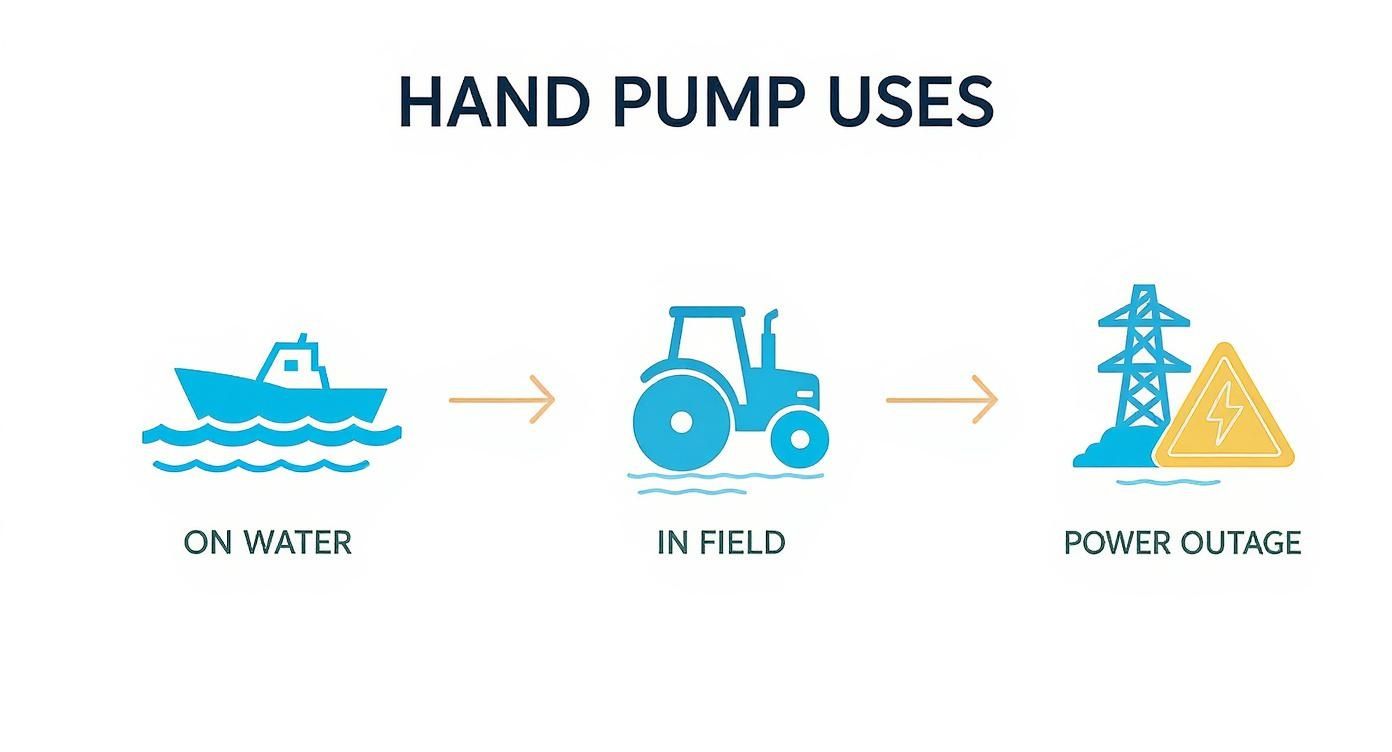

This visual gives you a great idea of just how handy these pumps can be in different scenarios.

As you can see, whether you're on a farm, at the marina, or just getting prepared for an emergency, having the right pump makes life a lot easier.

Piston Pumps: The Direct Pressure Movers

Next up are piston pumps. If you’ve ever used a bicycle pump, you already know how these work. Pulling the handle up draws fuel into a cylinder, and pushing it down forces that fuel right out the hose.

This direct action gives you a lot more power and control than a simple siphon. Because you're actively pushing the fuel, you can even handle slight uphill transfers. They're a solid, all-around choice for more regular use.

The real beauty of a piston pump is the hands-on control. You can feel the resistance with every stroke, making it easy to manage the flow and avoid messy overfills.

Rotary Vane Pumps: The Smooth Operators

When you've got a lot of fuel to move, a rotary vane pump is your best friend. Instead of an up-and-down motion, you just turn a crank handle. This spins a set of small vanes inside the pump, which scoop up the fuel and push it out in a smooth, continuous stream.

This design is incredibly efficient, which is why you’ll often find them mounted on 55-gallon drums on farms and job sites. Their steady, high-volume flow can turn a big refueling job into a quick task.

- How It Works: A hand crank spins internal vanes that push fluid out continuously.

- Best For: Refueling tractors or equipment from large drums.

- Key Advantage: Delivers a high, consistent flow that makes big jobs go much faster.

Diaphragm Pumps: The Heavy-Duty Workhorses

Finally, we have diaphragm pumps. These are the tough guys of the pump world, built to handle thicker fluids or liquids that might have some gunk in them. Inside, a flexible diaphragm pulses back and forth, creating suction and pressure to move the fluid along.

The magic here is that the diaphragm is the only moving part that actually touches the liquid. This makes these pumps super durable and almost impossible to clog. If you're dealing with waste oil or contaminated fuel that would jam up other pumps, this is the one you want.

To make things even clearer, here’s a quick side-by-side look at how they stack up.

A Quick Guide to Fuel Hand Pump Types

| Pump Type | How It Works | Best For | Key Advantage |

|---|---|---|---|

| Siphon Pump | Gravity and initial suction | Small, simple transfers | Lightweight and affordable |

| Piston Pump | Up-and-down piston action | General purpose refueling | Good control and pressure |

| Rotary Vane | Continuous crank rotation | High-volume transfers | Fast and smooth flow rate |

| Diaphragm Pump | Flexible diaphragm movement | Thick or contaminated fluids | Durable and clog-resistant |

Ultimately, choosing the right fuel tank hand pump is all about matching the tool to the job. By understanding how each design works, you can make sure you have the right one to get things done safely, cleanly, and without any hassle.

Why a Hand Pump Is Often Your Best Bet

In a world buzzing with electric gadgets, grabbing a manual tool can feel a bit old-school. But when it comes to a fuel tank hand pump, that simplicity is exactly what makes it so brilliant. Its design offers a handful of real-world advantages that battery-powered pumps just can't touch.

These aren't just minor perks, either. They're fundamental features that make manual pumps the go-to choice for reliability, safety, and all-around usefulness in countless situations. Let’s break down why this humble tool is still a must-have piece of gear.

Go-Anywhere Portability and Freedom

The most obvious win for a manual fuel pump? It’s completely untethered from electricity. You don't need a charged battery, a running engine, or a power outlet. That kind of independence isn't just convenient—it's a game-changer.

Think about it. You could be refueling your boat from a jerry can in a quiet cove, miles from the nearest dock. Or maybe you're on a remote job site, and the generator is running on fumes. An electric pump is just dead weight in those scenarios. A hand pump, on the other hand, works every single time, powered by nothing more than a little elbow grease.

- Works Anywhere: Use it on the water, out in a field, or even during a power outage.

- Light & Compact: It’s easy to tuck into a boat locker, truck toolbox, or your emergency kit.

- Always Ready: No more waiting for a battery to charge or hunting for a power source.

This self-sufficiency gives you incredible peace of mind. You know you have a reliable tool ready to go whenever and wherever you need it.

Unbeatable Reliability

When you're dealing with fuel, the last thing you want is a tool that might fail. Electric pumps have motors, wires, switches, and batteries—every one of them a potential weak link. Saltwater corrosion or just normal wear and tear can knock an electric pump out of commission right when you need it most.

A fuel tank hand pump, however, is beautifully simple. With very few moving parts, there's just not much that can go wrong. That mechanical simplicity means you get rock-solid dependability.

The real value of a manual pump is its consistency. With such a basic design, it's never a question of if it will work, but just how fast you can pump. That kind of reliability is crucial when failure isn't an option.

Because it’s so straightforward, it can sit in your garage for months on end, and you can still be confident it’ll work perfectly the moment you need it.

Better Safety and Pinpoint Control

Handling flammable liquids like gasoline or diesel requires total control. One of the biggest advantages of pumping by hand is the direct feel you get for the job. You are in complete command of the fuel flow, which dramatically cuts down the risk of messy, dangerous spills.

With an electric pump, you often just have an on/off switch, which can cause the fuel to surge and splash out or overfill the tank. A hand pump lets you:

- Start Slow: Begin with a few gentle pumps to make sure everything is connected right and the flow is smooth.

- Adjust on the Fly: You can pump quickly during the main transfer, then slow right down as the tank gets close to full.

- Stop Instantly: The second you stop pumping, the flow stops. This lets you prevent a tiny drip from turning into a big problem.

This level of precision is especially important around water, where even a small fuel spill can cause serious environmental damage.

Seriously Easy on the Wallet

Finally, let's talk cost. Manual hand pumps are way more affordable than their electric cousins right out of the box. You're not paying a premium for motors, batteries, and complicated electronics.

And the savings don't stop there. There are no ongoing costs—no batteries to replace and no electricity to use. Because the design is so simple, they barely need any maintenance and rarely break. Over its lifetime, a manual pump is an incredible value, giving you a reliable solution without the high price tag. It’s a smart investment for any toolkit.

How to Choose the Right Fuel Hand Pump

Picking the right fuel hand pump isn't complicated, but it does require a little thought. Think of it like buying any other tool—the best one is always the one that’s right for the job. You wouldn't use a tiny screwdriver on a massive bolt, right? The same logic applies here.

If you focus on just a few key details, you can easily find a pump that’s not just effective but also safe and built to last. Let's walk through what really matters so you can make a choice you’ll be happy with every time you use it.

Match the Pump to the Liquid

This is the big one. If you ignore everything else, pay attention to this: fluid compatibility. Not all pumps can handle all liquids, and using the wrong one can lead to leaks, contamination, or flat-out dangerous failures.

Gasoline, for instance, is surprisingly corrosive and will eat through the wrong kinds of plastics and rubber seals. A pump designed for water or oil might seem to work at first, but its internal parts could be slowly breaking down, ready to fail when you least expect it.

Always check what the manufacturer says the pump is for. You need to see that it’s rated for the exact fuel you plan to move. While a gasoline-rated pump is usually fine for diesel, you should never, ever use a water or oil pump for gasoline.

Consider Your Required Flow Rate

Next up, think about speed. How quickly do you actually need to move that fuel? The flow rate of a hand pump tells you how fast it works, usually measured in gallons per minute (GPM) or ounces per stroke. This isn't just about being patient; it’s about making sure the pump’s speed fits the task.

Here’s a simple way to think about it:

- High Flow Rate (e.g., Rotary Vane Pumps): If you're refueling a tractor or a boat from a 55-gallon drum, you want speed. A high-flow pump can turn a 20-minute chore into a quick 5-minute job.

- Moderate to Low Flow Rate (e.g., Piston or Siphon Pumps): For smaller tasks like filling up a lawnmower or an ATV from a 5-gallon can, a slower, more controlled flow is your friend. It gives you more precision and helps prevent messy overfills and splashes.

Matching the flow rate to your needs makes the whole process faster, cleaner, and safer.

Choose the Right Build Materials

The environment you’ll be working in has a big impact on whether you should go with plastic or metal. Each has its place, and the choice comes down to how and where you'll be using the pump.

A heavy-duty steel pump is probably overkill for topping off the mower once a month, but a lightweight plastic one might not survive long on a busy farm or construction site. For a closer look at specific models, check out our guide on the top manual transfer pumps for fuel in 2025 to see how different materials stack up in the real world.

Here’s a quick comparison to help you decide:

| Material Type | Best For | Key Advantages | Potential Downsides |

|---|---|---|---|

| Durable Plastics | Occasional or light-duty use, marine environments. | Lightweight, corrosion-resistant, affordable. | Can become brittle in extreme cold or degrade with UV exposure. |

| Metals (Steel, Aluminum) | Heavy-duty, frequent use in industrial or farm settings. | Extremely durable, long-lasting, resistant to impact. | Heavier, susceptible to rust (steel), higher initial cost. |

Choosing the right material from the start means your pump will hold up to whatever you throw at it for years to come.

Ergonomics and Hose Length Matter

Finally, don’t forget the small details that make a big difference in how easy the pump is to use. A pump's ergonomics and hose length can be the difference between a quick, simple job and a frustrating mess.

If a handle is uncomfortable, you'll get tired of pumping pretty quickly. Look for a design with a grip that feels good in your hand.

Hose length is just as important. If the hose is too short, you might find yourself lifting a heavy fuel can into an awkward and unsafe position. That’s a recipe for spills and a sore back. Before you buy, get a rough idea of the distance between your fuel container and the tank you're filling. Make sure the pump's hoses give you enough slack to work comfortably.

How to Use Your Fuel Pump Safely: A Step-by-Step Guide

Using a fuel tank hand pump is pretty simple, but let's be honest—fuel is serious business. It's volatile stuff, and getting careless can lead to a dangerous mess. If you follow a methodical process, what seems like a risky job becomes a clean, safe transfer every single time. Let's break down the process from setup to cleanup.

Before you even think about pumping, take a few minutes to get your area ready. A little prep work can save you from a major headache later. Think of safety not as a chore, but as the first step to getting the job done right.

Getting Set Up: Safety First

Always start with a quick check of your gear and your surroundings. This isn't a step you can skip; it sets the foundation for a safe transfer.

- Find Some Fresh Air: Fuel fumes are no joke—they're flammable and harmful to breathe. Always, always pump fuel outside or in a garage with the doors wide open. Never work in a closed room.

- No Sparks, No Flames: Get rid of anything that could ignite the fuel. That means no smoking, shutting off nearby engines, and staying far away from things like water heaters that have a pilot light.

- Check Your Equipment: Give your pump a quick look-over. Are the hoses cracked or brittle? Are all the connections tight? Make sure the pump itself is clean and moves freely.

Here’s a pro tip: always have a fire extinguisher rated for flammable liquids (Class B) nearby. You hope you never have to use it, but being prepared is what responsible fuel handling is all about.

The Pumping Process

Okay, your space is safe and your gear is good to go. Now it's time to move some fuel. The key here is control. A steady, unhurried pace is much safer—and less messy—than trying to rush it.

Step 1: Position Your Containers

Set both your source container (the full one) and the destination tank (the one you're filling) on a stable, level surface. If you're using a siphon-style pump, the source tank needs to be higher than the destination tank so gravity can do some of the work. For other pumps, it's less critical, but keeping them close helps avoid long, stretched-out hoses you could trip over.

Step 2: Secure the Hoses

Push the intake hose all the way into the source container until it hits the bottom. This ensures you can get out as much fuel as possible. Next, place the outlet hose securely into the opening of the tank you're filling. Make sure it's snug enough that it won't pop out once the fuel starts flowing.

Step 3: Prime and Start Pumping

Begin with slow, steady strokes. If you have a piston pump, use a smooth up-and-down motion. With a rotary pump, turn the crank at an even speed. Starting slow prevents the fuel from surging out and making a mess. For boat owners, preventing spills is especially important; a clean marine fuel fill is crucial for protecting your boat and the water.

Step 4: Keep an Eye on the Fuel Level

Pay close attention here. Watch the level in the destination tank as it rises. Once it starts getting close to the top, slow your pumping way down. This gives you the fine control you need to top it off without overfilling. Rushing at the end is a classic mistake that almost always leads to a spill.

Step 5: Finish the Job

When the tank is full, stop pumping. To get the last bit of fuel out of the lines, carefully lift the intake hose out of the source container, but keep the outlet hose in the destination tank for a moment. Let gravity drain the remaining fuel from the pump and hose. Once it's empty, remove the outlet hose and put the caps back on both containers nice and tight.

Keep Your Pump Running for Years with Simple Maintenance

Your fuel tank hand pump is a tough, simple tool, but a little care goes a long way in making it last. Like any good piece of gear, ignoring basic maintenance will eventually lead to poor performance or a complete failure—usually right when you need it most. The good news? Keeping your pump in prime condition is easy and only takes a few minutes.

This small time commitment is your best defense against the corrosive nature of fuel and premature wear. A pump that's looked after is a pump you can rely on. These simple habits will make sure it's always ready to go.

Clean the Pump After Every Use

If you do only one thing, make it this: clean the pump. As fuel evaporates, it can leave behind a sticky residue. Over time, that gunk will clog up the works, make parts stick, and eat away at the seals.

Plus, you have to think about cross-contamination. If you pump diesel and then switch to gasoline without cleaning it, you risk mixing fluids that could damage sensitive engines.

Here's a quick cleaning routine:

- First, pump air through the unit to push out any leftover liquid.

- Wipe down the outside body and hoses with a clean, dry rag.

- If your pump's materials allow, run a small amount of a neutral cleaning fluid (like mineral spirits for oil-based pumps) through it, then follow up with more air to dry it out.

Do a Quick Inspection Every Time

Before you store your pump, just give it a quick once-over. Spotting small issues early on is the best way to prevent them from becoming big headaches. You don't need to be a mechanic—just keep an eye out for obvious trouble.

Think of it like a quick health checkup for your tool. A 30-second scan can spot a cracked hose or a loose fitting, saving you from a dangerous fuel spill next time you use it.

Check these key spots:

- Hoses: Look for any cracks, kinks, or signs of becoming brittle.

- Seals and Gaskets: Are there any drips or signs of wear?

- Connections: Make sure all the fittings are snug and secure.

Store Your Hand Pump the Right Way

Where you keep your pump matters just as much as how you clean it. Extreme heat, direct sunlight, and moisture can wreck its components, especially the plastic and rubber parts.

For the best results, store your fuel tank hand pump in a cool, dry spot, like a garage cabinet or a dedicated toolbox. Never leave it lying around outside where the sun’s UV rays can degrade the hoses or rain can cause metal parts to rust. Following a system helps, which is why our preventive maintenance checklist template is a great way to stay organized with all your gear. This simple habit protects your investment and keeps your pump working like new for years to come.

Got Questions? We’ve Got Answers

Even with a tool as simple as a fuel tank hand pump, a few questions always seem to come up. Let's clear up some of the most common ones so you can use your pump safely and effectively.

Can I Use the Same Hand Pump for Gasoline and Water?

That’s a definite no. Using the same pump for different liquids is a recipe for disaster. Fuel residue can easily contaminate water, and even a tiny amount of water can introduce rust, debris, and performance issues into your fuel system.

Think of it this way: you wouldn't use the same glass for milk and orange juice without washing it. For your engine's health and your own safety, dedicate one pump for fuel and another for everything else. It’s a small investment that prevents big, expensive headaches later on.

My Siphon Pump Isn't Working. What Should I Check First?

Siphon pumps are all about creating a good vacuum. If yours isn't working, it's almost always because of an air leak or an issue with the setup. Before you get frustrated, run through this quick checklist:

- Check Your Heights: Is the tank you're pulling from sitting higher than the one you're filling? Siphons need gravity to do their thing, so this height difference is non-negotiable.

- Submerge the Hose: Make sure the intake hose is completely submerged in the fuel. If the end is sucking in even a little bit of air, the siphon will break, and the flow will stop.

- Hunt for Leaks: Give every connection a once-over. Are the hoses tight? Are there any tiny cracks or pinholes in the tubing?

A siphon pump relies on a perfectly airtight seal. Even a pinhole leak or a loose connection is enough to kill the vacuum and stop the fuel from flowing.

What Are the Most Important Safety Precautions for Pumping Fuel?

Working with fuel always requires your full attention. First and foremost, make sure you’re in a well-ventilated space—never in an enclosed garage or shed where fumes can build up. Keep any potential ignition sources, like open flames, sparks, or even a running engine, far away.

It's also a smart move to keep a Class B fire extinguisher within arm's reach, just in case. And don't forget your personal protective equipment (PPE)! A good pair of nitrile gloves and some safety glasses will protect your skin and eyes from any accidental splashes.

Ready to make fueling your boat simple and spill-free? Discover the innovative solutions from CLiX Fueling Solutions and experience a cleaner, safer way to refuel. Explore our products today!