For any boater, a reliable hand pump for fuel transfer isn't just another gadget to stow away—it's a critical piece of safety gear. This simple, often overlooked tool is your best defense against dangerous spills and the all-too-common nightmare of being stranded on the water.

Why a Hand Pump Is a Boater's Best Friend

There’s a special kind of dread that sets in when you see the fuel gauge needle dipping low and there's no marina in sight. A manual fuel pump is your get-out-of-jail-free card for this exact scenario. It's a dead-simple solution that works every time, no batteries or power source required.

Trying to refuel by tipping a heavy, awkward fuel can is just asking for trouble. Spills are messy, sure, but they also damage your boat's finish, pollute the water, and create a serious fire hazard. A dedicated hand pump gives you total control, letting you move fuel cleanly and safely.

The Problem with Guesswork and Spills

Let's face it, boating has its share of unknowns, but your fuel situation shouldn't be one of them. Between finicky gauges and the challenge of refueling on choppy water, spills happen way too often. And a spill is much more than a minor annoyance.

- Environmental Damage: A single quart of spilled fuel can contaminate thousands of gallons of water, devastating local marine life.

- Vessel Damage: Fuel is harsh stuff. It can stain your gelcoat, eat away at decking, and cause rubber seals and hoses to degrade prematurely.

- Safety Hazards: Fuel vapors are incredibly flammable. One stray spark is all it takes to cause a fire or a life-threatening explosion on your boat.

A manual pump puts you firmly back in control. It turns a risky, messy chore into a precise, managed task, protecting your boat, your wallet, and the waters you love to be on.

The Simple, Dependable Solution

The real genius of a manual pump is its simplicity. There are no finicky electronics to short out or batteries to go dead right when you need them most. It just works.

Whether you're topping off your main tank from a jerry can or shifting fuel between tanks to balance your boat's trim, a hand pump is the most reliable tool for the job. You can even find integrated systems, like gas cans with a pump, that make the process even smoother. This guide will cover everything you need to know to choose, use, and maintain the right pump, so you’re always prepared for whatever the water throws at you.

How a Manual Fuel Pump Actually Works

At its heart, a hand pump for fuel transfer works on a surprisingly simple bit of physics. Remember using a straw as a kid? When you suck the air out, you create a vacuum, and the higher pressure outside pushes the drink right up the straw. A manual fuel pump is basically a souped-up version of that.

It just uses a mechanical part—a piston, a diaphragm, or a spinning vane—instead of your lungs to create that low-pressure zone. Every turn of the crank or squeeze of the bulb pulls air out of the line, and the outside air pressure does the rest, pushing fuel from your jerry can up into the hose. This principle, called displacement, is exactly why these manual tools are so rock-solid reliable.

Breaking Down the Core Components

No matter the style, every manual pump uses a few key parts working together to move fuel. Once you know what they are, you can see how beautifully simple the whole setup is.

- The Actuator (Handle or Bulb): This is the part you actually operate. Whether you’re turning a crank, pumping a lever, or squeezing a bulb, you’re providing the muscle to get things moving.

- The Piston or Diaphragm: This is the engine of the pump. Its movement creates the vacuum that draws fuel into the pump’s body.

- The Valves: These are the real secret sauce. There are usually two one-way check valves. One lets fuel in but not back out to the source. The other lets fuel out through the hose but stops it from flowing back into the pump.

This clever arrangement ensures fuel only ever moves in one direction. As you work the pump, one valve opens to let fuel in while the other stays shut. On the return stroke, they swap roles, pushing that slug of fuel toward your tank.

The real beauty of a manual fuel pump lies in its mechanical simplicity. With no complex electronics or wiring, there are far fewer points of failure, making it an incredibly dependable tool for any boater.

The Pumping Action Step-by-Step

Let's walk through a single pump cycle. Imagine you're using a lever-action pump.

When you pull the handle up, the piston inside the cylinder slides back. This creates a vacuum that sucks fuel from your container, up the intake hose, and past the first one-way valve into the pump chamber.

Now, you push the handle down. The inlet valve snaps shut, trapping the fuel inside. The pressure you create forces the outlet valve to open, pushing that fuel out of the chamber, down the transfer hose, and into your boat’s tank.

Each up-and-down stroke repeats this cycle, creating a steady, controllable flow of fuel. It’s a simple mechanical dance, all powered by a little bit of your own effort.

A Look at the Most Common Fuel Hand Pumps

Picking the right hand pump for fuel transfer isn't a one-size-fits-all deal. What works for a massive yacht's diesel tank is probably overkill for a little dinghy. To find the perfect fit for your boat, you first need to get familiar with the three main players: Lever-Action, Rotary, and Siphon pumps.

Each one works a bit differently, and those differences matter. They affect everything from how fast the fuel flows to how easy the pump is to use and what kind of fuel it can handle. Getting this choice right means your refueling will be smooth, efficient, and—most importantly—safe.

The Sturdy Lever-Action Pump

If you need a real workhorse for moving fuel, look no further than the lever-action pump. Its simple up-and-down motion is a classic for a reason, much like an old-fashioned water pump. This design gives you the muscle needed to move thicker fluids like diesel and oils, delivering a powerful, high-volume flow with every stroke.

- How It Works: When you pull the lever up, it creates a vacuum that sucks fuel into the pump body. Pushing down then forces that fuel out through the hose.

- Best For: Moving fuel from big 55-gallon drums or large containers directly into your boat’s main tank.

- Key Advantage: These pumps are built tough. They generate serious pressure, which makes them perfect for bigger jobs where you want to get things done quickly.

The Smooth Rotary Pump

A rotary pump is all about continuous, smooth operation. You turn a crank, which spins a set of gears or vanes inside, creating a steady, uninterrupted flow of fuel. Think of it like a water wheel in reverse—your cranking scoops up fuel and sends it smoothly on its way.

This consistent action makes them surprisingly easy to use, with none of the jerky movements you might get from other pumps. They're also quite versatile and often work with both gasoline and diesel, as long as you get a model made with the right materials. With a typical output of around 7-8 liters per minute, they’ve become a go-to all-rounder for many boaters.

The Simple Siphon Pump

It doesn't get any simpler than a siphon pump. This design uses gravity and a little bit of priming to start the flow. Once you create that initial suction—usually with a squeeze bulb or a vigorous shake of the hose—gravity takes over and does the rest of the work, pulling fuel from a higher container down to a lower one.

While they're incredibly straightforward, siphon pumps are really meant for smaller jobs. They have the lowest flow rate of the bunch, but they're also super portable and cheap, making them ideal for topping off an outboard motor or transferring small amounts of fuel between jerry cans.

The need for good manual fueling tools is bigger than you might think. The global fuel transfer pump market was valued at $6.49 billion and is expected to hit $10.12 billion, driven by the need for safer fuel handling as environmental rules get stricter. If you're curious about what's driving this growth, you can dive deeper into the market trends in this detailed industry report.

To make the choice a bit clearer, let's break down how these pumps stack up against each other.

Comparison of Hand Pump Types for Marine Fuel Transfer

Here’s a quick comparison to help you visualize which pump type might be the best fit for your specific situation on the water.

| Pump Type | How It Works | Best For | Pros | Cons |

|---|---|---|---|---|

| Lever-Action | A piston creates suction with an up-and-down handle motion. | High-volume transfers from large drums; thicker fuels like diesel. | Powerful; high flow rate; durable construction. | Can be bulky; requires more physical effort per stroke. |

| Rotary | A hand crank spins internal vanes for a smooth, continuous flow. | General purpose fueling from various container sizes. | Easy to operate; consistent flow; versatile for many fuels. | More moving parts that can wear out over time. |

| Siphon | Uses gravity and initial priming (bulb or shake) to move fuel. | Small tanks, portable containers, and low-volume transfers. | Extremely simple; portable; inexpensive; no moving parts. | Slowest flow rate; requires a height difference to work. |

As you can see, the best pump really comes down to what you're trying to accomplish—whether it's a major refuel from a drum or just a quick top-off for your tender.

Essential Safety and Maintenance Practices

Sure, using a hand pump for fuel transfer is a world away from the sloshing mess of trying to tip a heavy gas can, but let’s be honest—handling fuel always requires your full attention. Gasoline and diesel are serious business, and one careless moment on the water can lead to a really bad day. Sticking to a few simple, non-negotiable safety rules is the best way to protect yourself, your crew, and your boat.

First things first: always refuel in a well-ventilated spot. The best place is out in the open air. Fuel vapors are heavier than air and can settle in low areas like the bilge, creating a ticking time bomb. Before you even unscrew a cap, kill the engine, shut down the generator, and turn off anything else that could create a spark. Yes, that includes your phone.

Your Pre-Transfer Safety Checklist

Think of this as your pre-flight check before every refueling. It only takes a minute, and it could prevent a disaster.

- Inspect Your Gear: Give your pump and hoses a quick once-over. Look for any cracks, brittle spots, or signs of leaking. A damaged hose is just a spill waiting to happen.

- Ground the Pump: Static electricity is the invisible enemy here. If your pump is equipped with a grounding wire or anti-static clamp, make sure you connect it to a metal part of your boat to safely get rid of any static buildup.

- Secure Your Containers: Check that both the fuel can and the boat’s tank are stable. The last thing you want is a container tipping over from the boat rocking or the shifting weight of the fuel.

Fuel transfer safety isn't just about avoiding spills; it’s about preventing fires. It’s the vapors, not the liquid fuel, that ignite. Good ventilation is your single best defense against this hidden danger.

Simple Maintenance for Long-Term Reliability

A little bit of care will keep your pump in good working order for years to come. After you're done, it’s a smart move to clear any leftover fuel from the pump and hoses. This simple step helps prevent the internal seals and components from drying out or degrading over time.

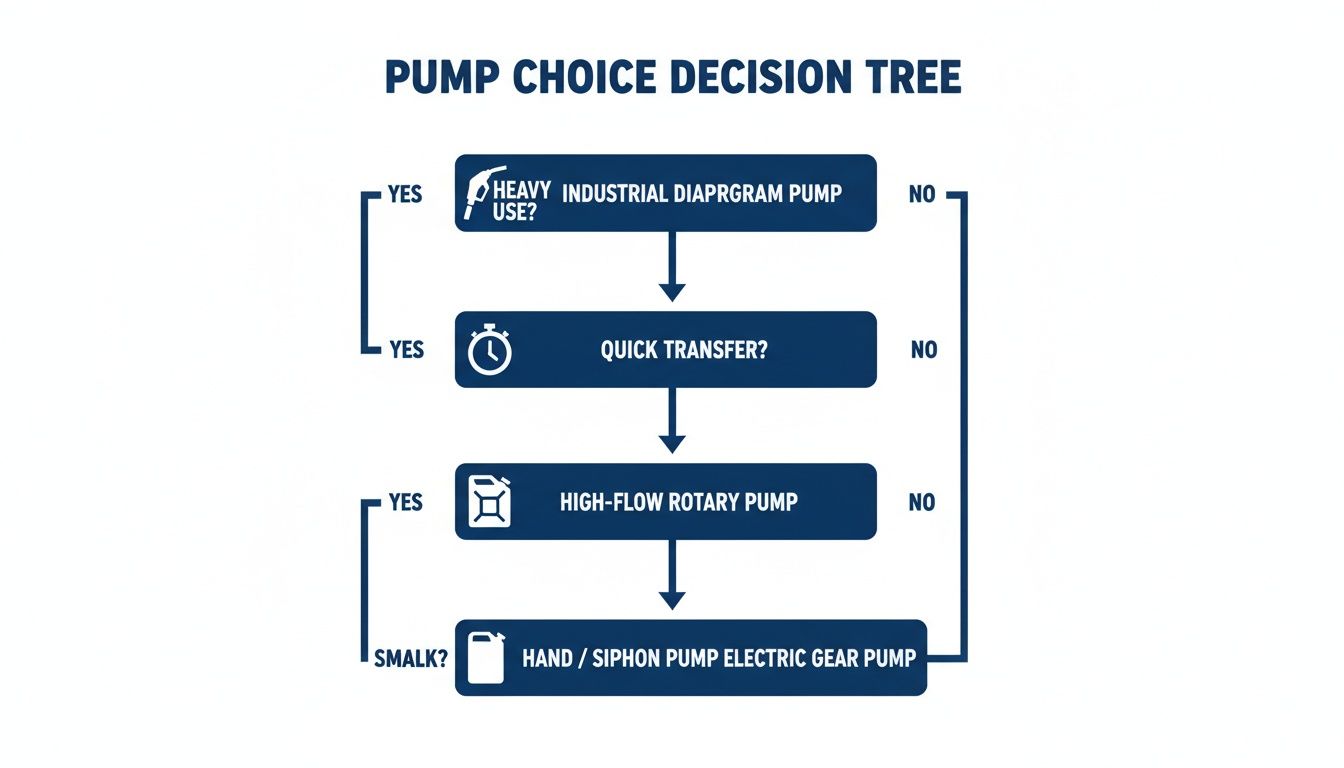

This decision tree can help you figure out which pump features really matter for how you use your boat.

As the chart shows, things like how fast you need to transfer fuel and the size of your tank will point you toward the right pump for the job.

When it's time to put it away, store your pump in a cool, dry place out of direct sunlight. UV rays can wreak havoc on plastic and rubber parts, causing them to become brittle and fail. For a closer look at specific models, take a look at our guide to the top manual transfer pumps for fuel in 2025.

The demand for safer fueling solutions is on the rise. In fact, the market is expected to grow from $1.87 billion to $2.45 billion. This trend makes sense when you consider that up to 25% of manual refueling on boats ends in a spill. You can learn more about these industry shifts in the full fuel transfer pump market report.

Choosing Between Manual and Powered Fuel Pumps

When you're out on the water, how you refuel is a bigger deal than you might think. Is a trusty old manual pump always the best call? While a hand pump for fuel transfer is about as reliable as it gets, it's smart to compare it to the convenience and safety of modern powered options. The right choice really boils down to your specific boat and how you use it.

The biggest win for a manual pump is its bulletproof simplicity. It doesn’t need batteries or any power source to work. That means you can count on it in a quiet, remote cove just as easily as you can at a busy marina. For any boater, that kind of self-sufficiency is priceless peace of mind.

Of course, that simplicity has its downsides. Manual pumps are slow, and if you’ve got a big tank to fill, you’re in for a workout. It’s more than just a hassle—getting tired while pumping for a long time can make you lose focus, which is exactly when messy, dangerous spills happen.

Speed and Effort: The Manual Drawback

The real bottleneck with a manual pump is the flow rate. Even a good rotary pump will only give you about 7-8 liters per minute. When you're trying to top off a large tank, that can feel like an eternity. The non-stop cranking or pumping gets old fast, especially if the boat is rocking.

This physical effort is where the danger of a spill sneaks in. It’s all too easy to get distracted by the repetitive motion and misjudge how full the tank is getting. That one moment of carelessness is all it takes to send fuel splashing across your deck, which can damage the gelcoat and pollute the water.

A powered pump takes the physical work out of the equation and slashes your refueling time. But the real leap forward is automation, which adds a safety net that manual pumping just can't offer.

The Rise of Smart Fueling Solutions

This is where automated systems like CLiX really shine, giving you the best of both worlds. You get the speed and convenience of a powered pump, but with smart technology built in to prevent the most common fueling nightmares.

These systems actively monitor the fuel level and shut off the pump the second the tank is full. No more guesswork, no more human error—just a perfect, clean fill every single time. It takes the stress out of refueling and protects both your boat and the environment.

Remember, keeping all your gear in prime condition is key to a good day on the water. For example, learning proper techniques for maintaining your fishing reels ensures everything works when you need it most. In the end, deciding on a fueling method is about balancing the rugged dependability of a manual pump with the safe, effortless precision of today's automated solutions.

Frequently Asked Questions About Fuel Hand Pumps

Even with the right gear, you're bound to have questions when you start using a hand pump for fuel transfer. Getting good, clear answers is the key to handling fuel safely and confidently. This section dives into the most common questions boaters ask, so you'll be ready for whatever a refueling job throws at you.

We'll cover everything from what kind of fuel you can use to spotting the first signs of wear and tear, all to help keep your fueling process as smooth and spill-free as possible.

Can I Use the Same Pump for Gasoline and Diesel?

This is a huge safety question, and the short answer is not always. You absolutely have to use a pump that's specifically rated for the type of fuel you're moving. Pumps built for gasoline use special materials that can stand up to its additives and are designed to prevent dangerous static electricity from building up.

Diesel pumps, on the other hand, might have seals and gaskets made from materials that gasoline would eat away at. The bottom line? Always check the manufacturer's specs. Using the wrong pump isn’t just a bad idea—it can lead to pump failure, nasty leaks, and a serious fire risk.

How Do I Choose the Right Flow Rate?

The best flow rate really comes down to two things: your tank size and how patient you are. For those small, portable tanks under 10 gallons, a basic siphon or a small lever pump that moves 2-4 gallons per minute (GPM) will get the job done. It’s a bit slow, but it’s manageable.

For larger built-in tanks, you’ll want a more serious rotary or piston pump that can deliver 5-10 GPM. That'll speed things up a lot. Just remember, a faster flow rate means you have to pay closer attention—it’s much easier to splash fuel or overfill the tank if you get distracted. This is one area where automated solutions really shine, since they can manage the whole process for you.

The market for fuel transfer pumps is booming, expected to grow from $1.8 billion to $3.2 billion. That growth is tied directly to the massive increase in recreational boating, which now accounts for over 100 million boats worldwide. You can dig into the numbers in this comprehensive market report.

What Is the Best Way to Prime a Manual Pump?

Priming a pump is just a fancy way of saying you need to get all the air out of the line so it can start pulling fuel. For a lever or rotary pump, make sure the intake hose is all the way in the fuel. Then, just work the handle at a steady pace for a few strokes. You'll feel the resistance change once the fuel starts flowing.

Siphon pumps are a little different. Many have a primer bulb you squeeze, while others use a "shake-to-start" valve that gets things moving with a few good shakes. Here’s a critical safety tip: never, ever try to start a siphon with your mouth. Swallowing fuel is incredibly dangerous.

What Are the Signs My Hand Pump Needs Replacing?

Keep an eye out for these tell-tale signs that your pump is on its last legs.

- Visible Cracks: If you see any cracks or feel brittle spots on the hoses or seals, that’s a major red flag for future leaks.

- Hard to Use: Does the pump feel stiff, make weird grinding noises, or just not move much fuel anymore? The internal parts are probably worn out.

- Fuel Leaks: This one is non-negotiable. If you see fuel leaking from the pump body itself, stop using it immediately and get a new one.

A failing pump isn't just an inconvenience—it's a real safety hazard. If you're thinking about moving on from manual pumps, you might find our guide on the benefits of an electric portable gas pump helpful.

For a truly effortless and safe fueling experience, explore CLiX Fueling Solutions. Our automated system prevents spills by stopping the flow the moment your tank is full, protecting your boat and the water. Discover the future of stress-free fueling at https://clixfueling.com.