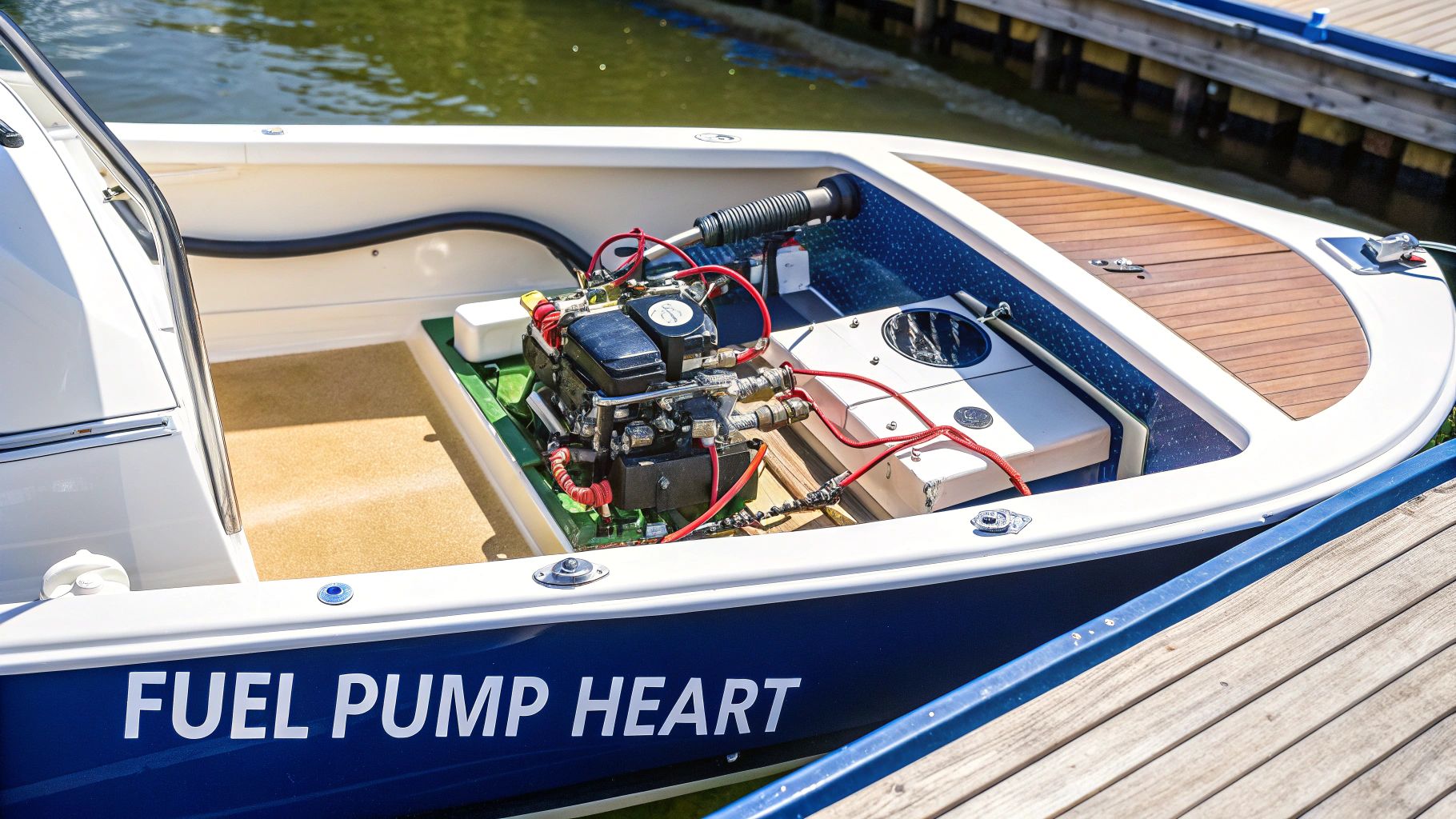

At the heart of every boat's engine is a component that works tirelessly, often unnoticed, to keep things running: the gas pump. This small but mighty device is the unsung hero of your fuel system, responsible for delivering a steady, reliable stream of gasoline from the tank to the engine.

Without it, you're not going anywhere. Understanding how it works is the first step to ensuring your boat has the power it needs, whether you're out for a lazy cruise or cutting through choppy waves.

Understanding Your Boat's Fuel System

It helps to think of your boat’s fuel system like its circulatory system. The fuel tank is the reservoir, the fuel lines are the veins, and the gas pump is the constantly beating heart. Its entire purpose is to pull fuel from the tank, push it through filters, and deliver it to the engine at just the right pressure.

If that pump falters, the engine starves. That's when you get sputtering, a sudden loss of power, or worse, a dead engine miles from shore.

This is why getting the right pump is so important. A pump that's too weak can't keep up with what the engine needs, but one that's too powerful can create its own set of problems. The performance and reliability of your boat—and your safety on the water—hinge on this one critical part.

The Core Components and Their Roles

The fuel pump is a team player; it doesn't work alone. Knowing how all the parts work together makes it much easier to spot a problem or decide on an upgrade. For a deeper dive into this, you can read our guide on the complete boat fuel system.

Here's a quick rundown of the key players:

- Fuel Tank: This is simply where the gasoline is stored.

- Fuel Lines: These are the hoses that carry fuel from the tank to the engine.

- Fuel Filter: Catches gunk, water, and other debris before it can damage your engine.

- Gas Pump: The workhorse that pressurizes the fuel and keeps it moving.

- Engine: Where all the magic happens and fuel is turned into power.

Why This Matters for Boaters

The demand for better, more reliable marine parts is exploding. The global market for marine fuel pumps was valued at USD 3.8 billion and is expected to hit nearly USD 7.1 billion by 2030. This isn't just a random statistic; it shows how much boaters and marine professionals are focusing on dependability.

You can read more about these market trends over at The Insight Partners. This context helps drive home just how critical these components are as we get into the different types of pumps available.

Comparing the Different Types of Boat Gas Pumps

When it comes to boat fuel pumps, one size definitely does not fit all. Picking the right one is a bit like choosing the right tires for your truck—what you need for a daily driver is completely different from what you'd put on a heavy-duty off-roader. The same idea applies to a gas pump for boats; getting it right means your engine runs smoothly and reliably when you're miles from shore.

Generally, your choices boil down to two camps: electric and manual. Each is built for different kinds of boats and engine requirements. Let's break down what makes them tick so you can make the right call.

Electric Fuel Pumps: Power and Precision

For most modern boats, electric pumps are the gold standard. They use a small electric motor to deliver a steady, high-volume stream of fuel directly to your engine. Think of it as the automated heart of your fuel system, doing its job quietly so you don't have to think about it.

Within the electric category, you'll find a couple of common designs:

- In-Tank Pumps: Just like the name says, these pumps live inside the fuel tank. This is a great setup because the surrounding fuel keeps the pump cool and muffles its operating noise. Since they push fuel forward instead of pulling it, they're typically more efficient and less likely to cause vapor lock.

- External (Inline) Pumps: These are mounted outside the tank, somewhere along the fuel line. The big win here is accessibility—they're much easier to get to for maintenance or replacement. This makes them a go-to for older boats or custom builds where dropping an in-tank pump isn't practical.

If you have a fuel-injected engine, an electric pump isn't just nice to have—it's a must. These engines demand constant, specific fuel pressure to run properly. A high-speed offshore boat, for example, absolutely depends on a high-flow electric pump to keep its thirsty engines fed.

Manual Fuel Pumps: Simple and Reliable

Manual fuel pumps are the old-school, tried-and-true solution. They work mechanically, often using a lever or diaphragm that runs off the engine's camshaft to create suction and pull fuel from the tank. They are wonderfully simple, incredibly durable, and have very few parts that can break.

You'll find these pumps on smaller, carbureted engines, like those on many classic fishing boats or older vessels. Their biggest perk? No electricity needed. In a basic boat setup, that’s a huge plus, offering a dependable, no-frills way to get fuel where it needs to go.

The most important thing to remember is to match the pump to your engine's demands. An underpowered pump will starve a high-performance engine, while a sophisticated electric pump is just overkill for a simple tiller-steer outboard.

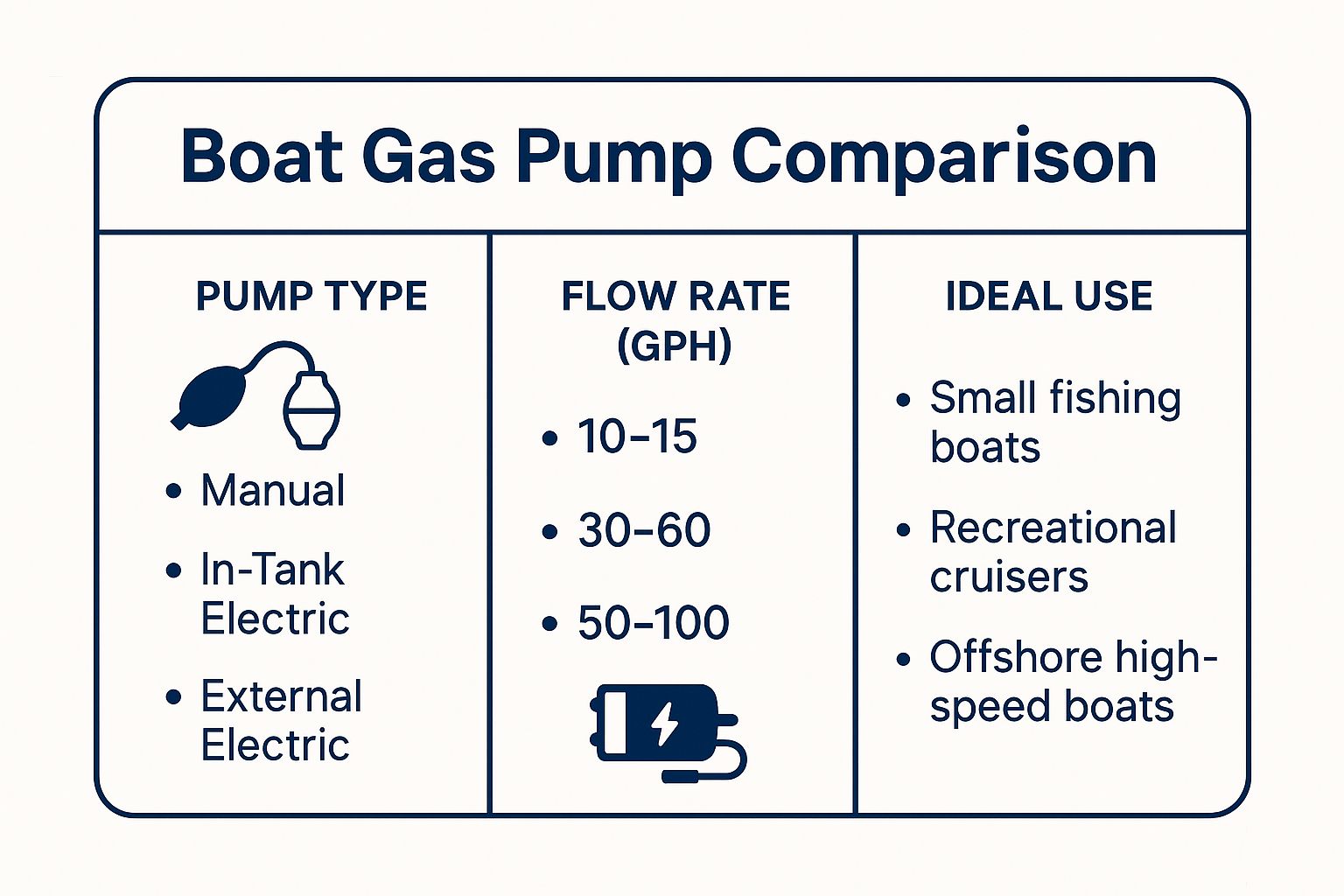

To help you see the differences at a glance, we've put together a handy comparison table.

Comparison of Boat Gas Pump Types

This table breaks down the common types of marine fuel pumps, showing where each one shines and what its limitations are.

| Pump Type | Best For | Pros | Cons |

|---|---|---|---|

| Electric (In-Tank) | Modern fuel-injected engines, high-performance boats | Quiet operation, efficient, stays cool, prevents vapor lock | Difficult to access for repairs, more complex installation |

| Electric (Inline) | Older boats, custom builds, easy-access needs | Easy to install and replace, versatile placement | Can be noisier, more susceptible to vapor lock |

| Manual (Diaphragm) | Smaller, carbureted engines (e.g., small outboards, older inboards) | Simple, reliable, no electrical power needed, inexpensive | Lower fuel flow, not suitable for high-demand or injected engines |

Ultimately, whether you choose an electric or manual pump comes down to what your boat's engine was designed for.

To give you a better visual, this infographic maps out the different pump types, their flow rates, and the kinds of boats they're best suited for.

As you can see, a pump’s flow rate is directly tied to its ideal job, from small runabouts to powerful high-speed cruisers.

The marine world is incredibly diverse, powering everything from small boats with engines under 2,000 HP to massive ships with engines topping 80,000 HP. This huge range is why there are so many specialized fuel pumps out there.

While understanding the main pump is key, don't forget about the other players in your fuel system. We've also put together a guide on the role of a marine fuel transfer pump, which handles a different but equally important job in managing your boat's fuel supply.

How to Select the Right Gas Pump for Your Boat

Picking the right gas pump for your boat isn’t about grabbing the most powerful or expensive one off the shelf. It’s about making a smart match for your engine and how you use your boat. Think of it like this: you wouldn't use a sledgehammer to hang a picture frame. The wrong tool just creates more problems.

Getting this choice right is your best bet for reliable performance, good fuel economy, and—most importantly—peace of mind when you’re out on the water.

Assess Your Engine's Fuel Needs

First things first, you need to know what your engine is thirsty for. It all boils down to two key numbers: flow rate and pressure. A common mistake is to under-power the engine, which leads to sputtering and poor performance right when you need to throttle up.

Dig into your engine manufacturer’s specs. You’re looking for two things:

- Flow Rate (GPH): This stands for Gallons Per Hour, and it tells you how much fuel the pump can deliver. A big V8 is going to need a much higher GPH than a small four-cylinder outboard.

- Pressure (PSI): This is the force, or Pounds Per Square Inch, pushing the fuel. Carbureted engines sip fuel at low pressure (usually 4-7 PSI), while modern fuel-injected systems demand much higher and steadier pressure—often 30-60 PSI or even more.

Getting these numbers right isn't just a suggestion; it's essential. A pump with the wrong GPH or PSI is one of the quickest ways to cause engine trouble or, worse, find yourself stuck.

Match the Pump to Your Fuel Type

Next up, check that the pump is built to handle the kind of fuel you use. Not all pumps are the same, and installing one that can't handle your fuel will quickly destroy its internal seals and components.

Think about what you fill your tank with:

- Gasoline: The vast majority of marine pumps are made for standard gasoline.

- Diesel: Diesel fuel is a different beast and requires a pump made with specific materials that can stand up to it.

- Ethanol Blends (E10, E15): Ethanol can be pretty harsh on certain types of rubber and plastic. If you use ethanol-blended fuels, make absolutely sure the gas pump for boats you're looking at is rated for it.

Prioritize Marine-Specific Safety Features

Finally, and this is the big one, safety on a boat is everything. In a confined space like an engine compartment, fuel vapors are incredibly explosive. That’s why you must choose a pump that is ignition protected.

An ignition-protected pump is completely sealed, which prevents any internal sparks from escaping and igniting those dangerous fumes. For most inboard gasoline engines, this is a U.S. Coast Guard requirement, not just a nice-to-have feature. Grabbing a standard automotive pump to save a few bucks is a huge risk you should never take.

This commitment to safety is a driving force in the industry. As global boating and shipping grow, the marine fuel injection system market, valued at USD 5.71 billion, continues to expand. You can learn more about how this trend influences fuel system design in the full report from Grand View Research.

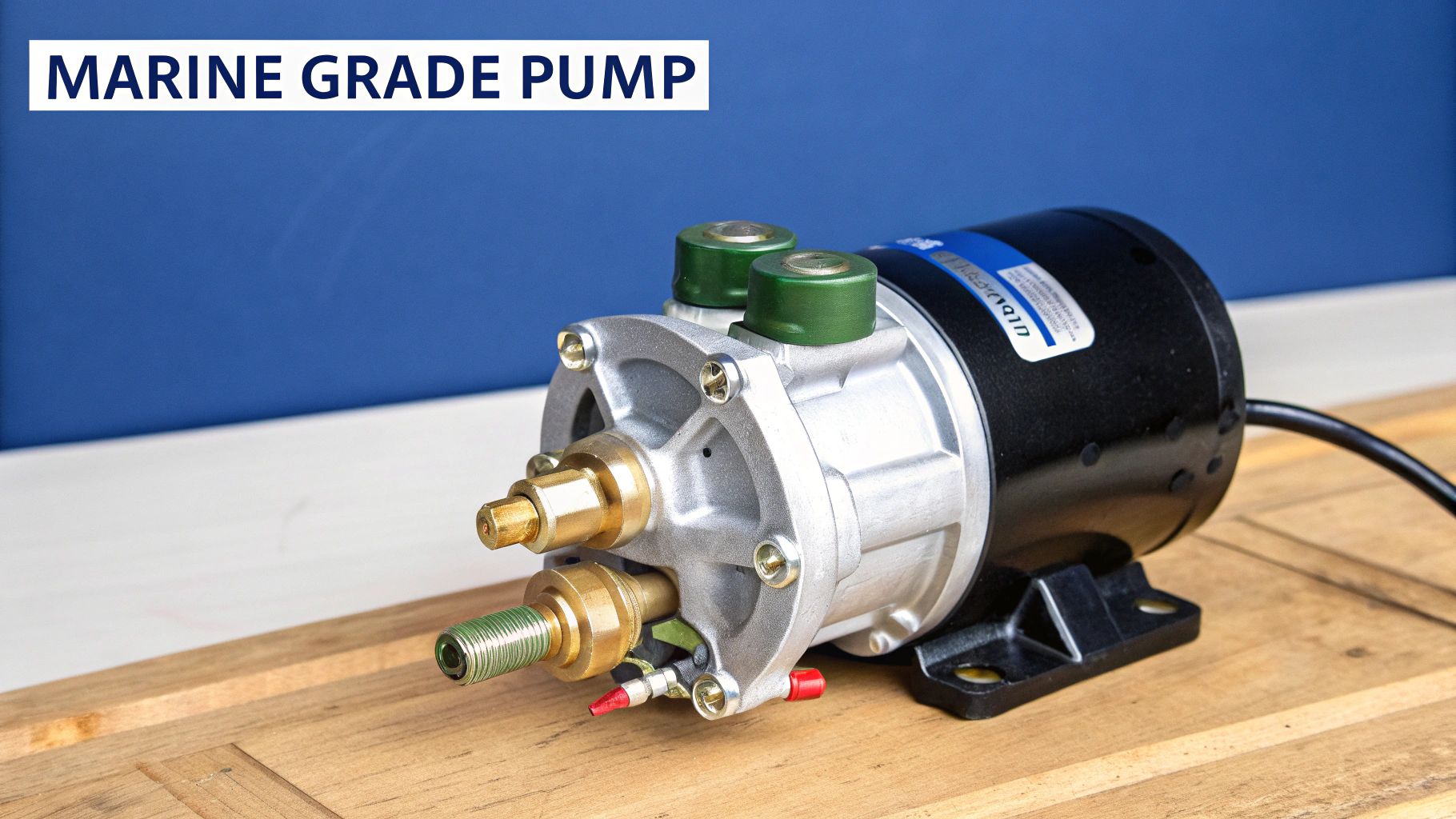

Key Features of a High-Quality Marine Fuel Pump

When you're miles from shore, the last thing you want to worry about is your equipment. A top-notch gas pump for boats isn't just a part; it's an investment in your safety and reliability, specifically engineered to handle conditions that would wreck a standard car part in no time. Knowing what separates a true marine-grade pump from the rest will help you choose one that protects your engine and gives you real peace of mind.

These features aren't just nice-to-haves. They are essential defenses against the brutal reality of the marine environment, where moisture is constant and explosive fumes are a real risk.

Built with Corrosion-Resistant Materials

On a boat, the number one enemy of anything metal is corrosion. The combination of saltwater, high humidity, and constant spray is a recipe for rust and decay. That’s why a dependable marine fuel pump is built from materials hand-picked to win this fight.

Look for pumps that are built with:

- Stainless Steel Housings: This is your first line of defense, offering fantastic resistance to rust and pitting, which keeps the pump structurally sound for years.

- Marine-Grade Coatings: Think of this as a suit of armor. Specialized epoxy or powder coatings create a shield that keeps moisture away from sensitive internal and external parts.

- Brass or Composite Fittings: Unlike basic steel fittings that can rust and seize, these materials hold tight without corroding, preventing dangerous fuel leaks right at the connection points.

This kind of rugged construction is what ensures the pump won't just quit on you because of the environment.

At its core, a marine-grade pump follows one simple rule: every single part must be able to survive in a constantly wet and salty world. This isn't optional—it's what separates a pump you can trust from one that could leave you stranded.

Essential Safety Mechanisms

Even more important than durability is safety. Fuel vapors are incredibly flammable, and a tiny spark in a confined engine bay can have disastrous consequences. A good marine pump is designed with specific features to prevent this from ever happening.

One of the most critical is thermal protection. This is a small, built-in sensor in electric pumps that acts like a bodyguard. If the pump starts to get too hot, it automatically shuts it down, preventing a motor burnout that could lead to a fire.

Another non-negotiable feature is anti-siphon protection. This is usually a valve that stops fuel from draining out of the tank if a line happens to break below the fuel level. This little device is crucial for preventing dangerous fuel spills into your bilge, which are not only an environmental hazard but can also come with some hefty fines. Choosing a pump with these safety features means your fuel system isn't just reliable—it's genuinely safe.

Installing and Maintaining Your Boat Fuel Pump

Your boat's fuel pump is the heart of its fuel system, and getting it right from the start is non-negotiable. Proper installation and a little bit of routine maintenance can be the difference between a perfect day on the water and a costly, frustrating tow back to shore.

Think of it this way: a securely installed and well-kept pump isn't just about performance. It’s your best defense against dangerous fuel leaks and other hazards. Let's walk through how to do it right.

Key Installation Steps

Putting in a new fuel pump is a job that demands patience and attention to detail. Cutting corners here can lead to everything from annoying performance issues to serious safety risks like leaks or electrical shorts.

Here are the three big things to focus on:

- Secure Mounting: Find a spot that's dry, has good airflow, and is away from engine heat—always follow the manufacturer's recommendation. Mount it solidly. Vibration is the enemy of tight connections, so make sure it’s bolted down securely.

- Correct Wiring: Grab the wiring diagram and stick to it. Always use marine-grade wiring and connectors; they're built to resist the corrosion that saltwater environments love to cause. A bad ground is a classic mistake that can kill a pump or cause all sorts of electrical gremlins.

- Fuel Line Connections: This is where safety is paramount. Every fitting needs to be tight and properly sealed to prevent leaks. For a deeper dive into this critical step, check out our guide on marine fuel line installation and care.

Creating a Simple Maintenance Checklist

Once your pump is in, it’s not a "set it and forget it" component. A simple, regular check-up will help you catch small problems before they leave you stranded. This is all about being observant and sticking to a schedule.

A sputtering engine, a sudden loss of power, or strange whining noises are often the first warning signs of a failing fuel pump. Don't ignore these symptoms—investigate them immediately to avoid getting stranded.

Add these simple tasks to your regular boat care routine:

- Look and Sniff for Leaks: Every time you're on the boat, give the fuel lines, fittings, and the pump itself a quick visual check. If you smell gas in the bilge, that’s a huge red flag that needs immediate attention.

- Change Your Filters: The fuel filter is your pump's bodyguard. A clogged filter forces the pump to work overtime, drastically shortening its life. Follow your engine's service schedule, or even change it more often if you're on the water a lot.

- Listen for Trouble: You’ll get used to the normal sound of your pump priming and running. If you start hearing a new, louder hum, a whine, or a grinding noise, that's the pump telling you it's wearing out. It's a sign that a replacement is likely in your near future.

The demand for reliable parts like these is massive, especially when you consider the scale of the global marine industry. Regions like Asia-Pacific are major players in a marine engine market valued at USD 5.97 billion. You can explore more about these global market trends over at metastatinsight.com. This just goes to show why sticking to maintenance best practices is so crucial for every single boater out there.

Troubleshooting Common Fuel Pump Problems

Even the best gas pump for boats will eventually hit a snag. The good news is that most issues are fixable, and knowing what to look for can save you from a ruined day on the water. Recognizing the signs is half the battle, helping you quickly figure out if the pump is actually the problem.

So, what are the tell-tale signs of a failing fuel pump? Watch out for an engine that refuses to start, sputters when you accelerate, or just seems to lose power randomly. Another big clue is a loud, whining noise coming from the pump—that’s often the sound of it struggling to do its job.

Diagnosing a No-Start Condition

You turn the key, the engine cranks, but it just won't catch. This classic scenario often points a finger straight at the fuel pump. But before you start ordering parts, it’s smart to run through a quick checklist to make sure you're not about to replace a perfectly good component.

A little bit of logical troubleshooting here goes a long way. Always start with the simple stuff and work your way up to the more complicated possibilities. It's the fastest way to pinpoint the real issue.

Here’s a straightforward process I always follow:

- Check the Fuse: Seriously, start here. It's the easiest and most frequent culprit. Find the fuel pump fuse in your boat's electrical panel. If it's blown, pop in a new one and see if that fixes it.

- Listen for the Prime: Turn your key to the "on" position (but don't crank the engine). You should hear a soft, two-second hum or buzz from the pump as it primes the fuel system. Dead silence is a bad sign—it usually means the pump isn't getting any power.

- Verify Power at the Pump: No hum? Grab a multimeter. Check for voltage right at the pump's electrical connector when the key is on. If you're getting no reading, the problem is likely in the wiring, a bad relay, or a loose connection somewhere upstream.

A fuel pump that gets power but stays silent is almost always a goner. It's likely seized up internally, and your only real move is to replace it.

Tackling Performance Issues

What if the engine runs, but poorly? If you're dealing with sputtering or a loss of power, the issue is probably more about restricted fuel flow than a dead pump. In these cases, something is making the pump work way too hard.

The first place you should always look is your fuel filters. A clogged filter is the number one cause of these symptoms, and it's a cheap and easy thing to replace. If the filters look good, the next step is to trace your fuel lines and check for any kinks or blockages that could be choking off the flow.

Answering Your Top Questions About Boat Gas Pumps

Even after getting familiar with all the parts, it's natural to still have a few questions rattling around about your boat's fuel system. Let's tackle some of the most common ones I hear from fellow boaters so you can feel completely confident out on the water.

Can I Just Use a Car Fuel Pump in My Boat?

This question comes up all the time, and the answer is an emphatic no. It's a dangerous idea. Your car's fuel pump isn't ignition-protected, which means it can create tiny electrical sparks.

In the open-air environment of a car's engine bay, that's not a big deal. But inside the enclosed, fume-filled engine compartment of a boat? That's a recipe for disaster. A single spark could lead to a catastrophic explosion. Always, always use a proper marine-grade fuel pump.

Is a Louder Pump Always a Bad Sign?

Not necessarily, but you need to know what to listen for. It's perfectly normal to hear a faint hum from an electric pump when it's priming the system.

However, if that quiet hum escalates into a loud, groaning whine that doesn't go away, that’s your pump telling you something is wrong. It's a classic sign that it's struggling, likely because of a clogged filter or a motor that's on its last legs. Don't just turn up the radio—a noisy pump is a pump asking for help.

How Often Should I Replace My Fuel Pump?

There isn't a simple "replace every X years" rule here. A well-cared-for pump can give you years of reliable service, while a neglected one might fail much sooner. It really comes down to usage and how well you keep up with maintenance.

The best signal is your boat's performance. If you're experiencing sputtering, stalling, or a noticeable loss of power—and you've already ruled out the usual suspects like filters and fuel lines—it's a good bet the pump is the culprit.

My advice? Be proactive. A little bit of routine maintenance, like inspecting your fuel system and changing filters on schedule, goes a long way. It’s the best way to extend your pump's life and avoid being stranded.

We're also seeing the industry push for better fuel efficiency and stricter environmental compliance, which is driving some pretty cool innovations. This trend is leading to more advanced pumps that genuinely improve how a boat performs. For a deeper dive into these industry shifts, you can review market research from Grand View Research. The bottom line is that the newer pumps hitting the market aren't just more powerful; they're smarter and safer, too.

At CLiX Fueling Solutions, we think fueling your boat should be the easiest part of your day. Our innovative system is designed to prevent those dangerous and messy overfills, protecting your boat, your wallet, and the water you love. See how a spill-free fueling experience works at https://clixfueling.com.