When you're out on the water, the last thing you want is engine trouble. A top-notch gas pump for your boat is the lifeline that keeps your engine humming, delivering a steady, reliable flow of fuel. It’s far more than just another part; it's a critical piece of safety equipment designed for the unique challenges of a marine environment.

Why Your Boat Gas Pump Matters

Think of your boat's fuel system like its circulatory system. The engine is the muscle, and the gas pump is the heart, tirelessly pumping the fuel—the lifeblood—that keeps everything going. If that heart fails, it's not just a stalled engine. It means you're stranded, potentially miles from the nearest shore. That's why getting to know your fuel pump is a cornerstone of responsible boat ownership.

Unlike a car, your boat is always on the move, surrounded by water and often corrosive salt spray. A standard automotive fuel pump just isn't built for that kind of punishment. But the real danger isn't just about durability. It's about the enclosed spaces in a boat's engine compartment, where gasoline fumes can build up and become a serious hazard.

The Critical Difference Marine-Grade Makes

So, what’s the big deal about using a "marine-grade" pump? It all comes down to a single spark.

A regular car pump can create a tiny electrical spark during normal operation. Under the hood of your car, with plenty of open air, that's no problem. But inside the tight confines of a boat's hull, that same spark can ignite trapped fuel vapors, leading to a devastating fire or explosion. Marine-grade pumps are ignition-protected, which means they're completely sealed to prevent any internal sparks from ever reaching the outside air.

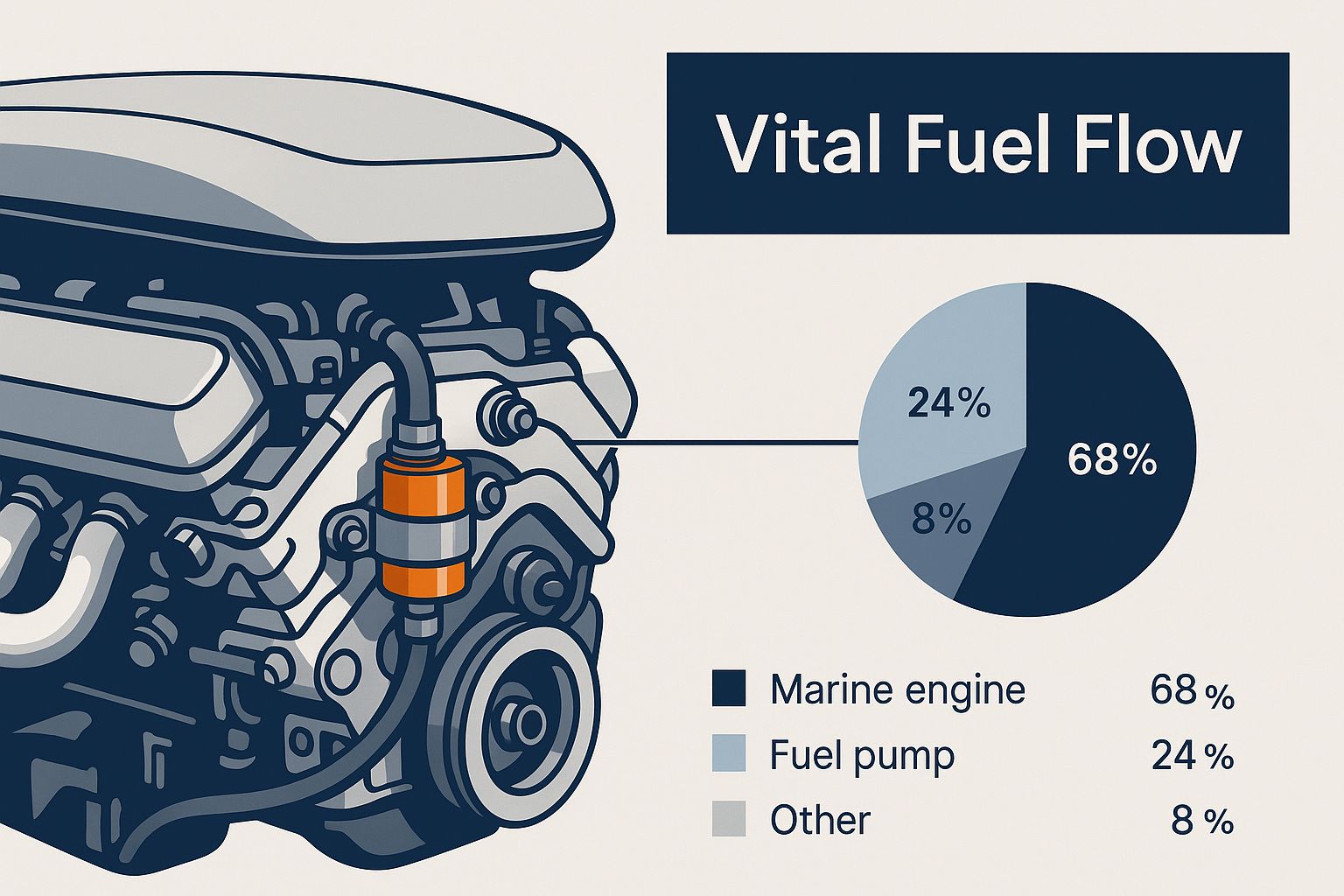

This infographic really drives home why specialized fuel flow is so vital in a marine engine compartment.

As the image shows, these pumps are engineered from the ground up to work safely inside that confined, vapor-prone space. This isn't just a casual recommendation from a mechanic—it’s a fundamental safety requirement.

Choosing a marine-specific gas pump isn't about getting better performance—it's about preventing a disaster. The safety features built into these pumps are non-negotiable for anyone who values their boat and their life.

On top of the ignition protection, marine pumps are also built with materials that stand up to saltwater corrosion. An automotive part would rust and fail in no time, but a proper marine pump is designed for longevity and reliability. When you invest in the right gas pump for your boat, you're buying peace of mind, knowing your vessel has a component truly built for the job.

Mechanical vs. Electric: Which Pump Is Right for You?

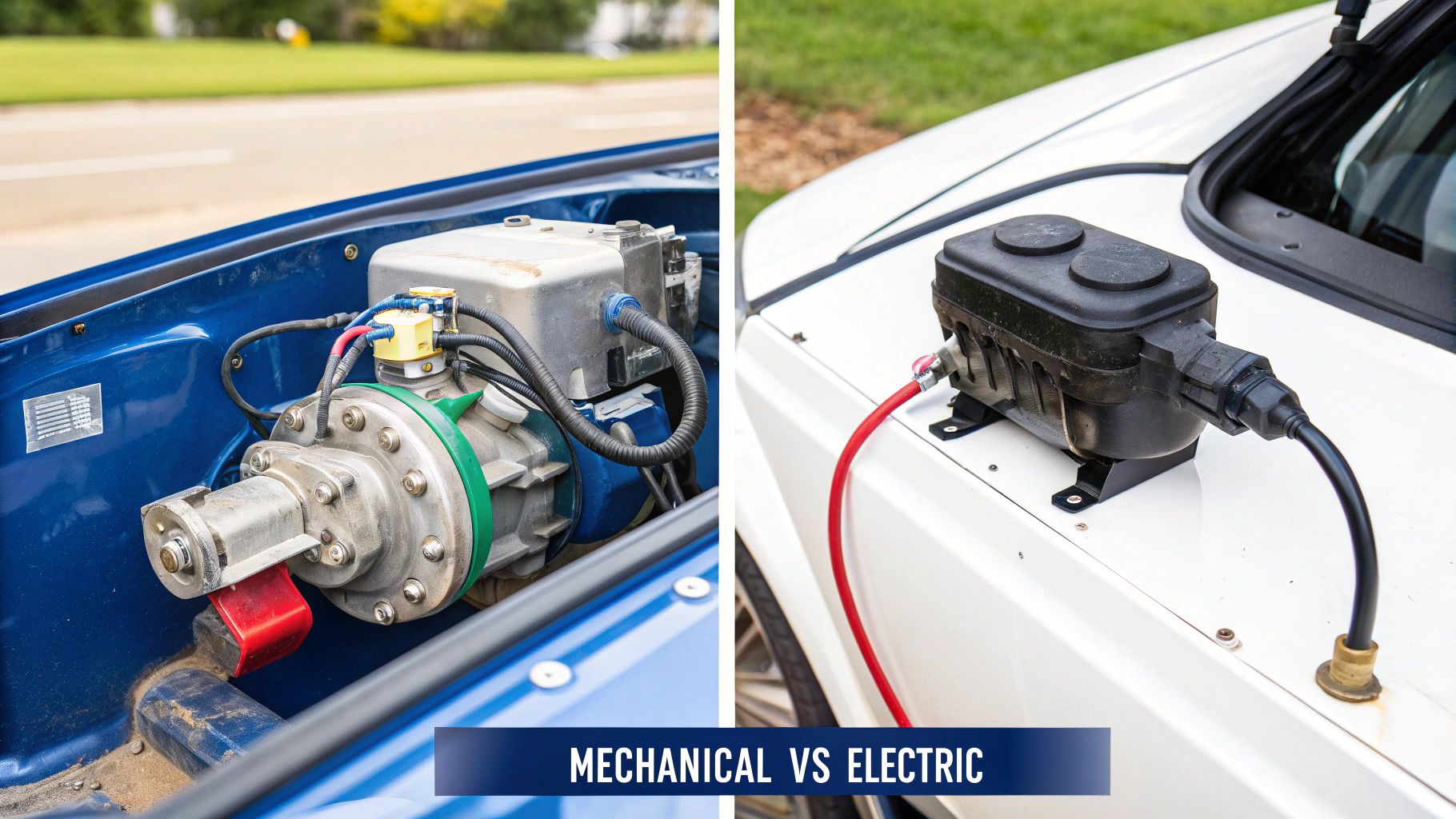

When you're picking a gas pump for your boat, the first major decision you'll face is whether to go with a mechanical or an electric model. It's a fundamental choice that sets the stage for how fuel gets to your engine.

Think of a mechanical pump like an old-school hand-cranked water well. It's driven directly by the engine's rotation, using a lever that moves with the camshaft. Its operation is brilliantly simple and tied completely to the engine itself.

An electric pump, on the other hand, is the modern equivalent. It runs on your boat’s battery, delivering fuel independently of what the engine is doing. This single difference creates a whole cascade of pros and cons that will steer you toward the right choice for your setup.

The Case for Mechanical Pumps

Mechanical fuel pumps are the tried-and-true workhorses of the marine world, and for good reason: they are incredibly reliable. Because they're physically bolted to the engine and run off its motion, there are no wires, fuses, or relays to worry about. Their simplicity is their biggest asset.

The design is about as straightforward as it gets. A diaphragm inside the pump pulls fuel from the tank on one stroke and pushes it to the carburetor on the next. Since its output is linked to the engine's RPM, it naturally delivers just enough fuel at idle and more when you open up the throttle. For most older, carbureted engines, this is all you need.

But that old-school design has its quirks. If your boat sits for a while, the fuel in the carburetor can evaporate. That means you'll be cranking the engine for what feels like an eternity while the mechanical pump slowly pulls fuel all the way from the tank to prime the system again. They also run at a lower, fixed pressure, which simply won't cut it for modern fuel-injected engines that need a steady, high-pressure supply.

The Power of Electric Pumps

This is where electric pumps really shine. They deliver instant and consistent fuel pressure the moment you turn the key, making for much faster and more reliable starts. If you have a modern, fuel-injected engine, this isn't just a nice-to-have; it's a necessity for smooth, efficient performance.

Another huge benefit is where you can mount them. A mechanical pump has to be bolted right onto the engine block. An electric pump, however, can be installed much closer to the fuel tank. This is a big deal because pumps are much better at pushing fuel than pulling it. Placing it near the tank creates a more efficient fuel supply and dramatically reduces the risk of vapor lock—that frustrating issue where fuel turns to vapor in the line on a hot day.

The marine industry is clearly moving toward more advanced fuel systems. The global market for marine fuel pumps is expected to grow from US$1.2 billion in 2025 to US$1.7 billion by 2032, a shift driven largely by these kinds of innovations.

Want to dive deeper into modern fueling technology? Our guide on the top electric fluid transfer pump solutions can show you how these systems ensure your engine gets the fuel it needs, precisely when it needs it.

Making the Right Choice

So, which one is for you? It really boils down to your boat's engine. An older boat with a classic carbureted engine will run happily and reliably with a tough-as-nails mechanical pump.

But for any boat with a fuel-injected engine, or for anyone who just wants faster starts and rock-solid fuel delivery, an electric gas pump for your boat is hands-down the better choice.

To help you see the differences at a glance, here’s a quick comparison.

Mechanical vs Electric Boat Gas Pumps Compared

| Feature | Mechanical Gas Pump | Electric Gas Pump |

|---|---|---|

| Power Source | Engine's camshaft | Boat's electrical system |

| Reliability | Extremely high due to simplicity | High, but reliant on wiring |

| Performance | Pressure varies with engine RPM | Constant, steady pressure |

| Best For | Older, carbureted engines | Modern, fuel-injected engines |

| Priming | Can be slow after storage | Primes system instantly |

| Installation | Restricted to the engine block | Flexible mounting options |

Looking at the two side-by-side makes the decision much clearer. It's all about matching the pump's strengths to your engine's demands.

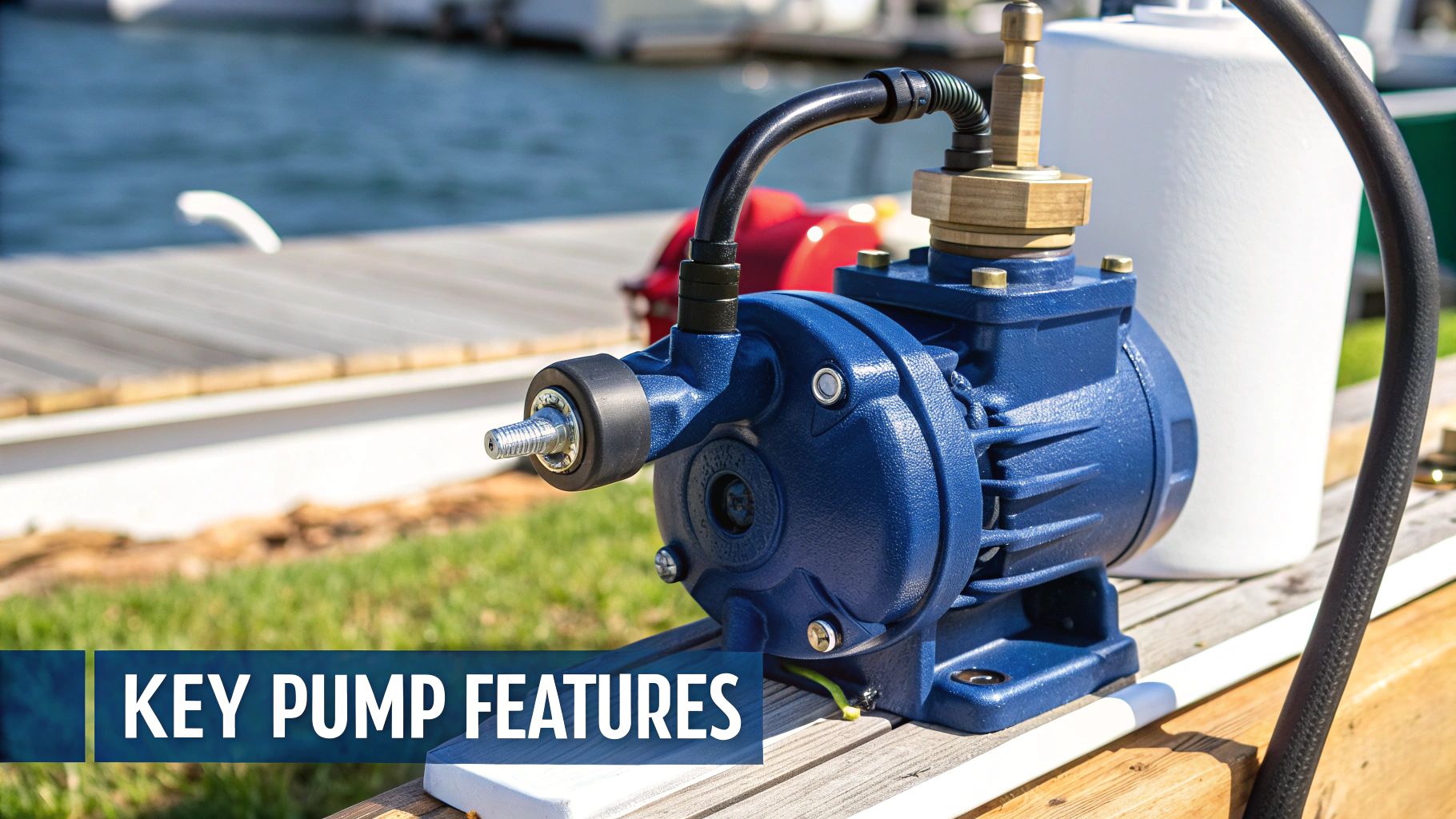

Essential Features of a High-Quality Marine Gas Pump

Deciding between a mechanical or electric pump is really just the starting line. To pick a truly reliable gas pump for your boat, you’ve got to dig a little deeper into the features that promise safety, a long life, and solid performance out on the water. These are the things that separate a pump you can trust from one that’s going to leave you stranded.

Without a doubt, the single most critical feature is ignition protection. Gasoline fumes are sneaky; they're heavier than air and love to settle in low, enclosed spaces like your boat’s engine compartment or bilge. An ordinary automotive pump can create a tiny spark inside itself while it runs. In a car, it's no big deal. In a boat, it’s a recipe for disaster.

Ignition-protected marine pumps are completely sealed. This design guarantees that no electrical spark can ever escape and meet those flammable vapors, preventing a potential fire or explosion. This isn't just a nice-to-have feature; it's a non-negotiable safety standard required by the U.S. Coast Guard for most inboard gas engines.

Decoding Flow Rate and Pressure

Once you've got safety covered, it's all about performance. Think of your fuel pump's output like the water coming out of a garden hose. You need enough volume to water the plants, but also enough pressure to spray it where you need it. Your boat's engine is the same—it has a "sweet spot" for fuel delivery, and it all comes down to two numbers.

-

Flow Rate (GPH): This is all about volume, measured in Gallons Per Hour. The pump needs to move enough fuel to keep the engine happy, even when you're pushing the throttle all the way forward.

-

Pressure (PSI): This is the force behind the fuel, measured in Pounds per Square Inch. An old-school carbureted engine sips fuel at a low, steady pressure, usually around 4-7 PSI. A modern fuel-injected engine, on the other hand, needs a much higher and more consistent pressure to work right.

Getting these numbers right is crucial. A pump that's too weak will starve the engine, making it sputter and die just when you need the power. Go the other way with a pump that's too strong, and you can overwhelm a carburetor, flooding the engine and creating a dangerously rich, fuel-wasting mix. Always, always check your engine’s service manual for the exact GPH and PSI it was designed for.

Investing in a pump that meets your engine’s precise fuel demands is like giving a high-performance athlete the exact nutrition they need to excel. Mismatching these specs is a recipe for poor performance and potential engine damage.

Built to Survive the Marine Environment

A boat lives in a tough neighborhood, especially if you're in saltwater. The environment is constantly trying to destroy everything with moisture, vibration, and corrosion. A proper marine gas pump has to be built from the ground up to fight back.

Here’s what to look for in a pump that's truly built for the water:

- Corrosion-Resistant Housings: Look for pumps with coated metal or tough composite housings. These are your first line of defense against rust and the decay that comes from constant salt spray.

- Sealed Electrical Connections: Watertight connectors and sealed wiring aren't optional. They're essential for preventing electrical shorts and other moisture-related failures that can shut you down.

- Ethanol-Compatible Components: The gas you buy today is loaded with ethanol, which is notorious for eating away at certain types of rubber and plastic. Make sure your pump's internal seals and diaphragms are certified to handle E10 or even E15 fuel without falling apart.

One last thing to check for is anti-siphon protection. This is a simple but vital safety valve that stops fuel from draining out of your tank into the bilge if a fuel line ever breaks below the tank's level. It’s another one of those small details that defines a true, marine-grade gas pump for a boat.

Proper Installation and Safety Checks

https://www.youtube.com/embed/jgeE9aQni-k

When it comes to installing a gas pump for a boat, this isn't a job you want to rush. Getting it right is about more than just performance—it's about safety. A small mistake can quickly turn into a dangerous fuel leak or an electrical short.

That's why we always suggest getting a certified marine mechanic to handle the installation. Still, knowing the proper steps helps you understand what they're doing and ensures the job meets the highest standards.

Getting Started: The Prep Work

Before a single wrench is turned, the boat needs to be prepped. The absolute first step is to kill all power. That means turning off the main battery switch and disconnecting the batteries entirely. This simple action prevents stray sparks, which are a massive risk when fuel vapors might be lingering.

Next, you need to get the air moving. Open up every hatch and get some fans running to ventilate the entire area, especially the bilge and engine compartment. Gasoline fumes are heavier than air and can settle in low spots, so clearing them out is non-negotiable for a safe workspace.

Key Installation Steps and Considerations

For an electric pump, the wiring is the most critical part. Every connection has to be completely secure and waterproof, and the wires must be carefully routed away from any hot parts of the engine. This means using marine-grade insulated connectors and hooking the pump up to its own circuit with a dedicated fuse. This prevents shorts that could kill your pump or, far worse, start a fire.

If you're dealing with a mechanical pump, it's all about the physical fit. The pump's actuator arm needs to line up perfectly with the engine’s camshaft. If it's even slightly off, the pump won't just fail early; it'll also deliver fuel inconsistently, leaving your engine sputtering when you need it most.

No matter which type of pump you have, you have to go back and double-check every single connection. Make sure all hose clamps are marine-grade stainless steel and are tightened down properly to prevent any leaks. For a closer look at getting this right, our guide on marine fuel line installation and care has some great tips for creating a truly leak-proof fuel system.

As marine engines get more complex, the need for perfect installation becomes even more critical. This is a big deal in the global marine engine market, which hit a value of $13.31 billion in 2024 and is expected to climb to $17.46 billion by 2032. You can read more about this trend from Fortune Business Insights. With more advanced engines, the fuel systems have to be flawless to keep everything running safely.

The Final Safety Sweep

Once the pump is in, you're not done yet. A final, thorough safety check is crucial before you even think about starting the engine. This last look-over ensures your fuel system is sealed tight and ready to go.

Safety First Checklist

- Power Off: Make sure the batteries are still disconnected before you start.

- Ventilate: Get the air clear in the engine bay and bilge.

- Check Fittings: Put a wrench on every clamp and fitting one last time to confirm they're tight.

- Sniff Test: After reconnecting the power and priming the system, use your nose. Do you smell any gasoline?

- Inspect for Leaks: Get a flashlight and visually inspect every connection for even the smallest drip or wet spot.

- Run and Re-Check: Start the engine for just a moment, then shut it down and immediately inspect everything again.

Following these steps ensures your new gas pump for a boat will do its job safely and reliably, giving you one less thing to worry about when you're out on the water.

Keeping Your Gas Pump in Top Shape

Your gas pump for a boat isn’t something you can just install and ignore. Think of it like the engine it feeds—it needs regular care to keep you safe and avoid leaving you stranded. A little proactive maintenance is your best defense against fuel system headaches.

The good news is, this doesn't mean a massive overhaul every weekend. It's really about building a few simple checks into your regular boating routine. This small time investment will head off the most common pump problems and make this critical part last a whole lot longer. A few minutes of care at the dock can save you a world of trouble out on the water.

Your Routine Maintenance Checklist

Treat this as a quick health checkup for your fuel system. Running through these steps before you head out or after you tie up will help you catch small issues before they become trip-ending failures.

- Inspect All Fuel Lines: Get your eyes on every inch of the fuel lines connected to your pump. You're looking for any signs of wear and tear—cracks, brittle sections, or spots that feel unusually soft. These are all red flags that a line is deteriorating and could spring a leak.

- Check for Leaks: The smell of raw gas is an unmistakable sign of a leak that needs your immediate attention. When the system is pressurized, you can also carefully check all the fittings and connection points.

- Ensure Tight Connections: Boats vibrate. A lot. That constant shaking can slowly work fittings and clamps loose. Give them all a gentle check to make sure everything is still snug and secure.

This whole process only takes a few minutes, but it’s one of the most powerful things you can do to keep your entire fuel system in good working order.

The Critical Role of the Fuel Filter

If there's one maintenance task you absolutely cannot skip, it's changing the fuel filter. The filter is basically a bodyguard for your pump, blocking all the gunk—dirt, water, and debris—from getting inside and wrecking the delicate internal components. When a filter gets clogged, the pump has to strain to force fuel through, which leads to overheating and, eventually, a dead pump.

A dirty, clogged fuel filter is one of the top reasons electric fuel pumps fail. It starves the pump of fuel, causing it to overheat and burn out. It's an expensive problem that's completely avoidable.

Make sure you stick to a replacement schedule. A solid rule of thumb is to swap out your fuel filter at least once a season or every 100 hours of engine time, whichever comes first. For a deeper dive, you can learn more about picking and caring for your marine fuel filter to ensure your engine gets nothing but clean fuel.

Listening for Trouble Signs

Your ears can be one of your best diagnostic tools. Your pump will often give you an audible warning when it's starting to struggle. A healthy electric pump should make a soft, steady hum when you first turn the key.

If that hum turns into a loud, high-pitched whine, that's the pump's way of screaming for help. It's a classic sign that the pump is either straining against a blockage or starting to fail internally. Paying attention to these sounds and acting on them early can be the difference between a simple fix and a total breakdown on the water.

Answering Your Questions About Boat Gas Pumps

When it comes to your boat's fuel system, you're bound to have questions. Getting the right answers is the key to staying safe on the water and making smart choices for your vessel. Let's walk through some of the most common questions boat owners have about their gas pumps.

It’s a bigger topic than you might think. The marine pump market, which includes these crucial fuel pumps, is a massive industry. It's on track to be worth around $5.86 billion in 2025 and is projected to climb to $8.43 billion by 2032. You can check out more details on this growth over at Metastat Insight. This just goes to show how vital quality parts are in modern boating.

Can I Use a Car Fuel Pump on My Boat?

Let me be crystal clear: absolutely not. This is one of the most important safety rules in all of boating. Putting a car fuel pump in a boat is incredibly dangerous and is something you should never, ever do.

The reason comes down to a single, critical difference: car pumps are not ignition-protected. During normal operation, they can create tiny internal sparks. In a car, this isn't an issue. But in the enclosed, unventilated space of a boat's engine compartment, those sparks can easily ignite trapped fuel vapors, leading to a devastating fire or explosion.

Beyond the fire risk, marine-grade pumps are also built tough with corrosion-resistant materials to handle the constant assault of moisture and saltwater. A standard automotive pump would rust and fail in no time, leaving you dead in the water.

How Do I Know if My Boat Gas Pump Is Failing?

Thankfully, a fuel pump rarely just quits without giving you some warning signs first. Your boat is pretty good at telling you when something is wrong with its fuel delivery.

Keep an ear and eye out for these classic symptoms:

- Engine Sputtering: You might notice the engine hesitating or feeling weak, especially when you hit the throttle to get on plane.

- Trouble Starting: A dying pump often struggles to build enough pressure to get the engine fired up easily.

- A Loud Whining Noise: This is the big one. A high-pitched, whining, or buzzing sound coming from the pump is a tell-tale sign that it's working way too hard, likely due to a clog or internal wear.

If you experience any of these, get your fuel system checked out by a professional right away. Don't wait.

Ignoring the early warning signs of a failing fuel pump is a gamble you don't want to take. A pump that's whining at the dock is one that's likely to die completely when you're miles from shore.

What Flow Rate (GPH) Does My Engine Need?

Getting the right flow rate, measured in Gallons Per Hour (GPH), is non-negotiable for your engine’s performance and long-term health. There’s no universal number here; it all depends on your engine’s horsepower and specific design. A little outboard has completely different fuel demands than a big inboard V8.

The most reliable source for this information is always your engine’s service manual. That manual will list the exact GPH and pressure (PSI) requirements straight from the manufacturer. When you buy a new gas pump for your boat, make sure it meets or slightly exceeds those specifications. This ensures your engine never gets starved for fuel, especially when it’s working its hardest.

Spills and overfills aren't just messy—they're a hazard to your boat and the environment. CLiX Fueling Solutions offers a simple, effective way to prevent them. Our innovative system automatically shuts off the fuel flow when your tank is full, ensuring a perfect fill every time. Protect your investment and the waterways you love. Discover a safer way to fuel your boat at CLiX Fueling.