A fuel water separator filter is a device that does exactly what its name says: it separates water and other junk from your fuel before it ever gets to your engine. Think of it as the first and most important line of defense for your engine's fuel system. It’s a simple component, but it prevents some of the most expensive and frustrating problems a boat owner can face.

The Bodyguard for Your Engine

Imagine trying to run a marathon after chugging a glass of sandy, murky water. It wouldn’t go well, right? Your body would protest, and your performance would tank. It's the exact same story with your engine when it gets a gulp of contaminated fuel.

Water is particularly nasty for an engine, especially the high-tech, high-pressure fuel systems in modern machines. A fuel water separator filter has one primary job: to protect those sensitive and costly components from water and solid gunk.

Water contamination in fuel is pretty much unavoidable. It creeps into fuel tanks from condensation, especially with the day-to-night temperature swings in a marine environment. That water leads to rust, corrosion, and can absolutely destroy high-precision fuel injectors.

This isn't just a basic mesh screen; it's a clever multi-stage system. It works using a simple law of physics: water is heavier than fuel. The filter is designed to make this separation happen much more effectively. Most modern filters work on the principles of coalescing filtration, a process that encourages tiny, suspended water droplets to merge—or coalesce—into larger, heavier drops. Once they're big enough, gravity takes over and they fall out of the fuel to be collected.

Core Functions and Benefits

The role of a fuel water separator filter is more than just straining out dirt. It’s an active defense system with a few critical responsibilities.

To break it down, here’s a quick look at what these filters do and why it matters.

Core Functions of a Fuel Water Separator Filter

| Core Function | Primary Benefit | Why It's Critical |

|---|---|---|

| Water Separation | Prevents rust and corrosion inside the fuel system and engine. | Water can destroy fuel injectors and cause a loss of lubrication, leading to catastrophic engine damage. |

| Particulate Filtration | Captures dirt, rust, and other solid particles. | Debris can clog tiny passages in injectors and fuel pumps, starving the engine of fuel and causing poor performance. |

| Improved Reliability | Ensures a steady supply of clean fuel for consistent performance. | A clean fuel supply prevents unexpected engine shutdowns, which is a matter of safety, not just convenience, when you're out on the water. |

Ultimately, this filter isn't just a nice-to-have accessory; it's a must-have for any modern engine. It stands guard between your fuel tank and your engine, ensuring you get the performance and longevity you paid for.

Putting a quality fuel water separator on your boat is one of the smartest, most cost-effective moves you can make for the health of your engine and your own peace of mind.

How These Filters Protect Your Engine from Damage

Ever shaken up a bottle of oil and vinegar dressing? No matter how much you shake it, the two liquids always find a way to separate again, with the heavier vinegar sinking to the bottom. A fuel water separator works on that same basic principle of density, but it's a whole lot more sophisticated.

It’s not just a simple strainer. This device is engineered to actively force water and fuel apart through a clever, multi-stage process. It’s designed specifically to exploit the physical differences between the two liquids, making sure only pure, clean fuel makes it to your engine.

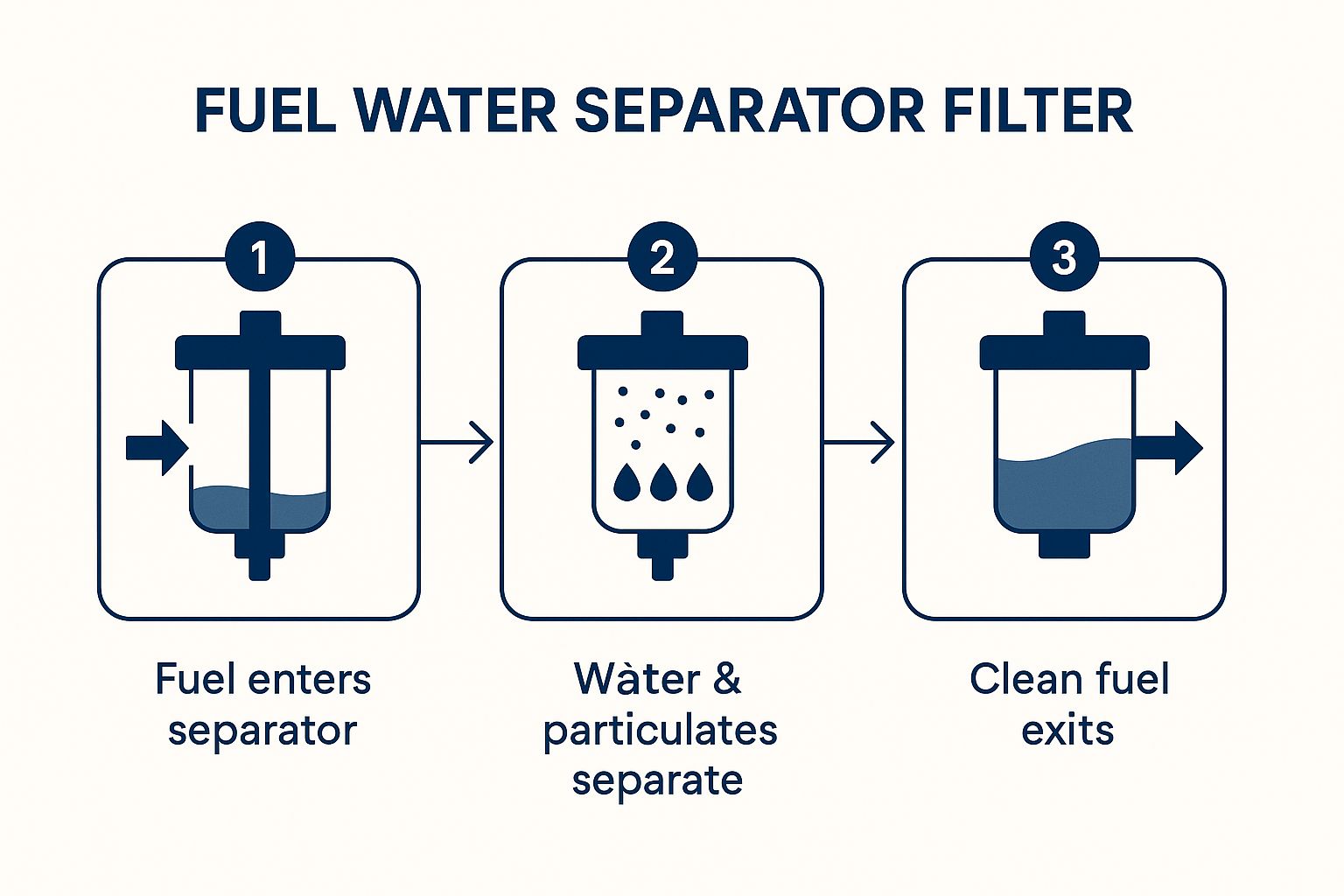

The diagram below gives you a great visual of how this all comes together, turning contaminated fuel into the clean stuff your engine needs.

As you can see, the filter uses physical forces to methodically isolate and remove junk before it can ever cause damage.

The Separation Stage

The first step is all about getting the big stuff out. When fuel enters the filter, it’s often sent into a spin. This centrifugal motion slings the heavier things—water droplets and solid gunk like rust or dirt—outward and down.

Just like our salad dressing, gravity does the heavy lifting. The water, being denser than the fuel, settles into a clear collection bowl at the bottom. This first stage knocks out the biggest water problems, but the job isn't done yet.

The Coalescing Stage

Next up is the coalescing stage. This is where the filter gets smart, tackling the tiny, emulsified water droplets that are still mixed in with the fuel. They're too small and light to separate on their own.

So, the fuel is pushed through a special filter media, which is usually made from treated, pleated paper or synthetic materials. This media is pretty clever; it’s designed to do two things:

- It lets fuel pass right through but attracts water.

- It forces those tiny water droplets to run into each other and merge—or coalesce—into much larger, heavier drops.

Once these newly formed drops get big enough, they can no longer stay suspended in the fuel. They fall out and drain down into the collection bowl with the rest of the separated water.

The Final Filtration Stage

Finally, for the last step, the fuel passes through one last fine-micron filter element right before it exits. Think of this as the final security checkpoint. It's there to catch any stray water and the absolute smallest solid particles that might have gotten through the first two stages.

This multi-stage approach is the secret to why these filters are so effective. It’s not just a single screen; it's a complete system using physics and specialized materials to progressively clean your fuel. This robust process is what saves you from clogged injectors, corroded fuel lines, and even catastrophic engine failure.

Of course, every boat and engine has slightly different needs. To get the full picture, you can learn more about the complete marine fuel filter system. Understanding how all the parts work together is the best way to ensure your engine only ever sees the clean, water-free fuel it needs to run reliably.

The Critical Role of Filtration in Modern Engines

Today's high-pressure common-rail diesel engines are incredible pieces of machinery. They squeeze out more power, deliver better fuel economy, and produce fewer emissions than ever thought possible. But there’s a catch to all that precision—they are extremely sensitive to the quality of fuel you feed them. The days of old-school diesels that could seemingly run on anything are long gone.

Modern engines are built with incredibly tight tolerances, often measured in microns. To put that in perspective, a single human hair is about 70 microns thick. The clearances inside a modern fuel injector? They can be as tight as 2-5 microns. It’s easy to see how even the smallest piece of dirt or a single drop of water can cause major wear, leading to poor performance, higher fuel burn, and eventually, eye-watering repair bills.

This is exactly why a high-quality fuel water separator filter isn't just a nice-to-have accessory anymore. It's an absolutely essential part of any modern fuel system. Clean, dry fuel is the lifeblood of your engine's performance and reliability.

Meeting Modern Demands

The constant push for better efficiency and stricter environmental rules has completely changed engine design. To meet today's standards, engines need to burn fuel as completely as possible. The only way to do that is by injecting fuel at mind-bogglingly high pressures, sometimes topping 30,000 PSI.

At those pressures, water in the fuel line doesn't just cause a bit of rust. It can instantly flash into steam, creating a tiny explosion that can shatter the delicate tips of your fuel injectors.

This heightened sensitivity is the driving force behind the booming market for advanced filtration. In 2022, the global fuel water separator filter market was valued at around USD 1.2 billion. It's projected to climb to roughly USD 1.8 billion by 2030, a clear sign of just how vital clean fuel is to industries like shipping and transportation. You can discover more about the growing market demand on Web Wizards Market.

Investing in a quality separator isn't just about preventing repairs. It's about maximizing engine performance, reducing your environmental impact, and ensuring the absolute reliability of your vessel.

More Than Just a Filter

It helps to think of your fuel water separator as more than just a screen. It's a complete fuel conditioning system, actively protecting your engine every hour it runs. A good filter working properly delivers a few key benefits that go far beyond just catching dirt:

- Peak Engine Performance: When your engine gets nothing but pure, clean fuel, it can run exactly as the engineers designed it to. That means you get the power and responsiveness you paid for.

- Improved Fuel Efficiency: Contaminated fuel doesn’t burn cleanly, which is just wasted energy. Clean fuel means a more complete burn, stretching every gallon further.

- Reduced Emissions: A complete burn doesn’t just save you money on fuel; it also means fewer harmful emissions. This helps you stay compliant with environmental regulations and shrinks your carbon footprint.

- Enhanced Reliability: For anyone who spends time on the water, engine failure is a serious safety risk, not just a hassle. A top-notch filtration system is your single best defense against being left stranded.

How to Choose the Right Fuel Water Separator Filter

Picking the right fuel water separator filter for your boat can seem like a daunting task, but it really just comes down to matching the filter to your engine's needs. Think of it like buying shoes—you wouldn’t wear running sneakers to a formal wedding. The wrong fit can cause all sorts of problems, from poor performance to leaving your engine completely vulnerable.

To get it right, you just need to nail three key factors: the filter's flow rate, its micron rating, and the materials it's made from. Get these right, and you’ll ensure your engine gets the clean, dry fuel it craves for a long, reliable life on the water.

Match the Flow Rate to Your Engine

The flow rate is probably the most important spec to look at. Measured in gallons per hour (GPH), it tells you how much fuel the filter can handle without becoming a bottleneck. It’s absolutely critical that your filter’s GPH rating is higher than your engine's maximum fuel burn.

If the filter’s flow rate is too low, you'll essentially be starving your engine for fuel, especially when you're pushing the throttle or under a heavy load. This restriction forces the fuel pump to work overtime and can lead to a frustrating loss of power right when you need it most.

As a simple rule of thumb, look for a filter with a flow rate that's at least double your engine's maximum fuel consumption. This gives you a nice safety margin, ensuring smooth fuel delivery even as the filter starts to get dirty.

For instance, if your engine tops out at 30 GPH, you should be shopping for a filter rated for 60 GPH or more. That extra capacity is your best insurance against fuel flow problems.

Understand the Micron Rating System

The micron rating simply tells you the size of the particles the filter can trap. A lower number means finer filtration. For the best protection, most marine engines rely on a two-stage filtering process.

Here’s how that setup usually looks:

- Primary Filter: This is the fuel water separator we're talking about, located between the fuel tank and the engine. It typically has a rating of 10 or 30 microns. Its main job is to catch the bigger gunk and separate out the water.

- Secondary Filter: This is the final line of defense, found on the engine itself. It has a much finer rating, often just 2 microns, to protect the super-sensitive fuel injectors from any tiny particles that got past the primary filter.

So, should you pick a 10-micron or 30-micron primary filter? A 30-micron filter is a great all-around choice because it clogs less quickly. If you want a bit more protection and don't mind changing filters more often, a 10-micron element is a solid option.

Consider Physical Size and Materials

Last but not least, think about where the filter will actually live. Before you buy, make sure you have a spot in your engine compartment or bilge where it will fit. You'll need enough room around it to easily drain the collection bowl and swap out the filter element. If it's a pain to get to, chances are it won't get maintained.

The material of the bowl is another important consideration:

- Clear Plastic Bowls: These are fantastic because you can see at a glance if there's water or junk in there. It makes your pre-trip checks super easy. However, due to fire safety rules, they generally can't be used in inboard engine compartments.

- Metal Bowls: These are much tougher and are the required choice for the high-heat environment of an inboard engine bay. Many come with a port for a water sensor, which can trigger an alarm at your helm to let you know it's time to drain the bowl.

Getting your filter selection and installation right is a huge part of maintaining a happy engine. To see how this piece fits into the bigger picture, you can check out this guide on the entire boat fuel system.

Getting Installation and Maintenance Right

Let's be honest: a top-of-the-line fuel water separator filter is worthless if it's installed poorly or completely ignored. The best filter in the world can't protect your engine if it's set up to fail. The good news? Turning installation and maintenance into a simple, repeatable habit is the key to getting maximum protection and total peace of mind on the water.

First things first, location is everything. You've got to mount the filter somewhere you can actually get to it easily. If you have to become a contortionist just to glance at the collection bowl, you’re probably not going to check it as often as you should. Make sure you leave enough space below the filter to drain the bowl and enough room above to spin the old canister off when it’s time for a change.

Your Installation Checklist

Getting the setup right from day one saves you from a world of future headaches. The biggest enemy here is an air leak, which can sneak into your fuel lines and starve your engine. Follow these steps for a solid, leak-free installation every time.

- Mount it Solidly: Secure the filter assembly to a bulkhead or another sturdy surface. Engine and boat vibrations are relentless and can loosen fittings over time, so make sure it's mounted firmly and won't be rattling around.

- Use the Right Hoses: Always use high-quality, marine-grade fuel hoses. Run them so they don't have any sharp bends or kinks that could choke off fuel flow. Double-check that every hose clamp is snug to prevent air from getting sucked into the fuel system.

- Seal it Right: Use a fuel-resistant thread sealant on all the pipe fittings. This is absolutely critical for creating an airtight seal. Just be sure to apply it only to the male threads and keep it off the first couple of threads to prevent any excess from squeezing into the fuel line.

A classic rookie mistake is overtightening the fittings. It’s tempting to crank down on them, but you can easily crack the filter housing. Snug is good; Herculean strength is bad and can lead to expensive damage and dangerous leaks.

Building a Simple Maintenance Habit

Once your filter is installed, it needs a little bit of regular attention. We're not talking about a major project, but it is a non-negotiable part of keeping your engine healthy. A simple routine makes it easy to stay on top of things. Think of it as a quick, five-minute health check before you head out.

Your entire routine boils down to two main tasks: draining the water and changing the filter element. This simple habit helps you catch contamination issues early before they can escalate into engine-killing problems.

Your Go-To Maintenance Checklist:

- Drain the Bowl Before Every Trip: Make it a habit to peek at the clear collection bowl before you start the engine. Water is heavier than fuel, so it will settle right at the bottom. See any? Just open the drain petcock and let it run until only clean fuel is coming out.

- Replace the Filter Element on Schedule: You should replace the filter element at least once a season or whenever your engine manufacturer says to. A surefire sign of a clogged filter is an engine that starts sputtering or losing power, so it should be the first thing you check.

- Watch for Warning Signs: Keep an eye out for more than just a little water. If you see a lot of it, dark sludge, or a milky "coffee and cream" mixture, you've got a serious contamination problem in your fuel tank that needs to be handled ASAP. On the flip side, a consistently clean bowl is a great sign that your fuel source is solid.

Why Diesel Engines Are So Vulnerable to Water

If you’ve spent any time around boats, you know that diesel engines are the go-to workhorses of the marine world. They’re built for torque and can run for thousands of hours. But they have an Achilles' heel, a specific weakness that gasoline engines don't share in quite the same way: water.

The problem comes down to the very design of the diesel fuel system. Unlike gasoline, diesel fuel isn't just for combustion—it's also a crucial lubricant. It forms a slick, protective film over the incredibly precise, high-pressure parts inside the fuel pump and injectors. When water gets in, it displaces that oily film, leaving sensitive metal components unprotected.

This loss of lubrication is a disaster waiting to happen. You get direct metal-on-metal grinding inside parts that are engineered to microscopic tolerances. This quickly leads to scoring, pitting, and the eventual failure of the fuel pump and injectors—two of the most expensive components on any diesel engine.

The Double Threat of Corrosion and Wear

Water wages a two-front war on your diesel engine. First, you have the obvious enemy: rust. Any water sitting in your fuel tank, lines, or filter housing will start corroding metal surfaces. Those rust particles then get pulled into the fuel system, causing even more damage. Our comprehensive boat fuel tank guide dives deep into how to prevent this from happening at the source.

The second threat, which is often more destructive, is the loss of lubricity we just talked about. Your high-pressure fuel pump and injectors absolutely depend on the natural oiliness of diesel fuel to operate without destroying themselves.

Water is the arch-nemesis of a high-pressure diesel fuel system. It's abrasive, corrosive, and critically, it offers zero lubrication. A single gulp of water-contaminated fuel can cause more wear in a few seconds than thousands of hours of normal operation.

This one-two punch is exactly why there’s such a massive market for dedicated diesel fuel water separator filter systems. In fact, the global market was valued at an estimated USD 1.63 billion in 2024, which shows just how vital this protection is for diesel owners everywhere. You can read the full research about these market trends on Business Research Insights.

At the end of the day, protecting your diesel isn't just about filtering out dirt and grime. It’s about aggressively removing every last drop of water before it can reach your engine. That's why a high-quality fuel water separator isn't just a good idea—it's non-negotiable for keeping your vessel reliable and avoiding a catastrophic, wallet-draining failure.

Frequently Asked Questions About Fuel Water Separators

Even after you get the hang of how a fuel water separator filter works, you're bound to have some real-world questions pop up. Getting straight answers to these common queries will give you the confidence to take great care of your system, making sure it keeps protecting your engine for years to come.

Let's dive into some of the most common questions we hear from boat owners about installing and maintaining their filters.

How Often Should I Drain the Bowl?

The best habit you can build is to check the collection bowl before every single trip. Seriously, it only takes a few seconds and should be as routine as checking your oil. Water is heavier than fuel, so it's easy to spot as a clear or sometimes amber-colored layer settled at the very bottom of the bowl.

How often you’ll actually need to drain it really depends on your local conditions and fuel sources. If you're boating in a humid, salty environment or just filled up from a questionable dockside pump, you might find yourself draining a little water each time. On the other hand, in drier areas with consistently clean fuel, you could go weeks without seeing a drop.

The real secret is consistency. Make checking that bowl a non-negotiable part of your pre-departure routine. This quick visual check is your absolute best early warning sign of a water contamination problem brewing in your fuel tank.

Can I Install a Fuel Water Separator Myself?

Absolutely. For most boaters who are reasonably handy with a wrench, installing a fuel water separator filter is a totally doable weekend project. You'll just need some basic tools like wrenches, a drill to mount the bracket, hose cutters, and some good-quality thread sealant. The most important thing is to get every connection completely tight to prevent any fuel or air leaks.

That said, if the thought of working on your boat's fuel lines makes you nervous, or if your engine room is particularly cramped and complex, hiring a professional marine mechanic is the smart call. They’ll get the job done right, ensuring it’s safe, leak-free, and up to all marine safety standards.

What Is the Difference Between a 10 and 30 Micron Filter?

The micron rating simply tells you the size of the smallest particle the filter can reliably catch. It's a bit like the mesh on a screen door—a smaller number means a tighter weave that stops smaller things from getting through.

- 30-Micron Filters: These are fantastic as primary filters. They do a great job of catching the bigger gunk and separating out water without getting clogged up too fast.

- 10-Micron Filters: These offer a finer level of filtration. They’ll trap much smaller particles, but the trade-off is that they clog more quickly and need to be changed more often.

A very common and effective setup is to use a 30-micron filter as your main, primary separator and then let the engine's own secondary filter (which is often a super-fine 2-micron filter) handle the final polishing. This gives you a great balance between effective filtration and a reasonable service life for your filters.

Spills and contamination are always on a boat owner's mind, but they don't have to ruin your day. For a truly stress-free experience at the fuel dock, trust CLiX Fueling Solutions to automatically prevent dangerous and expensive fuel overfills. See how you can get spill-free fueling every single time by visiting https://clixfueling.com.