Choosing the Perfect Boat Fuel Tank: Materials Matter

Picking the right fuel tank for your boat is a big decision. It affects how your boat performs, how safe it is, and how long it lasts. It's not just about how much fuel you can carry; the material of the tank matters too. The most common materials are aluminum, plastic, and sometimes, custom-built tanks for special needs. Each material has pros and cons that impact everything from the boat's balance to how well it resists corrosion.

Aluminum Boat Fuel Tanks: The Durable Standard

Aluminum tanks are a popular choice. They're strong and fairly light. They also offer great corrosion resistance, especially when coated to protect them from saltwater. This durability makes them a good fit for both inboard and outboard engines. However, aluminum tanks can be pricier than plastic ones.

Plastic Boat Fuel Tanks: Lightweight and Versatile

Plastic fuel tanks, usually made of high-density polyethylene (HDPE), are becoming more common. They're lightweight and affordable. They also resist corrosion and impacts well. These features make them a favorite for smaller boats and portable uses. However, plastic tanks might not be as tough as aluminum for larger vessels or rough conditions.

Custom-Built Boat Fuel Tanks: Tailored to Your Needs

If your boat has a unique design or needs a special type of fuel, a custom-built tank might be the answer. These tanks can be made from different materials, including stainless steel or composite materials, to meet specific needs for performance and fuel capacity. Custom tanks are expensive but can be necessary for the best performance and fit in complex boat designs. You might be interested in: CLiX Fueling Solutions Products.

Comparing Boat Fuel Tank Materials

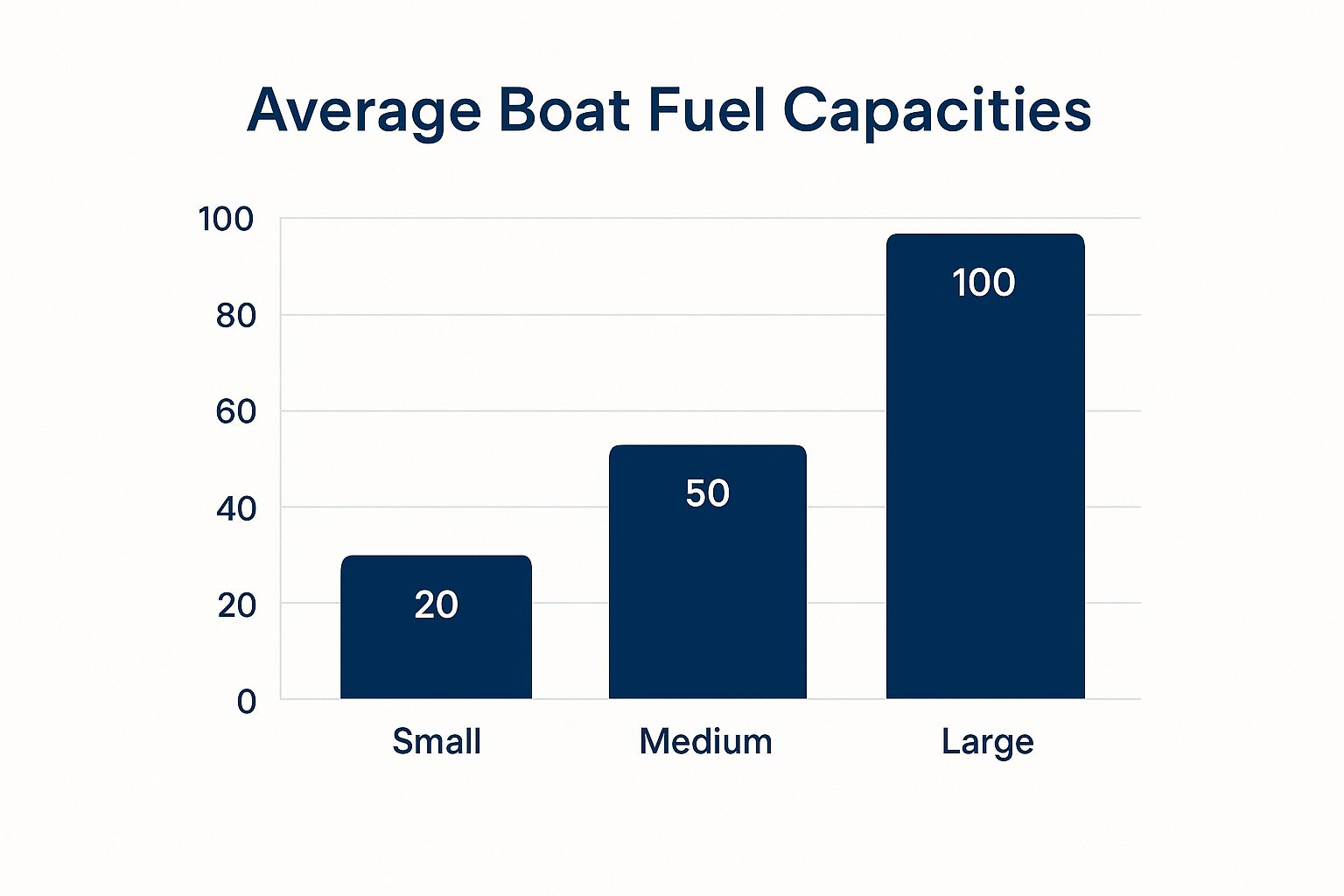

To give you an idea of how much fuel different sized boats hold, check out this infographic:

As you can see, fuel tank size typically goes up with boat size. Small boats average about 20 gallons, medium boats around 50 gallons, and larger boats need about 100 gallons. Picking the right size helps balance how far you can go with the weight and performance of your boat.

For a detailed comparison of materials, see the table below:

To help you choose the best material, the following table summarizes the key characteristics of each fuel tank type:

Comparison of Boat Fuel Tank Materials This table compares the key characteristics of common boat fuel tank materials to help readers select the most appropriate option for their vessel

| Material | Weight | Durability | Corrosion Resistance | Cost | Best For |

|---|---|---|---|---|---|

| Aluminum | Medium | High | Excellent | Medium-High | Inboard/Outboard, Saltwater |

| Plastic (HDPE) | Light | Medium | Excellent | Low-Medium | Smaller boats, Portable Applications |

| Custom-Built | Varies | Varies | Varies | High | Specialized Needs, Unique Vessel Designs |

Key takeaways from the table: Aluminum offers the highest durability, while plastic provides the best value due to its lightweight nature and affordability. Custom-built tanks offer flexibility but come at a higher cost.

Regulations and the increasing demand for efficient and eco-friendly fuel systems are also shaping the boat fuel tank market. Find out more about fuel tank market trends here. This means choosing a tank now also means thinking about how it will work with future fuel technologies and rules. Though focused on cars, some auto repair services offer troubleshooting tips for fuel systems that can also apply to boats. The best fuel tank material ultimately depends on your specific boat, how you use it, and your budget. Thinking about these factors will help you make a smart choice that keeps you safe and maximizes your boat's performance and lifespan on the water.

The Art of Perfect Boat Fuel Tank Installation

A properly installed boat fuel tank is essential for both safety and optimal performance. A faulty installation can create dangerous fuel leaks, lead to frustrating engine problems, and even cause catastrophic failures. This guide provides a clear path to a professional-grade fuel tank installation, whether you're a DIY enthusiast or working with a marine technician.

Positioning and Securing Your Boat Fuel Tank

The placement of your fuel tank greatly affects both your boat's performance and safety. Ideally, position the tank low in the boat to lower the center of gravity, improving overall stability. This lower placement ensures more even weight distribution, minimizing rocking and listing. Secure the tank firmly to prevent unwanted movement, especially in rough waters. A loose tank could be a serious hazard in choppy conditions.

- Center of Gravity: Position the tank low and centrally to optimize weight distribution.

- Secure Mounting: Use strong straps or brackets designed for marine fuel tanks.

- Accessibility: Ensure the tank is easy to access for regular inspection and maintenance.

Ventilation and Fuel Line Connections

Proper ventilation is crucial to prevent dangerous fuel vapor buildup. Install a vent line that leads outside the boat, allowing these vapors to dissipate safely. A blocked vent line can cause pressure buildup, potentially leading to leaks or even explosions. All fuel line connections should be double-clamped to prevent leaks. This added precaution stops a small leak from becoming a big problem.

- Vent Line: Install a vent line leading overboard to prevent vapor accumulation.

- Double Clamps: Use double clamps on all fuel line connections for extra leak protection.

- Fuel Line Material: Use marine-grade fuel line that is resistant to ethanol and other fuel additives.

Grounding and Electrical Considerations

A proper grounding system prevents electrical sparks that could ignite fuel vapors. Connect the tank to the boat's grounding system using a dedicated wire. This is a critical safety measure that can prevent fires or explosions. Any electrical components near the fuel tank should be ignition protected to minimize risk.

- Grounding Wire: Connect your fuel tank to the boat's grounding system with a dedicated wire.

- Ignition Protection: Use ignition-protected components for electrical equipment near the tank.

Installation Checklist and Common Mistakes

The following checklist will help ensure a safe and effective boat fuel tank installation. It details each step, necessary materials, safety considerations, and common mistakes to avoid.

Boat Fuel Tank Installation Checklist: Essential steps and safety considerations for proper boat fuel tank installation.

| Installation Step | Required Materials | Safety Considerations | Common Mistakes |

|---|---|---|---|

| Tank Positioning | Measuring tape, Level | Center of gravity, Accessibility | Improper weight distribution |

| Securing the Tank | Straps, Brackets, Bolts | Secure mounting, Movement prevention | Loose mounting, Inadequate hardware |

| Vent Line Installation | Vent hose, Clamps, Fittings | Vapor dissipation | Blocked vent, Incorrect routing |

| Fuel Line Connections | Fuel hose, Double clamps, Fittings | Leak prevention | Single clamps, Improper connections |

| Grounding | Grounding wire, Connectors | Spark prevention | Missing ground, Inadequate wiring |

By following these guidelines and avoiding common errors, you can achieve a perfect boat fuel tank installation. This careful approach prioritizes safety, efficiency, and long-term reliability, contributing to a more enjoyable and worry-free boating experience.

Maximizing Efficiency: Boat Fuel Tank Optimization Secrets

Proper boat fuel tank installation is only the beginning. Getting the most out of your boat's fuel system hinges on optimization. This involves strategically planning your tank's location and size, using smart monitoring practices, and even adjusting your fuel load depending on the trip.

Strategic Tank Placement and Weight Distribution

Where your fuel tank sits greatly impacts your boat's performance. It's not just about finding space; it's about the optimal location for weight distribution. Imagine a seesaw: uneven weight makes it unstable. Positioning the tank low and centrally lowers the center of gravity. This makes for a smoother, more stable ride, especially in rough seas. Naval architects often fine-tune this balance, ensuring the tank complements the boat's design and intended use.

Fuel Monitoring Technologies and Consumption Reduction

Technology is essential for fuel tank optimization. Advanced fuel monitoring systems, some using AI and IoT sensors, give real-time data on fuel levels, consumption, and even leaks. This lets boaters make smart decisions about fuel use and find ways to improve. Some systems analyze data to suggest the best cruising speeds for fuel efficiency. These advancements are significantly cutting fuel consumption, saving boaters money and reducing environmental impact. The marine fuel optimization market is growing quickly. Valued at $12.01 billion in 2024, it's projected to reach $23.37 billion by 2029, driven by sustainable practices and technological progress. See more detailed statistics here.

Calculating Optimal Fuel Load for Different Journeys

Extra fuel adds unnecessary weight, hurting performance and using more fuel. Calculating the optimal fuel load for each trip is crucial for efficiency. Consider distance, planned speed, weather, and required reserves. You'll use less fuel by carrying only what you need. Online calculators or experienced boaters can help determine the right amount for your trip.

Innovative Tank Configurations and Range Extension

Boat designers continually develop new tank designs to increase range without sacrificing safety. Saddle tanks, molded to the hull, and bladder tanks, fitted into awkward spaces, increase fuel capacity without affecting performance or stability. These designs allow boats to travel farther on one tank, opening up possibilities for longer journeys.

Efficiency Modifications from Experienced Captains

Many experienced captains modify their fuel systems for better efficiency. These range from simple changes, like regularly cleaning fuel filters and using fuel additives, to more involved upgrades, like installing fuel polishing systems. Some captains have seen substantial savings just by changing to a better propeller. These real-world results show that ongoing fuel system maintenance and optimization can create measurable improvements. This proactive approach helps boaters minimize their environmental impact while enjoying their time on the water.

Essential Boat Fuel Tank Maintenance: Beyond the Basics

Maintaining your boat's fuel tank isn't just about filling it up. Proper maintenance transforms your fuel system from a potential hazard into a reliable asset, ensuring smooth sailing and preventing costly repairs. This involves understanding warning signs, effective cleaning methods, and seasonal procedures.

Recognizing the Warning Signs of Fuel Tank Issues

Just like a car, your boat’s fuel system provides clues when something’s amiss. Decreased engine performance, sputtering, or difficulty starting are often the first indicators of a problem. A strong fuel smell in the bilge or around the tank is a major red flag, potentially signaling a leak. Changes in fuel efficiency can also indicate fuel tank issues. Ignoring these early warnings could lead to more extensive and expensive damage.

Effective Cleaning Techniques for Different Tank Materials

Cleaning your boat fuel tank is crucial for preventing contamination and maintaining performance. Your cleaning method should depend on the tank material. For aluminum tanks, specialized cleaning solutions are designed to remove sludge and debris without corrosion. Plastic tanks can often be cleaned with milder detergents. Thoroughly rinse the tank after cleaning to remove all cleaning agent residue. This ensures pure fuel and prevents chemical reactions that could impact your engine. For stubborn deposits or biological growth, professional cleaning might be needed.

Seasonal Maintenance for Your Boat Fuel Tank

Seasonal maintenance protects your tank during inactivity. Before winter storage, add a fuel stabilizer to prevent fuel degradation and the formation of gums and varnishes that can clog fuel lines and injectors. Learn more in this article about CLiX Fueling Solutions blog posts. Filling the tank almost completely minimizes condensation, which can cause water contamination and microorganism growth. These measures ensure your fuel system is ready for the next boating season.

Professional-Grade Inspection and Contamination Prevention

Regular inspections can prevent costly repairs. A professional inspection goes beyond a visual check, examining the tank for corrosion, leaks, and contamination. Professionals use specialized tools to check for water and sediment in the fuel, which can significantly impact engine performance. Early detection of these issues can save you money and keep your boat in top condition.

Removing Water and Biological Growth

Water and biological growth are common problems, especially in humid environments. Water can enter the tank through condensation or leaks, while microorganisms (often called "diesel bug") thrive in water. To remove water, use a fuel water separator or a specialized fuel additive. A biocide treatment can eliminate biological growth, but severe infestations might require professional cleaning. This proactive approach safeguards your tank and maintains fuel quality.

Extending Fuel Quality During Storage

Protecting your fuel during storage prevents engine problems. Fuel stabilizers prevent fuel degradation and the formation of varnish and gum, extending the storage life of your fuel and protecting your engine from harmful deposits. Storing your boat with a full tank minimizes condensation and water contamination. This strategy, combined with regular maintenance, keeps your fuel system in peak condition.

Navigating the Regulatory Maze: Boat Fuel Tank Compliance

Staying compliant with boat fuel tank regulations is crucial for several reasons. It's not just about avoiding fines; it's about the safety of your vessel and everyone on board. Properly maintained fuel systems reduce the risk of leaks, fires, and other hazards. Compliance also protects your investment and can even impact resale value down the line. This section helps decode the complex world of regulations impacting your boat's fuel system, from U.S. regulations to international standards.

Understanding the Key Regulatory Bodies

Several organizations set standards for boat fuel tanks. In the United States, the U.S. Coast Guard plays a significant role, particularly for commercial vessels. The American Boat and Yacht Council (ABYC) sets voluntary standards widely adopted across the industry, focusing on safety and best practices. ABYC standards are a valuable resource for boat owners. Internationally, the International Maritime Organization (IMO) influences regulations globally, particularly concerning environmental impact and fuel quality. The IMO works to improve maritime safety and prevent pollution from ships.

Regulations Specific to Your Vessel Type

Regulations can vary significantly based on the size and type of your boat. Recreational boats have different requirements than commercial vessels. For example, requirements for fuel tank capacity, material, and ventilation will differ between a small fishing boat and a large passenger ferry. Understanding these nuances is crucial for ensuring you meet the correct standards.

Impact of Recent Regulatory Changes

Regulatory changes frequently occur, often driven by advancements in technology and a growing focus on environmental protection. Much like how preventative auto repair helps avoid car trouble, staying on top of these changes helps you avoid issues with your boat. Recent changes may affect both new boat fuel tank installations and existing systems. For example, stricter standards on emissions control or fuel types might necessitate upgrades or modifications to your boat’s fuel tank. Staying informed about these changes helps avoid costly retrofits and ensures your boat remains compliant.

Certification and Insurance Implications

Certain certifications, like those from the ABYC, can positively impact your insurance premiums. Insurance companies often view certified systems as less risky, potentially leading to lower rates. Demonstrating compliance with regulations can also significantly boost your boat’s resale value. Prospective buyers often prioritize vessels with well-maintained and compliant systems, providing assurance of safety and future reliability. You can find more information on fuel systems here.

Common Oversights and How to Address Them

Even experienced boaters can sometimes overlook important regulatory details. One common oversight is inadequate venting, which can lead to a dangerous buildup of fuel vapors. Another frequently missed area is proper grounding, essential for preventing electrical sparks and potential fires. Addressing these issues is often straightforward, involving simple modifications or upgrades to your fuel system.

The global marine fuel market, which includes fuel for boats, was valued at $148.739 billion in 2019. It’s projected to reach about $156.426 billion by 2025, at a CAGR of 0.84%. Growth in worldwide seaborne trade, which accounts for about 90% of global trade, drives this market. Regulations, such as the IMO 2020 sulfur cap requiring cleaner fuels, influence the market and the need for modern boat fuel tanks. More information on the marine fuel market can be found here.

Documentation and Inspections

Maintaining proper documentation of your boat fuel tank system is vital for demonstrating compliance during inspections. Keep records of installations, maintenance, and any modifications made to the system. This organized documentation streamlines the inspection process and provides valuable proof of your adherence to regulations. By understanding the regulations, staying informed about changes, and addressing potential issues proactively, you ensure safety, protect your investment, and contribute to responsible boating practices.

Troubleshooting Boat Fuel Tank Issues Like a Pro

A well-maintained boat fuel tank is essential for a smooth and safe boating experience. However, problems can occur, and knowing how to troubleshoot them can save your engine and your day out on the water. This section explores common fuel system issues, provides diagnostic tips, and offers solutions for both minor and major problems.

Recognizing the Signs of Trouble

Identifying a fuel tank issue early can prevent it from becoming a major headache. Decreased engine performance, such as sputtering or difficulty starting, is a common early warning sign. A strong fuel odor in the bilge or near the tank indicates a potential leak and demands immediate attention. Sudden changes in fuel efficiency can also suggest a problem within the fuel system. Finally, if your boat's engine stalls frequently or struggles to maintain consistent power, the fuel tank could be the root cause.

Diagnosing Common Boat Fuel Tank Problems

Once you've noticed a potential issue, it's time to pinpoint the specific problem.

- Fuel Contamination: Water or debris in the tank can clog fuel lines and injectors. This often leads to engine sputtering or difficulty starting.

- Fuel Leaks: Leaks can develop in the tank itself, the fuel lines, or connections. Inspect for visible fuel, stains, or a strong fuel odor.

- Vent Blockage: A blocked vent prevents air from entering the tank, creating a vacuum that restricts fuel flow. This can cause engine stalling or reduced power.

- Fuel Pump Failure: A failing fuel pump has difficulty delivering fuel to the engine, resulting in poor performance and starting problems.

- Clogged Fuel Filters: Dirty fuel filters restrict fuel flow and mimic symptoms of vent blockage or pump failure.

Troubleshooting Techniques and Solutions

Effective troubleshooting involves a systematic method for identifying and resolving the problem's source.

- Contamination: Drain a small fuel sample from the tank and check for water or sediment. If found, the tank needs to be drained and cleaned. A fuel water separator can prevent future contamination.

- Leaks: Carefully inspect the tank, fuel lines, and connections for visible leaks. A pressure test can identify leaks in hard-to-reach areas. Repair or replace damaged components as needed.

- Vent Blockage: Check the vent line for kinks, blockages, or obstructions. Clear the vent line to allow proper airflow.

- Fuel Pump Problems: Listen for the pump's operation when the engine is started. If the pump is silent or sounds weak, test its pressure and replace it if necessary.

- Clogged Filters: Regularly inspect and replace fuel filters. Keep spare filters onboard for emergencies.

Emergency Procedures on the Water

Fuel tank issues can arise miles offshore. Knowing how to react in these situations is vital.

- Shut off the Engine: This prevents further damage and minimizes fire risk if there's a leak.

- Check for Leaks: Locate the source and assess the severity of any leaks. Contain the leak if possible.

- Contact for Help: If the problem is serious or you cannot fix it, contact the Coast Guard or a towing service.

- Carry Spare Filters and Tools: Having essential tools and spare parts on hand can help you address minor problems and get back on the water.

Repair vs. Replacement: Making the Right Decision

Sometimes, repair is a suitable option. However, if the boat fuel tank is severely corroded, badly damaged, or constantly causing problems, replacement may be the more effective long-term solution. Weigh the cost of repairs, the tank's age, and the potential for future issues when making this decision.

Are you tired of fuel spills and the worry of overfilling your boat's fuel tank? CLiX Fueling Solutions provides a solution to eliminate spills, prevent overfilling, and simplify fueling. Their automatic shut-off system guarantees a clean and safe fueling experience every time. Visit CLiX Fueling Solutions today to learn more.