At its core, a fuel vent for boats is a simple device that lets your boat's fuel tank "breathe." It's a small but absolutely essential safety component that serves three key purposes: it releases pressure from fuel vapors, prevents fuel spills during fill-ups, and lets air in so your engine gets a smooth, uninterrupted flow of fuel.

Why Your Boat’s Fuel Vent Is a Critical Safety Device

Ever shake a soda can? You know that feeling of pressure building up inside. Your boat's fuel tank does something similar. As fuel sloshes around and temperatures change, gasoline or diesel creates vapor that expands and contracts. Without an escape route, that pressure could easily deform, crack, or even rupture the tank.

That's where the fuel vent comes in. It provides a safe path for these flammable vapors to exit, directing them outside and away from enclosed areas like the engine room. In those spaces, a single stray spark could be catastrophic. It’s a tiny part that plays a huge role in keeping you safe on the water.

More Than Just a Hole in the Hull

It’s easy to think of a fuel vent as just a simple hole, but that's a common misconception. Modern vents are smartly engineered to solve a few different problems at once, mainly preventing fuel spills and keeping water out.

A good vent system allows air to escape quickly when you're refueling. This stops that annoying "burp" of fuel that can splash back out of the fill pipe, making a mess on your deck and polluting the water. On top of that, quality vents are designed to block rain and spray from getting into your tank, which protects your engine from the serious damage that water contamination can cause.

The need for proper fuel system safety is no joke. A recent U.S. Coast Guard alert, issued after a fatal explosion on a commercial fishing vessel, drove home the risks of working near fuel systems without proper precautions. It was a tragic reminder of just how volatile fuel vapors are.

The Financial and Environmental Stakes

A bad fuel vent isn't just a safety hazard—it can hit your wallet, too. A clogged vent can starve your engine of fuel, leading to performance issues and expensive repairs. Spilling fuel overboard can also lead to hefty fines and cleanup costs.

These regulations are a big reason why the entire marine ventilation market, which includes these vents, was valued at USD 1.2 billion in 2024. If you want to dive deeper into the market trends and the growing importance of these systems, you can check out this detailed report on marine ventilation.

How a Boat Fuel Vent System Works

Ever left a sealed plastic water bottle in a hot car? You probably came back to find it bulging and misshapen. That's because the air inside expanded. Squeeze that same bottle, and it crumples. Your boat's fuel tank is susceptible to the exact same forces, and it needs a way to "breathe" to avoid damage.

That’s where the fuel vent comes in. It’s a simple, but absolutely critical, part that acts as a two-way valve for air. It’s designed to keep the pressure inside your tank equal to the atmospheric pressure outside, preventing a whole laundry list of potential headaches, from a damaged tank to a dead engine.

Proper venting is a cornerstone of the marine fuel management market, an industry valued globally at USD 5.32 billion in 2024. These vents aren't just accessories; they are fundamental safety components.

Managing Air During Fueling and Operation

A fuel vent really shows its importance in two scenarios: when you're filling up the tank and when you're running the engine.

Think about what happens at the fuel dock. As you pump gallons of fuel in, an equal volume of air needs to get out. Without a clear path, that air would get trapped, creating serious back pressure. This is what causes the pump nozzle to constantly click off or, even worse, spray fuel all over you and the dock. The vent gives that displaced air an easy escape route, letting you fill up smoothly and safely.

The opposite happens when the engine is running. It’s constantly sipping fuel from the tank. For every bit of fuel that leaves, an equal amount of air must come in to replace it. If the vent is clogged and can't let air in, a powerful vacuum forms inside the tank.

A vacuum-locked tank can literally starve your engine of fuel. The engine will sputter, struggle, and eventually stall—usually at the most inconvenient and dangerous time. It’s one of the most common, and completely preventable, fuel-related engine problems.

Keeping Water and Gunk Out

A good fuel vent does more than just move air; it's a smart gatekeeper. Its job is to let air and fuel vapor pass through while blocking water, dirt, and debris. This is all down to the design of the vent fitting and how the hose is routed.

- Protective Caps: Most modern vents have specially designed caps with baffles or fine mesh screens. These are built to block splashing water from waves or heavy rain from ever getting into the vent line.

- The Gooseneck Loop: This is a crucial installation trick. The vent hose should always have a high upward loop—like the neck of a goose—before it connects to the tank. Gravity is your friend here; any stray water that sneaks past the cap will get trapped in the loop and drain back out instead of flowing down into your precious fuel.

By managing air pressure and blocking contaminants, the humble fuel vent protects the entire boat fueling system, keeping you safe and your boat running reliably.

Choosing the Right Fuel Vent for Your Boat

Picking out a new fuel vent for your boat isn’t just about grabbing some shiny hardware off the shelf. It’s a critical decision that directly affects your boat's safety, performance, and even its compliance with regulations. The simple truth is, not all vents are created equal. What works for a small fishing skiff is completely different from what a large offshore cruiser needs.

Your choice ultimately determines how well your fuel tank can "breathe" and, just as importantly, how well it keeps water out. Let's walk through what you need to know.

Common Types of Fuel Vents

You'll generally run into three main types of fuel vents on the market. Each design offers a different approach to balancing airflow with protection from the elements, which is a major concern for any boater.

- Standard 90-Degree Vent: This is the old-school, no-frills option. It's basically a simple right-angle fitting. While it gets the basic job done on smaller, inland boats, it offers very little defense against heavy spray or a rogue wave.

- Splash-Proof and Clamshell Vents: A big step up in design. These vents use built-in baffles, screens, or a protective clamshell cover to knock down water splashes before they can get into your vent line. They strike a great balance between performance and protection, making them a solid choice for most recreational boats.

- Fuel/Air Separators: These are the most advanced systems, often called fuel surge protectors. They're designed to meet modern environmental rules by doing more than just venting air. If fuel surges up the vent line while you're filling up, these devices capture it and send it right back to the tank, preventing any accidental spills into the water.

A quick but serious note on safety: A blocked vent is just as dangerous as the wrong type. In a tragic 2024 incident, welding near a vent pipe that hadn't been certified as gas-free caused a fatal explosion on a commercial fishing vessel. It's a sobering reminder of why a clean, fully functional vent system is non-negotiable.

To help you visualize the differences, here’s a quick comparison of the common designs you'll encounter.

Comparison of Common Boat Fuel Vent Types

This table breaks down the features and best uses for each vent type, helping you narrow down the right option for your vessel.

| Vent Type | Key Feature | Best For | Water Intrusion Risk |

|---|---|---|---|

| Standard 90-Degree | Simple, open design | Small boats in calm, protected waters | High |

| Clamshell/Splash-Proof | Protective cover or baffle system | Most recreational boats, moderate conditions | Low to Medium |

| Fuel/Air Separator | Prevents fuel spills during refueling | Vessels needing to meet environmental standards | Low |

Ultimately, the best vent is one that matches your boat's specific needs—protecting your fuel system without choking off airflow.

Key Factors for Your Decision

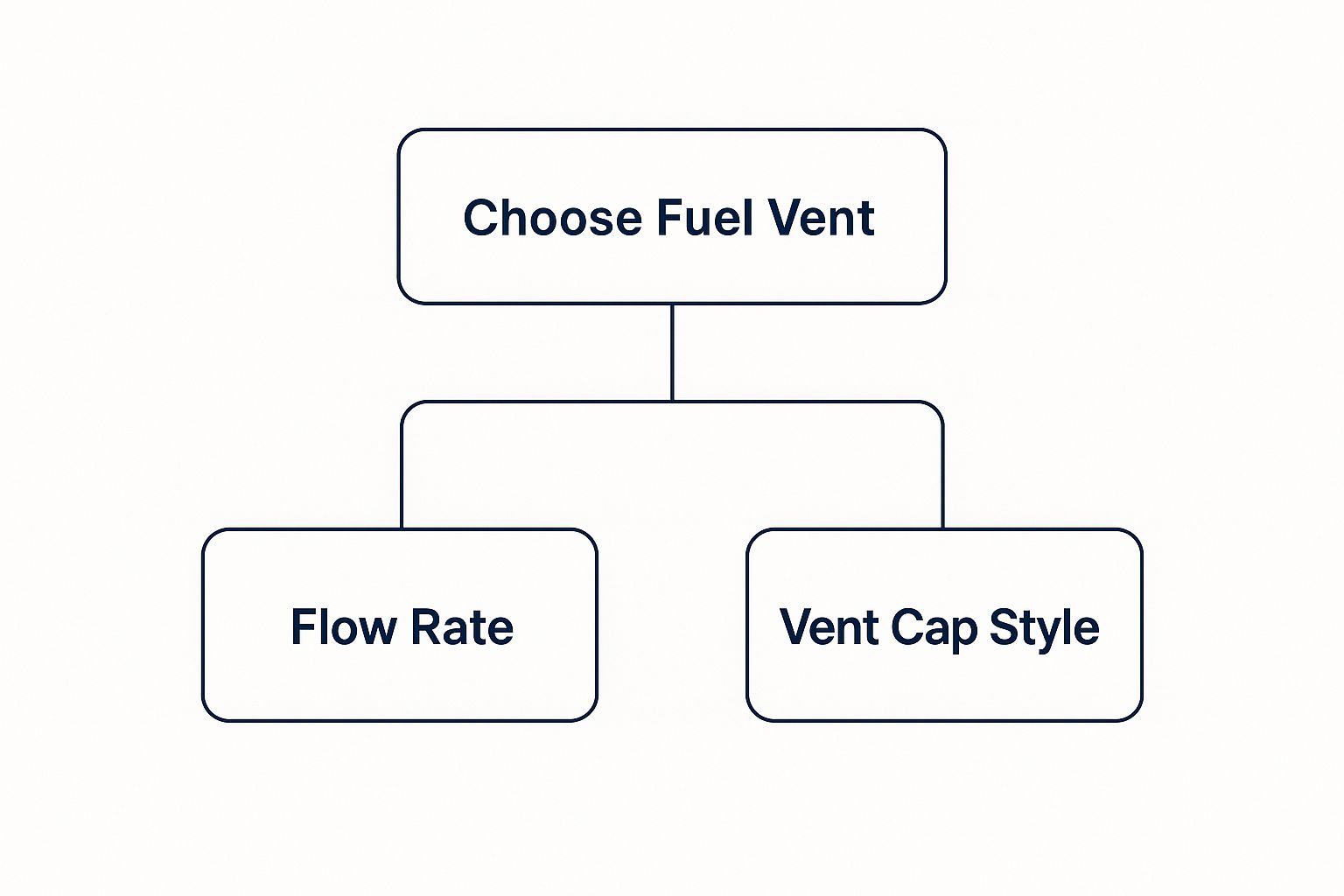

Making the right call comes down to thinking through a few key factors. The image below points out two of the most critical elements: the vent's flow rate and its cap style.

As you can see, a good vent needs to let enough air out during high-speed refueling to prevent dangerous back-pressure. At the same time, the design of its cap is your first line of defense against water getting in.

Your boat's tank size and where it's located are also hugely important. A bigger tank pushes out more air when being filled, so it needs a vent with a higher flow rate to keep up. Likewise, a tank positioned low in the hull or in a spot that gets wet often requires a vent with top-notch water protection. For a deeper dive into this, our boat fuel tank guide is a great resource for understanding your entire fuel system.

How to Install a New Boat Fuel Vent

Replacing your boat's fuel vent is one of those DIY projects that pays off big time in safety and performance. Don't be intimidated. With the right tools and a little patience, you can get this done yourself and ensure your fuel system is in top shape.

Let’s walk through the whole process, from picking the perfect spot to getting everything sealed up tight.

First things first, let's get our gear together. A smooth installation starts with having everything you need within arm's reach.

- New Fuel Vent: Make sure it's the right type and size for your specific boat.

- Fuel Vent Hose: You'll want a USCG-approved Type A2 hose. Double-check that the diameter matches your new vent fitting.

- Marine-Grade Sealant: This is no place to cut corners. Grab a high-quality polyurethane sealant like 3M 5200 or SikaFlex 291.

- Hose Clamps: Get stainless steel clamps, and plan on using two for each connection.

- Tools: A drill with the right bits, a screwdriver, and a sharp utility knife will do the trick.

Finding the Right Location

Deciding where to mount the new fuel vent for boats is easily the most important step. Your goal is simple: let air in and out, but keep water from getting into your fuel tank. You need to place it high on the hull, well above the waterline, in a spot that won't get drenched by constant sea spray.

Think about where you tie up at the dock. You'll want to find a location that's also protected from getting bumped or scraped. A great spot is usually on the side of the hull, just a bit below the gunwale, where it’s out of the way of waves and fenders.

Pro Tip: Whatever you do, never install a fuel vent on the transom. That area is a vacuum for engine exhaust and water spray—a recipe for disaster. Always mount it on the side of the hull.

Once you’ve found the perfect home for it, drill a small pilot hole to get started. Then, use a hole saw that matches the vent's diameter to cut the final opening. Pop the vent in for a quick test fit to make sure it's nice and snug.

Securing the Vent and Hose

With the hole cut, it's time to make a bulletproof, waterproof seal. Apply a good, generous bead of your marine sealant around the base of the fuel vent fitting. Carefully insert it into the hole you drilled and wipe away any excess sealant that squeezes out. This keeps it looking clean and professional. If your vent model has them, secure it with the included screws.

Now for the hose—this is your main line of defense against water intrusion.

- Attach to the Vent: First, slide two stainless steel hose clamps onto the end of the hose. Then, push the hose firmly over the vent's barbed fitting.

- Create the Gooseneck: This part is critical. Route the hose upward from the fitting, creating a high loop or "gooseneck" that sits well above the vent itself. This simple loop is your best friend for stopping water from ever reaching the tank.

- Connect to the Tank: Run the rest of the hose down to the tank's vent nipple. Make sure there are no weird kinks or low spots where fuel or water could get trapped.

- Secure the Clamps: Trim any extra hose for a clean run. Position your two hose clamps at each end (one at the vent, one at the tank) and tighten them down securely. Double-clamping is a non-negotiable best practice for a vapor-tight seal.

Once the sealant has had time to fully cure, you're all set. A proper installation like this protects your engine, prevents dangerous pressure from building up in your tank, and stops fuel from spilling into the water.

Common Fuel Vent Problems and How to Fix Them

Even the most reliable fuel vent for boats can cause headaches. Because this little part is constantly exposed to the marine environment, it’s a magnet for blockages, corrosion, and general wear. When you ignore the early warnings, you're setting yourself up for engine trouble, messy fuel spills, and dangerous fumes.

The good news is that most of these problems are easy to catch and fix. A little bit of routine maintenance goes a long way. Trust me, it’s much better to clear a tiny bug nest at the dock than to deal with a dead engine miles from anywhere.

Quick Fuel Vent Inspection Checklist

A quick visual check can spare you a lot of grief. Before casting off, just take a minute to look for these common issues that can mess with your vent system.

- Insect Nests: Wasps and mud daubers see that small opening as a perfect, pre-built home.

- Salt and Debris: Saltwater spray dries and leaves behind crusty salt deposits, which can easily block airflow.

- Cracked or Kinked Hoses: Old rubber and plastic hoses get brittle. A simple crack or a kink can choke off the vent line completely.

- Loose Fittings: Engine vibrations can work hose clamps loose over time, creating a path for hazardous fuel vapors to escape.

If you spot any of these red flags, it's time for a closer look. For a deeper dive into how all these parts function together, our complete safety guide to boat fuel tank vents is a great resource.

Troubleshooting Common Symptoms

Is your boat trying to tell you something? These classic symptoms are often your first clue that a fuel vent is clogged or failing. Each one points toward a specific problem you can track down and fix.

Key Insight: A persistent fuel smell around your boat is a major warning sign. It almost always points to a leak somewhere in the fuel system, and a bad vent hose or loose fitting is a very common culprit. Never, ever ignore that smell.

If you get fuel "burping" or splashing back at you while filling the tank, the vent is almost certainly blocked. It simply can't let the air out fast enough to keep up with the incoming fuel. A whistling sound from the tank is another classic—it’s air being forced through a tiny, partially clogged opening.

What about an engine that sputters or dies, especially when you try to open it up? That could be fuel starvation. A blocked vent can create a vacuum in the tank, preventing the fuel pump from pulling fuel effectively. Each of these signs is a call to action to keep your boat running safely.

Of all the parts on your boat, the fuel vent is one of the easiest to overlook—until it causes a problem. When you're out on the water, you need everything working right, and a tiny blockage in your vent line can bring your day to a screeching halt.

Let's clear up some of the most common questions boaters ask about this small but mighty component.

Can a Clogged Fuel Vent Really Cause Engine Problems?

You bet it can. In fact, a blocked fuel vent is a surprisingly common culprit behind engine issues that can have you chasing your tail, thinking you have a major fuel pump or carburetor problem.

Here’s what happens: as your engine sips fuel from the tank, air needs to flow in through the vent to take its place. If that vent is plugged, a vacuum starts to build inside the tank. This vacuum fights against the fuel pump, making it work harder and harder until it simply can't pull any more fuel. The engine gets starved, and you'll notice it start to sputter, lose power, or stall out completely—especially when you try to accelerate.

What Are the Telltale Signs of a Blocked Vent?

Your boat is pretty good at telling you when something's wrong. You just have to know what to listen for. Catching a blocked vent early can save you from getting stranded.

Keep an eye (and ear) out for these classic symptoms:

- Fuel “Burps” Back at the Pump: If fuel spits back at you while you're filling the tank, that’s a dead giveaway. The air being displaced by the incoming fuel has nowhere to go, so it forces fuel back out the fill pipe.

- A Hissing or Whistling Sound: You might hear a faint whistle coming from the vent or tank area while the engine is running. That's the sound of air being desperately sucked through a tiny, partially blocked opening.

- A Collapsed-Looking Tank: In serious cases, the vacuum can be so strong it actually causes a plastic or aluminum tank to buckle inward. If you see this, you've got a severe blockage.

A strong, lingering smell of gasoline or diesel around your boat is a major red flag. Don't ignore it. While there can be a few causes, a leaky or poorly sealed vent hose is a common offender. Always track down the source of fuel odors immediately.

How Often Should I Check My Fuel Vent?

Regular checks are your best defense. A good habit is to inspect your fuel vent at least twice a season—once when you're de-winterizing the boat and again around mid-season.

However, if you boat in areas known for wasps or mud daubers, you’ll want to check it more often. Those little critters love to build nests in the small, sheltered opening of a fuel vent, and they can create a complete blockage in just a day or two. The inspection is simple: a quick look at the vent cover and maybe a gentle puff of air through the line is all it takes to know it's clear.

What’s Causing My Fuel Vent to Whistle?

That whistling is the sound of a partial blockage. Think of it like putting your thumb over the end of a garden hose. As your engine draws fuel, it creates a vacuum in the tank, pulling air in through the vent line to equalize the pressure.

If that opening is narrowed by a bug's nest, salt crystals, or some other piece of debris, the air gets squeezed through a much smaller space. This makes the air speed up and creates that distinct high-pitched whistle. Consider it an early warning sign that your vent needs a good cleaning before the blockage gets bad enough to stall your engine.

Can I Clean My Own Fuel Vent?

Absolutely. For most boat owners, cleaning a fuel vent is a simple DIY job.

Start by looking at the external vent cap on your hull. Can you see an insect nest, spider web, or salt buildup? You can usually clear that out with a small piece of wire or a shot of compressed air.

If you think the blockage is deeper in the hose, disconnect the vent line from the tank fitting. Always do this in a well-ventilated area with no sparks or flames nearby. Gently blow low-pressure compressed air from the tank side of the hose out toward the hull fitting. This should push any hidden gunk out. Never blow air from the outside in, or you risk pushing debris right into your fuel tank. If the hose looks old, cracked, or brittle, just replace it. It's cheap insurance.

Even with a clear vent, refueling can be a messy guessing game. We've all seen those rainbow sheens at the fuel dock from overfills. Below is a quick guide to help you troubleshoot common issues you might run into with your vent system.

Troubleshooting Common Fuel Vent Issues

This table is a handy reference for quickly figuring out what's wrong and what to do about it.

| Symptom | Likely Cause | Recommended Action |

|---|---|---|

| Fuel spits back during fill-ups | Blocked vent line or fitting. | Inspect and clear the vent opening and hose of any obstructions like insect nests or debris. |

| Engine sputters or stalls | Severe vent blockage creating a vacuum. | Immediately check the vent. If blocked, clear it. Also, inspect the fuel tank for deformation. |

| Whistling or hissing noise | Partial blockage in the vent line. | Clean the vent line and fitting. This is an early warning sign; don't ignore it. |

| Strong fuel odor near the vent | Cracked, loose, or deteriorated vent hose. | Inspect the entire length of the vent hose for cracks or loose clamps and replace it if necessary. |

| No air movement from vent | Complete blockage. | Disconnect the hose and use compressed air (from tank to hull) to clear the line. Replace the hose if it's damaged. |

Running into these issues is frustrating, but most of the time, the fix is straightforward once you know where to look. Regular maintenance is the key to preventing them in the first place.

Tired of the guesswork and the messy, dangerous fuel spills at the dock? The innovative system from CLiX Fueling Solutions takes the stress out of refueling by automatically stopping the flow when your tank is full. Protect your boat, the environment, and your peace of mind with this essential upgrade. Learn more and make fueling effortless by visiting their website.