Think of a fuel transfer system as the circulatory system for any machine with an engine. Its job is to move fuel safely and efficiently from a storage tank right to where it's needed, ensuring a clean, steady supply for peak performance.

The Heartbeat of Modern Machinery

Could you imagine trying to power a massive farm tractor or a hospital's backup generator by pouring fuel from a little red can? It would be slow, messy, and downright dangerous. This is exactly why fuel transfer systems are so crucial. They are the unsung heroes that automate and secure the entire process, bridging the gap between stored fuel and the power we rely on.

At its most basic, the system solves a simple problem: getting liquid fuel from point A to point B. But there's more to it than just that. It's about delivering the right amount of fuel, at the right pressure, and making sure it's completely free of contaminants along the way.

Why Is This System So Critical?

A solid fuel transfer system is non-negotiable in countless industries, and for a few very good reasons. Without one, the equipment that keeps our world running would simply stop. The importance really boils down to three key benefits:

- Safety and Efficiency: A well-designed system dramatically cuts down the risk of spills and leaks. This not only prevents environmental headaches but also stops you from wasting expensive fuel. It takes a hazardous manual task and turns it into a safe, contained process.

- Engine Protection: Fuel can easily pick up contaminants like water, dirt, or rust from storage tanks. A good system has filters that act like kidneys, cleaning the fuel before it can damage sensitive and expensive engine parts like injectors and pumps.

- Operational Reliability: Whether you're refueling a boat out on the water or counting on an emergency generator during a blackout, you need a fuel supply you can trust. A fuel transfer system provides that consistency, which is absolutely vital in situations where downtime is not an option.

A fuel transfer system isn't just a convenience; it's a core component for safety, engine longevity, and operational readiness. It's what makes sure the energy sitting in a tank is ready to go the moment you need it.

Every fuel transfer system is built around four main components that have to work together perfectly. Think of them like organs in a body, each with a specific job: the pump (the heart), hoses (the arteries), nozzles (the control valve), and filters (the kidneys). Getting a handle on how these parts interact is the first step to understanding what makes this technology so essential.

Understanding the Core Components

Every fuel transfer system, whether it's a simple hand pump or a sophisticated industrial setup, is built around a few essential parts working together. To really get a feel for how these systems operate, it helps to think of them like a living organism, with each component playing a critical role.

At the very center of it all is the fuel pump. This is the heart of the operation. Its entire job is to create the pressure that moves fuel from a storage tank to wherever it needs to go. Without it, the fuel would just sit there. The pump is the engine that drives the whole process.

The Arteries and Veins of the System

Once the pump gets things moving, the fuel needs a safe path to follow. That's where hoses and lines come in. Think of them as the arteries and veins, channeling the pressurized fuel from the tank, through the pump, and finally out to the dispensing nozzle.

The material these hoses are made from is a huge deal. You can't just use any old hose; gasoline, for instance, will eat right through certain types of rubber, causing leaks and dangerous spills. That’s why fuel hoses are specifically designed to resist the chemicals they carry. Of course, the fuel has to be stored somewhere, and moving large containers requires its own expertise. For more on that, check out this guide on shipping fuel tanks.

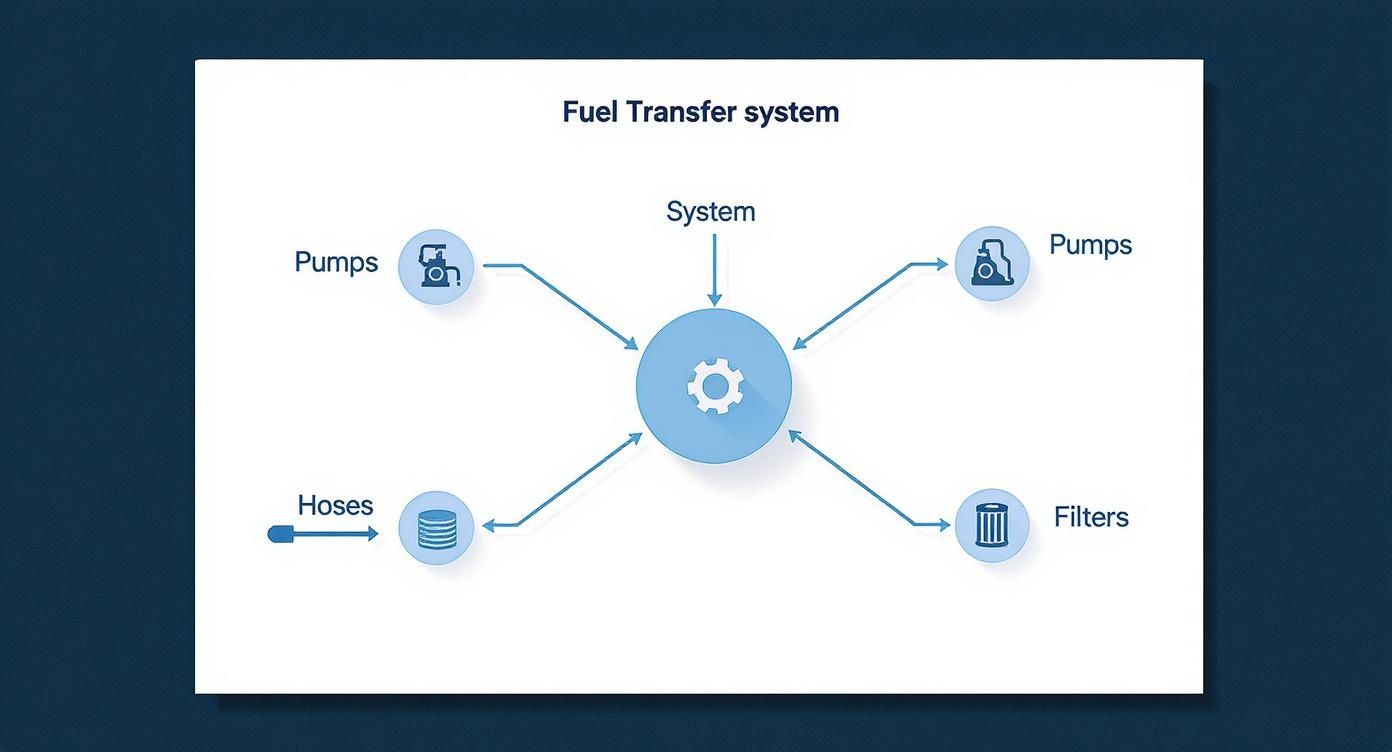

This image shows how all the key pieces fit together to move fuel safely and efficiently.

As you can see, the pump, hoses, nozzle, and filters all work in concert to form a complete, functional system.

Control and Purity

Next up is the nozzle. If the pump is the heart and the hoses are the arteries, the nozzle gives you control. It’s what lets an operator start, stop, and regulate the flow of fuel, preventing messy and wasteful spills. Many modern nozzles even include an automatic shut-off feature, which is a fantastic safety backup.

Finally, we have the filters. These are the kidneys of the system. Their purpose is simple but vital: to clean the fuel by trapping gunk and contaminants before they can get into an engine and cause serious damage.

Water, rust, dirt, and even microbial growth (the dreaded "diesel bug") are silent killers for engines. A good filter is your best and most important defense against expensive repairs down the road.

Even fuel that appears clean can be loaded with tiny particles that can wreak havoc on sensitive components like fuel injectors. A filter physically blocks these troublemakers, protecting your equipment and keeping it reliable. The demands can be even tougher in marine settings; you can dive deeper into the specifics of a marine fuel transfer pump in our detailed guide.

To give you a clearer picture, here’s a quick breakdown of these essential parts.

Key Components and Their Functions

| Component | Primary Function | Common Types / Materials |

|---|---|---|

| Fuel Pump | Creates pressure to move fuel from the tank to the destination. | Centrifugal, Diaphragm, Gear Pumps (Electric or Manual) |

| Hoses/Lines | Provide a safe, contained pathway for fuel to travel. | Reinforced Rubber, PVC, Stainless Steel Braiding |

| Nozzle | Controls the start, stop, and flow rate of fuel dispensing. | Manual, Automatic Shut-Off (Aluminum, Plastic) |

| Filter | Removes contaminants like water, dirt, and rust from the fuel. | Spin-On Canisters, Water Separators, In-Line Strainers |

When these four components—pump, hoses, nozzle, and filter—work in harmony, you get a dependable and efficient system. Knowing what each part does makes it much easier to spot problems, handle maintenance, and just appreciate the smart engineering that keeps our world moving.

How Fuel Transfer Systems Power Key Industries

When you hear "fuel transfer system," you might just picture the pump at your local gas station. But that's only a tiny part of the story. These systems are the workhorses of the global economy, quietly operating behind the scenes to make sure power gets exactly where it's needed, often in some of the toughest environments you can imagine.

Think about a farmer working a thousand-acre field. A combine harvester can't just pop over to the corner station for a fill-up. Instead, a mobile fuel transfer system—often mounted on a truck or trailer—brings the diesel directly to the machinery. This on-the-spot refueling is what keeps tractors, combines, and irrigation pumps running day and night during planting and harvesting. Without it, farm productivity would grind to a halt.

Keeping Construction and Infrastructure Moving

It’s the same story on a sprawling construction site. Those towering cranes, massive bulldozers, and heavy-duty excavators all run on a constant diet of fuel. Since these job sites are often in remote areas without any permanent fueling stations, a reliable fuel transfer system isn't just a convenience; it's a lifeline.

These systems are the reason heavy equipment can keep running without interruption, shaping our cities and building our highways. They are the unsung heroes powering the machinery that constructs everything from skyscrapers and bridges to our homes and hospitals.

The chart below shows just how important sophisticated fuel delivery has become, focusing on the massive market share of gasoline direct injection (GDI) systems in cars.

While this is specific to automotive tech, it reflects a much broader trend: industries everywhere are demanding more precise and efficient ways to handle fuel.

Mission-Critical Applications in Aviation and Marine

Nowhere is reliability more crucial than in aviation and marine operations. When a plane is refueled on the tarmac, a highly specialized fuel transfer system is doing the work. It has to deliver huge volumes of jet fuel incredibly fast, but also with extreme care. These systems use advanced filters to make sure the fuel is perfectly clean and free of water—because any kind of contamination at 30,000 feet could be disastrous.

The marine industry has its own term for this: "bunkering." It's the process of refueling gigantic container ships and tankers, often from a smaller vessel or a dockside station. This requires serious muscle—high-capacity pumps and heavy-duty hoses capable of moving thousands of gallons of fuel safely and quickly.

For emergency services and critical facilities, a fuel transfer system isn't just about keeping things running. It's a lifeline. Hospitals, data centers, and communications hubs all rely on backup generators that have to kick in the second the power goes out. An automated fuel transfer system is what ensures those generators never run dry, protecting lives and critical data.

This widespread reliance is fueling major economic growth. The global market for fuel transfer pumps—the heart of any system—was valued at USD 1.87 billion and is expected to hit USD 2.45 billion by 2029. This boom is directly linked to the growing needs of industrial development, vehicle manufacturing, and energy projects across the globe. You can read more about the fuel pumps market growth on researchandmarkets.com.

A Summary of Key Industrial Roles

The real beauty of the fuel transfer system is its versatility. It's found in just about every major industry, performing a vital role. Here’s a quick rundown of where they make the biggest impact:

- Agriculture: On-site refueling for tractors, combines, and irrigation pumps to maximize uptime during critical seasons.

- Construction: Keeps heavy machinery like excavators, cranes, and bulldozers running on remote job sites without interruption.

- Aviation: Handles the fast, safe, and highly filtered refueling of commercial and private aircraft.

- Marine: Manages the large-scale "bunkering" of ships, tankers, and even recreational boats.

- Emergency Services: Guarantees a continuous fuel supply to backup generators at hospitals, data centers, and other essential facilities.

From feeding the world to building our cities, the humble fuel transfer system is one of those foundational technologies that truly powers modern life.

How to Choose the Right Fuel Transfer System

Choosing the right fuel transfer system can seem complicated, but it doesn't have to be. If you break it down, the decision really comes down to answering four simple questions about your specific needs. Get these right, and you’ll land on a setup that’s safe, efficient, and built to last.

Gasoline vs. Diesel: Why It's Not Negotiable

First things first: what kind of fuel are you moving? This is the most critical question, and the answer is non-negotiable for safety reasons. Gasoline and diesel are fundamentally different, and the systems designed for them are not interchangeable.

Gasoline is incredibly volatile, creating explosive vapors even at low temperatures. Any pump, hose, or nozzle used for gasoline must be explosion-proof and designed to prevent any possible spark. Trying to use a standard diesel pump for gasoline is a recipe for disaster.

On the other hand, diesel is a light oil. It’s far less volatile but can degrade seals and hoses that aren't designed for it, eventually causing leaks and pump failure. The bottom line is simple: always use a system specifically rated for your fuel type.

To spell it out, here’s a quick comparison of what you’ll need for each.

Gasoline vs. Diesel Fuel Transfer System Comparison

The table below breaks down the key differences in components and safety features you need to be aware of when choosing a system.

| Feature | Gasoline System Requirements | Diesel System Requirements |

|---|---|---|

| Pump Motor | Must be explosion-proof to prevent ignition of flammable vapors. | Standard-duty motor is acceptable as diesel is less volatile. |

| Seals & Gaskets | Made from materials like Viton that resist gasoline's corrosive effects. | Typically made from Buna-N or similar materials suited for oil-based fuels. |

| Hoses | Must be rated for gasoline to prevent degradation and static buildup. | Require hoses designed to handle oil-based diesel fuel without deteriorating. |

| Safety Priority | Preventing sparks and containing highly flammable vapors is the top concern. | Preventing leaks and ensuring material compatibility are primary goals. |

As you can see, the requirements are driven by the chemical nature of the fuel. Mismatching them isn't just a bad idea—it's dangerous.

How Fast Do You Need to Pump?

Once you’ve settled on the right fuel type, think about speed. The flow rate, measured in gallons per minute (GPM), tells you how quickly the system moves fuel. The right speed for you depends entirely on what you're filling.

If you’re just topping off a small generator or a lawn tractor, a lower flow rate of 8-10 GPM is plenty. In fact, a slower flow is often easier to control for smaller tanks. But if you’re refueling a massive combine or filling a 100-gallon auxiliary tank on your truck, you’ll want something much faster—think 20-25 GPM or more—to get the job done without wasting half your day.

Power Source and Portability

Where will you be doing your refueling? Your answer will point you to the right power source. Fuel transfer pumps generally come in two flavors.

-

12V DC Power: These are the kings of portability. They hook right up to a vehicle’s battery, making them the perfect solution for refueling in the field, on a remote job site, or out on the water. If you need to refuel on the go, this is your answer.

-

120V AC Power: This is your workhorse for fixed locations. If you have a fuel tank at your shop, in a barn, or at a permanent docking station, an AC-powered pump plugs into a standard wall outlet. It gives you steady, reliable power without ever worrying about draining a battery.

So, it's a simple trade-off: choose 12V DC for mobile applications and 120V AC for a stationary setup.

Can Your Pump Handle the Workload?

The final piece of the puzzle is the pump's duty cycle. This spec tells you how long the pump can run continuously before it needs a break. Ignoring the duty cycle is one of the fastest ways to burn out a perfectly good motor.

An intermittent-duty pump is designed for shorter tasks, typically running for 15-30 minutes before it needs to cool down. This is more than enough for most everyday refueling jobs.

A continuous-duty pump, however, is built tough with better cooling and heavy-duty components. It can run for hours without stopping, making it essential for big jobs like transferring fuel between large bulk storage tanks.

Installation and Maintenance Best Practices

A fuel transfer system is a solid investment in your operation's efficiency, but like any piece of heavy-duty equipment, its real value comes down to proper installation and regular care. Think of it like a new truck—you wouldn't just drive it off the lot and never check the oil. From day one, giving your system the right attention is what guarantees a long, reliable service life and keeps you safe.

Skimping on setup is one of the fastest ways to run into trouble. A rushed or sloppy installation is the root cause of countless performance issues, dangerous leaks, and expensive breakdowns. This isn't just about hooking up a few hoses; it's about building a secure, leak-proof fuel path you can count on every single time.

A Quick Installation Checklist

Getting the installation right from the start prevents 90% of common problems. Stick to these fundamentals for a setup that’s both safe and effective.

-

Ensure Proper Electrical Grounding: This is non-negotiable, especially when you're dealing with flammable fuels. A good ground connection stops static electricity from building up, which can easily create a spark and ignite vapors. Always follow the manufacturer's instructions to the letter on this one.

-

Use High-Quality Thread Sealant: Pipe threads alone will not create a perfect seal. Ever. Always apply a fuel-resistant thread sealant or tape to every single fitting. This simple step is your best defense against those slow, annoying leaks that waste fuel and create a serious hazard.

-

Secure Hoses and Prevent Kinks: Map out a path for your hoses that avoids sharp bends, kinks, or anywhere they might get crushed or rubbed raw. Use clamps to secure them firmly, stopping them from vibrating against sharp edges, which is a surefire way to cause cracks and premature failure.

Of course, handling fuel safely goes beyond just the pump. Always follow strict safety regulations during transport and storage, including the proper flammable liquids placard guidelines.

Developing a Simple Maintenance Routine

Once your system is up and running, a simple, consistent maintenance routine is the key to making it last. We're not talking about a full-on mechanical teardown. This is all about quick visual checks that can spot small problems before they turn into huge headaches.

Get in the habit of inspecting all hoses and fittings before you use the system. Look for any signs of cracking, brittleness, or wear on the hoses. Check every connection for dampness or drips—the classic tell-tale signs of a loose fitting or a failing seal. Tighten things up as needed, but don’t go overboard and strip the threads.

Think of maintenance as a quick health checkup for your equipment. A five-minute inspection can save you from hours of downtime and hundreds of dollars in repairs by catching a failing hose or a loose connection early.

Next up, the filters are the lifeblood of your engine's protection. A clogged filter chokes the fuel flow, which forces the pump to work harder and can cause it to overheat. Worse, it stops doing its job, letting grit and grime get into your expensive equipment. Replace your fuel filters based on the manufacturer’s schedule—or even sooner if you notice a drop in performance.

Finally, don't forget the nozzle. A faulty nozzle that doesn't close properly can cause a major spill. If you want to dive deeper into how these critical parts work, check out our guide on the fuel nozzle auto shut off feature.

The Future of Fuel Transfer Technology

The way we move fuel is changing, and fast. The simple pump and hose we’re all used to is getting a serious upgrade, pushed by two big things: the need to protect our environment and the constant drive to be more efficient. The fuel transfer system of tomorrow isn't just about moving fuel from A to B; it's about doing it smarter, cleaner, and with incredible precision.

A huge part of this shift comes from the global demand for cleaner air. As governments tighten up on emissions, every drop of spilled fuel and every wisp of vapor matters. This pressure is sparking real innovation—think better seals, ultra-precise automatic shut-off nozzles, and vapor recovery systems that trap fumes before they ever hit the atmosphere.

The Rise of Smart Fuel Management

The real game-changer, though, is bringing digital tech into the hardware. We're leaving basic mechanical controls behind and entering an age where fuel systems can monitor themselves and tell us what they need.

- Integrated Fuel Monitoring: Imagine systems with built-in sensors that constantly check fuel quality, temperature, and volume. This isn't just data for data's sake; it's an early warning system that can flag contamination or other issues before they wreck expensive machinery.

- Predictive Maintenance: Smart systems will track things like pump pressure and motor temperature, learning the signs of wear and tear. They'll be able to predict a potential failure long before it happens, letting you schedule maintenance on your terms instead of dealing with a costly, unexpected breakdown.

- Leak Detection: Tiny, almost invisible leaks can now be caught instantly. Advanced sensors can pick up the slightest drop in pressure, shut the whole system down automatically, and ping you with an alert. This is huge for preventing environmental spills and saving money on lost fuel.

The fuel transfer system of the future won't just move fuel; it will manage it. It’s about getting a live feed of information that helps you use every drop wisely, cut waste, and keep everything running smoothly.

Adapting to New Energies and Global Demands

It's not just about getting smarter; it's about getting more versatile, too. As the world explores biofuels and synthetic fuels, the core technology has to keep up. New systems are being built with advanced materials that can handle the unique chemical makeup of these alternative fuels, heading off corrosion and breakdown that would cripple older equipment.

And this isn't happening in a vacuum—it's a global trend. The Asia-Pacific region is leading the charge, especially in places like Japan where over 62% of vehicles already use advanced direct injection systems that depend on high-pressure fuel transfer. Europe is right there with them, with its market growing thanks to high-end car manufacturers and the boom in hybrid vehicles. To get a better sense of the scale, you can dive into the global fuel delivery system market dynamics and see how these forces are shaping the industry.

The message is loud and clear: the humble fuel transfer system is becoming a central piece in the much bigger puzzle of building a more sustainable and efficient world.

Common Questions About Fuel Transfer Systems

When you're dealing with fuel transfer systems, a few questions always seem to pop up.Getting straight answers is key to keeping things safe and efficient, so let's tackle some of the most common ones we hear.

First up, the big one: can you use the same pump for both gasoline and diesel? The answer is a hard no. Gasoline is incredibly flammable and its fumes can easily ignite. That's why gas pumps need a special explosion-proof motor. Diesel pumps don't have this, and using one for gasoline is just asking for a fire.

Why Do Fuel Transfer Pumps Fail?

It’s frustrating when a pump gives out, but the good news is that most failures are totally preventable. We see two main culprits time and time again: dirty fuel and running the pump dry.

Think of debris like dirt, rust, and water as sandpaper grinding away at the pump's insides. It just chews up the components. A quality filter is your pump's best friend and first line of defense.

Running a pump without any fuel moving through it is just as bad. The fuel itself actually lubricates and cools the motor. When it runs dry, the pump overheats in a hurry, causing parts to seize up and the motor to burn out.

The two biggest killers of fuel transfer pumps are contaminated fuel and dry running. Keep the fuel clean and flowing, and your pump will thank you for it.

Of course, even with the best precautions, spills can happen. It pays to be ready. Knowing the right fuel spill cleanup procedures and having an expert response guide on hand is just smart planning.

Choosing the Right Flow Rate and Pump Type

"What flow rate do I need?" That's another question we get all the time. The answer really comes down to your tank size.

- For smaller tanks (under 50 gallons): A pump with a lower flow rate of 8-15 GPM (gallons per minute) gives you much better control and prevents messy overfills.

- For larger tanks: Go for a higher flow rate of 20-25 GPM. It’ll get the job done much faster and save you a ton of time.

Finally, what about old-school manual hand pumps? Are they still worth it? Absolutely. While electric pumps are fast and convenient, a simple hand pump is a fantastic, low-cost backup. It doesn't need electricity, making it a lifesaver in an emergency or out in the middle of nowhere. For small, infrequent jobs, it's still a perfectly reliable tool.

At CLiX Fueling Solutions, we believe every fueling experience should be safe and spill-free. Our innovative system automatically stops the flow when your tank is full, protecting your boat and the environment. Discover a smarter way to fuel up at clixfueling.com.