A good fuel pump gas can setup is your best friend for avoiding dangerous spills and making refueling less of a chore. It's simple: a quality, marine-approved gas can paired with a dependable transfer pump. This combo transforms a potentially risky task into a controlled, clean process, letting you get fuel from the dock to your boat without the usual mess and hazards of just pouring it in.

Choosing the Right Gear for Boat Refueling

Before you even think about transferring fuel, your success and safety depend entirely on the gear you've got. Putting together a solid refueling kit is more about safety than convenience. Every piece, from the pump right down to the hose, is critical for preventing spills and making sure the fuel gets where it needs to go.

The portable fuel transfer pump is the core of your whole system. These aren't all the same, so don't just grab the first one you see. They can be anything from a basic manual siphon to a beefy, battery-operated model that can transfer several gallons per minute. While a hand pump might be fine for a small skiff, a bigger boat will really benefit from an electric pump that delivers a steady, controlled flow. It saves your back and dramatically cuts down on the risk of splashing fuel everywhere.

Selecting Your Fuel Transfer Pump

When you're shopping for a pump, pay close attention to its flow rate, how it's powered, and what it's made of. A battery-powered pump is great for portability, but you have to be certain it’s built for marine use with spark-proof parts. These tools are becoming more popular for a reason; the global fuel transfer pump market was valued at USD 129 million and is projected to reach USD 184 million by 2032.

Here’s a quick checklist for a quality pump:

- Marine-Grade Materials: You need components that can stand up to saltwater corrosion and won't break down from fuel additives.

- Sufficient Hose Length: The hose needs to comfortably reach from your gas can to the boat's fuel inlet without being stretched tight or kinking up.

- Intrinsic Safety Features: Look for pumps that are specifically rated for use with flammable liquids. This is key to preventing accidental ignition.

More Than Just a Container

The gas can is just as important as the pump. Not all fuel containers are up to the job, especially out on the water. A cheap, flimsy can is just asking for trouble.

A top-tier marine gas can should have a flame arrestor—that little screen in the opening that stops external sparks from igniting vapors inside the can. For any boater, this tiny feature is an absolute must-have.

Look for cans made from thick, durable plastic that won’t get brittle from sun exposure. A well-designed spout that keeps drips to a minimum is also a huge plus. To learn more about what to look for, check out our guide on finding the best gas cans with a pump.

Lastly, don't overlook the accessories that bring it all together. An automatic shutoff nozzle, like the one on the pump at a gas station, is a lifesaver for preventing messy overfills. Grounding clips are also essential for getting rid of static electricity, which can easily build up during fueling and create a spark. Putting together this complete kit from the start gives you one less thing to worry about on the water.

Your Pre-Fueling Safety Checklist

Let's talk about the most important part of fueling your boat, and it has nothing to do with the actual fuel pump gas can. The real work happens before you even twist off the first cap. I’ve seen enough close calls over the years to know that this pre-fueling routine is non-negotiable. Skipping it is just rolling the dice, and the stakes are way too high.

First things first: get your boat tied up securely. You don't want a rogue wave or a gust of wind shifting the boat while you've got fuel flowing. Once it’s snug against the dock, get everyone off. This isn't just about being polite; it’s a critical safety step. It minimizes potential ignition sources (like a cell phone) and keeps everyone clear of dangerous fumes.

Kill Every Spark

Gasoline vapors are sneaky. They’re heavier than air and love to collect in low places like the bilge. It only takes one tiny, invisible spark to ignite those fumes, and the result can be catastrophic. I’m talking about a spark from a battery switch, static electricity, or even a smartphone.

That’s why you need to go on a "spark hunt" before bringing any fuel near the boat.

- Kill the engines. That means the main engine, the generator, even the little kicker motor. Everything off.

- Shut down all electronics. Yes, all of them. Your GPS, VHF radio, cabin lights, bilge pump—if it has a switch, turn it off.

- No open flames. This one's a no-brainer. Put out cigarettes, turn off the galley stove, and ditch any lighters.

This isn't overkill; it's smart boating. For a deeper dive into managing fire risks, these effective fire prevention strategies offer great principles that apply well beyond just the workplace.

Give Your Gear and Boat a Once-Over

Now, take a good look at your equipment. Is the gas can cracked? Is the hose on your pump brittle? Are the seals on the cap in good shape? A small leak you don't notice can quickly turn into a serious spill and a huge headache.

To make this second nature, I recommend using a simple checklist every single time. It takes 60 seconds and builds a powerful safety habit.

Pre-Fueling Safety Checklist

Run through this quick list before you start pumping. It’s a simple way to ensure you haven’t missed a critical step in the heat of the moment.

| Check | Purpose | Status (OK / Not OK) |

|---|---|---|

| Boat Secured | Prevents movement during fueling. | |

| All Passengers Ashore | Minimizes ignition risks and keeps people safe. | |

| Engines & Generator Off | Eliminates a major source of sparks and heat. | |

| All Electronics Off | Prevents electrical sparks from igniting fumes. | |

| No Open Flames | Removes obvious ignition sources like cigarettes or stoves. | |

| Fueling Gear Inspected | Checks for leaks or damage in cans, hoses, and nozzles. | |

| Hatches & Doors Open | Ensures proper ventilation to dissipate fumes. |

Once you can tick "OK" on every item, you're in a much safer position to begin fueling.

I always tell new boaters to remember this simple mantra: No Smoking, No Sparks, No Flames. Make it a hard-and-fast rule for anyone near the boat during fueling. Post a sign if you have to.

Finally, get some air moving. Open every port, hatch, and door you can. Good ventilation is your best friend when dealing with fuel. It helps whisk away any vapors that escape, preventing them from building up to dangerous levels. It’s a simple action, but it's one of the most effective things you can do to keep a routine task from turning into an emergency.

How to Transfer Fuel Without Spills

Alright, you've done your safety checks, and now it's time to actually get the fuel into the boat. The whole game here is about a smooth, controlled transfer. We want to avoid any spills or static sparks, so let's walk through it. This isn't a race; doing it right is far more important than doing it fast.

First, think about where you're placing your gas can. If you can, set it on a stable spot on the dock that’s a little higher than your boat's fuel tank inlet. It’s a simple trick, but using gravity like this makes the pump's job easier and gives you a much steadier flow.

Grounding Your Equipment

Before a single drop of fuel moves, we have to tackle the invisible threat: static electricity. A tiny, unseen spark is more than enough to ignite gasoline fumes, and that's a situation nobody wants. Grounding your equipment is non-negotiable.

So many boaters either forget this step or just get it wrong. The correct way is to touch the metal nozzle of your pump to the metal rim of your boat’s fuel fill pipe before you start pumping. The key is to maintain this metal-to-metal contact the entire time you're fueling. This creates a safe path for any static charge to dissipate harmlessly.

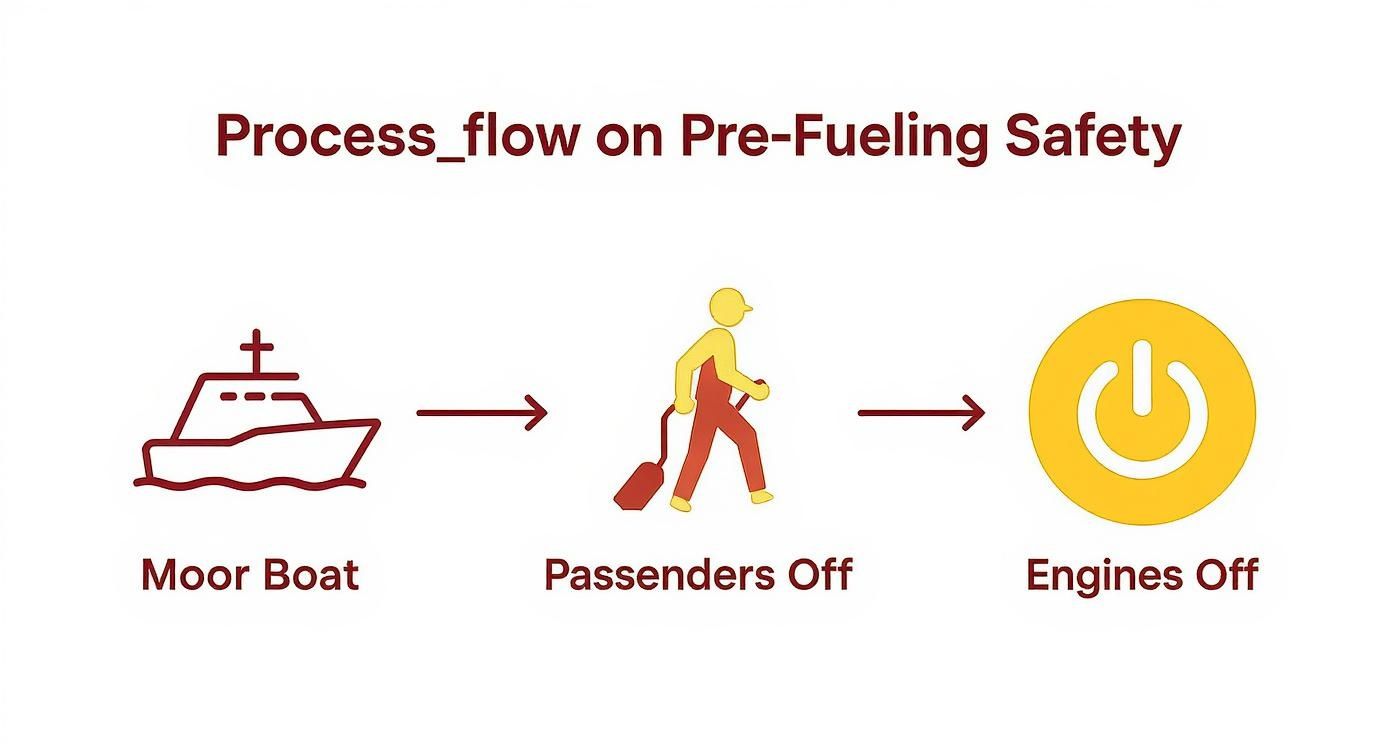

This simple process flow covers the absolute must-dos before you even pick up the nozzle.

Tying up, getting everyone off the boat, and shutting down all power creates the safe zone you need to work in.

Pumping with Precision

With the nozzle firmly grounded against the fill pipe, you're ready to go. Insert the nozzle all the way in and begin pumping at a slow, deliberate pace. One of the biggest mistakes I see is people rushing, which causes "fuel burps" and backsplash. That’s how you get gasoline on your deck and, even worse, in the water.

Pay attention to the sound. As the tank gets full, you'll hear the tone change—it usually becomes a higher-pitched gurgle. That's your cue to slow way down and get ready to stop.

This is exactly why automatic shutoff units are a game-changer; they take the guesswork out of the equation. A methodical approach gives you complete control. If you want to take it a step further, using a good fuel funnel with a filter is a great way to add another layer of defense against any debris getting into your tank.

Watch out for these common missteps:

- Pumping Too Fast: This churns up the fuel in the tank, which can trip an automatic shutoff nozzle too early or cause a splash-back.

- Not Inserting the Nozzle Fully: If the nozzle isn't deep in the pipe, it can pop out easily and cause a major spill.

- Losing Contact: The moment the nozzle breaks contact with the fill pipe, you've lost your ground. That instantly raises the risk of a static spark.

Keeping these things in mind turns what could be a dangerous chore into a simple, routine part of boating. A steady hand and a bit of focus are all you need to get it done without a single drop spilled.

Troubleshooting Common Fuel Transfer Problems

https://www.youtube.com/embed/8X5L0NmUOxU

Even when you’ve done everything right and have the best gear, things can still go sideways at the pump. A pump that won’t prime or a flow that’s painfully slow can turn a quick top-off into an afternoon-long chore. The good news is that most of these headaches are usually simple to diagnose and fix on the spot.

If your pump is completely dead, start with the obvious: the power source. For battery-powered models, make sure the battery has a full charge and that the connections are solid and free of corrosion. It's amazing how often a little bit of gunk on the terminals is all it takes to kill the power. With a manual pump, you might be looking at a stuck valve or a bad seal on the can that’s preventing it from building suction.

Of course, part of the challenge is just the sheer amount of gear on the market. The global fuel storage containers market, which includes the portable cans we all use, was valued at USD 28.6 billion recently and is only getting bigger. With that many products out there, making sure your fuel pump gas can and hoses are all compatible is the first step to a hassle-free transfer. You can dig into the full research about the growth in the fuel storage containers market if you're curious.

What to Do When the Fuel Flow Slows to a Trickle

One of the most frequent frustrations is a slow transfer rate. When the fuel is barely dribbling out, it’s almost always a blockage or an air leak messing things up. First, take a quick look at your hoses. Any sharp kinks or bends will choke the flow, so make sure you have a straight, clear path from the can to the tank.

If the hoses look good, it’s time to hunt for a blockage. Here are the usual suspects:

- A Clogged Filter: A lot of pumps have a small inline filter to catch gunk. Over time, it can get clogged with sediment from your gas can, slowing everything down.

- Debris in the Nozzle: It doesn't take much—just a tiny piece of debris—to get stuck in the nozzle and create a bottleneck.

- Air Leaks: Double-check that every connection is tight. Even a small air leak on the suction side can make the pump lose its prime and struggle to pull fuel.

A slow pump isn't just an annoyance—it's often a warning sign. By checking your filter regularly, you're not just fixing the flow; you're stopping that same sediment from getting into your boat's fuel tank, where it can cause some serious engine trouble down the road.

Dealing with Nozzle Shutoffs and Spills

Ever had an automatic shutoff nozzle that constantly clicks off, even when the tank is nowhere near full? That’s usually caused by back-pressure. It happens when you’re trying to pump too fast, and the fuel "burps" back up the fill pipe, tricking the nozzle into thinking the tank is full. The fix is easy: just slow down your pumping speed. This gives the air in the tank enough time to vent properly.

And if you do have a small spill, don't panic. The trick is to act fast. Stop the fuel flow immediately, then grab your absorbent pads or a bilge sock to contain it. Whatever you do, never try to wash the fuel into the water with a hose. That just spreads the problem and is terrible for the environment. Every boater should have a well-stocked spill kit on board for exactly this reason.

Post-Fueling Steps and Equipment Care

It’s tempting to relax once the tank is full, but don't rush it. What you do in the moments after fueling is just as crucial as the fueling process itself. These last few steps are all about buttoning everything up to prevent spills and, more importantly, a dangerous buildup of explosive fuel vapors.

The first thing to do is pull the nozzle out of the fuel fill pipe, keeping it pointed up so you don't drip gas all over your deck. Have an absorbent pad handy just in case. Then, get that fuel cap back on immediately and make sure it's tight. A loose cap is a classic mistake that lets vapors escape and water get in.

Clearing the Air Before You Start

The biggest, most immediate threat after you've fueled up isn't a fire—it's the invisible gasoline fumes. They're heavier than air, which means they sink and collect down in your boat’s bilge. All it takes is one stray spark to turn that into a disaster.

This is where your bilge blower becomes the most important tool you have. You need to let that blower run for a solid four to five full minutes before you even think about turning the key. It’s actively pushing all those heavy, flammable fumes out of the engine compartment and other low spots.

Never, ever skip this step or cut it short. Firing up an engine with a bilge full of fumes is how most boat fires and explosions happen at the dock. A few minutes of waiting is a small price to pay for safety.

Even after running the blower, it's a good practice to do a quick "sniff test" around the engine compartment and bilge. If you still smell gas, something's not right. Keep the blower running and find the source before you try to start the engine.

Maintaining Your Fuel Pump and Gas Cans

Taking care of your fuel pump gas can and hoses isn't just about making them last longer; it's about making sure they work safely every single time. Most fueling problems I've seen trace back to poorly maintained gear.

Make a quick inspection and cleaning part of your routine after every fill-up:

- Inspect Seals and Gaskets: Today's ethanol fuels are tough on rubber and plastic. Give the seals on your gas can and any pump gaskets a quick check for cracks, stiffness, or swelling.

- Clean and Dry Hoses: Wipe down your hoses to get any fuel residue off. When you store them, make sure they aren't kinked, as that can cause weak spots and leaks down the road.

- Check for Debris: Before you put a can away, shine a flashlight inside. Look for any gunk or sediment that could clog up your pump or get into your boat's fuel system.

Storing your equipment correctly is the final piece of the puzzle. For a complete rundown, check out our guide on how to store gasoline safely. A little bit of proactive care goes a long way in keeping your gear—and you—safe.

Your Top Questions About Fuel Pump Gas Cans, Answered

Even the most seasoned boaters run into questions when fueling up. It's just part of the deal. Getting straight answers not only helps you get the job done right but also builds the confidence you need on the water. Here are some of the most common things we get asked about using a fuel pump gas can setup.

Can I Just Use Any Old Gas Can with My Fuel Pump?

Technically, you might be able to make it work, but it's a really bad idea. I always tell people to stick with marine-grade gas cans. They're built for the job—thicker walls, UV protection, and essential safety gear like flame arrestors. You won't find those on a cheap can from the hardware store.

The biggest issue with a non-marine can is the seal. If it's not airtight, your pump will struggle to maintain its prime, pulling in air instead of fuel. You also need to make sure the pump's suction tube actually reaches the bottom of the can. A proper, secure fit is non-negotiable for safe and efficient fueling.

What’s the Best Flow Rate for a Fuel Transfer Pump?

There’s no single magic number here; it really comes down to your boat’s tank size and how much time you have. For most weekend boaters, a pump that delivers 2-4 gallons per minute (GPM) hits the sweet spot. It's quick enough that you're not standing there forever but slow enough that you stay in complete control and avoid messy backsplash.

Don't fall into the trap of thinking faster is better. A pump with a massive GPM can easily overwhelm your tank's vent, causing fuel to spit right back at you. This can also prematurely trigger automatic shutoff nozzles, which is incredibly frustrating. A steady, controlled flow wins every time.

My Battery-Powered Pump Is Barely Pumping. What Gives?

When a battery pump feels weak, it’s almost always one of two things: a power issue or a blockage. The first place to look is your batteries. Are they fully charged? Performance plummets as they drain. Also, give the terminals a quick check for corrosion—that green gunk can choke off the electrical flow.

If your batteries are fresh, the next culprits are a clogged filter or a kinked hose. It's amazing how often a simple twist in the line is the cause of a slow flow. Think of a weak pump as a cry for help; it's telling you something is making its job harder.

Here’s a piece of advice I give everyone: try not to let your boat’s tank dip below a quarter full. Running on fumes can suck up all the sediment and gunk from the bottom of your tank, and that junk can do a number on your engine's much more expensive fuel pump and components.

The world of fuel pumps is always improving. Just look at the big commercial pumps at gas stations—the global market for those was valued at USD 2,479.5 million and is expected to grow like crazy by 2035. Your portable pump is a simpler beast, but the core goals of safety and reliability are exactly the same. You can dive deeper into the growth of the fuel dispenser market to see where the technology is headed.

Tired of spilling fuel and wasting money? CLiX Fueling Solutions has a simple, automatic shutoff system that makes refueling clean and easy every single time. Protect your boat, your wallet, and our waterways. Visit https://clixfueling.com and grab your CLiX unit today.