A fuel funnel with a filter is one of the simplest and most effective tools in your arsenal. It’s a pretty basic concept: a funnel designed to catch nasty stuff like dirt, rust, and water before it gets into your fuel tank. Think of it as a bouncer for your fuel system, making sure only clean fuel gets past the velvet rope and into your engine.

It's a small investment that can save you from huge headaches and expensive repair bills down the road.

The Hidden Dangers Lurking in Your Fuel Tank

Picture this: you're miles from shore, enjoying a perfect day on the water, when your engine starts to sputter and die. Or maybe your backup generator gives up the ghost right in the middle of a power outage. More often than not, the culprit is something you never even saw coming—dirty fuel.

Every time you grab a fuel can or fill up at the pump, you're rolling the dice. You could be introducing all sorts of invisible enemies into your tank.

These tiny troublemakers come in all shapes and sizes. We're talking about small particles of dirt, flakes of rust from an old fuel can, and even tiny droplets of water that can easily mix with your gas or diesel. Once they get into your fuel system, they start acting like liquid sandpaper, slowly grinding away at critical engine components.

How Contaminants Wreak Havoc

The damage isn't always dramatic and immediate. Instead, it's a slow, grinding process that leads to some serious problems over time:

- Clogged Fuel Injectors: Tiny bits of debris can easily block the super-fine nozzles on your fuel injectors. This throws off the engine's fuel-to-air mix, causing poor performance, rough idling, and terrible gas mileage.

- Fuel Pump Failure: Larger particles can jam up and destroy your fuel pump. That’s a critical part, and trust me, it’s not cheap to replace.

- Internal Corrosion: Water is especially bad news. It's heavier than fuel, so it settles at the bottom of the tank and starts causing rust. Those rust flakes then get sucked into the fuel system, starting the whole cycle of damage over again.

This is where a fuel funnel with a filter proves its worth. It acts as your first line of defense, catching all that gunk before it even has a chance to get into your tank. Of course, keeping a clean tank is just as important. For a deeper dive, check out this expert guide on marine fuel tank cleaning.

Let's take a quick look at the most common villains found in fuel and the kind of trouble they can cause.

Common Fuel Contaminants and Their Effects

| Contaminant | Source | Potential Engine Damage |

|---|---|---|

| Water | Condensation, poor storage, contaminated supply | Corrosion, microbial growth (diesel bug), injector damage, poor combustion |

| Dirt & Sand | Dirty fuel cans, airborne particles during refueling | Clogged filters, injector wear, abrasive damage to pumps and engine internals |

| Rust & Scale | Aging fuel tanks and storage containers | Clogged fuel lines and filters, fuel pump failure, injector blockage |

| Organic Debris | Leaves, insects, or other matter entering the tank | Clogging the entire fuel system from the pickup to the injectors |

As you can see, none of these are things you want circulating in your engine. A simple filter funnel helps you stop them at the source.

The push for cleaner fuel isn't just a niche concern; it's a massive global market. The fuel filters market, which includes these essential funnels, was valued at around USD 4.3 billion and is expected to grow to about USD 7.4 billion by 2035. This shows just how critical fuel purity has become for keeping modern engines running smoothly.

How a Filter Funnel Actually Cleans Your Fuel

A fuel funnel with filter looks pretty basic, but there’s some smart science at work inside. The best way to picture how it operates is to think about making a great cup of pour-over coffee. The paper filter lets all the rich, flavorful coffee through but stops the bitter grounds in their tracks.

Your fuel funnel does something very similar, but it’s designed to stop two of your engine’s biggest enemies: solid gunk and water. It’s a simple-looking tool that provides a two-stage defense. The first line of defense is an incredibly fine mesh screen, usually made of stainless steel so it won’t rust.

The Physical Barrier for Debris

When you pour fuel through the funnel, that mesh screen is the first thing it hits. This screen is like a bouncer at a club—it's very selective about what gets past.

Fuel molecules are small enough to slip right through the tiny openings. But larger contaminants get caught. We’re talking about things like:

- Rust Flakes: Little bits that break loose inside old metal fuel cans or storage tanks.

- Dirt and Sand: Gritty stuff that always seems to find its way into an open fuel can.

- Organic Debris: Tiny pieces of leaves or other junk that can contaminate your fuel source.

By stopping these particles from getting into your tank, the funnel protects sensitive engine parts like your fuel pump and injectors from getting clogged or damaged.

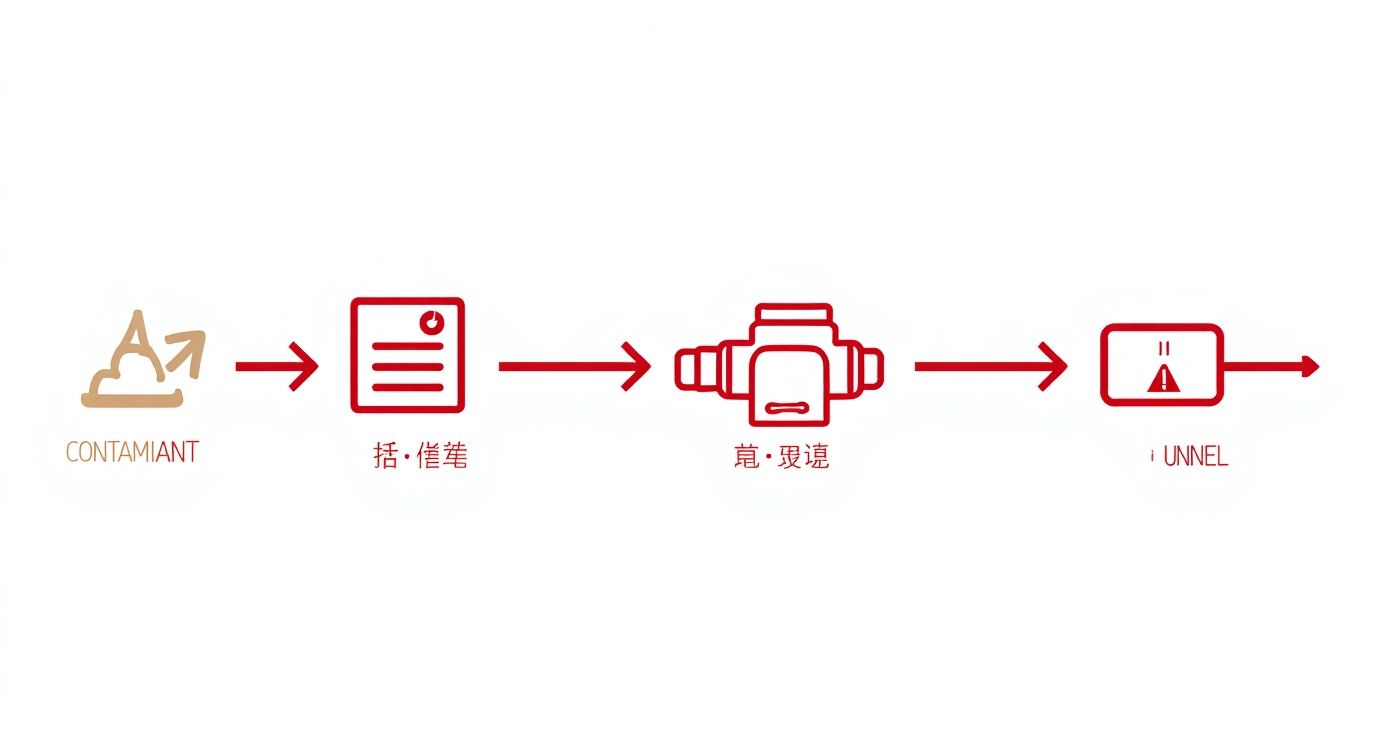

This infographic breaks down just how a filter funnel stands between a contaminated fuel source and your engine.

As you can see, without that filter, all sorts of junk has a straight shot at causing problems. The funnel acts as that critical gatekeeper.

Separating Water from Fuel

Catching solids is one thing, but many of the best filter funnels also tackle water contamination. This part of the process isn't about straining; it's more about clever material science. These funnels often have a special fluoropolymer coating on the mesh screen.

This coating is hydrophobic, which is just a technical term for "water-hating." It actively pushes water away.

While fuel flows through the coated screen without any trouble, water beads up and gets rejected. Since water is denser than gasoline or diesel, these repelled droplets sink to the bottom of the funnel into a small sump area.

They collect there, safely away from the spout where clean fuel is flowing into your tank. Once you’re done fueling, you can just tip the funnel and pour out the trapped water and debris. It's this one-two punch—physically blocking solids and chemically repelling water—that ensures only pure fuel ends up powering your boat.

How to Choose the Right Fuel Funnel With Filter

Picking the right fuel funnel with filter isn't a one-size-fits-all deal. It’s all about matching the tool to your specific job. The funnel you need for your lawnmower is a world away from the one you’d use to refuel a large boat, and getting it right from the start saves a ton of headaches.

Think of it like picking the right kitchen knife. You wouldn't use a tiny paring knife to carve a Thanksgiving turkey, right? It's the same idea here. Trying to fill a 100-gallon boat tank with a small, slow funnel will be frustrating, to say the least.

So, how do you make the right call? It comes down to a few key things: the material it's made of, how fast it can handle fuel (flow rate), and how finely it filters (micron rating). Let's break these down so you can find a funnel that protects your engine and makes refueling a breeze.

Material and Durability

The first big choice you'll face is what the funnel is made of. Your main options are typically a tough plastic or a sturdy, conductive metal, and each has its own set of pros and cons.

-

Plastic Funnels: These are the most common for a reason. They're lightweight, won't rust or corrode, and are usually easier on the wallet. A good quality polymer funnel is plenty durable for most jobs, and it's an excellent choice for boaters who are constantly around saltwater.

-

Metal Funnels: Usually crafted from steel or aluminum, metal funnels are built to last. They’re super rigid and can take a beating. Many are also designed with anti-static properties, which is a huge safety plus when you're working with something as flammable as gasoline.

This idea of picking the right material for the job is universal. For example, when choosing essential fishing gear, anglers have to consider strength and resistance to the elements to make sure their equipment holds up. The same logic applies here.

Comparing Fuel Funnel Materials and Features

To make it even clearer, here’s a quick look at how plastic and metal funnels stack up against each other.

| Feature | Plastic Funnels | Metal Funnels | Best Use Case |

|---|---|---|---|

| Durability | High-quality polymers are strong and impact-resistant. | Extremely durable, rigid, and resistant to punctures. | Heavy-duty, industrial, or workshop environments. |

| Corrosion | Excellent resistance, especially to saltwater. | Can rust if not properly coated or maintained. | Marine and outdoor applications. |

| Safety | Non-conductive, which can be a pro or a con. | Can be conductive and feature anti-static properties. | Handling gasoline or other highly flammable fuels. |

| Cost | Generally more affordable. | Typically more expensive upfront. | Budget-conscious users and general-purpose needs. |

| Weight | Lightweight and easy to handle. | Heavier, which provides stability but can be less portable. | Situations where a stable, heavy funnel is needed. |

Ultimately, the best material depends on your environment and how you plan to use the funnel.

Understanding Flow Rate and Micron Rating

Next up are two numbers that really matter: flow rate and micron rating.

The flow rate simply tells you how fast fuel can pour through the funnel. It's measured in gallons per minute (GPM), and a higher number means faster fueling. If you're filling up big tanks, you’ll want a high-flow model—something like 5 GPM or more—to avoid standing around forever. For smaller engines, a lower flow rate is perfectly fine.

The micron rating is arguably the most important spec. This number tells you how small of a particle the filter can trap. It’s simple: a lower micron number means a finer, more thorough filtration.

For most cars and boats, a filter rated between 74 and 100 microns hits the sweet spot. It’s fine enough to catch nasty debris and separate out water, but not so fine that it slows your fuel flow to a crawl.

Matching the Funnel to Your Application

Now you can put it all together. A boater who’s always worried about water in their fuel should look for a high-flow, water-separating funnel. Someone fueling up a classic car might lean toward a metal funnel with those anti-static features for extra peace of mind.

If you want to see how these features come together in real-world products, take a look at our guide to the top 6 fuel funnels with filters for clean fueling. By thinking through your own needs, you can easily find a funnel that gives you the right mix of protection, speed, and safety.

Using and Maintaining Your Funnel for Safe Fueling

Owning a quality fuel funnel with a filter is one thing, but knowing how to use it right is what really protects your engine. It’s not just about pouring gas; it's about developing a safe, clean routine that prevents spills and keeps contaminants out of your fuel tank every single time.

The biggest danger when handling fuel is static electricity. A tiny, unseen spark can ignite fuel vapors in an instant. The best way to prevent this is by always keeping the fuel can, the funnel, and the fuel tank opening in direct contact with each other. This simple touch grounds everything, stopping a dangerous static charge from building up.

Also, never forget about ventilation. Fuel fumes are highly flammable and unhealthy to breathe, so always refuel in an open, airy space. Good airflow helps disperse the vapors, making the whole process much safer for you.

Essential Safety Steps for Every Refuel

Making safe fueling a habit starts with a consistent routine. Before you even unscrew the cap on your fuel can, make sure you're on stable ground and the boat or equipment you're fueling is level. It’s a small thing that makes a big difference in preventing spills.

Here’s a simple checklist to run through every time:

- Inspect Your Funnel: Give it a quick once-over before you start. Look for any cracks or damage to the filter screen that could cause problems.

- Ensure a Secure Fit: The funnel should sit snugly in the tank's fill neck. A wobbly funnel is just asking for a mess, so make sure it's stable before you pour.

- Pour Slowly and Steadily: Don't just dump the fuel in. A controlled pour lets the filter do its job without getting overwhelmed, which can cause fuel to back up and spill over.

- Stay Grounded: As we mentioned, keep the fuel can touching the rim of the funnel. This continuous contact is your number one defense against static sparks.

Remember, the goal is to create an unbroken, grounded connection from the can to the tank. This simple physical contact mitigates one of the biggest risks associated with handling flammable liquids.

A Simple Maintenance Routine

Keeping your fuel funnel with a filter in top shape is easy and only takes a minute. A little care after each use goes a long way in making sure it works perfectly next time.

Once you're done, empty any leftover fuel. Then, just flip the funnel upside down and tap it gently to knock out any water or debris caught in the filter. If it needs a deeper clean, you can rinse the screen with a splash of clean fuel or a solvent that won't damage the material. For boaters, getting familiar with the ins and outs of the marine fuel fill process is always a good idea.

Finally, store it properly. Find a clean, dry spot for your funnel where it won’t collect dust. Tucking it away in a bag or covering it ensures it’s clean and ready to go for the next refuel.

Why Clean Fuel Is a Non-Negotiable on the Job Site

If you’re in construction, farming, or landscaping, you know that equipment downtime is more than just an inconvenience. It’s a direct hit to your wallet. When a single excavator, tractor, or generator goes down because of bad fuel, it can bring an entire project to a grinding halt, triggering a domino effect of costly delays.

Clean fuel isn’t just a nice-to-have; it's the lifeblood of your operation.

These heavy-duty machines are huge investments, with powerful engines designed to take a beating. But here's the catch: their high-performance fuel systems are surprisingly sensitive. A little bit of dirt, rust, or—worst of all—water can cripple a modern diesel engine. We're talking clogged injectors, damaged pumps, and repair bills that can easily climb into the thousands.

The High Cost of Contaminated Fuel

When a critical piece of equipment fails, the financial pain goes way beyond the mechanic's invoice. The real damage is in the lost productivity and the chaos it creates.

- Project Delays: A dead earthmover can stop an entire phase of construction in its tracks, messing up the schedule for every other crew on site.

- Labor Costs: Your crew is on the clock whether the equipment is running or not. Every hour of downtime means you're paying people who can't do their job.

- Rental Fees: If your primary machine is down for the count, you might need to scramble for a last-minute rental just to stay on schedule, adding a hefty, unplanned expense.

This is exactly why a fuel funnel with filter is such a vital piece of gear. It’s not just for boaters; it’s a must-have tool for any crew that depends on heavy machinery out in the field.

On a job site, every minute counts. Using a filter funnel during field refueling is a simple, proactive quality control measure that protects six-figure investments and prevents a five-dollar problem from turning into a $10,000 repair.

A First Line of Defense in the Field

Let's face it, refueling often happens in less-than-ideal conditions—dusty sites, windy fields, you name it. Contamination is a constant threat. A heavy-duty fuel funnel with a built-in filter acts as your gatekeeper, making sure only clean fuel gets into the tank. It’s a simple step that stops the vast majority of contaminant-related engine issues before they even start.

The demand for reliable filtration is booming across industries. The oil and gas sector, for example, makes up a huge part of the industrial fuel filters market simply because they can't afford not to have dependable filtration. If you're interested, you can discover more insights about the growing industrial fuel filter market and what's driving it.

Ultimately, taking this small, preventative step pays off big time in equipment reliability, job site efficiency, and your bottom line.

Here's the rewritten section, designed to sound completely human-written and natural.

Troubleshooting Common Filter Funnel Problems

Even the best tools can give you a headache sometimes. A fuel funnel with filter is about as simple as it gets, but that doesn't mean you won't run into a couple of common hiccups. Knowing what to look for can save you a ton of frustration at the fuel dock or on the trailer.

By far, the most common issue is a flow rate that slows to a crawl. Your first instinct might be to blame the funnel, but nine times out of ten, the filter is just doing its job. A screen choked with rust, dirt, or water acts like a dam, and the fuel just can't get through. This happens a lot if you're pouring from an old jerry can that's been sitting around.

Another sneaky problem is an air lock. If the funnel creates a perfect seal with your boat’s fuel neck, the air inside the tank has nowhere to go as the fuel rushes in. That trapped air pushes back, slowing your pour to a frustrating trickle.

Quick Fixes for Common Funnel Headaches

If you hit one of these snags, don't sweat it. The fixes are usually dead simple and take just a minute to sort out.

- Painfully Slow Flow: The moment you notice the flow slowing down, stop pouring. Pull the funnel out and take a look at the screen. You’ll probably see a collection of gunk or a little puddle of water sitting on the filter. Just tip the funnel over a trash can to empty it out, and you’re good to go.

- Wobbly or Awkward Fit: A wobbly funnel is just asking for a spill. If yours doesn't sit snugly, you might need a different style. Look for one with a flexible spout or an offset design that can handle an awkward fill angle.

- Suspected Air Lock: This is the easiest fix of all. Just lift the funnel slightly to one side, breaking the seal. That little gap is all it takes for the trapped air to escape, and the fuel will start flowing freely again.

A good rule of thumb is to pour steadily, not just dump the fuel in. Pouring too fast can actually force small particles into the filter mesh, causing clogs that are harder to clear.

One last thing people often ask is whether they can use the same funnel for gas and diesel. While most are made from materials that can handle both, it’s not the best idea. To avoid any chance of cross-contamination, either give the funnel a serious cleaning between fuels or—better yet—just keep a separate, dedicated funnel for each one. Following these simple tips will help you get the most out of your fuel funnel with filter.

Got Questions? We've Got Answers

Even with the best guides, some practical questions always come up when you start using a new piece of gear. Let's tackle some of the most common things people ask about filter funnels.

Think of this as the quick-start guide to using your funnel with confidence, so you can get back to what matters—keeping your engine running smoothly.

Can I Use the Same Funnel for Gas and Diesel?

Technically, yes. Most well-made funnels use materials that can handle both gasoline and diesel just fine. The real issue is cross-contamination.

If you absolutely must switch, you have to clean it out meticulously. A better, safer approach? Just get two. Having a dedicated funnel for each fuel type is the simplest way to prevent any chance of engine trouble later on.

What Filter Micron Rating Do I Need?

The right micron rating really depends on what you're fueling. Remember, a smaller number means it's filtering out smaller particles.

For most everyday uses—think boats, cars, or your lawn mower—a filter in the 74 to 100 micron range is the sweet spot. It's fine enough to catch the nasty stuff and separate water but won't choke off the fuel flow.

If you're running a high-performance or newer, more sensitive engine, it might need something finer. When you're not sure, your owner's manual is your best friend.

How Often Should I Clean the Filter Screen?

Easy one: clean it after every use. Making this a habit is the single best thing you can do to keep your funnel working like new.

Just give the screen a quick rinse with a little clean fuel or a safe solvent, then let it air dry completely. The screens on quality funnels are built tough from non-corrosive metal, so you won't need to replace one unless it gets physically damaged or torn.

Ready to eliminate fueling guesswork and prevent costly spills for good? CLiX Fueling Solutions offers an automatic shut-off system that makes refueling simple, safe, and spill-free. Discover how CLiX can transform your boating experience today.