At its core, a diesel transfer tank pump is the muscle that moves diesel from a storage container right into your boat’s main tank. Think of it as the heart of your boat’s extended fuel system, making sure you have power when you need it, without the mess or hassle.

Why a Reliable Diesel Transfer Pump Is Your Boat's Lifeline

When you're miles from the nearest fuel dock, the last thing you want to be thinking about is running on fumes. A diesel transfer pump isn't just another piece of gear; it’s your key to longer voyages, operational security, and genuine peace of mind. It turns a simple storage tank into your personal, on-demand refueling station.

Without a pump you can count on, that extra tank is just dead weight. But with the right pump, that stored fuel becomes usable range, letting you explore further and stay out longer with total confidence. It’s the critical link between having extra fuel and being able to use it safely and efficiently.

More Than Just Moving Fuel

A good diesel transfer tank pump does a lot more than just push liquid from one place to another. It’s also the guardian of your fuel's integrity, protecting your expensive engine from damage. Contaminants like water and sediment love to settle at the bottom of storage tanks. A cheap or poorly designed pump can easily stir them up and send that gunk straight into your main tank and, ultimately, your engine.

A well-chosen system, however, is designed to maintain fuel quality during the transfer. This simple but vital function is what prevents engine sputtering, stalling, or more serious long-term mechanical problems, keeping your boat running like it should.

A pump on its way out often gives you hints—maybe the engine has trouble starting or acceleration feels jerky. On a boat, these aren't just minor annoyances; they're serious safety hazards a dependable pump helps you avoid.

The Foundation of Safe and Clean Refueling

Fuel spills are a nightmare for any boater. They can ruin your boat's finish, devastate fragile marine ecosystems, and hit you with some hefty fines. Trying to refuel by manually siphoning or using makeshift equipment is just asking for a messy, dangerous overflow. A proper pump gives you a controlled, sealed, and efficient transfer every time.

This controlled process is a cornerstone of responsible boating. By preventing spills, you’re not just protecting your investment—you're doing your part as a steward of the marine environment. For a deeper look into this, check out our complete guide on boat fueling safety.

The growing demand for reliable equipment like this isn't just a hunch. The global fuel transfer pump market was valued at around $6.49 billion and is expected to climb to $10.12 billion by 2035. That's a clear signal of just how crucial these pumps are, not just in the marine world but across many other industries.

Decoding the Different Types of Diesel Transfer Pumps

Picking a diesel transfer tank pump can feel a bit overwhelming at first, with terms like "vane," "gear," and "diaphragm" getting thrown around. But don't worry, it's simpler than it sounds. At the end of the day, a pump is just a machine built to move fuel from point A to point B, and each type uses a slightly different mechanical trick to get it done.

Think of it like choosing the right tool for a job in your workshop. You wouldn't use a sledgehammer for a finishing nail, right? The same logic applies here. The three main players you'll run into are rotary vane, gear, and diaphragm pumps, and each one has its own set of strengths and weaknesses, especially in the tough marine world.

Let's break them down.

Rotary Vane Pumps: The Consistent Performer

Imagine a revolving door, but for fuel. That's essentially a rotary vane pump. Inside the pump's housing, a rotor with small, spring-loaded vanes spins around. As it turns, these vanes slide out, trapping little pockets of diesel against the pump wall and pushing them smoothly from the inlet to the outlet.

This design is what makes rotary vane pumps so popular. They're known for their consistent pressure and quiet operation, making them fantastic all-rounders for most fuel transfer jobs on a boat.

- Key Advantage: They deliver a very smooth, non-pulsating flow, which is much easier on your hoses and fittings over the long haul.

- Main Disadvantage: Those sliding vanes can be a bit sensitive to gunk or debris in the fuel. A little sediment can cause them to wear out prematurely, so good fuel filtration is non-negotiable.

Gear Pumps: The Heavy-Duty Workhorse

A gear pump works on a beautifully simple principle: two gears mesh together, trapping fuel in the teeth against the pump casing. As the gears spin, they carry the fuel around the outside from the intake to the outlet, creating a powerful and incredibly reliable flow.

It's a bit like two water wheels turning against each other to move water. This tough, straightforward mechanism allows gear pumps to handle thicker fluids and generate higher pressures than many other types.

For boaters in colder climates where diesel fuel can thicken up, a gear pump's ability to muscle through that more viscous fuel can be a real game-changer.

Thanks to their durability, these pumps are often the top choice for more demanding commercial marine applications where you just can't afford a failure. The trade-off? They tend to be a bit louder and can produce a more pulsed flow compared to their vane-style cousins.

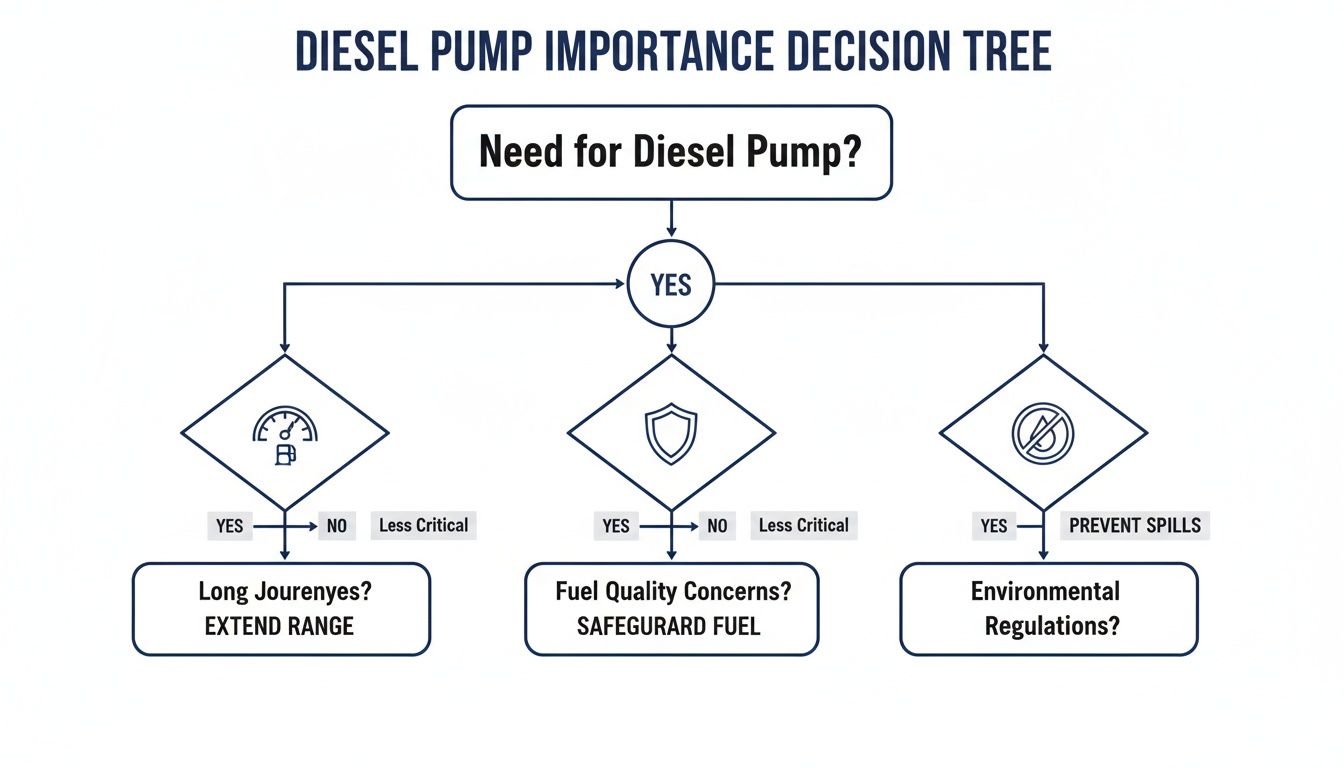

This decision tree helps visualize why picking the right pump is so critical for boaters, highlighting how it impacts your cruising range, keeps your fuel clean, and prevents nasty spills.

As you can see, achieving these goals depends entirely on having a pump that's perfectly matched to the job and the environment it's working in.

Diaphragm Pumps: The Versatile and Forgiving Option

A diaphragm pump works a lot like the human heart. It uses a flexible membrane—the diaphragm—that moves back and forth. On the backstroke, it creates a vacuum that sucks fuel into a chamber. On the forward stroke, it pushes that fuel out.

This design has one massive advantage: the pump's mechanical guts never actually touch the fuel. This makes diaphragm pumps exceptionally good at running dry for short periods without self-destructing, and they can handle fuel that might have a bit of debris in it. Seeing how services like Mobile Fueling Trucks operate can also give you a broader perspective on just how versatile these transfer systems can be.

The main drawback is that they naturally produce a pulsating flow, which isn't always ideal, and they generally have lower flow rates than gear or vane pumps of a similar size. Still, their forgiving nature makes them a solid choice for smaller boats or for secondary transfer tasks where you need reliability over raw speed.

Comparing Marine Diesel Transfer Pump Types

To make things even clearer, here’s a quick side-by-side look at how these pumps stack up. This table breaks down their ideal uses, main strengths, and potential downsides in a marine setting.

| Pump Type | Best For | Key Advantage | Main Disadvantage |

|---|---|---|---|

| Rotary Vane | General-purpose fueling, onboard day tanks, and applications needing quiet operation. | Smooth, consistent, non-pulsating flow that is gentle on system components. | Sensitive to fuel debris, requiring excellent filtration to prevent premature wear. |

| Gear | High-volume transfer, commercial use, and fueling in cold climates with thicker diesel. | Extremely durable, reliable, and can generate high pressures to move viscous fluids. | Can be noisy and produces a more pulsed flow compared to vane pumps. |

| Diaphragm | Smaller boats, auxiliary transfers, or situations where fuel might have debris or the pump may run dry. | Can run dry without damage and is very tolerant of fuel contaminants. | Produces a pulsating flow and typically has a lower flow rate than other types. |

Ultimately, the best pump is the one that fits your specific needs on the water. By understanding these core differences, you’re already well on your way to making a smart choice that will keep your fuel flowing reliably for years to come.

Choosing Your Pump: The Specs That Actually Matter

Picking the right diesel transfer tank pump isn't about fancy brand names. It's about matching the pump's capabilities to your real-world needs on the water. Think of it like picking an engine for a boat—you wouldn't put a tiny outboard on a massive yacht, and the same logic applies here. The pump's specs are the language that tells you exactly what it can and can't do.

Get these details right, and you're looking at a quick, clean refueling process. Get them wrong, and you're in for a frustratingly slow, messy ordeal. Let's break down the critical numbers so you can turn a product sheet into a smart purchase.

Flow Rate: The Speed of Your Refuel

The very first number you should check is the flow rate. Measured in Gallons Per Minute (GPM) or Liters Per Minute (LPM), this spec tells you exactly how fast the pump moves fuel. It’s the single biggest factor in determining how long you'll be standing there holding the nozzle.

But bigger isn't always better. A pump that’s too powerful for a small tank can cause the diesel to foam and splash, which is not only messy but also a serious spill risk. On the flip side, a pump with a low GPM will turn filling a large tank into a mind-numbing chore.

The trick is to find that sweet spot. A simple way to figure this out is to decide on your ideal fill time and work backward. If you want to move 50 gallons in about 5 minutes, you’ll need a pump rated for at least 10 GPM.

As a general rule, look for a pump that can fill your largest tank in a reasonable window, somewhere between 5 and 15 minutes. This keeps the job efficient without being dangerously fast.

Power Source: Matching Your Boat’s Electrical System

Your pump needs electricity, and it has to be compatible with what your boat can provide. This is a non-negotiable gut check. Most marine pumps are designed for one of three common power sources:

- 12V DC: This is the standard for most recreational boats. These pumps hook right up to your boat's battery, making them incredibly versatile and simple to install.

- 24V DC: You'll typically find 24V systems on larger yachts and commercial vessels. They deliver more power, which is necessary for the heavy-duty pumps that move fuel at higher flow rates.

- 110V AC: This is your standard household voltage. On a boat, it's usually available only when you're running a generator or plugged into shore power. While powerful, these pumps are less portable, making them a better fit for a fixed fueling station at a marina.

Choosing the wrong voltage is like trying to plug a European appliance into an American outlet—it just won't work. Worse, it could fry the pump or damage your boat's electrical system. Always, always confirm your boat’s voltage before you add a pump to your cart.

Materials: Built for the Harsh Marine World

The ocean is relentless. Between the saltwater, humidity, and constant UV exposure, it will chew up and spit out any equipment that isn't up to the task. A diesel transfer tank pump meant for a boat has to be built to survive this environment.

Look for pumps made with corrosion-resistant materials. This is what separates quality, marine-grade gear from the cheap automotive pumps that won’t make it through a single season on the water.

Your checklist for materials should include:

- Bronze Pump Housings: The gold standard for resisting saltwater corrosion.

- Stainless Steel Gears and Shafts: Delivers the strength and durability needed for parts constantly exposed to fuel and moisture.

- Marine-Grade Seals and Gaskets: Look for materials like Viton, which won’t break down when exposed to diesel and the elements.

Don't even consider a pump made of standard steel or cheap plastic. It’s a recipe for disaster. Rust flakes can break off, contaminate your fuel, and cause catastrophic engine problems. Keeping your fuel clean is everything, which is why understanding the role of a good fuel water separator filter is just as critical as choosing the right pump.

Duty Cycle: How Long Can Your Pump Actually Run?

Finally, take a look at the pump's duty cycle. This spec tells you how long the pump can run continuously before it needs a cool-down break. It's often expressed as a time limit, like “30 minutes on, 30 minutes off.”

For most boaters just transferring fuel between tanks, a pump with an intermittent duty cycle (like that 30-minute example) is perfectly fine. It's rare you'd need to run it longer than that in one go.

But for a marina operator filling multiple boats back-to-back, or a commercial vessel with massive fuel tanks, a continuous duty pump is the only way to go. These are built like workhorses, designed to run for hours without overheating. Ignoring the duty cycle is a surefire way to burn out your pump motor, leaving you high and dry in the middle of a transfer.

Essential Safety Features for Marine Fueling

When you're moving diesel around on a boat, you're dealing with a flammable liquid in an environment where things can go wrong fast. There's simply no room for error. A good diesel transfer tank pump isn't just a tool to make your life easier; it's a critical piece of safety gear. The best ones are designed from the ground up with safeguards to prevent the very situations that can turn routine fueling into a disaster.

These features aren't just bells and whistles. They are your first line of defense against spills, equipment failure, and accidents. If you're serious about boating, you need to know what they are and why they matter.

Thermal Overload Protection

Picture this: it's a hot day, and your pump is working hard, maybe pushing thicker, cold diesel or just running for a long time. Any electric motor will heat up under load. Without protection, that heat can cook the pump's internal parts, leading to a sudden failure mid-transfer or, even worse, creating a spark. We all know what sparks and diesel fumes lead to.

That's where thermal overload protection steps in. Think of it as a smart, built-in circuit breaker for the pump's motor.

- How it works: It constantly senses the motor's temperature.

- What it does: If things get too hot, it automatically kills the power, shutting the pump off before it can damage itself.

- The benefit: Once the motor cools back down to a safe temperature, you can get back to work. This simple feature prevents motor burnout and seriously lowers the risk of fire.

Integrated Bypass Valves

Sooner or later, the fuel flow is going to get blocked. The nozzle might be closed, you might get a nasty kink in the hose, or a filter could clog up. In a pump without a bypass valve, that blockage creates an immediate and dangerous pressure spike. That pressure has to go somewhere, and it usually results in a burst hose, blown seals, or a wrecked pump motor.

An integrated bypass valve is the pump's pressure relief system.

It's like the safety valve on a pressure cooker. When the pressure inside gets too high, the valve opens just enough to let off steam and prevent an explosion. A bypass valve does the exact same thing for your fuel system.

It senses that sudden pressure spike and reroutes the diesel internally within the pump. This lets the motor keep running without straining against a dead end. It protects every single component in your setup—the pump, the hoses, the fittings—and helps everything last a lot longer.

Environmental Compliance and Preventing Spills

Ultimately, these safety features aren't just about protecting your gear; they're about protecting the water we all enjoy. A fuel spill is a boater's worst nightmare. Under regulations like the Clean Water Act, even a small sheen on the water can lead to hefty fines and cleanup responsibilities.

A pump with thermal protection and a bypass valve is far less likely to fail in a way that causes a spill. But here's the catch: these features can't stop the single biggest cause of fuel spills—human error that leads to tank overfills. Even the best pump in the world will keep on pumping until you shut it off.

This is where your pump becomes just one part of a complete safety system. A quality pump is the heart of your fueling operation, but modern solutions like the CLiX Fueling system act as the brain. It works with your nozzle to automatically stop the fuel the instant your tank is full, taking the risk of an overfill completely off the table. When you pair a reliable pump with an automatic shutoff device, you create a truly responsible fueling process that protects both your boat and the environment.

Getting Your Pump Set Up Right and Keeping It Running Strong

Buying a quality diesel transfer tank pump is a great first step, but how you install and care for it makes all the difference. It's just like a boat engine—you can't just set it and forget it. A proper setup from the start, paired with simple, regular check-ups, is your best defense against surprise breakdowns.

Taking this approach protects your gear from unnecessary wear. Little installation mistakes, like using an undersized hose or mounting the pump in a bad spot, can snowball into expensive headaches later on. Let’s walk through how to do it right.

The Basics of a Solid Installation

A good installation is the bedrock of a reliable pump. It’s more than just hooking up hoses and wires; you're building a system that can stand up to the tough marine environment.

- Location, Location, Location: Find a dry, well-ventilated spot to mount your pump, and get it as close to the fuel tank as you can. The shorter the distance the pump has to pull fuel, the less strain you put on its motor. Bolt it down to a solid surface to keep vibrations from shaking it apart over time.

- Don't Choke the Flow: Never use a hose smaller than the pump's inlet and outlet ports. It's like trying to drink a thick milkshake through a coffee stirrer—it forces the pump to work way too hard, which leads to overheating and early failure. Make sure you’re using hoses specifically rated for diesel.

- Wire It for Success: Use the right gauge of marine-grade wire to avoid voltage drop, which can starve the pump of the power it needs. All connections should be tight, waterproof, and protected by a correctly sized fuse or circuit breaker. This is your main defense against electrical shorts.

Your Simple Maintenance Checklist

Once your pump is installed, spending just a few minutes on it every so often will save you a world of hurt. Downtime never comes at a good time; it usually pops up when a small, fixable problem finally gives out. This checklist will help you spot trouble before it starts.

A healthy pump has a steady, quiet hum. If you start hearing new or weird noises—like a high-pitched whine or a grinding sound—that’s your first clue something is wrong. It means the pump is straining or a part is about to fail.

A Quick Monthly Once-Over:

- Hunt for Leaks: Look closely at every hose, fitting, and the pump body itself for any sign of diesel. Even a tiny drip is a serious fire and environmental hazard.

- Clear the Gunk: Debris is public enemy number one for a pump. Clean the inlet strainer regularly to keep fuel flowing freely.

- Check the Wires: Scan the electrical connections for any corrosion. Clean up any green or white fuzz you see and double-check that everything is still tight.

- Listen Up: Like we said, your ears are one of your best tools. Any change in how the pump sounds means it's time for a closer look.

This kind of proactive care is important everywhere, but it's interesting to see how different regions approach it. For instance, North America makes up about 60% of the global fuel transfer pump market right now. But the Asia-Pacific region is catching up fast, accounting for 45.1% of the revenue in 2021, thanks to a boom in manufacturing. These global fuel transfer pump trends often shape what kinds of pumps and replacement parts are easiest to find near you.

A Smarter Way to Prevent Fuel Spills

Even the best diesel transfer tank pump on the market has a blind spot—it's great at moving fuel, but it has no idea when your boat's tank is full. It just keeps pumping until you tell it to stop. This is the simple truth behind the most common, expensive, and damaging problem boaters run into: fuel spills from overfilling.

All it takes is a moment of distraction, a sticky fuel gauge, or just getting it wrong on how much space is left in the tank. Suddenly, you've got a messy, hazardous spill on your hands. The fact is, human error is the one thing your pump can't control. Your pump is really only one half of a safe fueling system. The other half is the "brain" that knows when to quit.

This is exactly why we need a more modern, automated way to handle things. It's not about ditching your pump, but giving it the intelligence it's missing.

Beyond the Pump: An Automatic Shutoff Solution

Picture a system that acts like a trusty co-pilot every single time you fuel up. That’s what an automatic shutoff device does. It works hand-in-hand with your pump and nozzle to physically stop an overfill before it can even start, taking all the guesswork out of the equation.

Here’s a simple way to think about it: your transfer pump is the heart, reliably pushing the fuel. The automatic shutoff system is the brain, sensing the tank is full and instantly cutting the flow. This partnership turns a basic transfer tool into a complete safety solution that protects your boat, your money, and the water.

Shifting from a reactive "clean it up" mindset to proactive prevention addresses the real cause of spills—overfilling. This is the new standard for fueling responsibly and without the stress.

The Real-World Impact on Boaters and Marinas

If you're a boater, the benefits hit home immediately. A diesel spill can permanently stain your fiberglass, eat away at teak decking, and flat-out ruin your boat’s finish. Preventing just one spill saves you from back-breaking cleanup and expensive repairs. More importantly, it gives you peace of mind, so you can refuel with complete confidence.

For marina operators, the stakes are even higher. A fuel spill isn't just an environmental headache; it's a huge liability. Automated shutoff systems are a game-changer for staying compliant with safety and environmental rules, dramatically cutting the risk of hefty fines or even getting shut down.

At the end of the day, when you pair a quality diesel transfer tank pump with an intelligent shutoff system, you create a foolproof process. You can see how a simple diesel fuel nozzle adapter can be the missing piece to this puzzle. It's all about making sure every last drop of fuel gets where it’s supposed to go: inside your tank.

Got Questions? We've Got Answers

Even after you've got the basics down, a few questions always seem to pop up when you're dealing with diesel transfer pumps. Let's run through some of the most common ones we hear from boaters and marina pros to make sure you're fueling with total confidence.

Can I Use a Diesel Transfer Pump for Gasoline?

Let's make this crystal clear: absolutely not. This is a hard-and-fast safety rule you can't ever bend. Diesel and gasoline are fundamentally different fuels with different flash points and properties.

Putting gasoline through a pump built for diesel creates a massive risk of sparks, which can easily lead to a fire or a catastrophic explosion. Always, always use a pump that is specifically designed, rated, and certified for the fuel you're handling. Gasoline pumps have special components to prevent static and sparks—a critical feature that standard diesel pumps just don't have.

What Does "Self-Priming" Mean, and Do I Need It?

A self-priming pump is a smart piece of equipment. It can create enough of a vacuum to pull fuel up from the tank on its own, even if there’s air in the line. Think of it like a straw that can start working without you having to suck the liquid all the way to the top first.

For just about any marine setup where your pump sits higher than the fuel tank, a self-priming feature is a lifesaver. It saves you the headache of manually priming the hose and makes the whole process much more reliable.

How Often Should I Replace My Fuel Hoses?

There's no single "use by" date stamped on fuel hoses, so your eyes are your best tool. Regular inspection is key. You should give your hoses a thorough check at least once a season, looking over their entire length for any red flags.

Be on the lookout for:

- Cracks and splits, especially around the fittings where the stress is highest.

- The hose feeling unusually stiff or brittle.

- Any swelling, bubbles, or soft spots along the hose wall.

The marine environment is tough. Salt, sun, and constant contact with diesel will eventually break down the hose material. If you spot any of these signs, don't wait—replace the hose immediately with one that’s specifically rated for diesel. A small leak on the water is a big problem.

Stop guessing and start fueling with confidence. CLiX Fueling Solutions provides the automatic shutoff technology that works with your pump to make every refuel safe, clean, and spill-free. Discover how to upgrade your fueling system today.